High-performance glass fiber reinforcement polyphenyl ether/polyamide alloy and production method thereof

A polyphenylene ether, high-performance technology, applied in the field of high-performance glass fiber reinforced polyphenylene ether/nylon alloy and its preparation, can solve the problems of difficult development of PPO/PA alloy products, poor impact performance, notch sensitivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~8

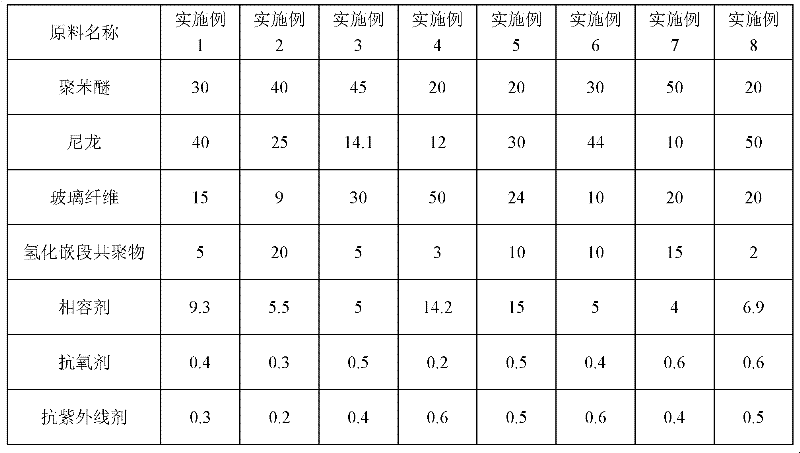

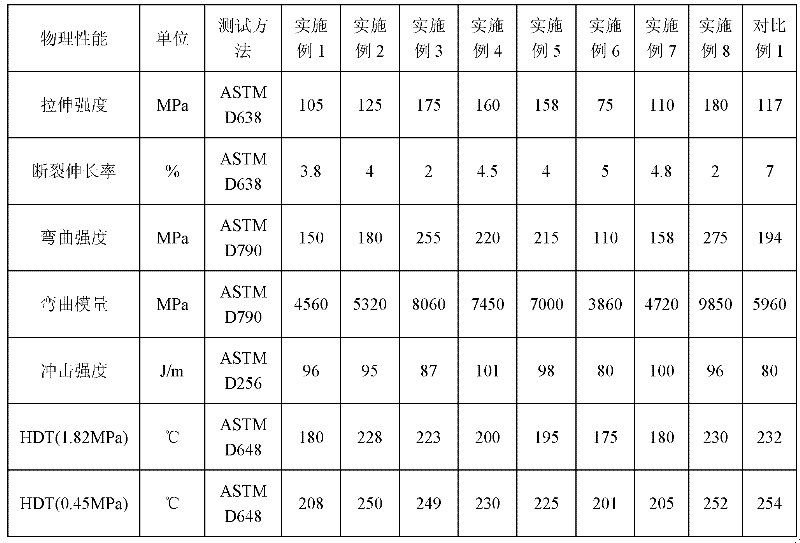

[0033] The specific components are shown in Table 1.

Embodiment 1

[0035] (1) Take raw materials by weight percentage content:

[0036] Polyphenylene ether 30%;

[0037] Nylon 6 40%;

[0038] Kraton G1643 5%;

[0039] CMG-W-01 9.3%;

[0040] Antioxidant 0.4%;

[0041] Anti-ultraviolet agent 0.3%;

[0042] (2) The above-mentioned mixed materials are added by the main feed of the twin-screw extruder, and the long glass fiber with a weight ratio of 15% is added through the side feed, and then extruded and pelletized. The rotating speed of the screw machine is 350 rpm / min at a temperature of 250°C.

Embodiment 2

[0044] (1) Take raw materials by weight percentage content:

[0045] Polyphenylene ether 40%;

[0046] Nylon 66 25%;

[0047] Kraton G1657 20%;

[0048] CMG-W-01 5.5%;

[0049] Antioxidant 0.3%;

[0050] Anti-ultraviolet agent 0.2%;

[0051] (2) The above-mentioned mixed materials are added by the main feed of the twin-screw extruder, and the long glass fiber with a weight ratio of 9% is added through the side feed, and then extruded and pelletized. The rotating speed of the screw machine is 550 rpm / min at a temperature of 260°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com