Processing equipment and processing method for gasification furnace body

A machine body and multi-station technology, applied in the direction of metal processing equipment, manufacturing tools, forging press drive devices, etc., can solve problems such as difficult to handle, environmental pollution, etc., and achieve the effect of improving processing efficiency and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

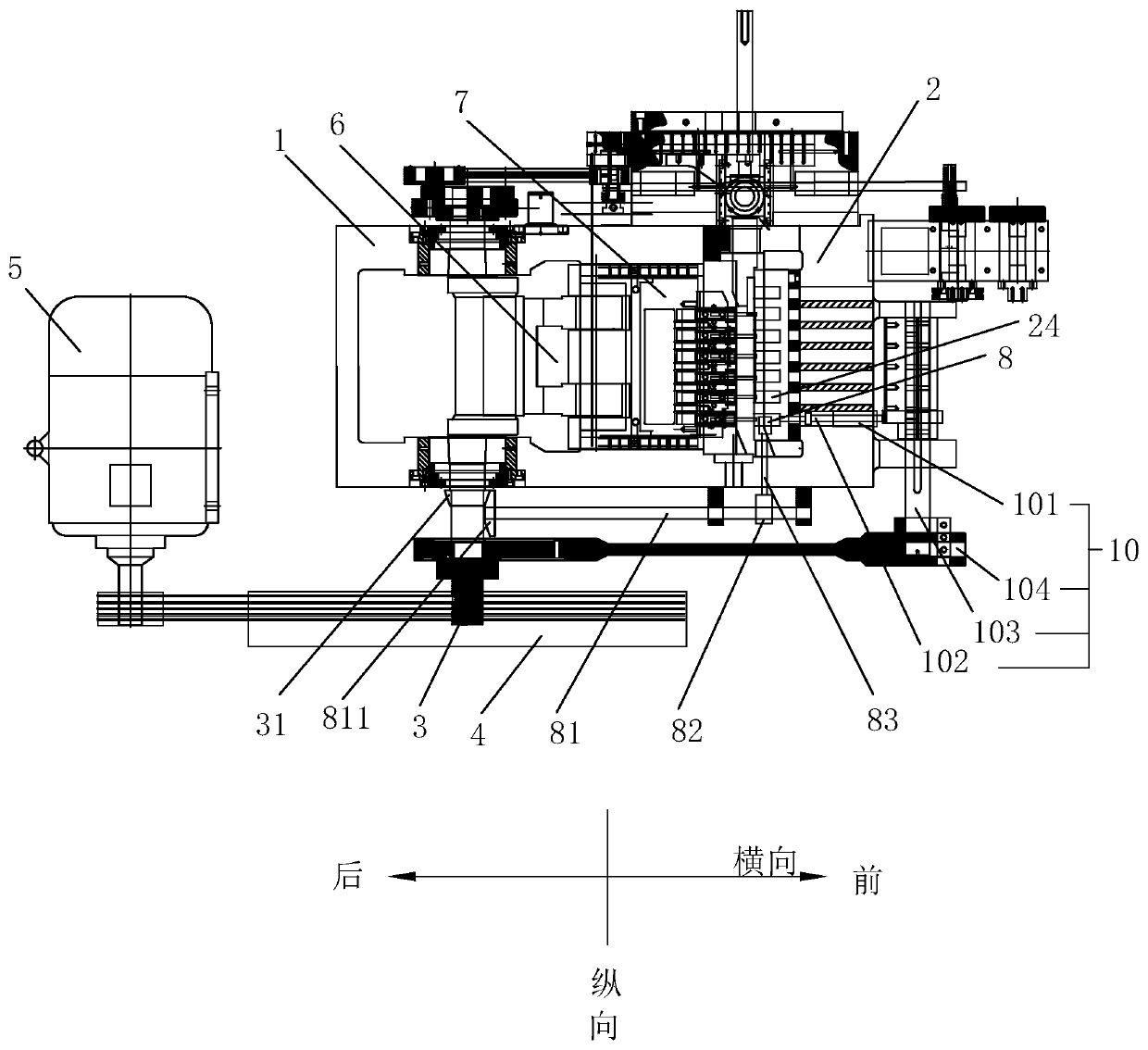

[0041] refer to figure 1 The schematic diagram of the structure principle of the whole machine is shown. figure 1 Schematically, a multi-station side double-hole cold heading machine includes a body 1 equipped with a mold box 2, a crankshaft 3 is installed at the rear end of the body 1, and one end of the crankshaft 3 is connected to a control crankshaft 3 through a belt pulley 4 for rotation. A motor 5, a connecting rod 6 is provided on the crankshaft 3, and a slide block 7 driven by the connecting rod 6 is provided on the body 1. The motor 5 is used as the main power output and realizes the rotation of the crankshaft 3 through the belt and the pulley 4 . The crankshaft 3 is placed on the machine body 1 to drive the slider 7 back and forth. A mold box 2 is set on the slider 7, and the material enters the mold box 2 and is subjected to front and rear impacts for cold pier forming.

