Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

751 results about "Hydrogen embrittlement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrogen embrittlement (HE) also known as hydrogen assisted cracking (HAC) and hydrogen-induced cracking (HIC), describes the embrittling of metal after being exposed to hydrogen. It is a complex process that is not completely understood because of the variety and complexity of mechanisms that can lead to embrittlement. Mechanisms that have been proposed to explain embrittlement include the formation of brittle hydrides within certain metals, the creation of voids that can lead to bubbles and pressure build-up within a material and enhanced decohesion or localised plasticity that assist in the propagation of cracks.

HIGH STRENGTH STEEL PLATE WITH ULTIMATE TENSILE STRENGTH OF 900 MPa OR MORE EXCELLENT IN HYDROGEN EMBRITTLEMENT RESISTANCE AND METHOD OF PRODUCTION OF SAME

ActiveUS20120222781A1Reduce resistanceImprove plasticityHot-dipping/immersion processesSurface reaction electrolytic coatingCarbideUltimate tensile strength

High strength steel plate with an ultimate tensile strength of 900 MPa or more which is excellent in hydrogen embrittlement resistance characterized in that, in the structure of the steel plate, (a) by volume fraction, ferrite is present in 10 to 50%, bainitic ferrite and / or bainite in 10 to 60%, and tempered martensite in 10 to 50%, and (b) iron-based carbides which contain Si or Si and Al in 0.1% or more are present in 4×108 (particles / mm3) or more.

Owner:NIPPON STEEL CORP

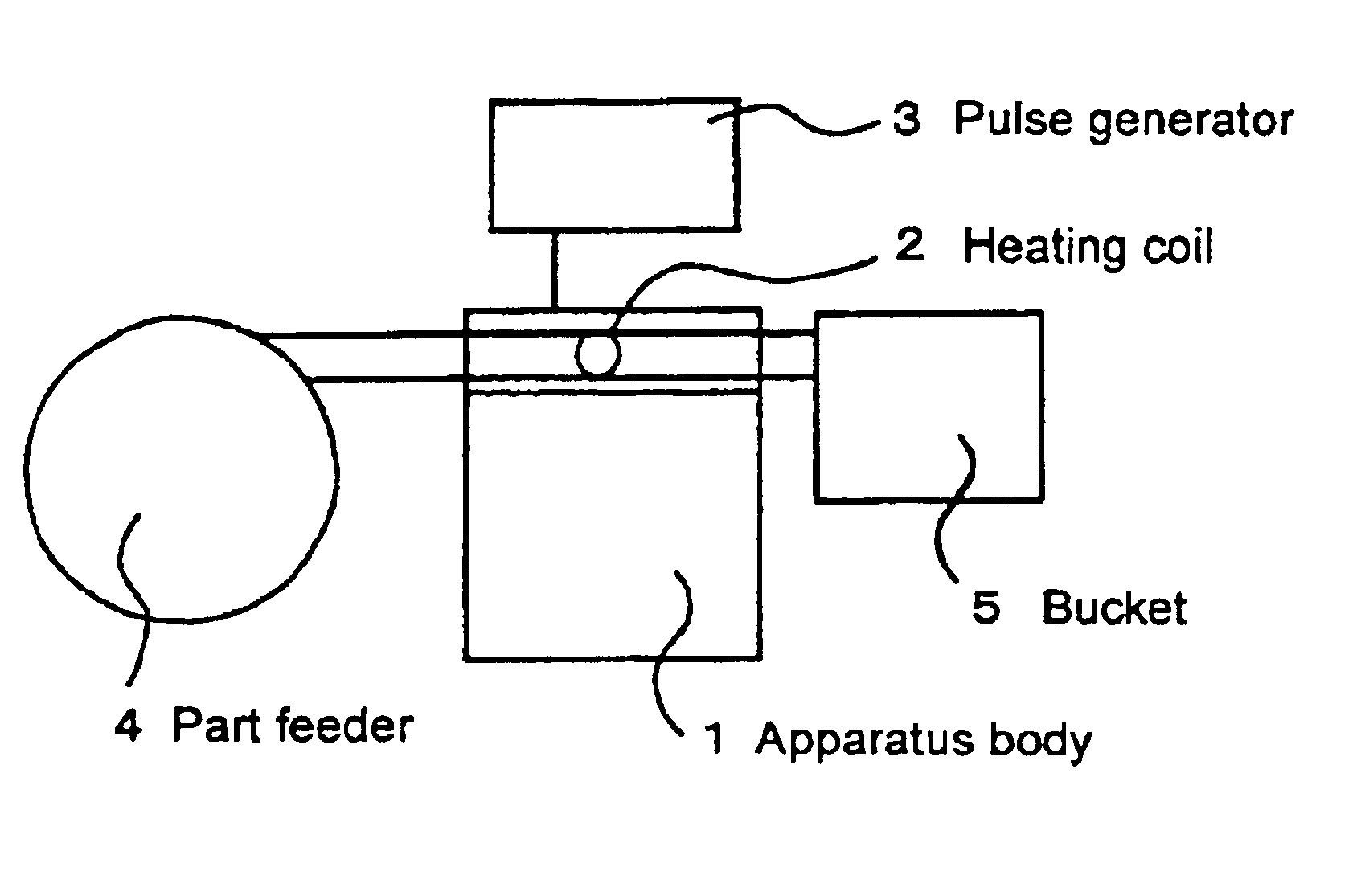

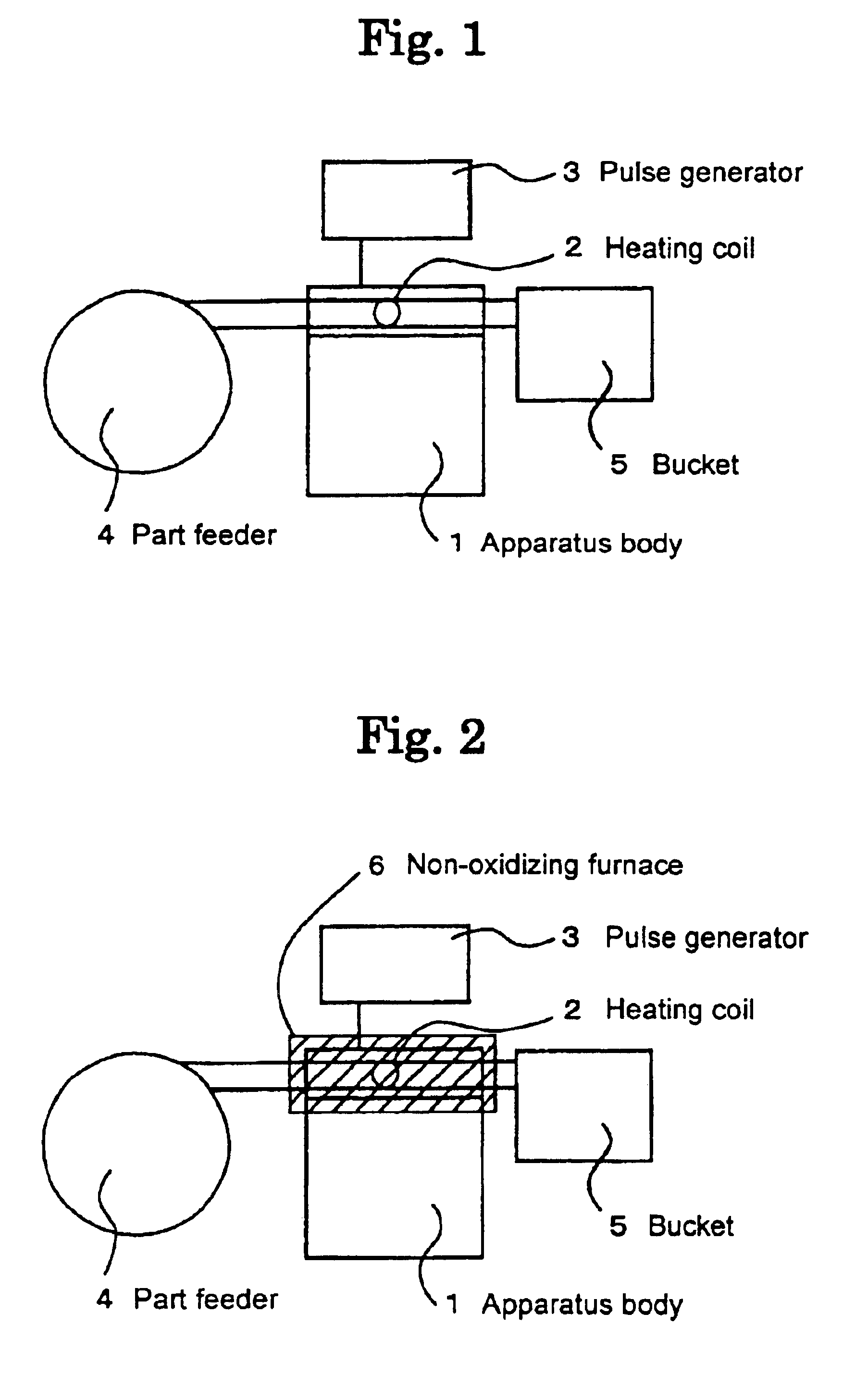

Method of baking treatment of steel product parts

InactiveUS6855217B2Shorten the timeImprove facilitiesIncreasing energy efficiencyFurnace typesSurface layerMetallurgy

The present invention relates to a method of baking treatment of steel product parts using a high frequency or ultra-high frequency for preventing delayed fracture from occurring due to diffusive hydrogen occluded in steel parts, for example, screws, bolts and the like, or for heating surface layers of the steel parts to generate a difference in temperature between the surface layers and interiors of the steel parts, thereby causing distortion in lattices, wherein the surface layers of the steel parts are rapidly heated to 100 to 300° C. with a high frequency or ultra-high frequency at 10 KHz or higher to remove the diffusive hydrogen which is involved in hydrogen embrittlement, or to transfer an existing state to non-diffusive hydrogen which is not involved in the hydrogen embrittlement.

Owner:AOYAMA SEISAKUSHO CO LTD

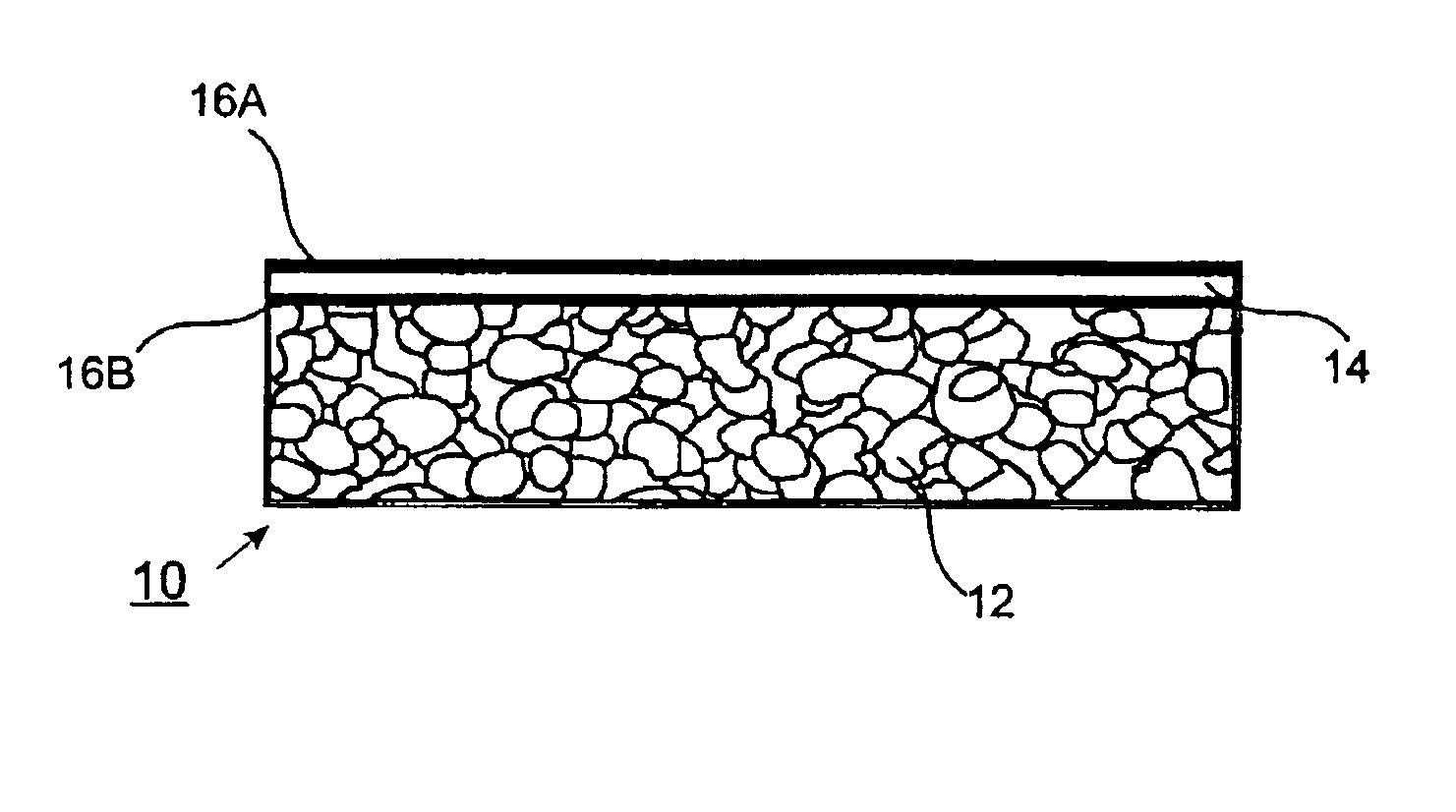

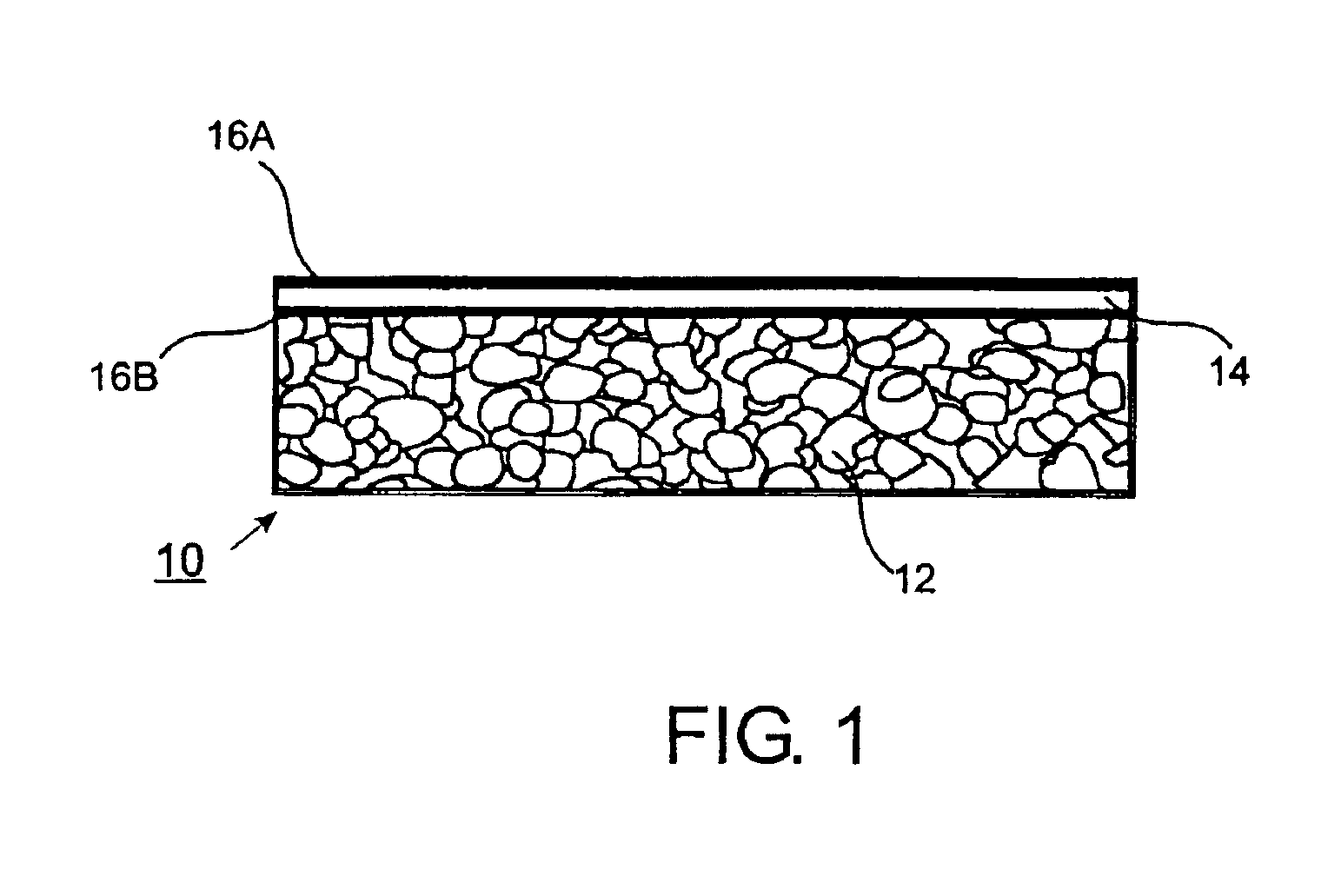

Hydrogen transport membranes

InactiveUS6899744B2Increase ratingsThickness minimizationSemi-permeable membranesMembranesSupport matrixNiobium

Composite hydrogen transport membranes, which are used for extraction of hydrogen from gas mixtures are provided. Methods are described for supporting metals and metal alloys which have high hydrogen permeability, but which are either too thin to be self supporting, too weak to resist differential pressures across the membrane, or which become embrittled by hydrogen. Support materials are chosen to be lattice matched to the metals and metal alloys. Preferred metals with high permeability for hydrogen include vanadium, niobium, tantalum, zirconium, palladium, and alloys thereof. Hydrogen-permeable membranes include those in which the pores of a porous support matrix are blocked by hydrogen-permeable metals and metal alloys, those in which the pores of a porous metal matrix are blocked with materials which make the membrane impervious to gases other than hydrogen, and cermets fabricated by sintering powders of metals with powders of lattice-matched ceramic.

