Method for preparing nanoscale silicon carbide copper alloy material

A technology of nano-scale silicon carbide and silicon carbide copper, which is applied in the field of nano-scale silicon carbide copper-based alloy materials, can solve problems such as difficult performance, and achieve the effects of performance improvement, high strength, and high wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

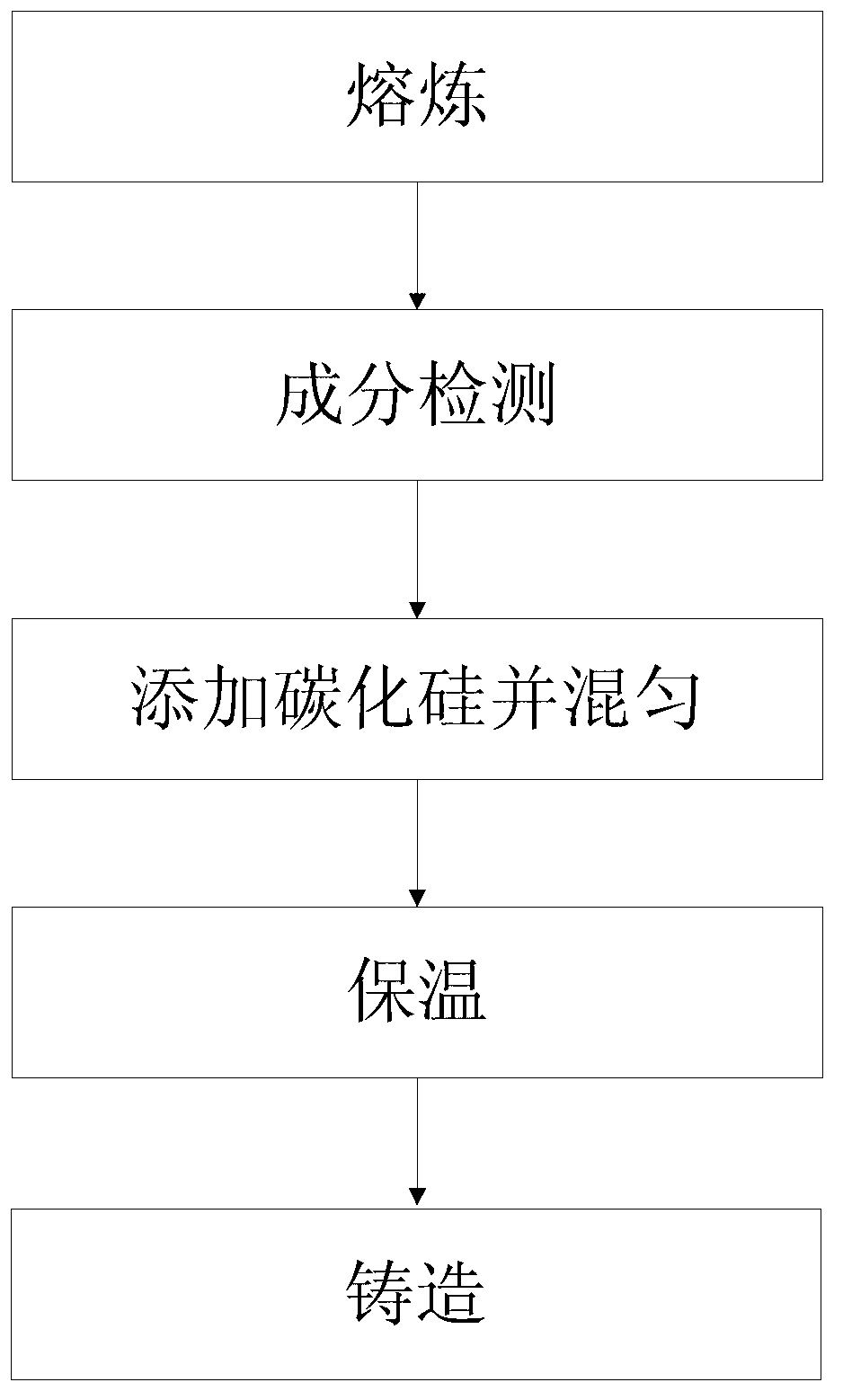

[0024] A preparation method of nano-scale silicon carbide copper-based alloy material:

[0025] Step 1: According to the national standard GB / T1176-1987 and the chemical composition requirements of the copper alloy material QAL9-4, put electrolytic copper, aluminum ingots and iron ingots into the electric furnace for melting according to the weight ratio, and control the copper according to the volume of the melting furnace during the melting period. The alloy liquid volume is 82% of the furnace volume; the melting temperature is 1300-1380°C; the time is 3-3.5 hours;

[0026] Step 2: detecting the composition of the copper alloy liquid formed after the copper alloy material is smelted.

[0027] Step 3: Put 10% of the total volume of nano-scale silicon carbide powder into the surface of the copper alloy liquid that has passed the inspection, turn on the vibration device of the power frequency electric furnace and stir it with a graphite rod to make it evenly mixed to form nano-...

Embodiment 2

[0032] A preparation method of nano-scale silicon carbide copper-based alloy material:

[0033] Step 1: According to the national standard GB / T1176-1987 and the chemical composition requirements of the copper alloy material QAL9-4, put electrolytic copper, aluminum ingots and iron ingots into the electric furnace for melting according to the weight ratio, and control the copper according to the volume of the melting furnace during the melting period. The alloy liquid volume is 82% of the furnace volume; the melting temperature is 1300-1380°C; the time is 3-3.5 hours;

[0034] Step 2: detecting the composition of the copper alloy liquid formed after the copper alloy material is smelted.

[0035] Step 3: Put 8% of the total volume of nano-scale silicon carbide powder on the surface of the copper alloy liquid that has passed the inspection, turn on the vibration device of the power frequency electric furnace and stir it with a graphite rod to make it evenly mixed to form nano-sca...

Embodiment 3

[0040] A preparation method of nano-scale silicon carbide copper-based alloy material:

[0041] Step 1: According to the national standard GB / T1176-1987 and the chemical composition requirements of the copper alloy material QAL9-4, put electrolytic copper, aluminum ingots and iron ingots into the electric furnace for melting according to the weight ratio, and control the copper according to the volume of the melting furnace during the melting period. The volume of the alloy liquid is 85% of the volume of the furnace; the melting temperature is 1300-1380°C; the time is 3-3.5 hours;

[0042] Step 2: detecting the composition of the copper alloy liquid formed after the copper alloy material is smelted.

[0043] Step 3: Put 5% of the total volume of nano-scale silicon carbide powder on the surface of the copper alloy liquid that has passed the inspection, turn on the vibration device of the power frequency electric furnace and stir with a graphite rod to make it evenly mixed to fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com