Sealing detection fixture

A seal detection and fixture technology, applied in the detection field, can solve problems affecting production efficiency, simulation is not realistic enough, processing accuracy is not high, etc., to achieve the effect of improving processing accuracy and service life, ensuring consistency and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0021] The sealing detection jig of the present invention is a device for testing the waterproofness of semi-finished components. The product to be tested is composed of multiple small plastic parts assembled and combined, and has multiple matching stations. There are leakage problems after assembly of semi-finished components caused by poor assembly of multiple coordinating stations and defects of small plastic parts. Semi-finished products need to be tested.

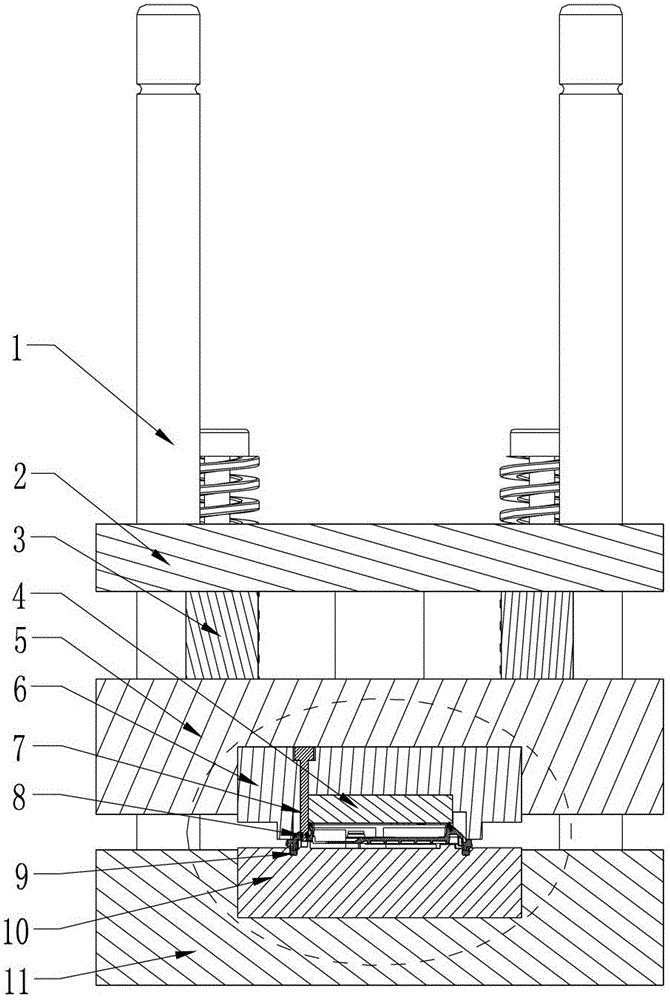

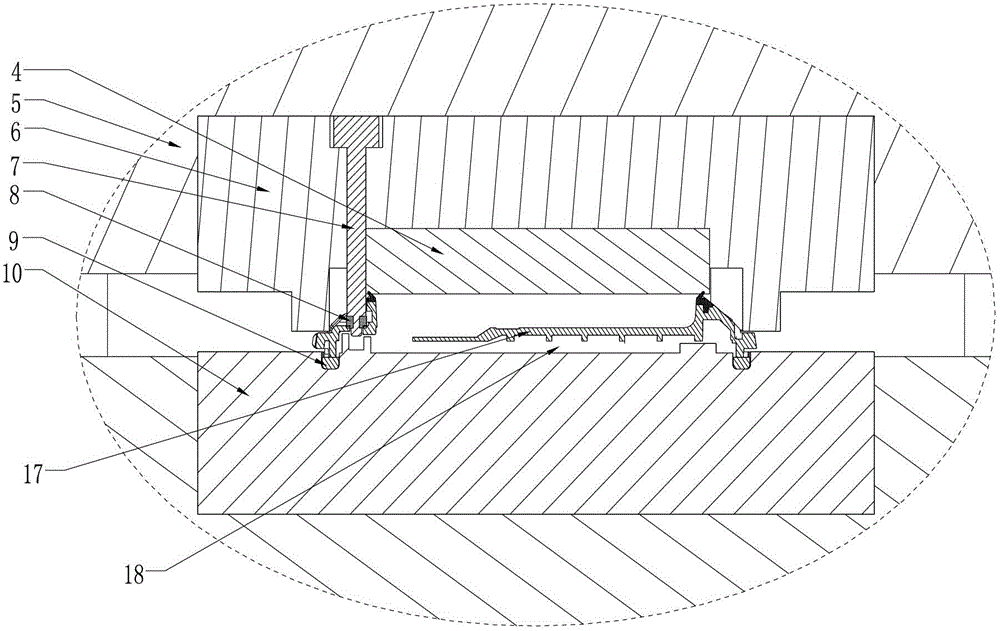

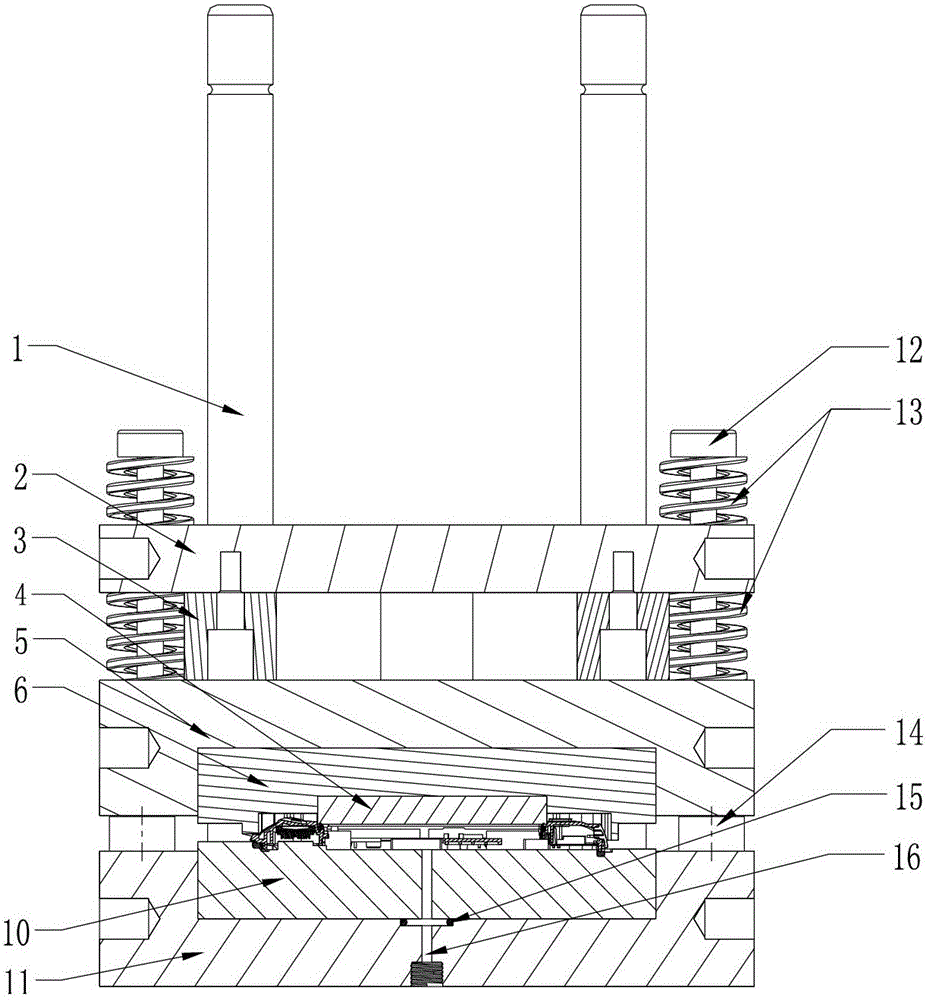

[0022] Such as figure 1 , figure 2 and image 3 As shown, the seal detection fixture can be divided into two parts, the lower mold and the upper mold. The upper surface of the lower mold is provided with an annular seal 9 that contacts the parting surface of the produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com