Owner:ELTRON RES

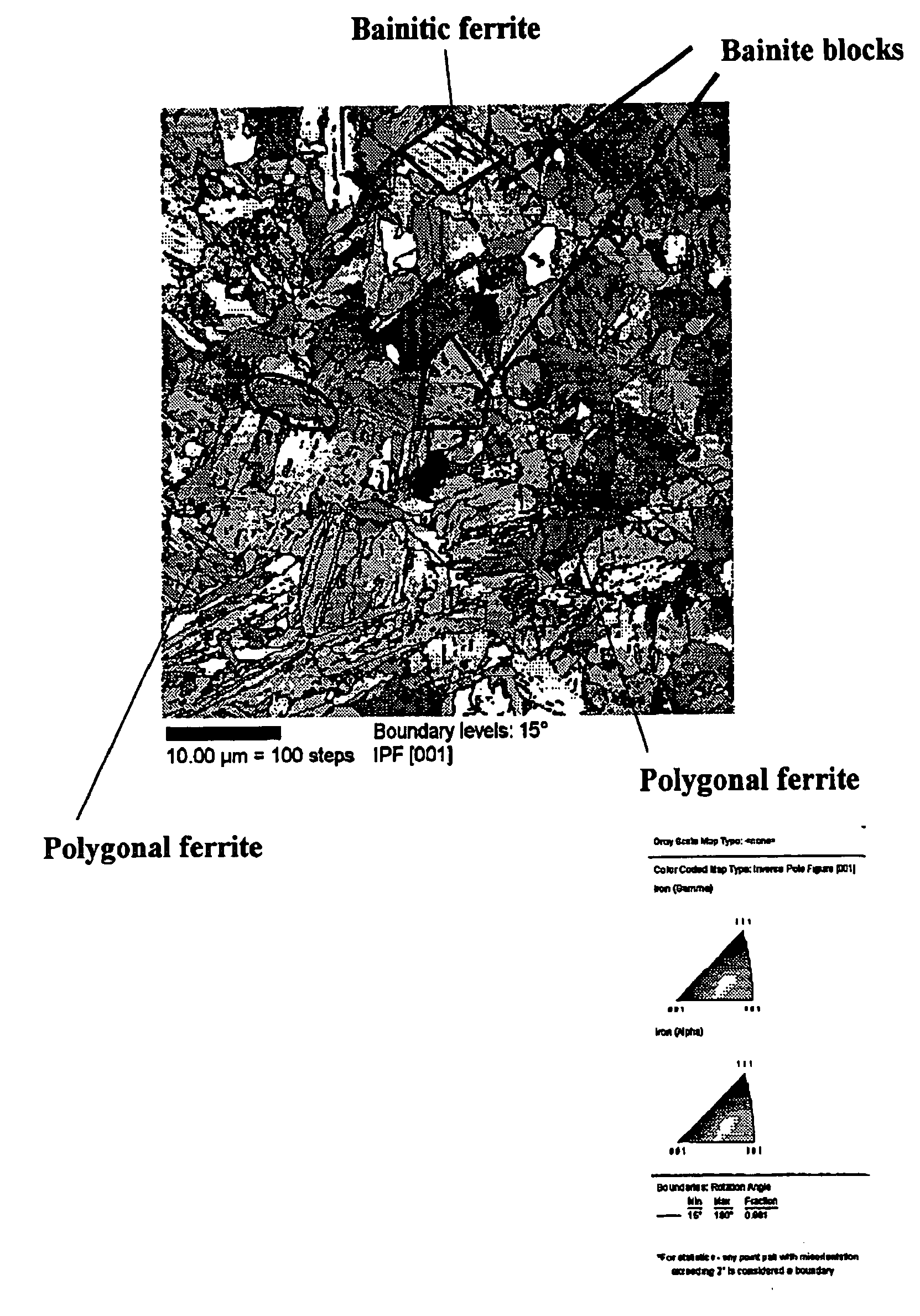

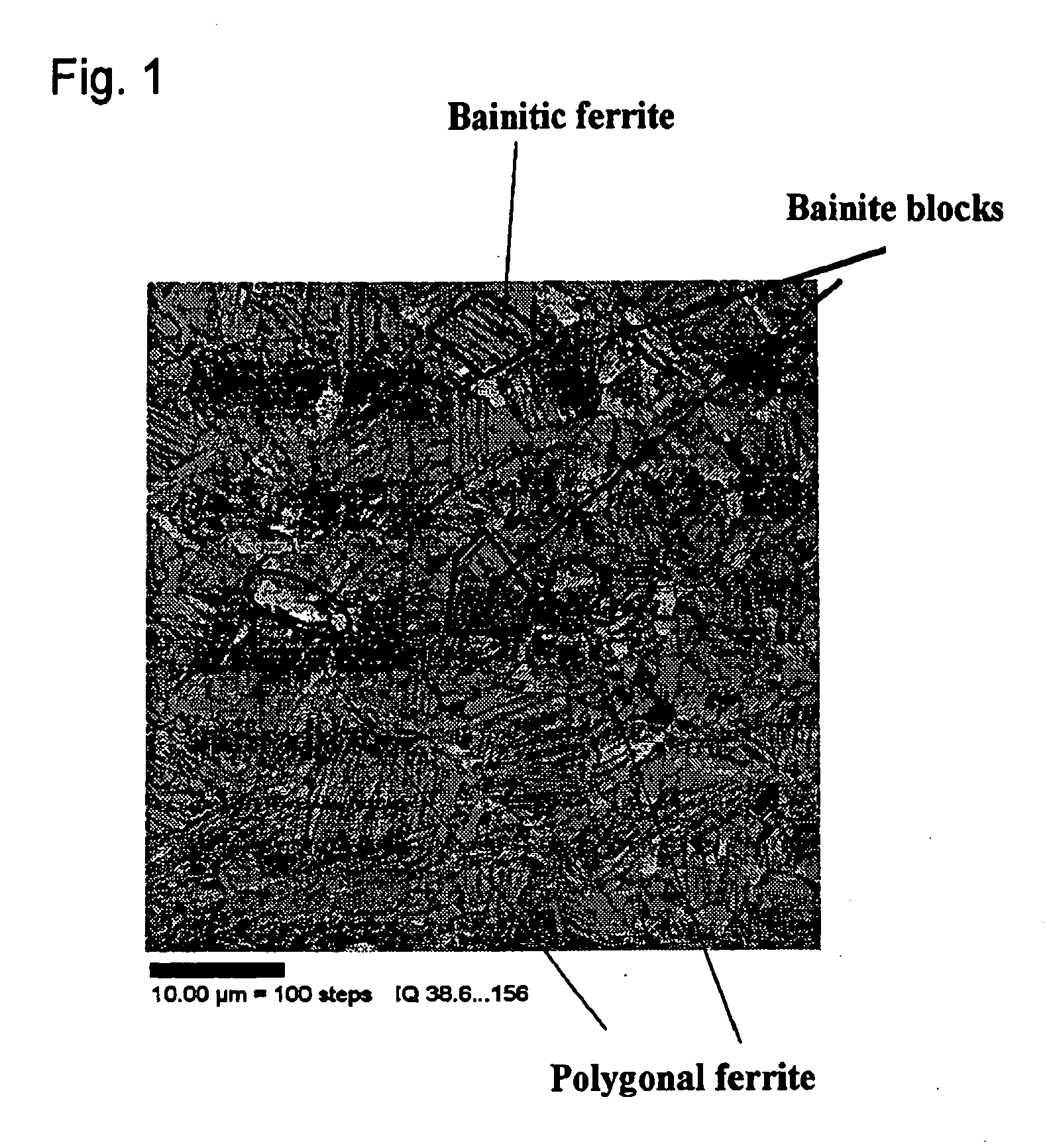

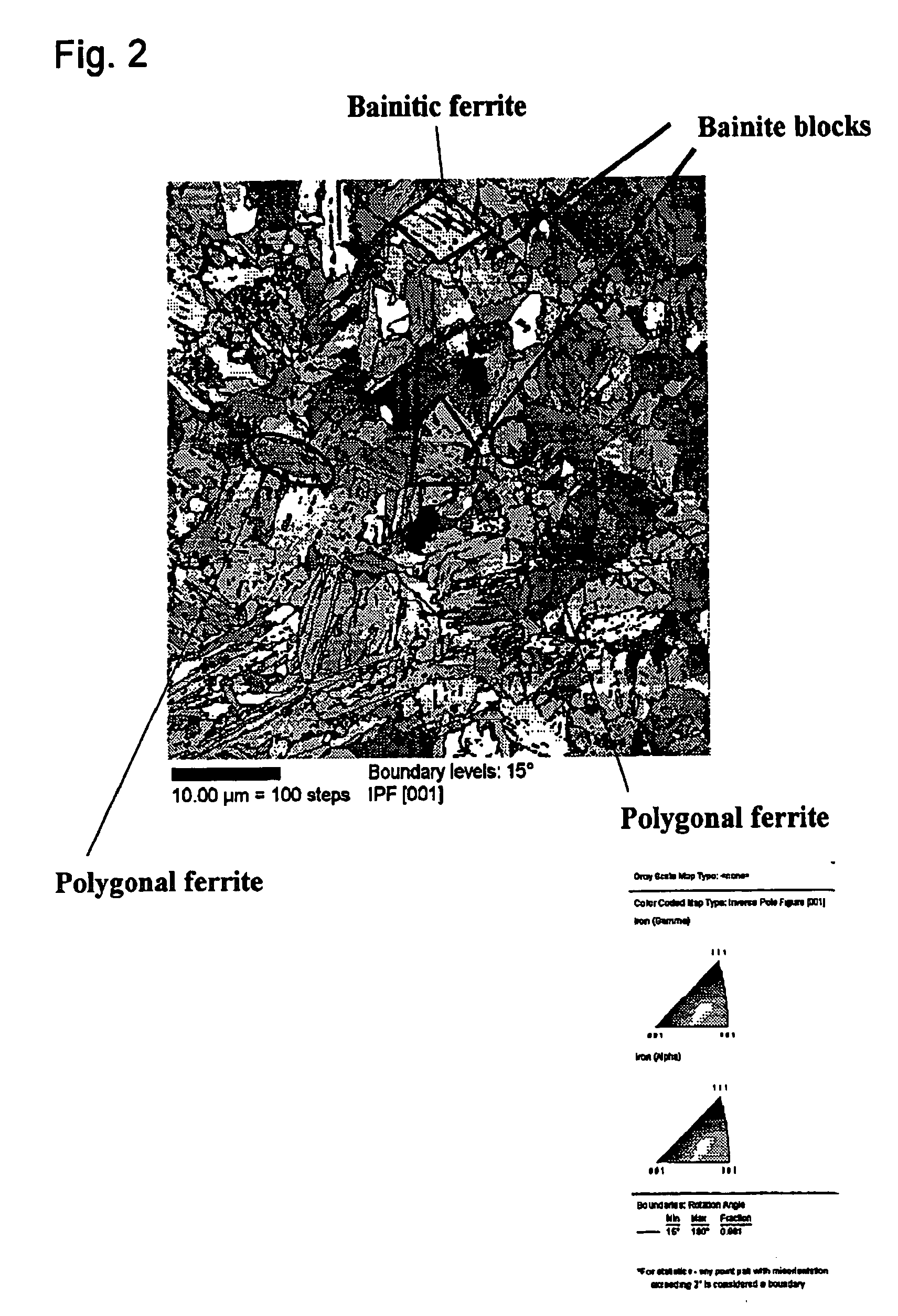

Ultra-high strength steel sheet having excellent hydrogen embrittlement resistance, and method for manufacturing the same

InactiveUS20050150580A1High strengthImprove hydrogen embrittlement resistanceManganeseUltimate tensile strength

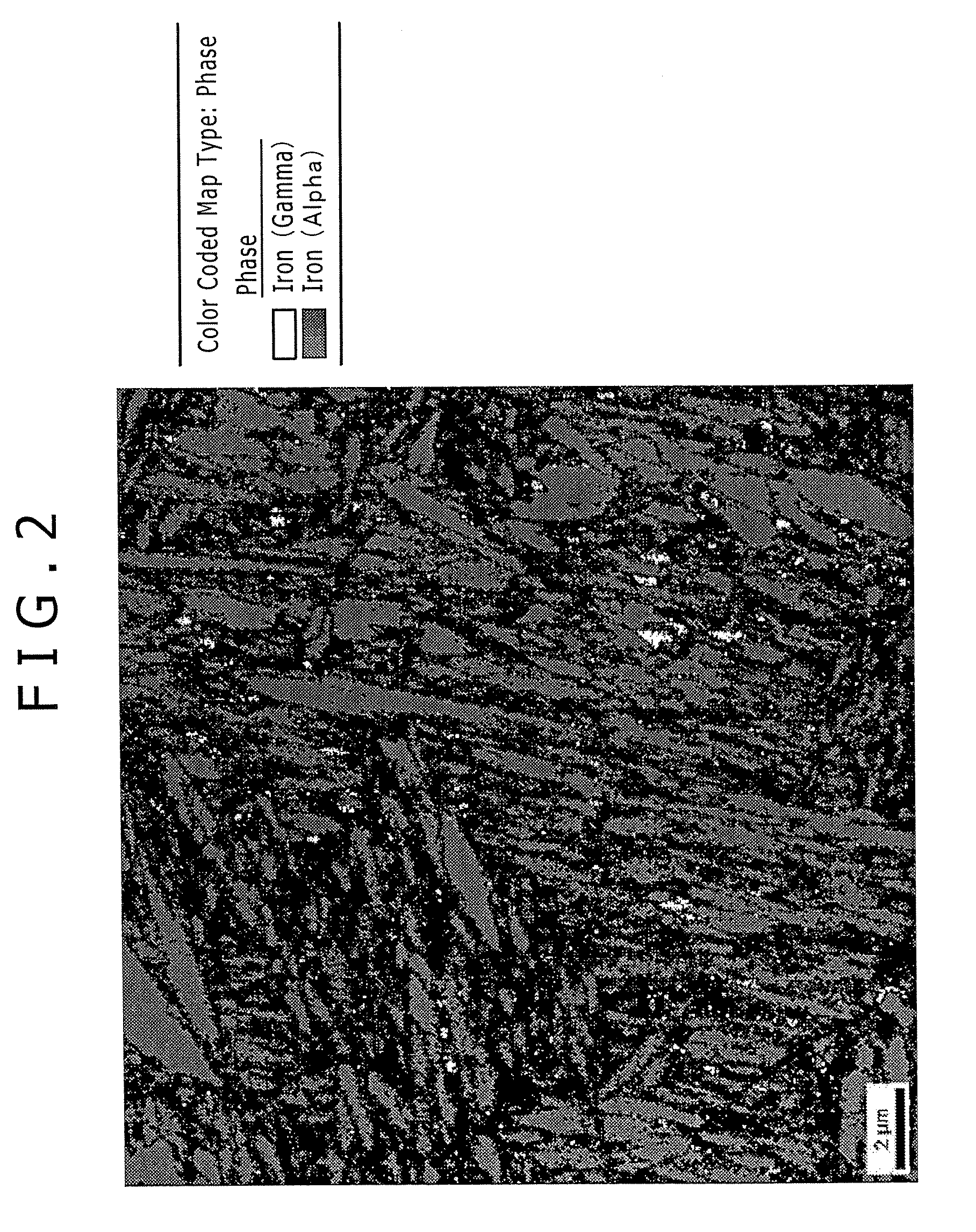

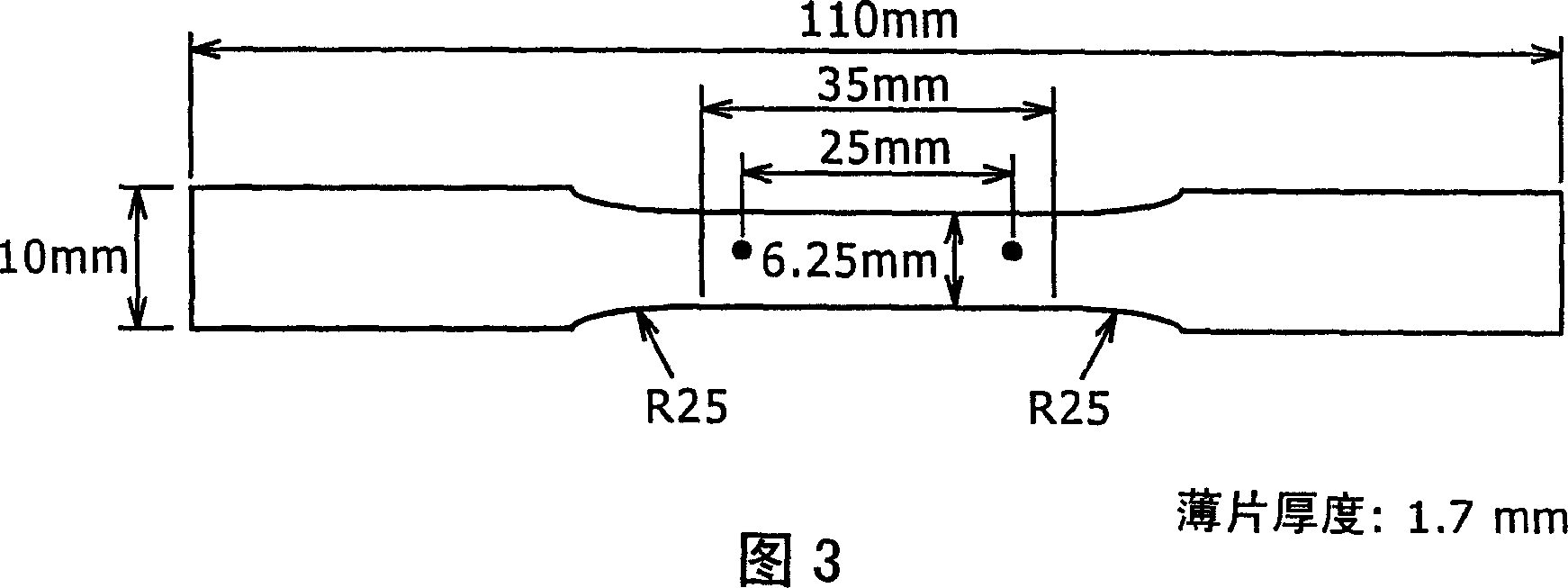

The present invention provides an ultra-high strength steel sheet having excellent hydrogen embrittlement resistance, which includes: 0.06 to 0.6% of C; 0.5 to 3% of Si+Al; 0.5 to 3% of Mn; 0.15% or lower of P; and 0.02% or lower of S in terms of mass percentage, and also includes 3% or higher of residual austenite structure, 30% or higher of bainitic ferrite structure, and preferably 50% or lower of polygonal ferrite in terms of an areal ratio to the entire structure, wherein a mean grain size of bainite blocks is smaller than 20 μm as determined by comparing observations of the same region of the bainitic ferrite structure by EBSP (electron back scatter diffraction pattern) and SEM.

Owner:KOBE STEEL LTD

High strength thin steel sheet having high hydrogen embrittlement resisting property