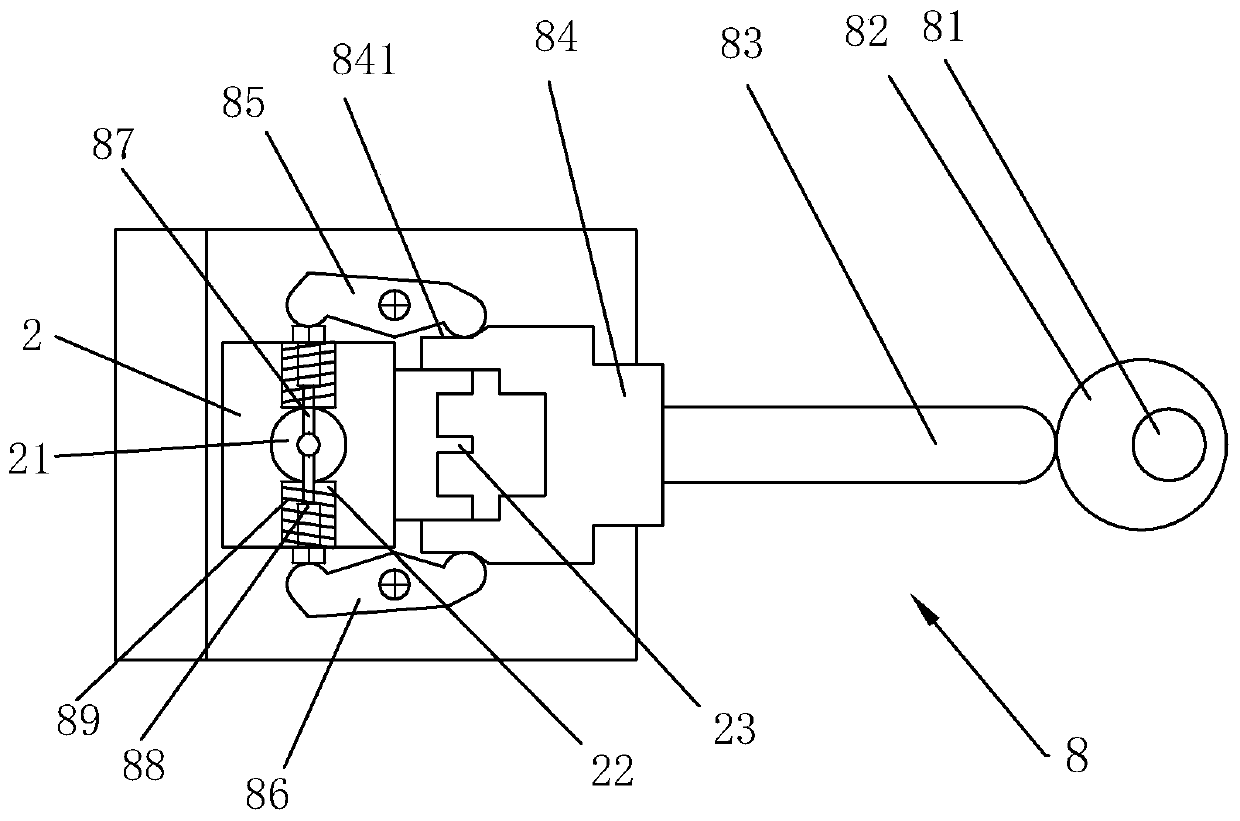

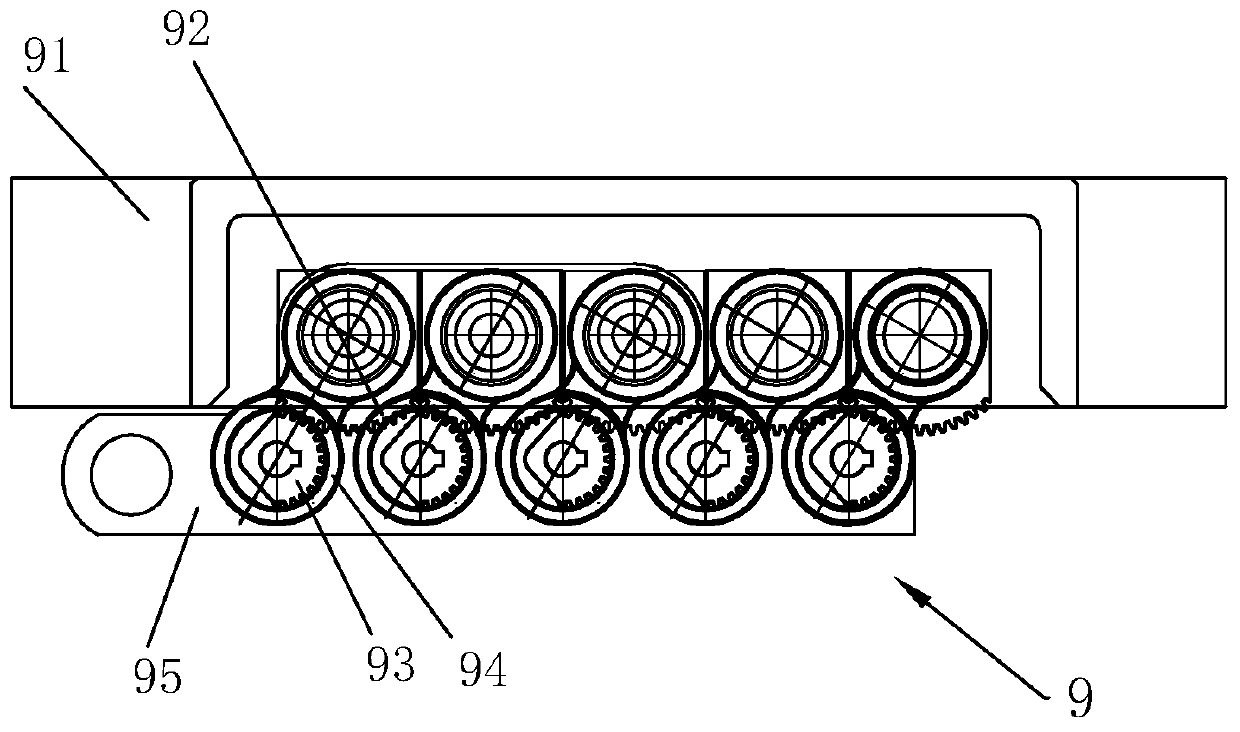

[0042] combine figure 1 with figure 2 shown, specifically in figure 2 The structural pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com