High temperature resistant high impact polyphenylene ether/polypropylene alloy material and preparation method thereof

A technology of alloy material and polyphenylene ether, which is applied in the field of high-temperature-resistant and high-impact polyphenylene ether/polypropylene alloy material and its preparation, can solve the problems of difficult process control and high requirements for production equipment, and overcome compatibility problems , Improve compatibility and improve impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

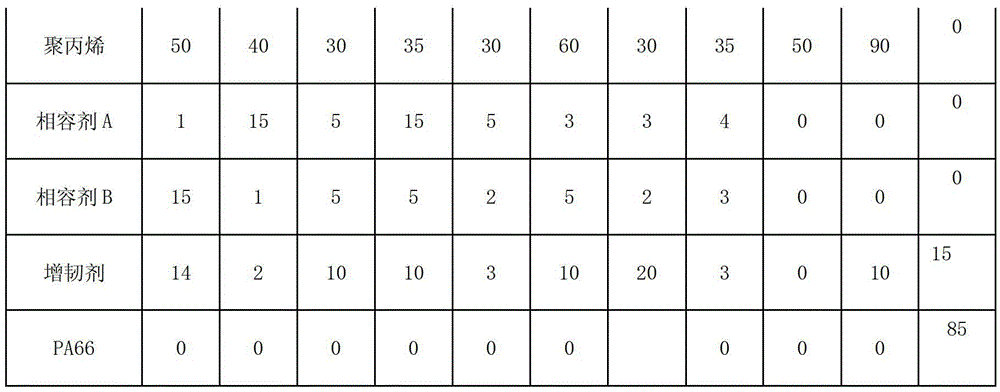

Embodiment 1

[0038] In this embodiment, a method for preparing a high-temperature-resistant and high-impact polyphenylene ether / polypropylene alloy material, the method includes the following steps:

[0039] (1) Weigh raw materials according to the weight percentage content:

[0040] PPOLXR03820%;

[0041] PPK792650%;

[0042] KratonG16571%;

[0043] MODIPERA140115%;

[0044] DF60514%;

[0045] (2) Put the above materials into a high mixer and mix for 3 minutes, extrude and granulate through a twin-screw extruder, the speed of the twin-screw extruder is 400 rpm, and the extrusion temperature is 255°C.

Embodiment 2

[0047] In this embodiment, a method for preparing a high-temperature-resistant and high-impact polyphenylene ether / polypropylene alloy material, the method includes the following steps:

[0048] (1) Weigh raw materials according to the weight percentage content:

[0049] PPOLXR04542%;

[0050]PPS70040%;

[0051] KratonG164315%;

[0052] MODIPERA34001%;

[0053] ENGAGE88422%;

[0054] (2) Put the above materials into a high-mixer and mix for 5 minutes, extrude and pelletize through a twin-screw extruder, the speed of the twin-screw extruder is 450 rpm, and the extrusion temperature is 235°C.

Embodiment 3

[0056] In this embodiment, a method for preparing a high-temperature-resistant and high-impact polyphenylene ether / polypropylene alloy material, the method includes the following steps:

[0057] (1) Weigh raw materials according to the weight percentage content:

[0058] PPOLXR03850%;

[0059] PP66M60T30%;

[0060] KratonG16455%;

[0061] MODIPERA14015%;

[0062] ENGAGE840210%;

[0063] (2) Put the above materials into a high mixer and mix for 3 minutes, extrude and granulate through a twin-screw extruder, the speed of the twin-screw extruder is 450 rpm, and the extrusion temperature is 265°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com