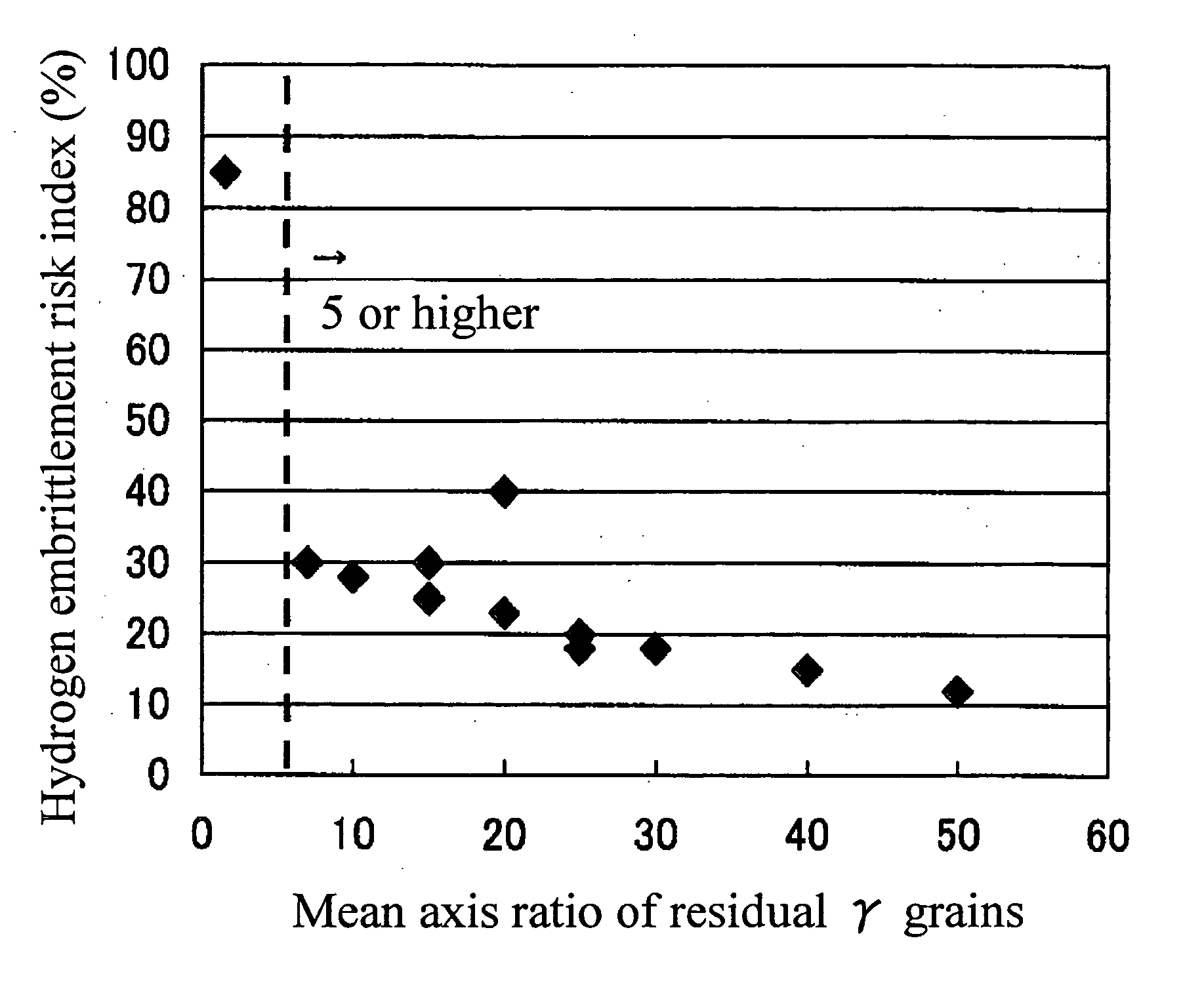

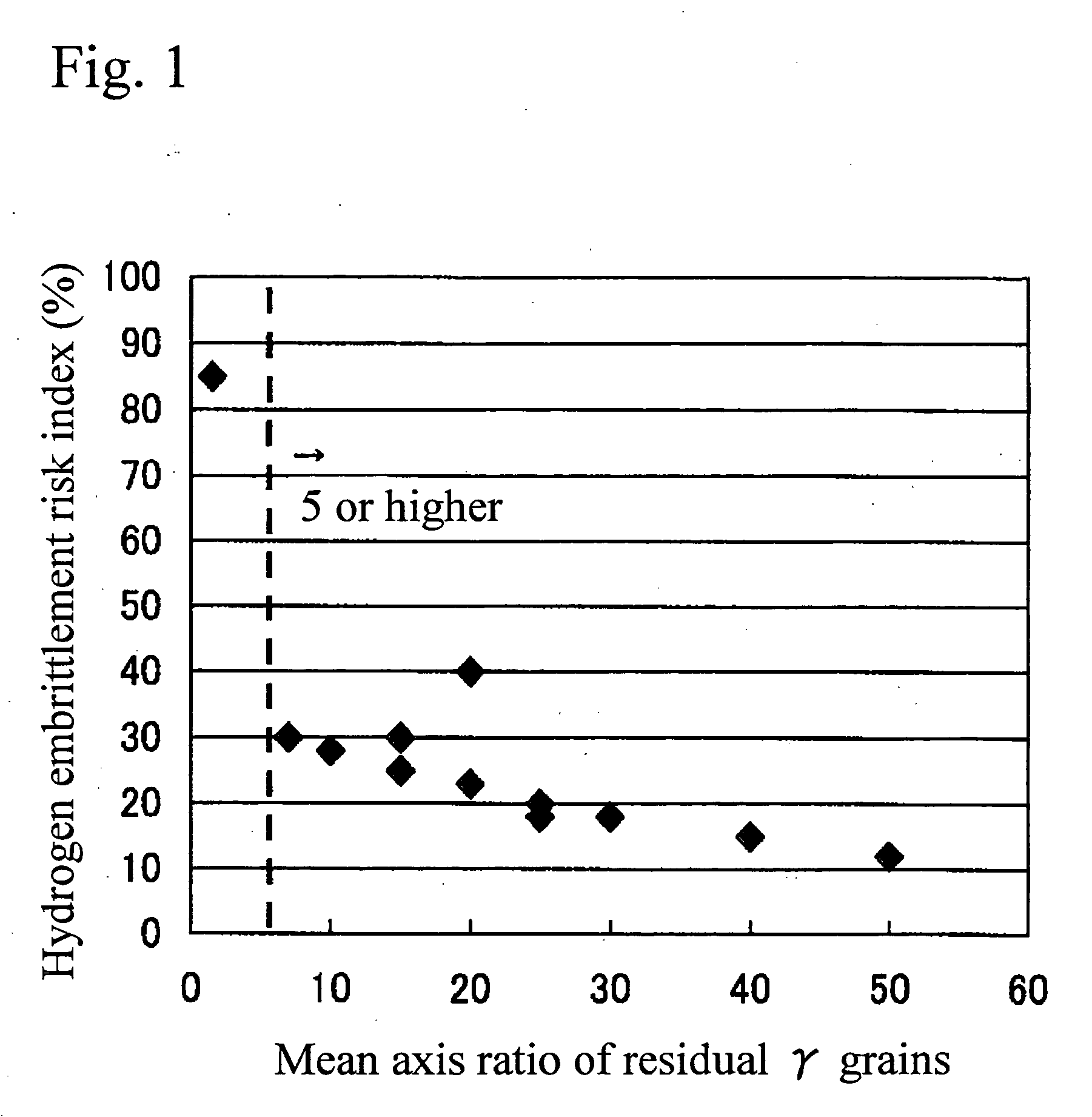

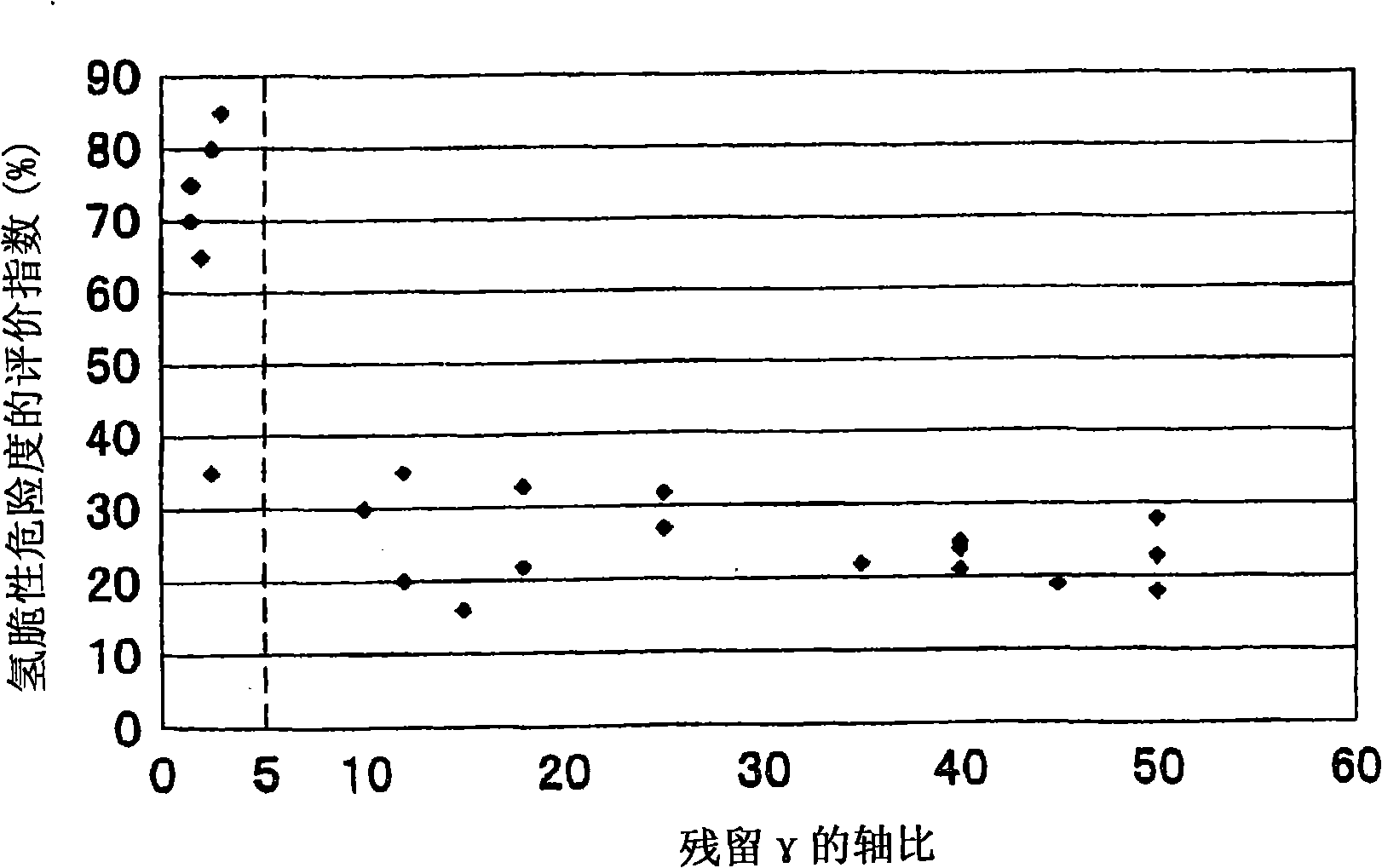

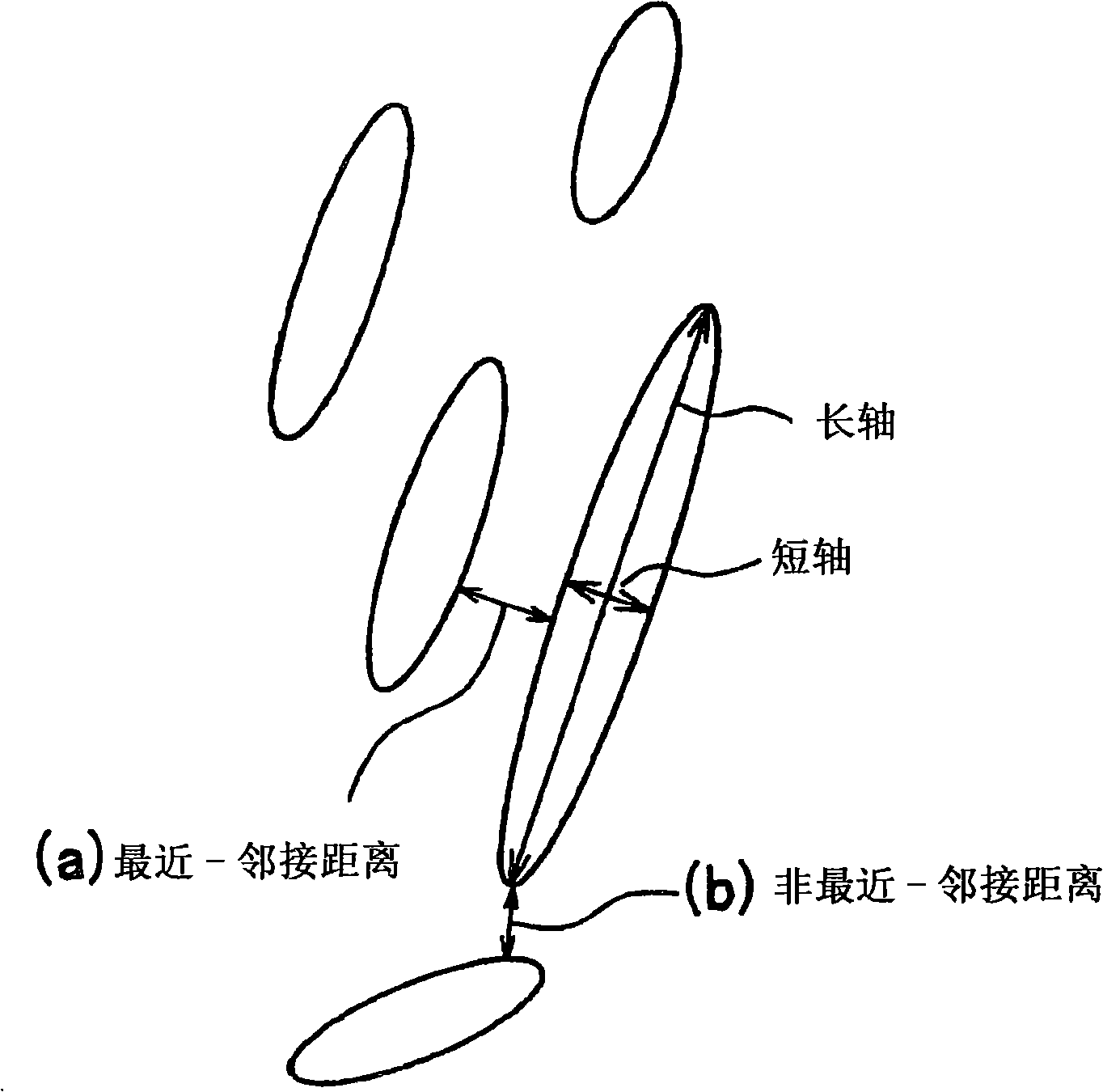

The purpose of the present invention is to provide a high strength thin steel sheet that has high hydrogen embrittlement resisting property. In order to achieve the above purpose, a high strength thin steel sheet having high hydrogen embrittlement resisting property comprises: C: 0.10 to 0.25%; Si: 1.0 to 3.0%; Mn: 1.0 to 3.5%; P: 0.15% or less; S: 0.02% or less; and Al: 1.5% or less (higher than 0%) in terms of percentage by weight, with balance of iron and inevitable impurities; and the metal structure comprises: residual austenite; 1% by area or more in proportion to the entire structure; bainitic ferrite and martensite: 80% or more in total; and ferrite and pearlite: 9% or less (may be 0%) in total, while the mean axis ratio (major axis / minor axis) of said residual austenite grains is 5 or higher, and the steel has tensile strength of 1180 MPa or higher.

Owner:KOBE STEEL LTD

Ultrahigh-strength thin steel sheet

ActiveCN101351570AImprove corrosion resistanceReduce contentFurnace typesHeat treatment furnacesSheet steelUltimate tensile strength

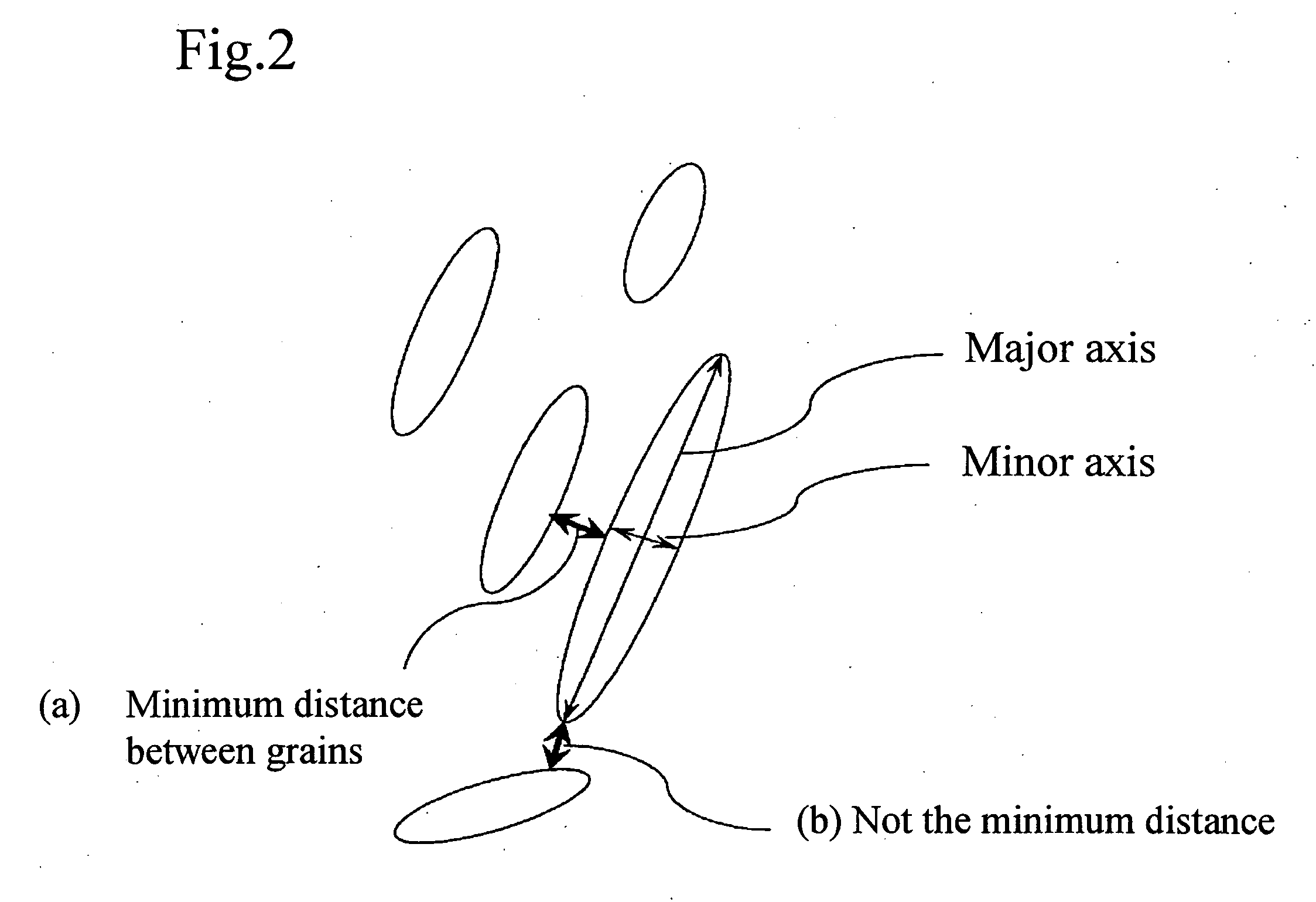

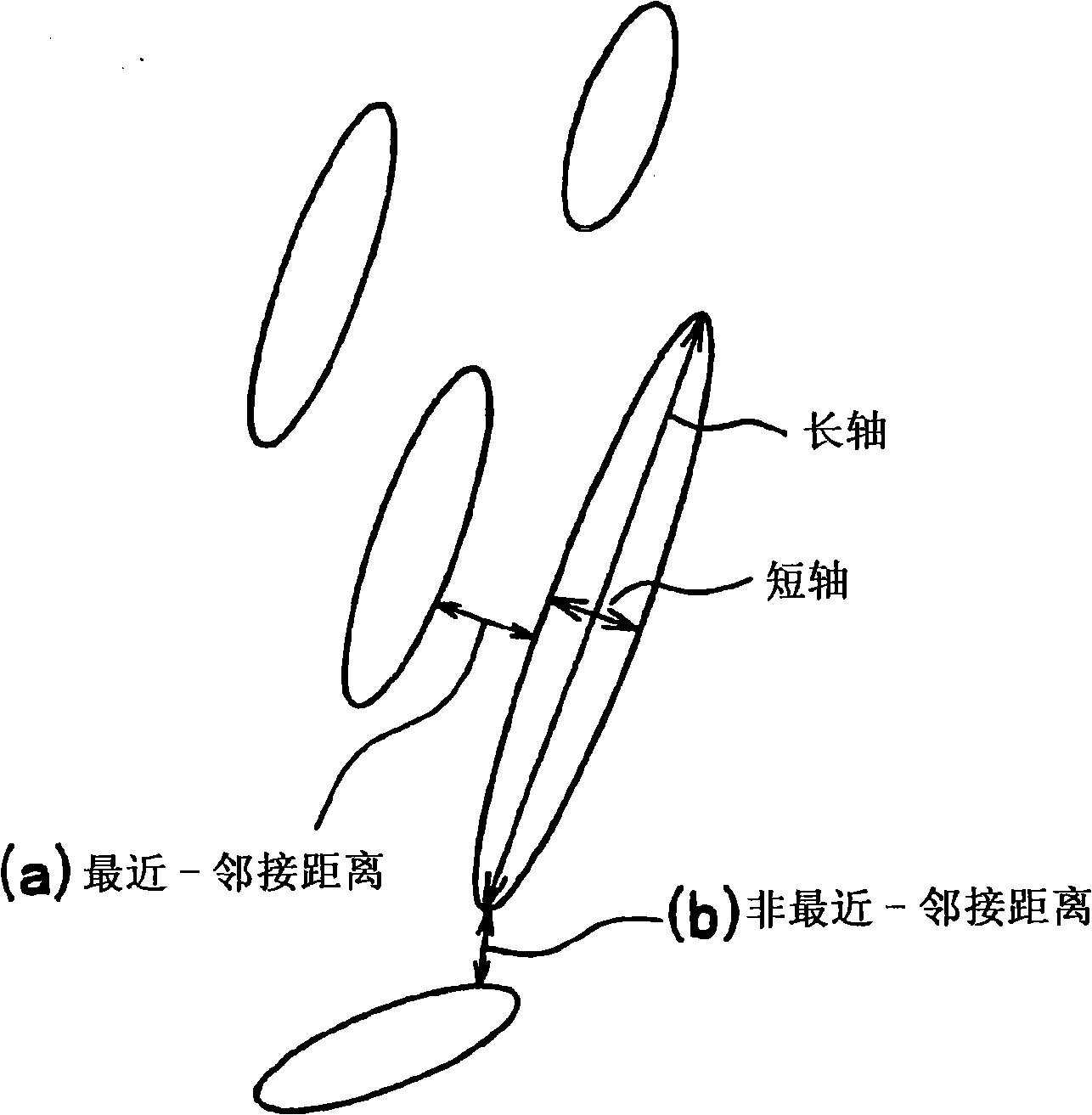

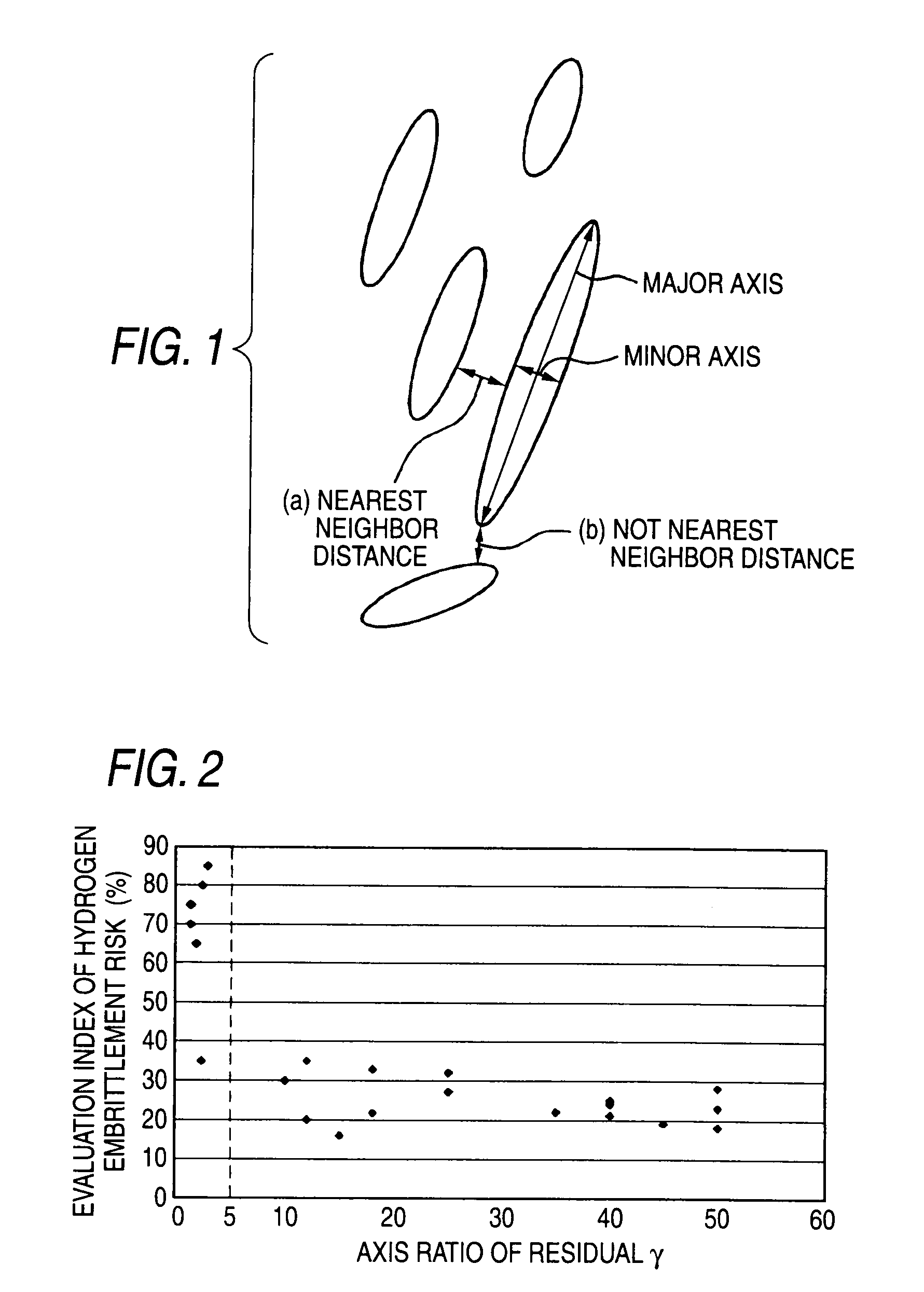

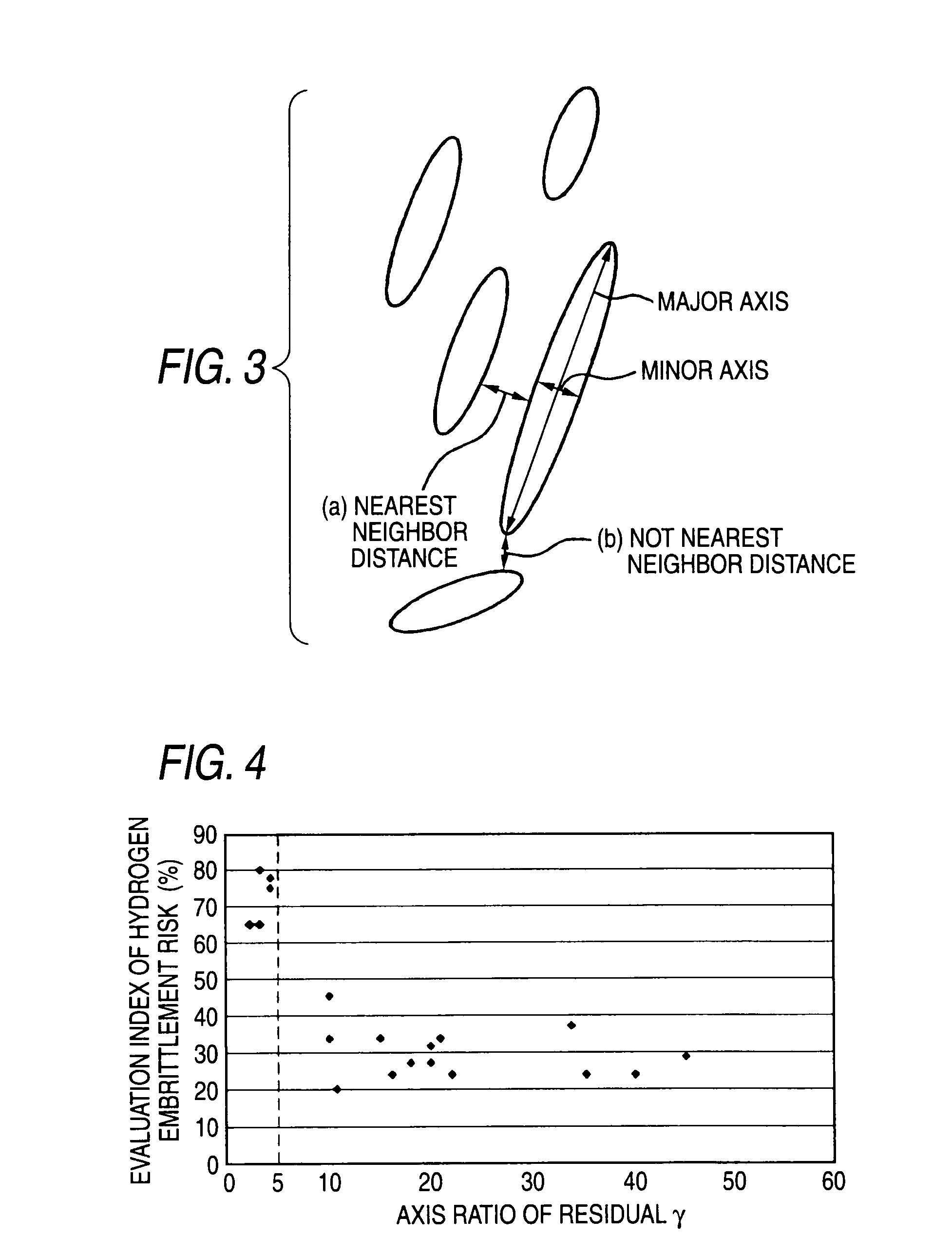

The present invention relates to an ultrahigh-strength steel sheet, which comprises, in terms of wt.%, 0.10-0.60% C, 1.0-3.0% Si, 1.0-3.5% Mn, up to 0.15% P, up to 0.02% S, up to 1.5% Al, and 0.003-2.0% Cr, with the remainder being iron and unavoidable impurities, and in which the crystal grains of residual austenite have an average aspect ratio (major axis / minor axis) of 5 or higher, an average minor-axis length of 1 [mu]m or shorter, and a minimum grain-to-grain distance of 1 [mu]m or shorter. It has excellent unsusceptibility to hydrogen embrittlement.

