Halogen free inflaming retardant polyphenylene oxide alloy and preparation method thereof

A polyphenylene ether and alloy technology is applied in the field of alloy materials and their preparation, and achieves the effects of wide practicability, easy insulation, and good high and low temperature mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~9

[0030] In the following Examples 1-9:

[0031] The specific viscosity of polyphenylene ether (PPO) resin in chloroform at 25°C is 0.2-0.6 dl / g.

[0032] Hydrogenated block copolymers are A-B-A triblock copolymers or A-B diblock copolymers of styrene and butadiene, or a blend of the two; Kraton G1650, Kraton G1651, Kraton G1657, Kraton G1660, Kraton G1643 et al.

[0033] The polyolefin is low density polyethylene.

Embodiment 1

[0035] The components of the halogen-free flame-retardant polyphenylene ether alloy of this embodiment and the parts by weight of each component are as follows:

[0036] PPO LXR035: 50

[0037] High Impact Polystyrene: 34

[0038] Melamine polyphosphate: 3

[0039] Triphenyl Phosphate: 8

[0040] Kraton G1660: 3

[0041] LDPE: 2

[0042] Antioxidant: 0.3

[0043] Anti-ultraviolet agent: 0.3.

[0044] The steps of the preparation method of the halogen-free flame-retardant polyphenylene ether alloy are as follows:

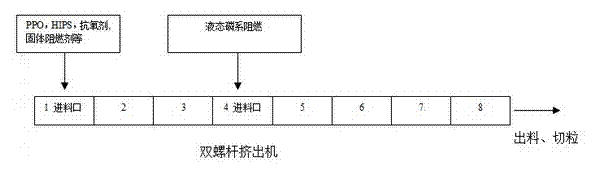

[0045] Step 1: Take each component according to parts by weight, put each component into a high mixer and mix for 2 to 5 minutes, and then add it from the first section of the twin-screw extruder;

[0046] In step 2, the above-mentioned materials are extruded and granulated by a twin-screw extruder with a rotation speed of 180-600 rpm and a temperature of 235-255° C. to obtain a halogen-free flame-retardant polyphenylene ether alloy.

Embodiment 2

[0048] The components of the halogen-free flame-retardant polyphenylene ether alloy of this embodiment and the parts by weight of each component are as follows:

[0049] PPO LXR045: 58

[0050] High Impact Polystyrene: 24

[0051] Melamine polyphosphate: 2

[0052] m-Phenylene tetraphenyl bisphosphate: 10

[0053] Kraton G1650: 4.5

[0054] LDPE: 1.5

[0055] Antioxidant: 0.3

[0056] Anti-ultraviolet agent: 0.3.

[0057] The steps of the preparation method of the halogen-free flame-retardant polyphenylene ether alloy are as follows:

[0058] Step 1, taking each component by weight parts;

[0059] Step 2, mixing the above materials except m-phenylene tetraphenyl bisphosphate in a high-speed mixer for 2 to 5 minutes, and adding them from the main feeding pump of the twin-screw extruder;

[0060] Step 3, m-phenylene bisphosphate is added from the fourth section of the twin-screw extruder through a feed pump;

[0061] Step 4, the above-mentioned materials are extruded an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com