Method for performing metal forging by using metal forging device

A metal and gripping technology, applied in the field of metal forging, can solve the problems of resource and property loss, spending a certain amount of time, etc., to increase profits, reduce material damage, and avoid oxidation reactions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] All features disclosed in this specification, or all disclosed steps in a method or process, may be combined in any way except mutually exclusive features and / or steps.

[0027] Any feature disclosed in this specification (including any accompanying claims, abstract and drawings), unless expressly stated otherwise, may be replaced by other equivalent or alternative features serving a similar purpose. That is, unless expressly stated otherwise, each feature is but one example of a series of equivalent or similar features.

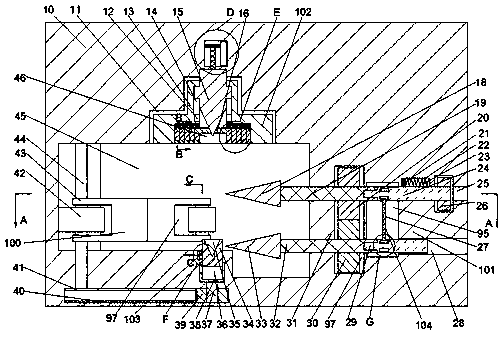

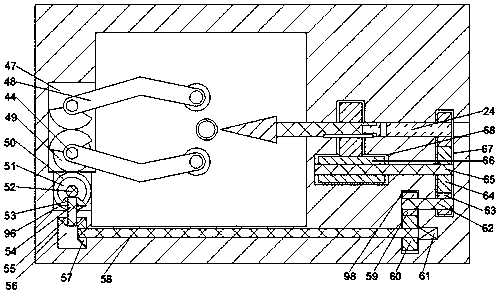

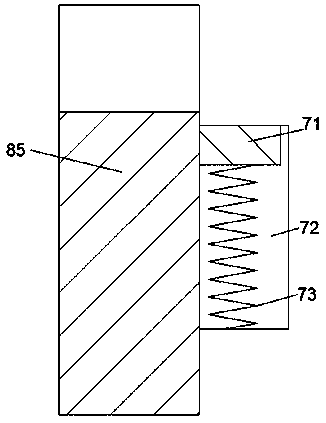

[0028] see Figure 1-8 , an embodiment provided by the present invention: a metal forging method using a metal forging device, wherein the metal forging device includes a forging box 10, and the forging box 10 includes a processing chamber 45, and the processing chamber 45 is equipped with There is a gripper mechanism 100, and the gripper mechanism 100 includes a crank 43, the crank 43 can rotate back and forth in the processing cavity 45, and the fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com