Owner:KOBE STEEL LTD

Ultrahigh-strength steel sheet

ActiveUS20090238713A1Improve hydrogen embrittlement resistanceImprove corrosion resistanceFurnace typesHeat treatment furnacesAustenite grainUltimate tensile strength

The invention relates to an ultrahigh-strength thin steel sheet excellent in the hydrogen embrittlement resistance, the steel sheet including, by weight %, 0.10 to 0.60% of C, 1.0 to 3.0% of Si, 1.0 to 3.5% of Mn, 0.15% or less of P, 0.02% or less of S, 1.5% or less of Al, 0.003 to 2.0% of Cr, and a balance including iron and inevitable impurities; in which grains of residual austenite have an average axis ratio (major axis / minor axis) of 5 or more, the grains of the residual austenite have an average minor axis length of 1 μm or less, and the grains of the residual austenite have a nearest-neighbor distance between the grains of 1 μm or less.

Owner:KOBE STEEL LTD

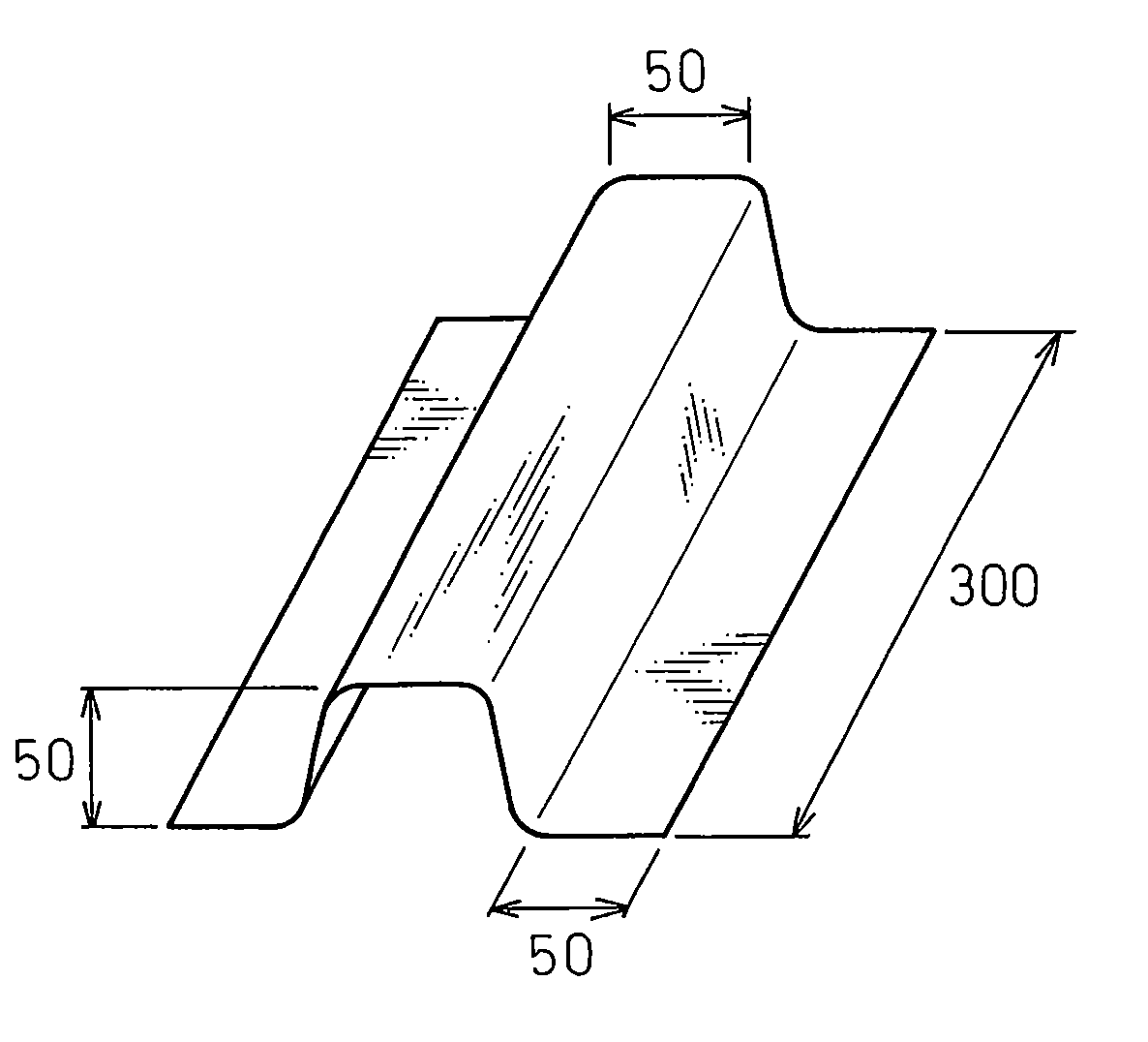

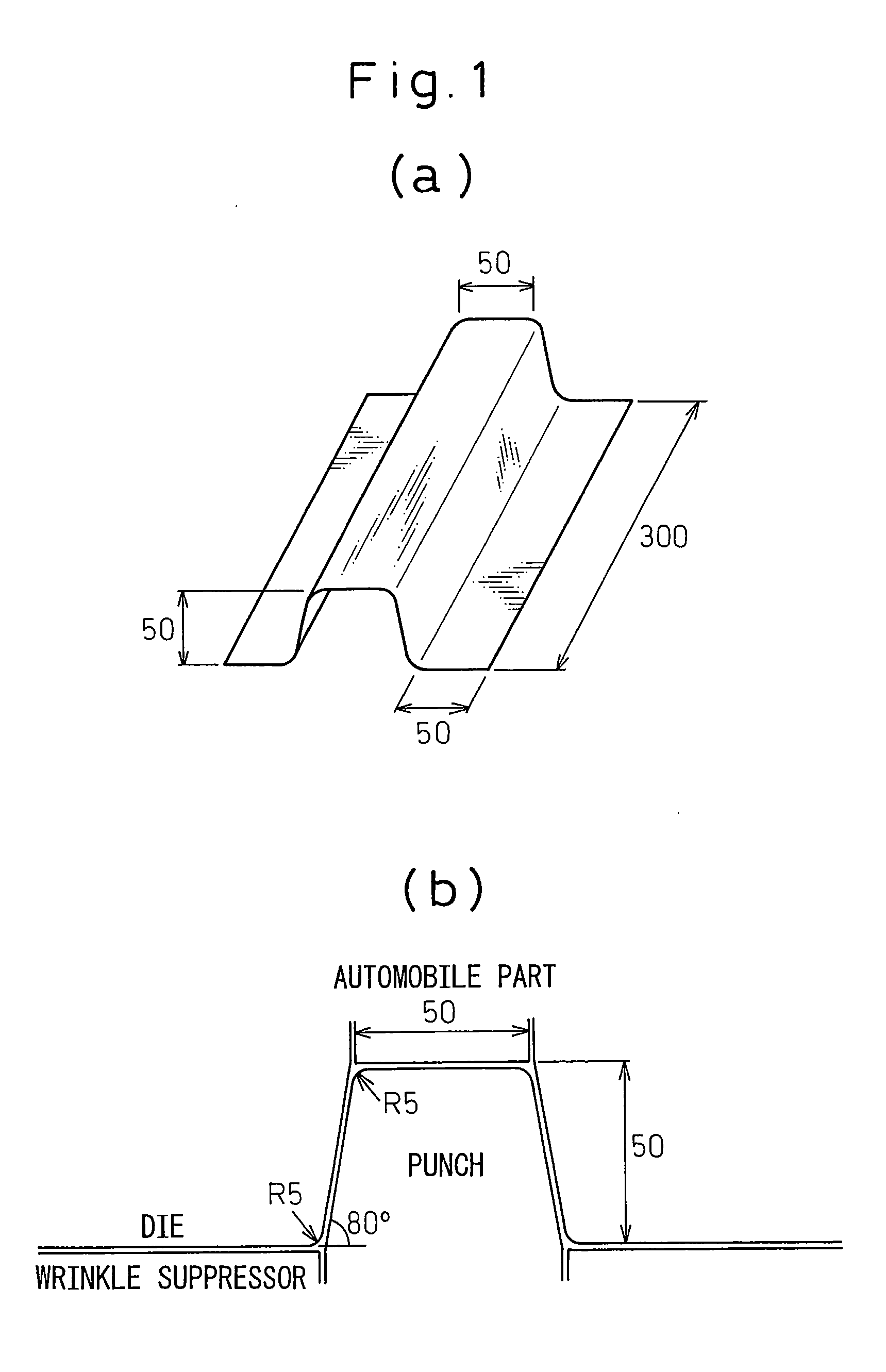

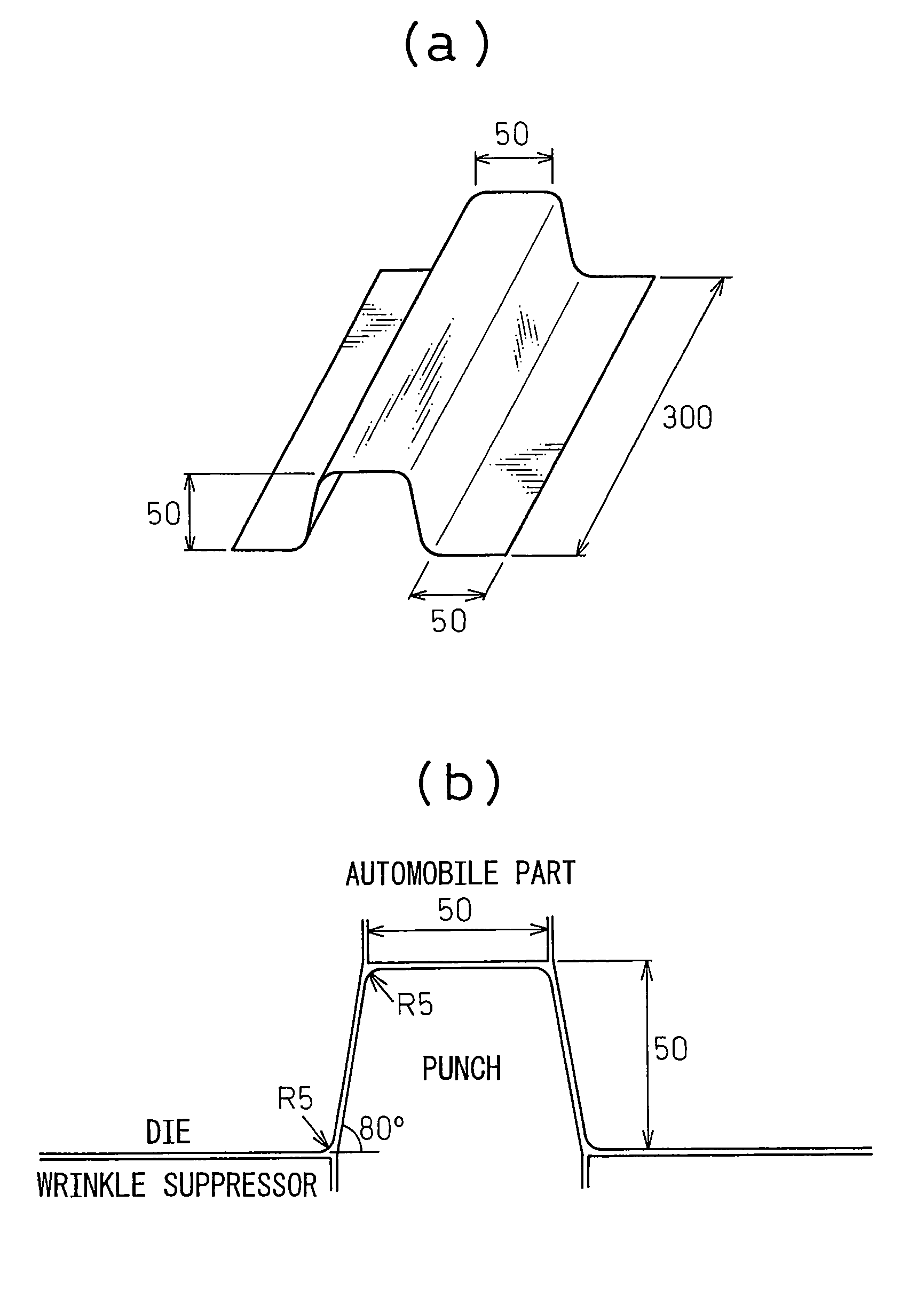

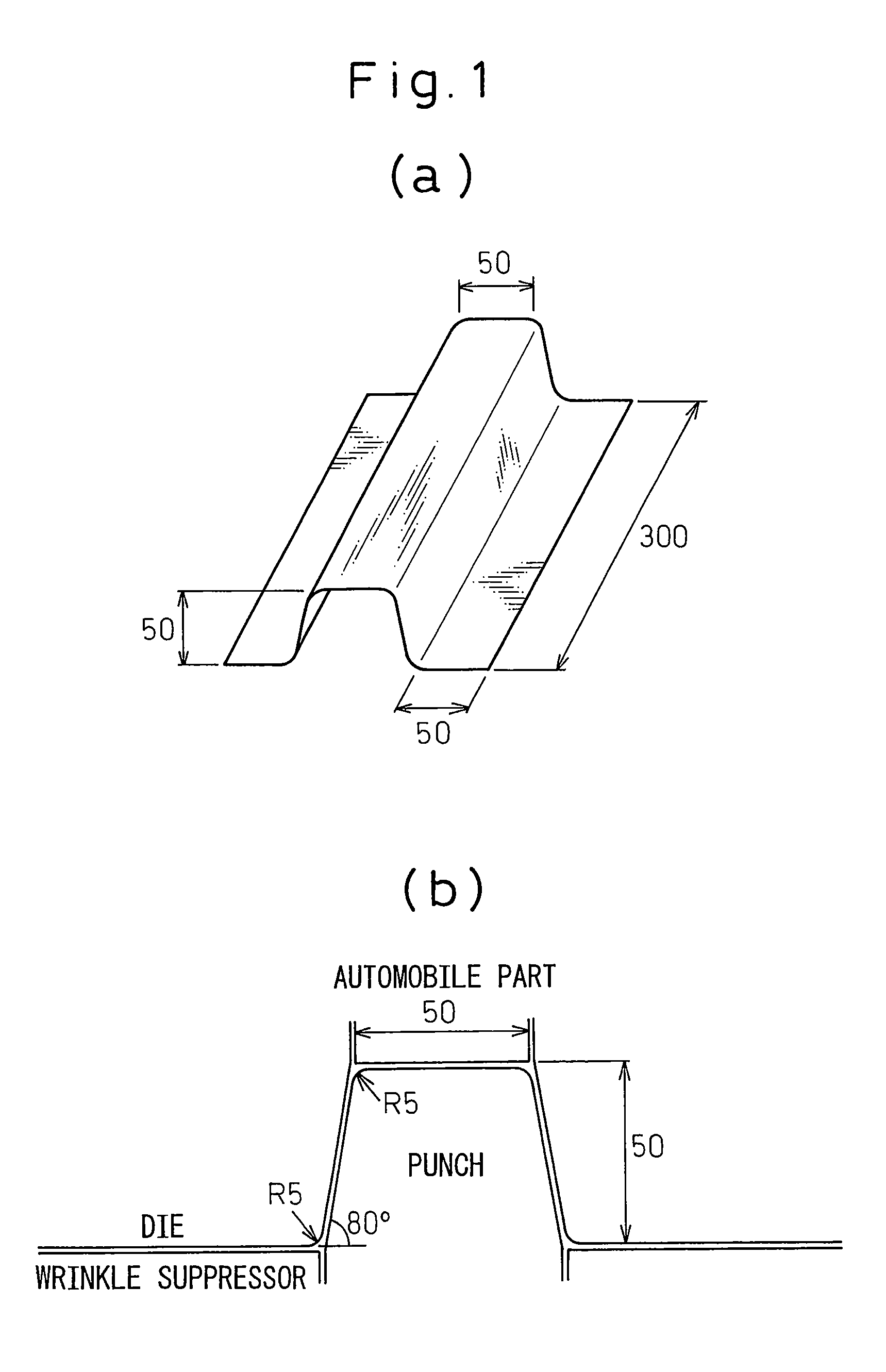

Hot pressing method for high strength member using steel sheet and hot pressed parts

ActiveUS20070163685A1Little riskImprove hydrogen embrittlement resistanceHot-dipping/immersion processesThin material handlingHydrogen concentrationHigh intensity

The present invention provides a method of hot pressing using hot rolled and cold rolled steel sheet or Al-based plated steel sheet or Zn-based plated steel sheet enabling a strength of at least 1200 MPa to be obtained after high temperature forming and with extremely little possibility of hydrogen embrittlement and such hot pressed parts, that is, a method of hot pressing a high strength automobile parts comprising using steel sheet containing as steel compositions by wt % C:0.05 to 0.5% or steel sheet plated mainly with Al or Zn to produce automobile members by hot pressing during which making the heating temperature before pressing Ac3 or more to 1100° C. or less, making the hydrogen concentration in the heating atmosphere 6 vol % or less, and making the dew point 10° C. or less and such hot pressed parts.

Owner:NIPPON STEEL CORP +1

High strength spring steel having excellent hydrogen embrittlement resistance

InactiveUS20060169367A1High strengthLow priceFurnace typesOhmic-resistance heatingAustenite grainHigh intensity

The present invention provides a high strength steel used for spring steel that has excellent hydrogen embrittlement resistance. The high strength steel which spring steel having excellent hydrogen embrittlement resistance comprises 0.20 to 0.60% of C, 1.0 to 3.0% of Si, 1.0 to 3.5% of Mn, higher than 0% and not higher than 1.5% of Al, 0.15% or less P, 0.02% or less S, and balance of iron and inevitable impurities and the structure includes: 1% or more residual austenite; 80% or more in total of bainitic ferrite and martensite; and 10% or less (may be 0%) in total content of ferrite and pearlite in the proportion of area to the entire structure, and also the mean axis ratio (major axis / minor axis) of the residual austenite grains is 5 or higher and the steel tensile strength is 1860 MPa or higher.

Owner:KOBE STEEL LTD +1

Metal surface treatment agent

InactiveCN1786281ANo "hydrogen embrittlement" phenomenonGood effectSurface-active agentsNuclear chemistry

The invention relates to a deoiling, derusting and rust preventing metal surface treating compound. It is made up of ammonia or amine, organic acid, auxiliary agent, surface active agent, chelating agent. Its pH value is 7-8. The organic acid belongs to food, participating reaction, and has no waste acid and water after using. The treated metal surface appears virgin metal natural color. It will not corrode the metal. And the í‹hydrogen embrittlementíŒ will never happen.

Owner:王开平

Hot pressing method for high strength member using steel sheet and hot pressed parts

ActiveUS7867344B2Little riskImprove hydrogen embrittlement resistanceHot-dipping/immersion processesQuenching agentsSheet steelHigh intensity

A method is proved for hot pressing hot rolled steel sheet, cold rolled steel sheet, Al-based plated steel sheet or Zn-based plated steel sheet, where the hot pressed sheet can exhibit a strength of at least about 1200 Mpa, and my be prevented from exhibiting hydrogen embrittlement. The steel sheet may include between about 0.05 to 0.5 wt % C, and / or it may be plated with an Al-based or Zn-based plating material. The steel sheet may be heating to a temperature greater than an Ac3 temperature and not more than about 1100° C. before pressing. An atmosphere can be provided during heating which contains not more than about 6 vol % of hydrogen and a dew point of not more than about 10° C. The exemplary methods may be used to form high strength parts which may be used, e.g., in automobiles.

Owner:NIPPON STEEL CORP +1

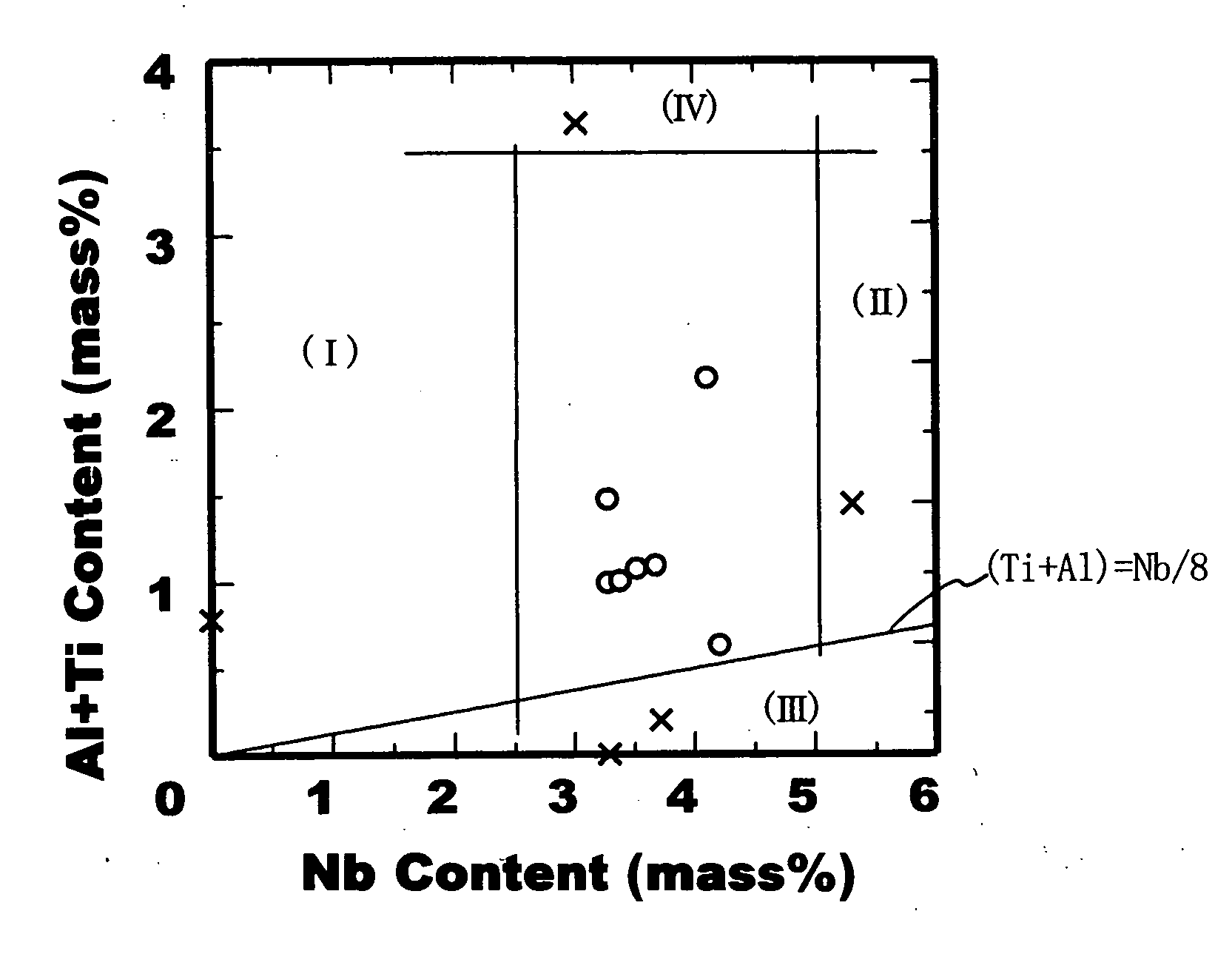

Welded joint made of an austenitic steel

InactiveUS20060191606A1High strengthIncrease resistanceArc welding apparatusMachines/enginesChemical compositionHigh pressure hydrogen

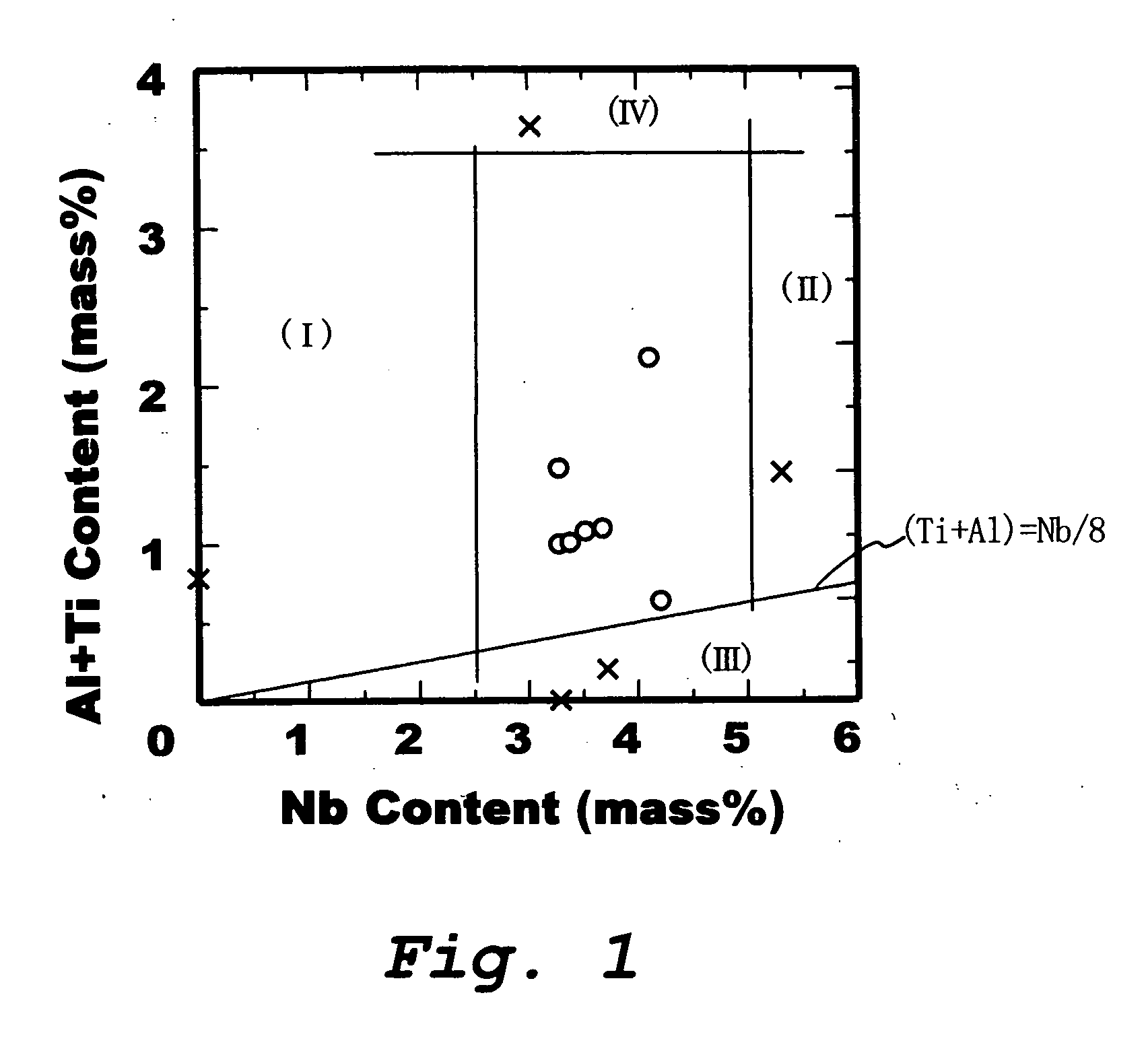

A weld joint having a base material and a weld metal both of an austenitic steel, wherein the weld metal has a chemical composition, in mass %, that C: 0.04% or less, Si: 1.0% or less, Mn: 3% or less, P: 0.02% or less, S: 0.005% or less, Cr: 15 to 25%, Ni: 30% or more, Mo: 10% or less, Nb: 2.5 to 5%, Al: 3.0% or less, Ti: 0.5% or less, and the balance: Fe and inevitable impurities, the contents of Al and Ti satisfying the following: (Ti+Al)>Nb / 8. The weld joint is a high strength austenitic steel weld joint which exhibits excellent toughness at a low temperature and excellent resistance to hydrogen embrittlement, which are required for a piping and a vessel for high pressure hydrogen, particularly also in a welded zone.

Owner:NIPPON STEEL CORP

High-strength cold-rolled steel sheet excellent in coating adhesion, workability and hydrogen embrittlement resistance, and steel component for automobile

InactiveUS20090053096A1Good film adhesionImprove machinabilityFurnace typesHeat treatment furnacesChemical compositionComposite oxide

A cold rolled steel sheet satisfying on the basis of percent by mass the chemical composition of 0.06-0.6% C, 0.1-2% Si, 0.01-3% Al, 1-4% Si+Al, 1-6% Mn, Si / Mn≦0.40, in which there exists 10 or more pieces / 100 μm2 of Mn—Si composite oxide having Mn—Si atom ratio (Mn / Si) of 0.5 or over and major axis of from 0.01 μm to 5 μm and also having a covering ratio of 10% or below at which the surface of the steel sheet is covered with oxide containing Si as the main component.

Owner:KOBE STEEL LTD

Rare earth element sintered magnet and method for producing rare earth element sintered magnet

ActiveUS20050028890A1Incur damageResistance can be maintainedInorganic material magnetismSolid state diffusion coatingRare-earth elementSintered magnets

Owner:SHIN ETSU CHEM IND CO LTD

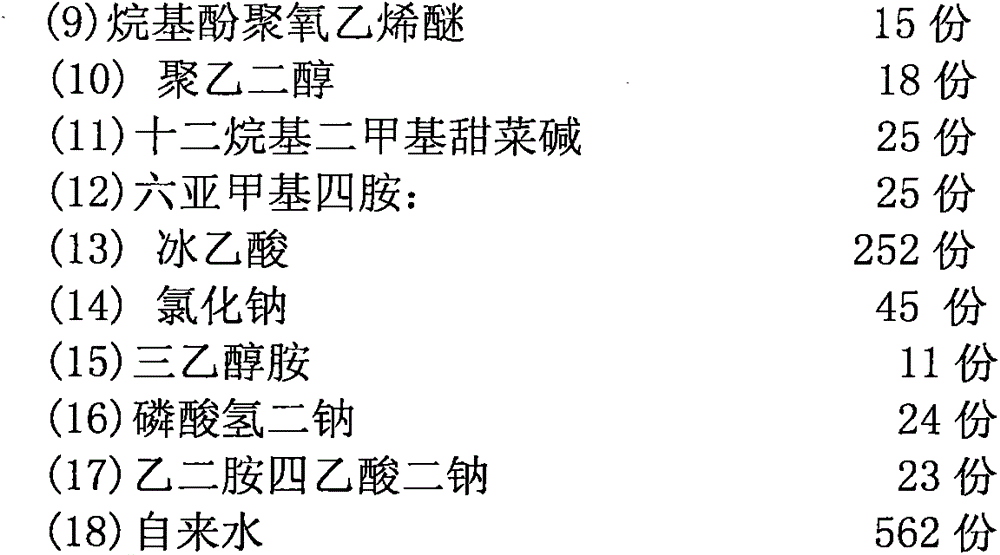

Zero-emission metal and nonmetal surface cleaning agent with effects of oil removal, rust removal, scale removal, phosphorization, passivation, oxidation resistance and corrosion prevention

InactiveCN104629945AAchieving zero emissionsAchieve emissionsOrganic detergent compounding agentsAmpholytes/electroneutral surface-active compoundsSurface cleaningOxidation resistant

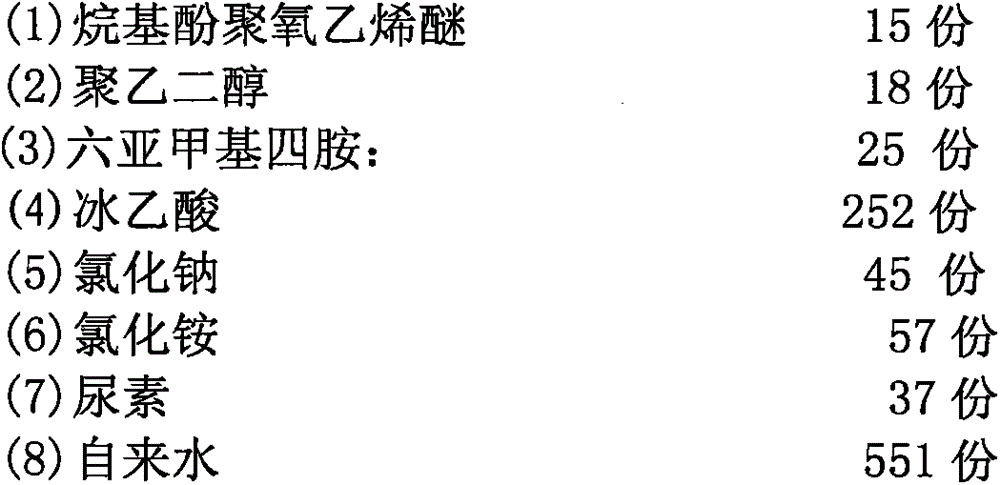

The invention discloses products of a Han ecological cycle method from the first to the seventh (HC, HW and HM series products) and relates to a recycled zero-emission metal and nonmetal surface multifunctional cleaning agent with effects of oil removal (used for nonmetals only), rust removal, scale removal, phosphorization, passivation, oxidation resistance and corrosion prevention. The cleaning agent comprises the following main active ingredients in parts by mass: 1.65-111 parts of a nonionic surfactant, 1.25-115 parts of a zwitterionic surfactant, 12.6-152 parts of a complexing agent, 0.2-157 parts of a chelating agent and 2.25-131 parts of aids. The cleaning agent has wide applicability for the concentrated type multiple metals and nonmetals and synchronous multifunctional complexing property, over-corrosion of exterior of the metals is avoided and hydrogen embrittlement of interior of the metals is avoided, the cleaning agent is safe to use, three wastes are not produced, the resources are saved, and the environmental friendliness is achieved.

Owner:韩刚

Preparation technology of nanometer multi-component alloy co-cementation anti-corrosive coating

InactiveCN101280410AGood processing conditionsReduce consumptionSolid state diffusion coatingWear resistantActive agent

The invention relates to a preparing process of a nanometer complex alloy co-permeation anticorrosion coating layer, which belongs to the technical field of the metal surface modified or alloying treatment. The preparing process comprises computer analog computation, preliminary treatment of steel members, complex configuration of co-permeation agent, energizing agent, active agent and filling agent, co-permeation processing of steel members and after-treatment of steel members. The preparing process has the advantages that firstly, the computer simulation is adopted to calculate optimal machining conditions, and to reduce the various consumption under the conditions; secondly, partial zinc powder is replaced by aluminum powder as the co-permeation agent, the hardness and the wear resistant property of a co-permeation layer are improved, and the co-permeation cost is reduced; thirdly, nanometer mixed rare earth oxide with low price and good effect is adopted as the energizing agent; fourthly, the co-permeation layer contains no heavy metal cadmium, is environmentally protective and is free from pollution; fifthly, the preparing process has no hydrogen embitterment damage, the processing temperature is low, the time is short, the hydrogen embitterment damage occurring on the co-permeation layer is avoided, and the energy consumption is reduced simultaneously.

Owner:天津市钰源地紧固件有限公司

Titanium alloying milling solution and milling technique used for the same

The present invention discloses a titanium alloy chemical milling solution and its application milling process, which mainly contains nitric acid and hydrofluoric acid as the main components of mixed acid acidic corrosion solution, sodium lauryl sulfate, ethylene glycol n-butyl ether and / or or urea additives. The surface tension of the solution is maintained at a stable value by using the present invention. The adsorption of ethylene glycol n-butyl ether can reduce the interfacial tension and increase the chemical milling rate. Sodium lauryl sulfate, which improves the fluidity of the solution, can eliminate excessive corrosion of the metal at the root of the chemical milling fillet, and prevent the appearance of "grooves", "slopes" and "ripples". Sodium nitrate prevents the formation of scale of alloying elements on the surface of the chemical milling groove, improves the surface finish of the chemical milling surface and facilitates maintenance of the equipment. Urea can effectively absorb the nitrogen-containing gas produced in the chemical milling process, reduce the volatilization of acid liquid, and avoid pollution to the environment. The invention does not need heating equipment, the amount of hydrogen added is less than 9ppm, the service life of the solution is long, hydrogen embrittlement does not occur, and the process has little influence on the fatigue performance of the material.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

Steel surface compact oxide layer scavenging agent

The invention discloses a steel surface compact oxide layer scavenging agent, which is composed of mixed acid, oxidizer, surfactant, corrosion inhibitor, anti-rust agent and pure water with the weightpercent of the components as follows: 5-20% of H2SO4, 10-30% of HCl, 0.5-3% of oxalic acid, 0.25-3.5% of oxidizer, 1-3% of surfactant, 0.25-3% of corrosion inhibitor, 1-3% of anti-rust agent and remainder of water; the scavenging agent is colorless transparent, has no pungent smell, has obvious effect in scavenging steel surface compact oxide layer and rust, and is sucked on pure steel surface compact to form a film, the contact between the scavenging agent and metal can be isolated, the over-corrosion of steel and hydrogen embrittlement can be avoided; the invention has low cost, small investment, simplified technique and good effect in steel surface treatment, and needs no temperature control equipment.

Owner:JIANGSU HAIXUN IND GROUP SHARE

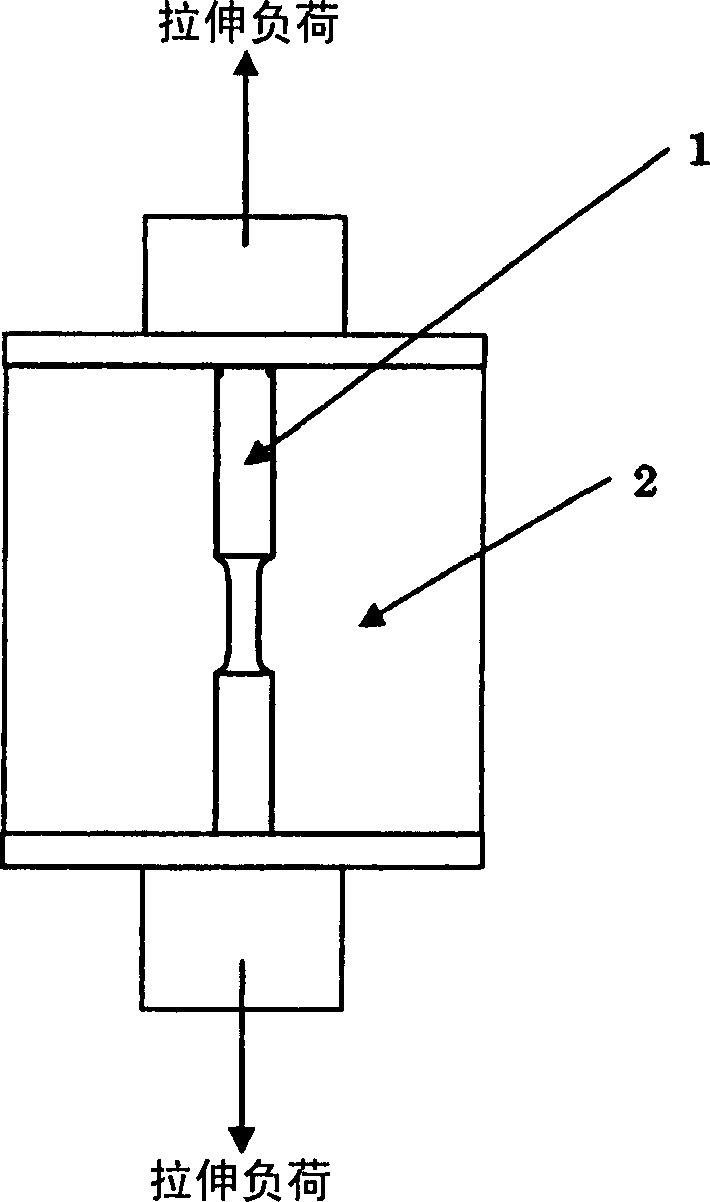

Steel for forging having excellent hydrogen embrittlement resistance and crankshaft

InactiveCN1873042AImprove fatigue strengthEasy to useCrankshaftsMetal rolling arrangementsCrankshaftHydrogen embrittlement

The invention provides a hammered steel with good resistant property for hydrogen brittleness and crank made of said hammered steel, said steel comprises following components: C 0.2-0.6% (by weight percent, the same with following ones); Si 0.1-0.4%; Mn 0.7-1.5%; Ni less than 1.0%; Cr 1.2-3.5%; Mo 0.1-0.6%, Al 0.01-0.05%, and mixture containing at least one of Ti, Zr, Hf larger than 0.005%; the average circular degree of foreign material with maximum chord length being larger than 1 um is larger than 0.5; the number of foreign material with maximum chord length being larger than 20 um (100mm2) is less than 100, and the average circular degree is larger than 0.25, and the number of foreign material with maximum chord length being 1-10 um (100mm2) is larger than 100.

Owner:KOBE STEEL LTD

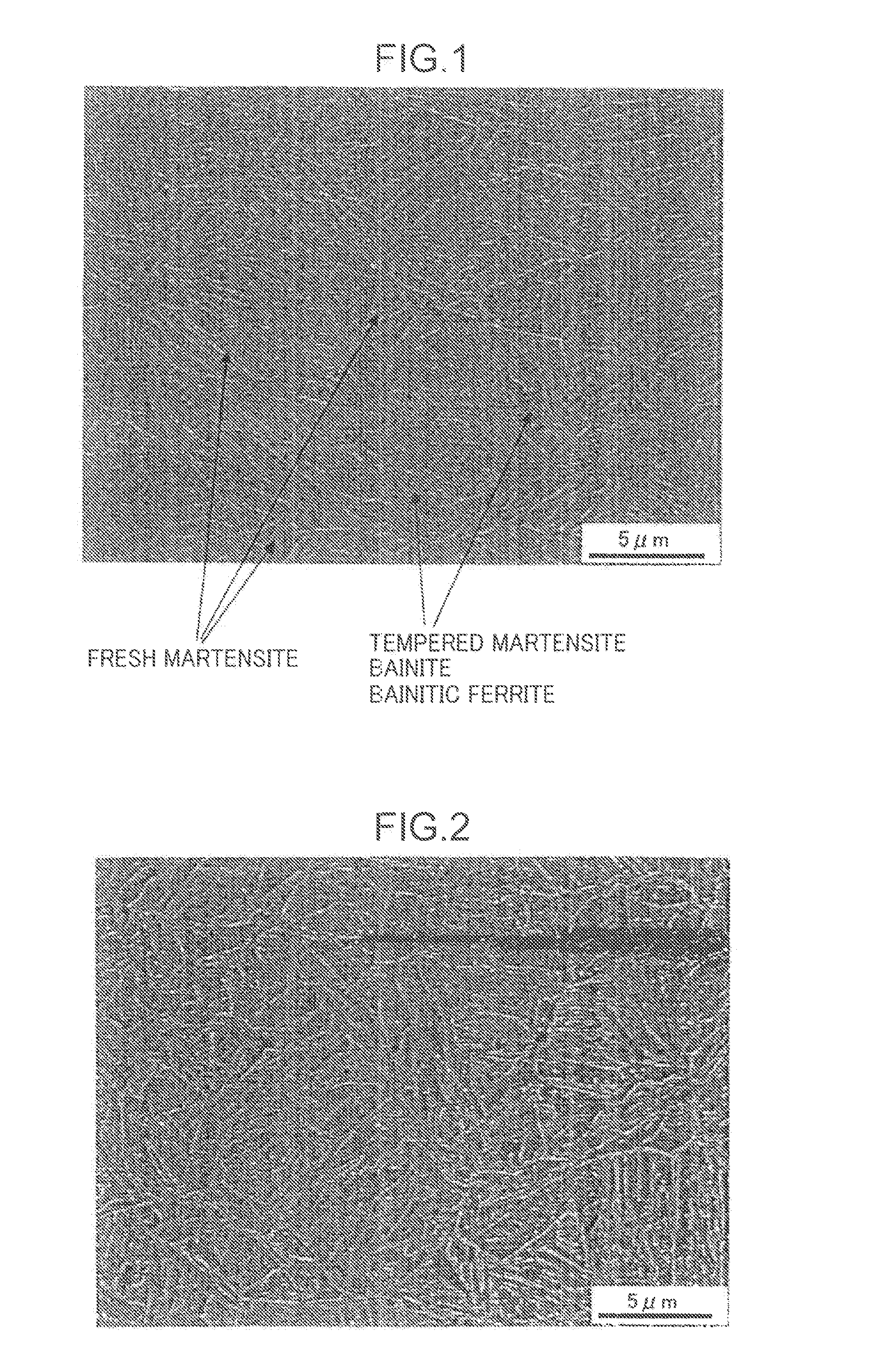

High strength steel sheet having excellent hydrogen embrittlement resistance

ActiveUS20120132327A1Improve hydrogen embrittlement resistanceHigh strengthFurnace typesHeat treatment furnacesHydrogen embrittlementBainite

Disclosed is a high strength steel sheet having excellent hydrogen embrittlement resistance. The steel sheet has a tensile strength of 1180 MPa or more, and satisfies the following conditions: with respect to an entire metallographic structure thereof, bainite, bainitic ferrite and tempered martensite account for 85 area % or more in total; retained austenite accounts for 1 area % or more; and fresh martensite accounts for 5 area % or less (including 0 area %).

Owner:KOBE STEEL LTD +1

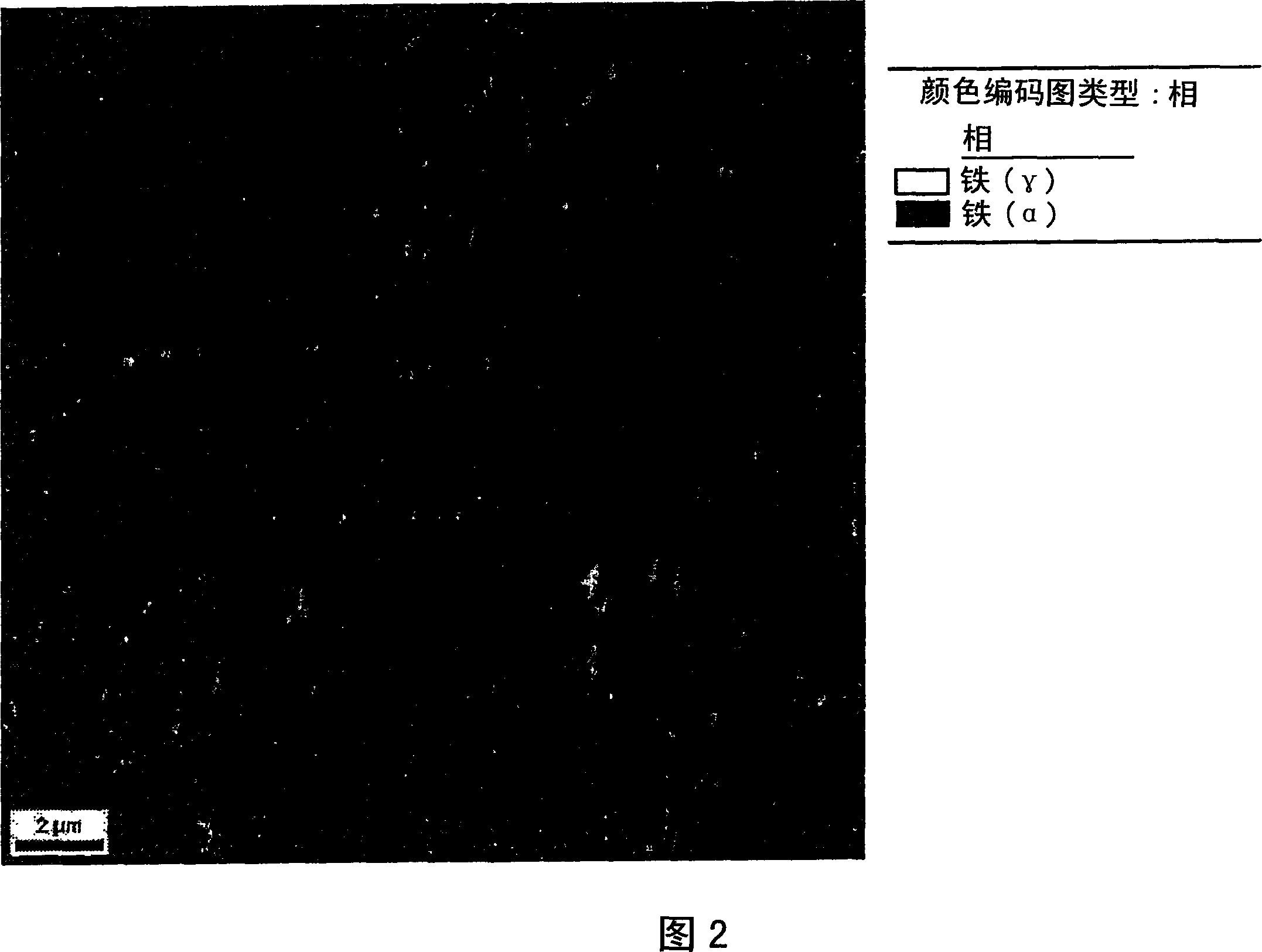

Steel for structural part of automobile and method for producing the same

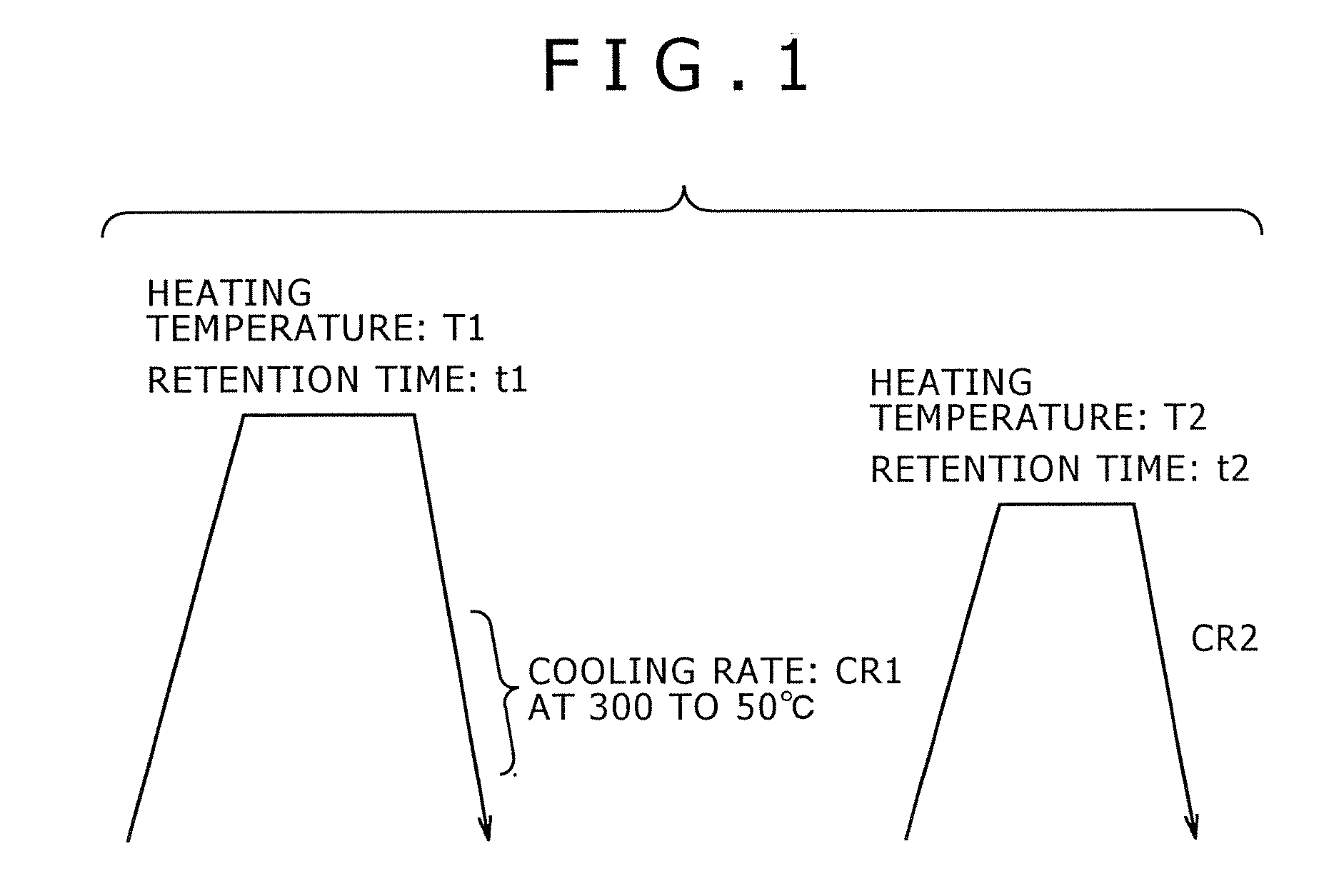

InactiveUS20070144632A1Improve fatigueGood formabilityFurnace typesIncreasing energy efficiencySlow coolingCorrosion fatigue

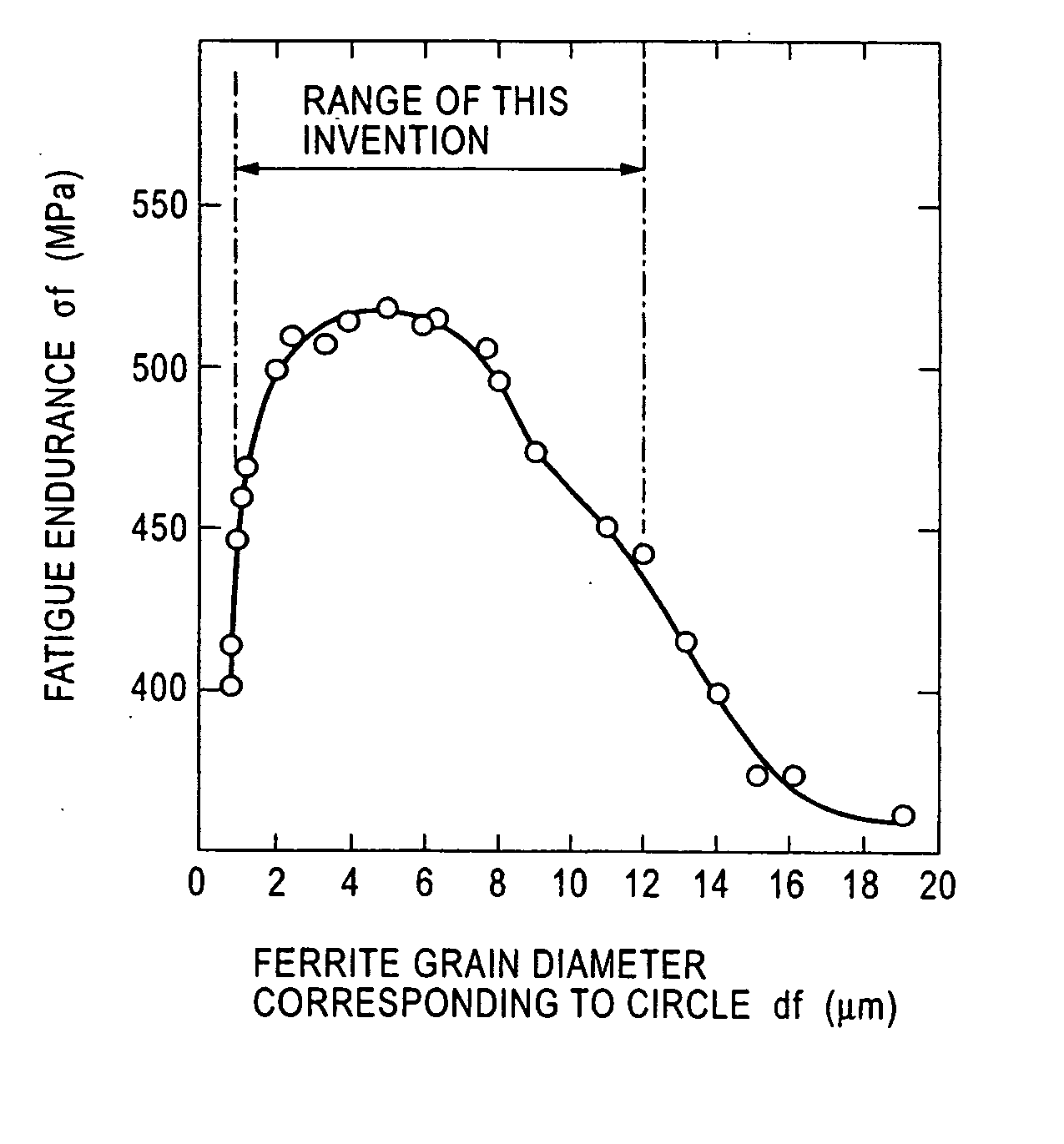

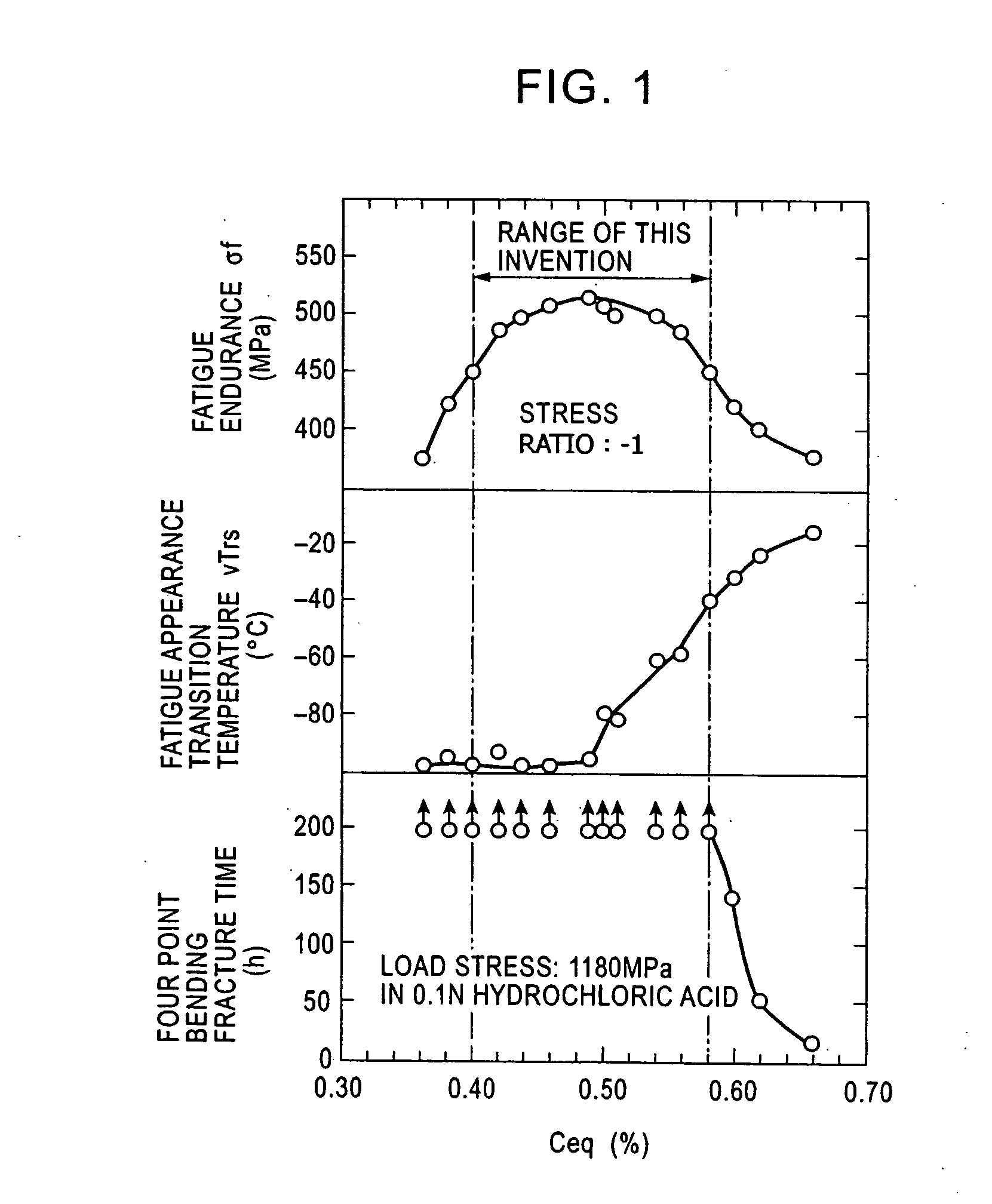

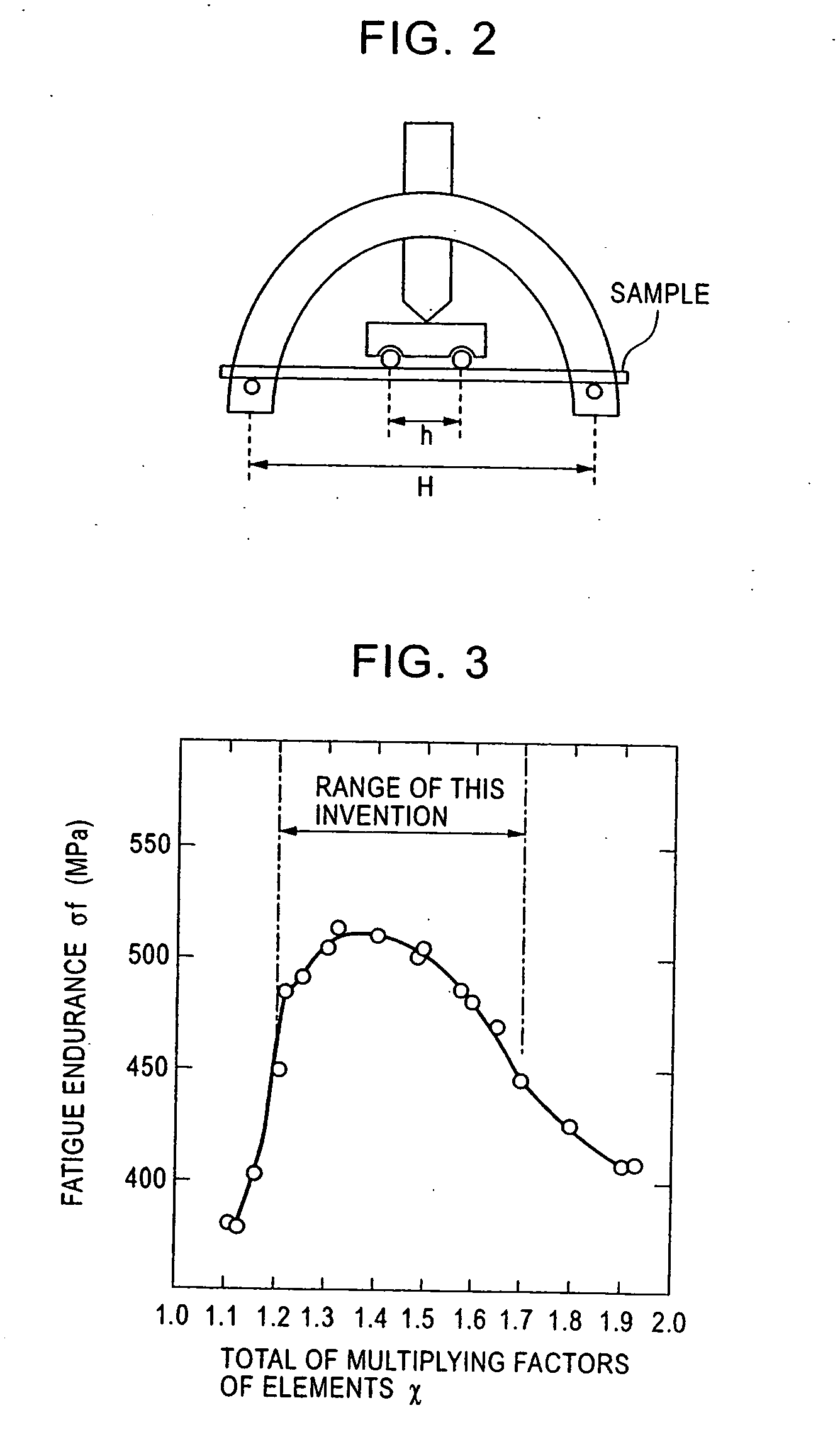

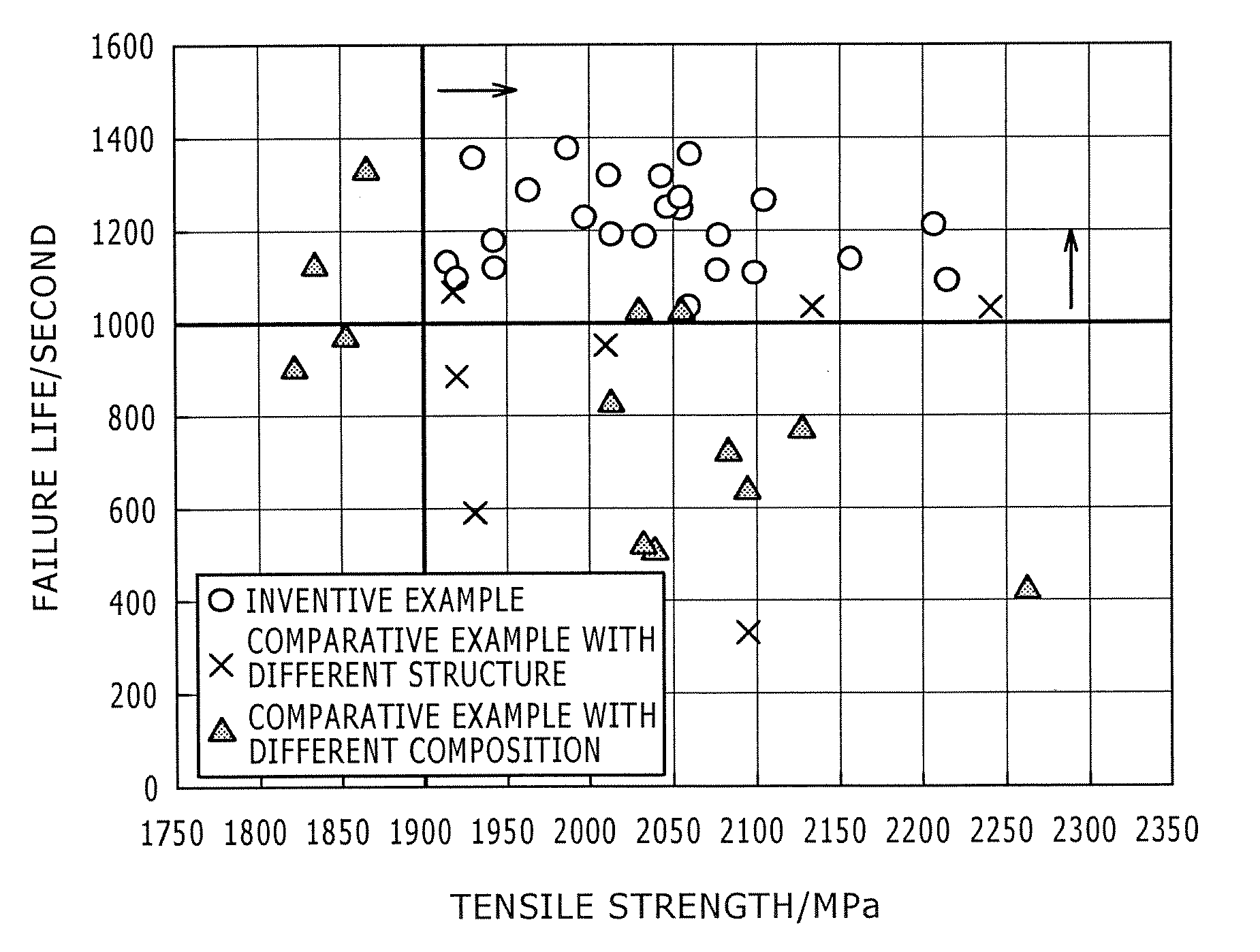

A steel having excellent formability, fatigue endurance after quenching, low temperature toughness, resistance for hydrogen embrittlement, and corrosion fatigue endurance. A method includes heating a steel slab at 1160° C. to 1320° C., hot-finish-rolling the steel slab at a finisher delivery temperature of 750° C. to 980° C., and then coiling the hot-rolled steel at a coiling temperature of 560° C. to 740° C. after slow cooling for a time of 2 seconds or more to produce a hot-rolled steel strip having a structure in which the ferrite grain diameter df corresponding to a circle is 1.1 μm to less than 1.2 μm and the ferrite volume fraction Vf is 30% to 98%, the steel slab containing 0.18 to 0.29% of C, 0.06 to 0.45% of Si, 0.91 to 1.85% of Mn, 0.019% or less of P, 0.0029% or less of S, 0.015 to 0.075% of sol. Al, 0.0049% or less of N, 0.0049% or less of O, 0.0001 to 0.0029% of B, 0.001 to 0.019% of Nb, 0.001 to 0.029% of Ti, 0.001 to 0.195% of Cr, and 0.001 to 0.195% of Mo so that the carbon equivalent Ceq satisfies a value of 0.4 to less than 0.58, and the total x of multiplying factors including that for B according to Grossmann satisfies a value of 1.2 to less than 1.7.

Owner:JFE STEEL CORP +1

High strength spring steel wire with excellent coiling properties and hydrogen embrittlement resistance

Disclosed herein is a high strength spring steel wire with excellent coiling properties and hydrogen embrittlement resistance. The steel wire comprises, by mass, 0.4 to 0.60% of C, 1.7 to 2.5% of Si, 0.1 to 0.4% of Mn, 0.5 to 2.0% of Cr, 0.015% or less of P (exceeding 0%), 0.015% or less of S (exceeding 0%), 0.006% or less of N (exceeding 0%), 0.001 to 0.07% of Al, and the remainder being Fe and unavoidable impurities. The steel wire has a structure wherein prior austenite has an average grain size of 12 μm or less, and retained austenite exists in an amount of 1.0 to 8.0 vol. % with respect to a whole structure of the steel wire. The retained austenite has an average grain size of 300 nm or less and a maximum grain size of 800 nm or less. The steel has a tensile strength of 1,900 MPa or more.

Owner:KOBE STEEL LTD

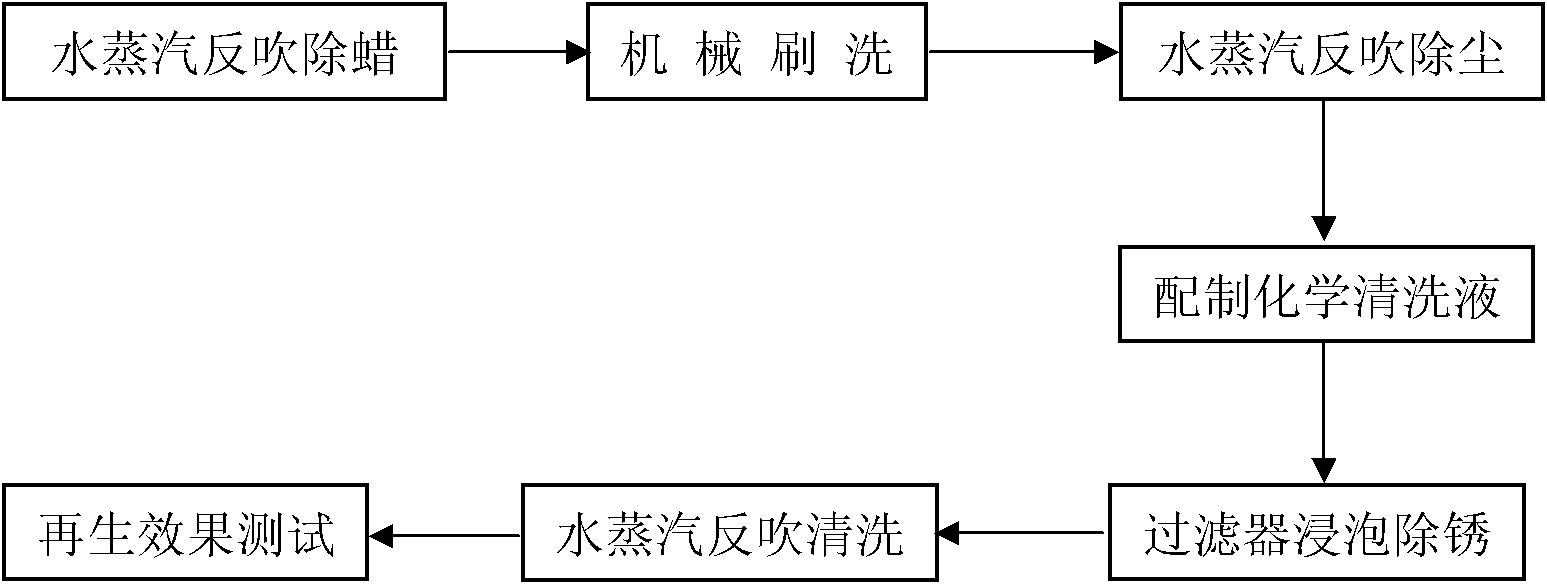

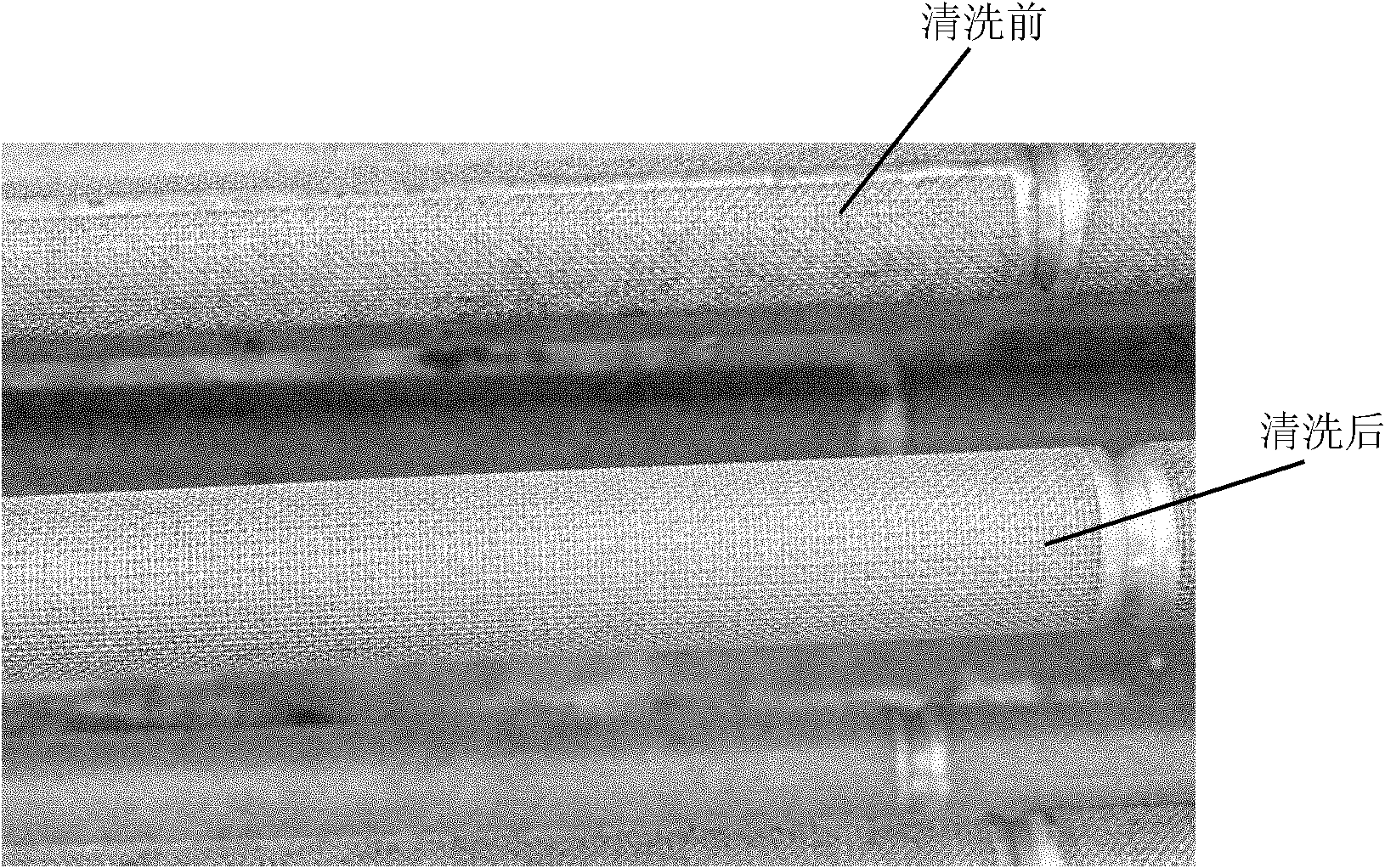

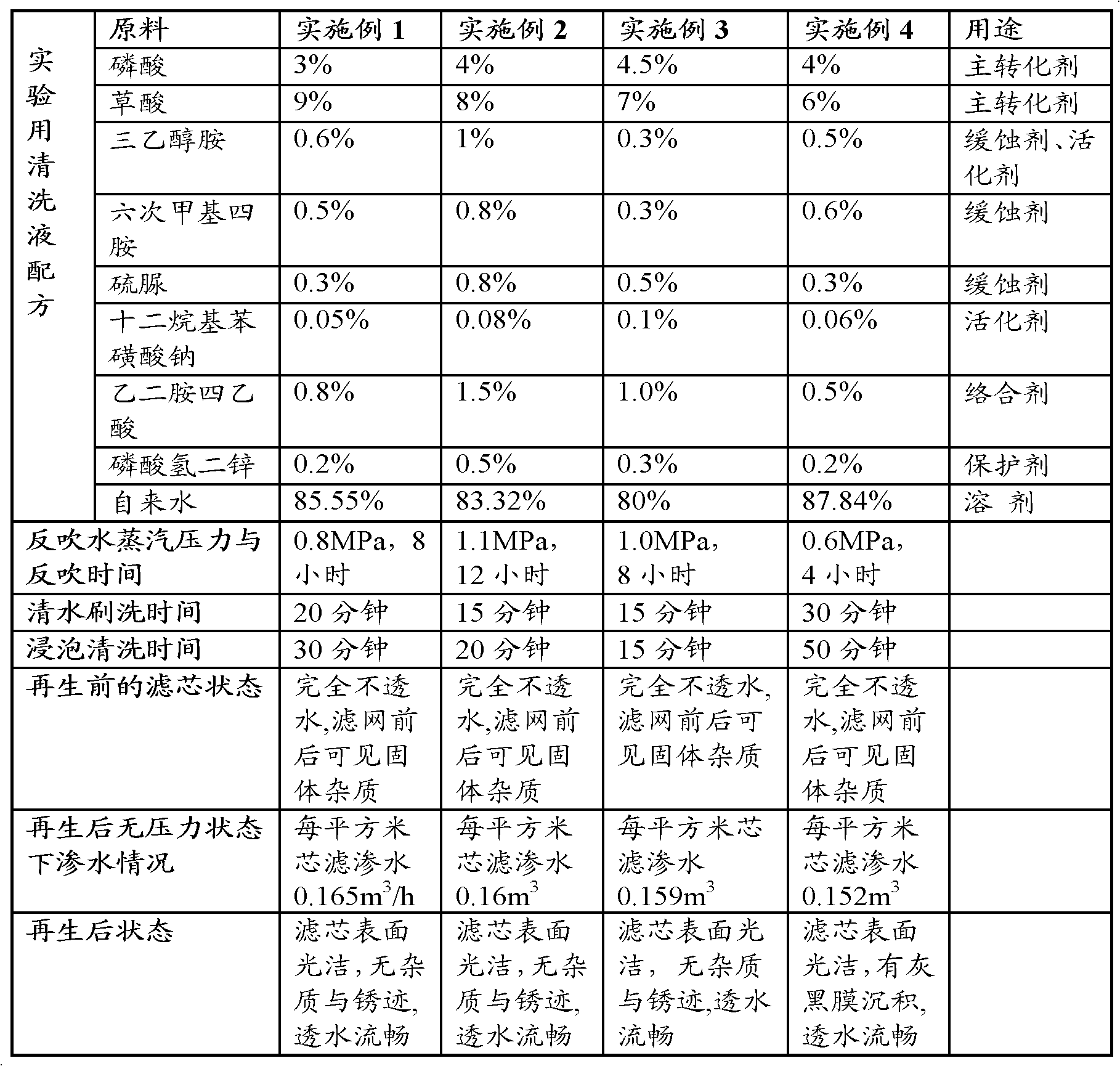

Preparation and application of chemical derusting cleaning agent

ActiveCN102071416ASolve hydrogen embrittlementSolve corrosiveMetallic material coating processesThioureaPhosphate

The invention provides a chemical derusting cleaning agent for removing iron rust and other iron compounds on the surface of iron and inside iron components, and a preparation method and application thereof. The chemical derusting cleaning agent consists of the following substances in percentage by weight: 4 to 10 percent of oxalic acid, 0.5 to 1.5 percent of triethanolamine, 3 to 10 percent of phosphoric acid, 0.3 to 1.5 percent of thiourea, 0.2 to 0.6 percent of zinc dihydrogen phosphate or zinc oxide, 0.5 to 2 percent of ethylene diamine tetraacetic acid, 0.5 to 1.2 percent of hexamethylene tetramine, 0.05 to 0.1 percent of sodium dodecyl benzene sulfonate and the balance of water. Chemical derusting cleaning solution prevents over-corrosion and hydrogen embrittlement on a filter matrix through combination effects of a passivator, a corrosion inhibitor, a protective agent and other components in the derusting process, the waste liquor discharge frequency is low, acid mist does not overflow in the cleaning process, and the cleaning agent is environmentally-friendly and harmless to the health of an operator.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

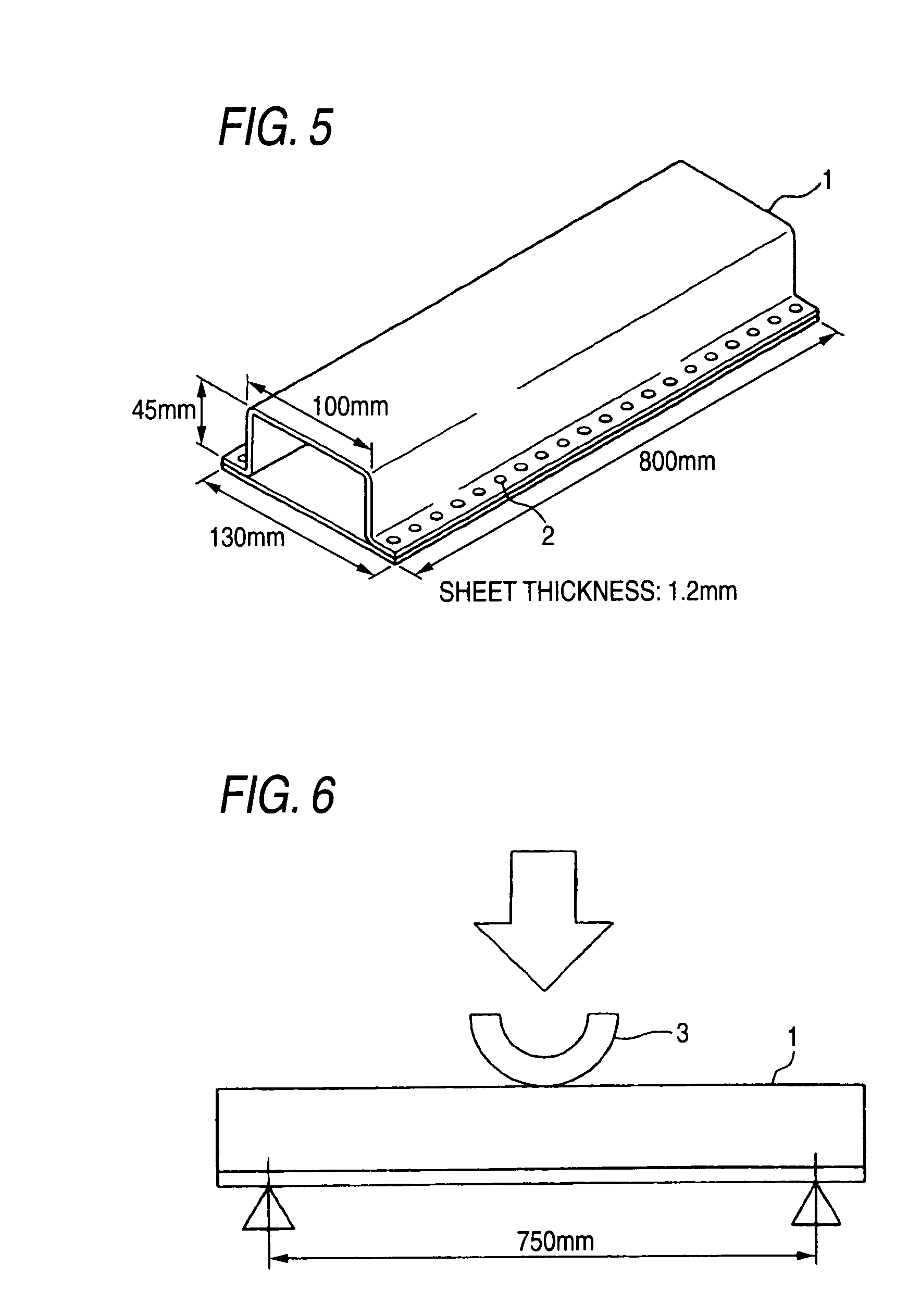

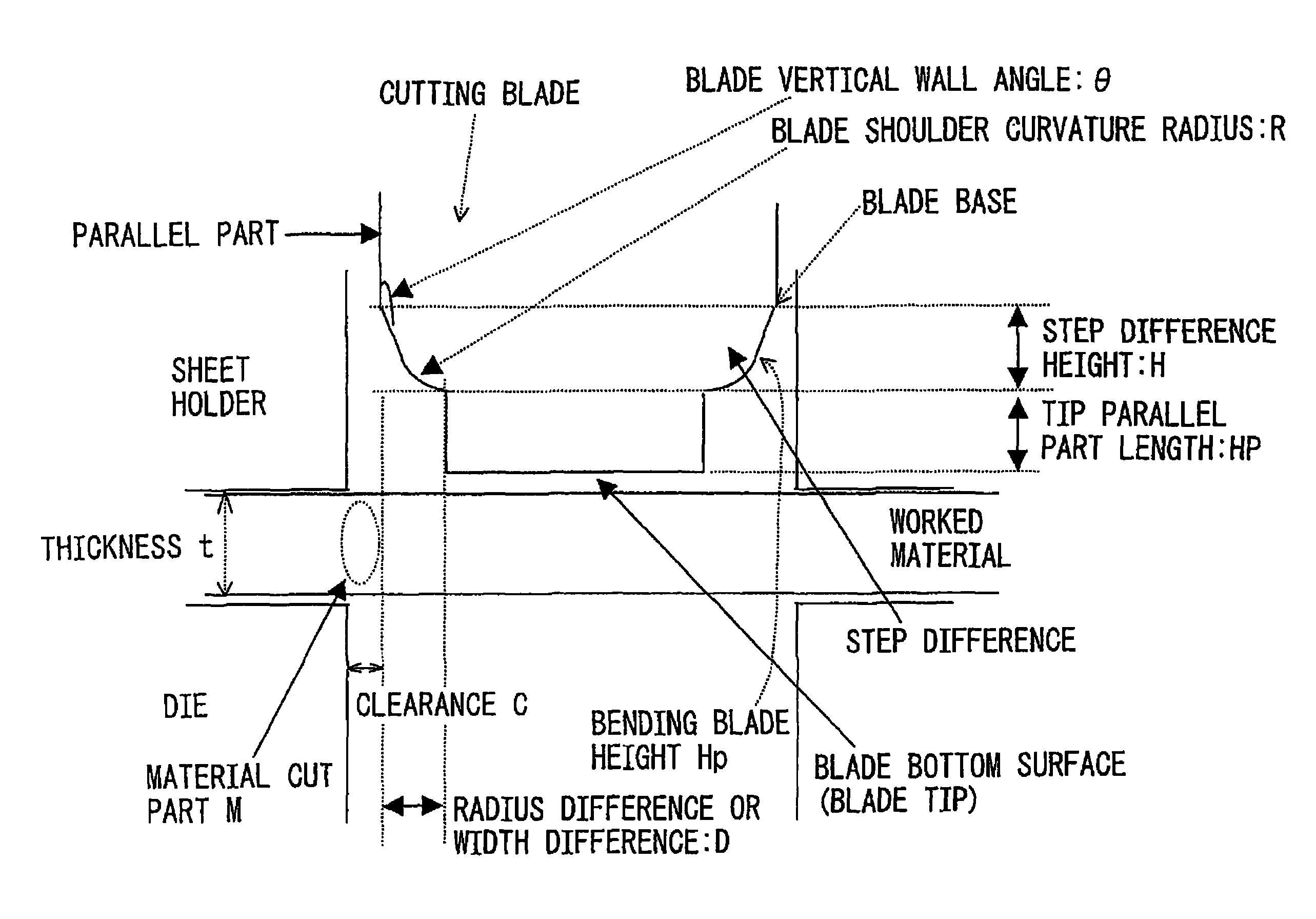

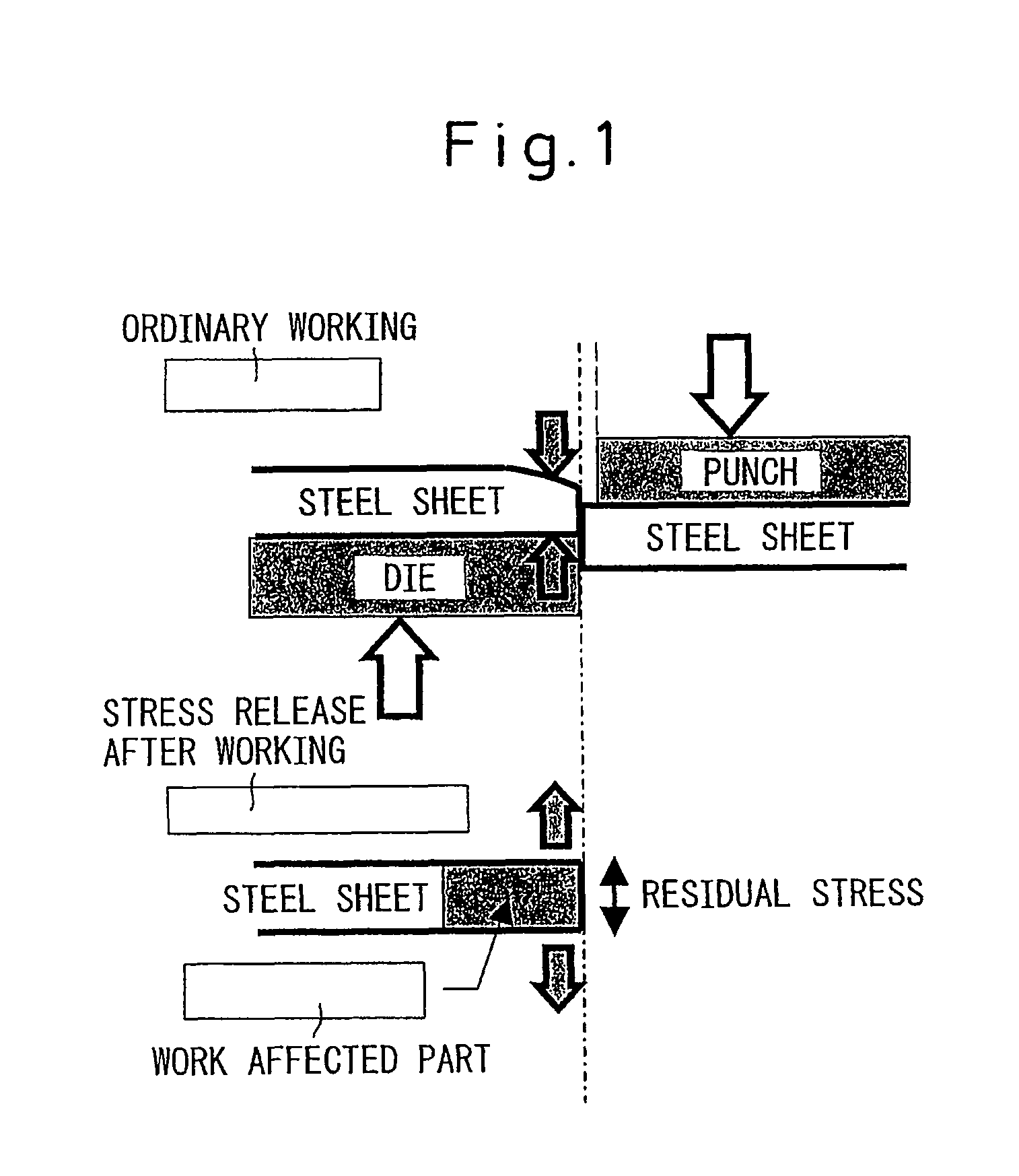

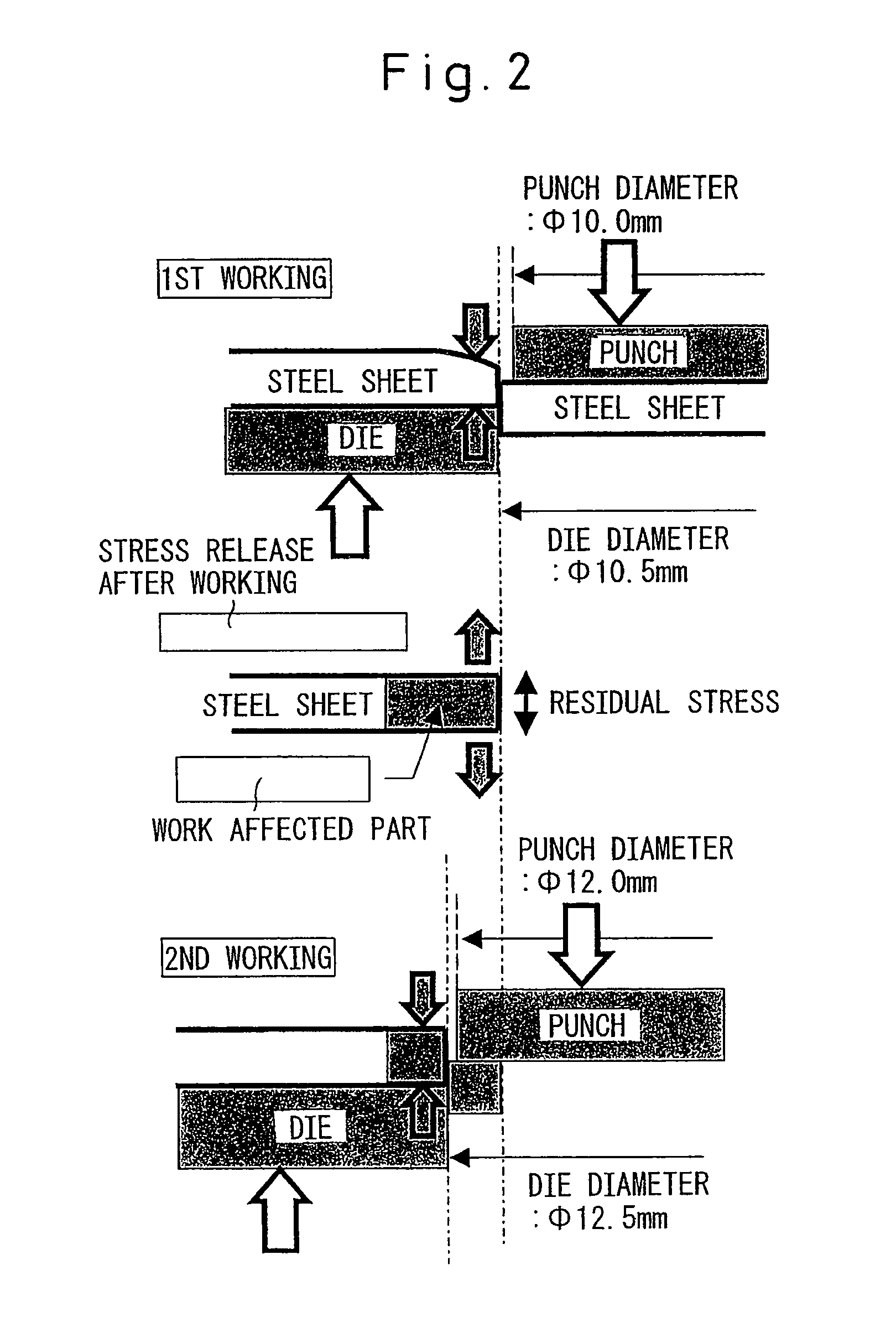

High strength part and method for producing the same

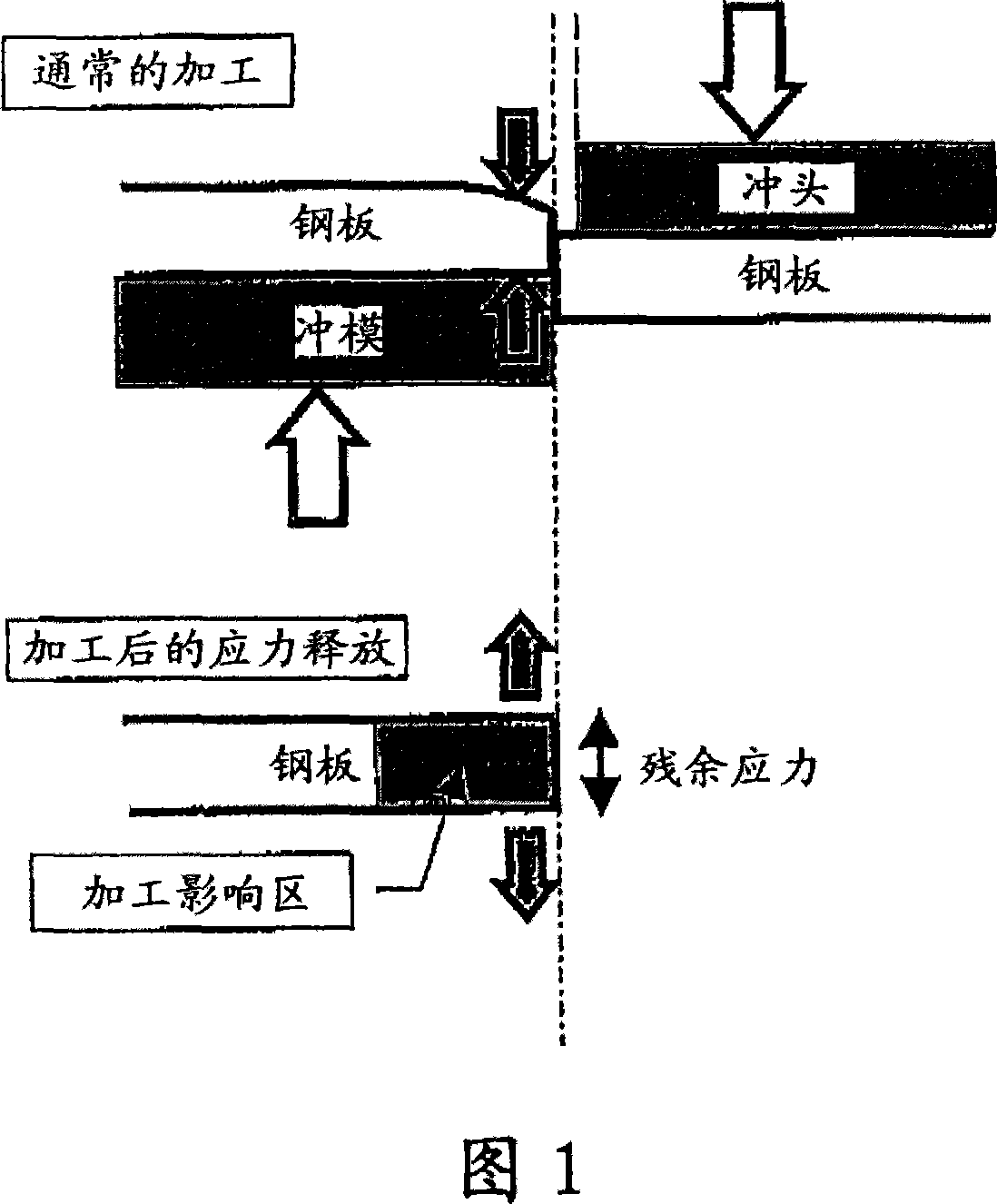

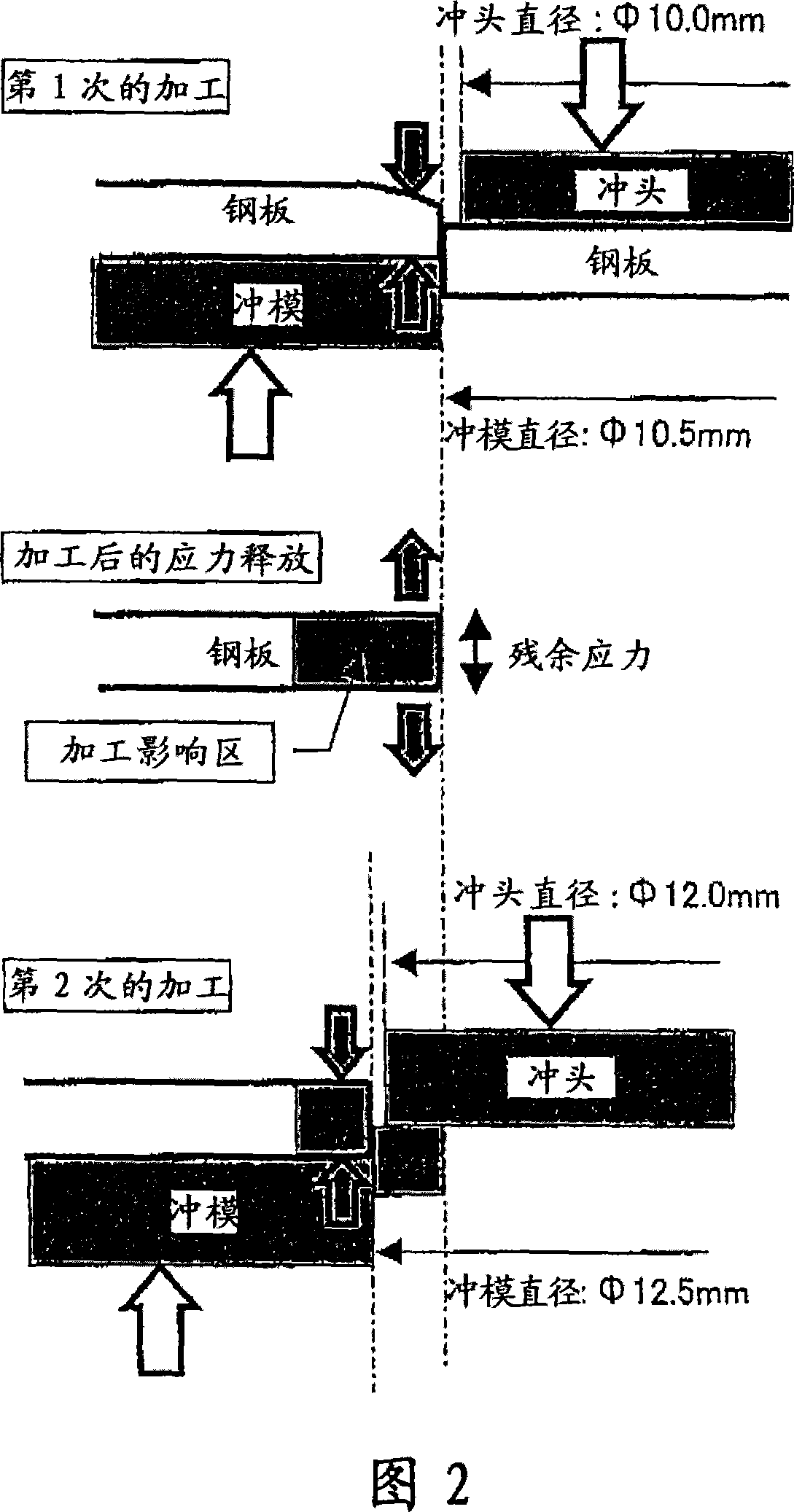

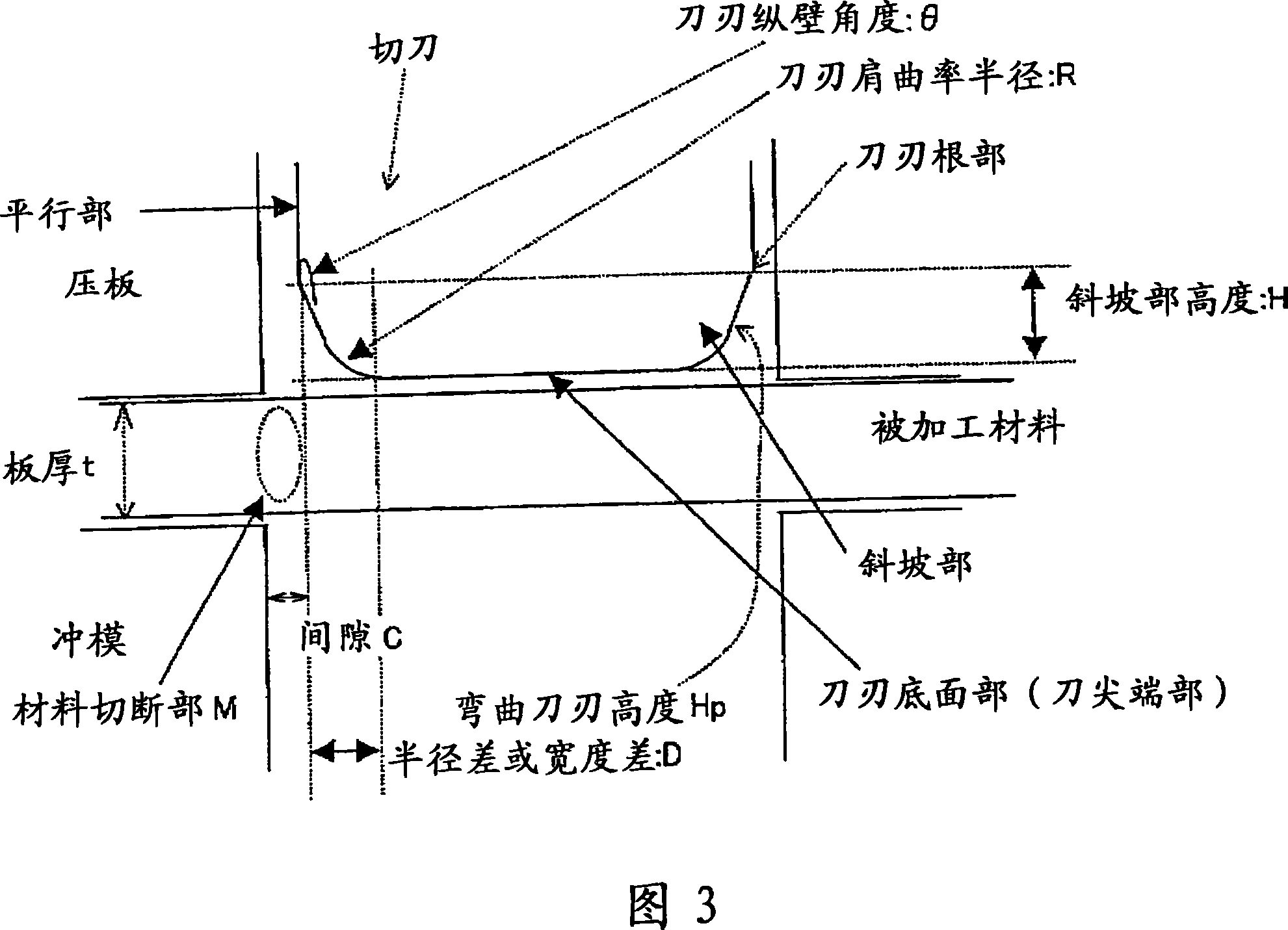

ActiveUS7842142B1Improve the immunityReduce the amount requiredHot-dipping/immersion processesFurnace typesPunchingHigh intensity

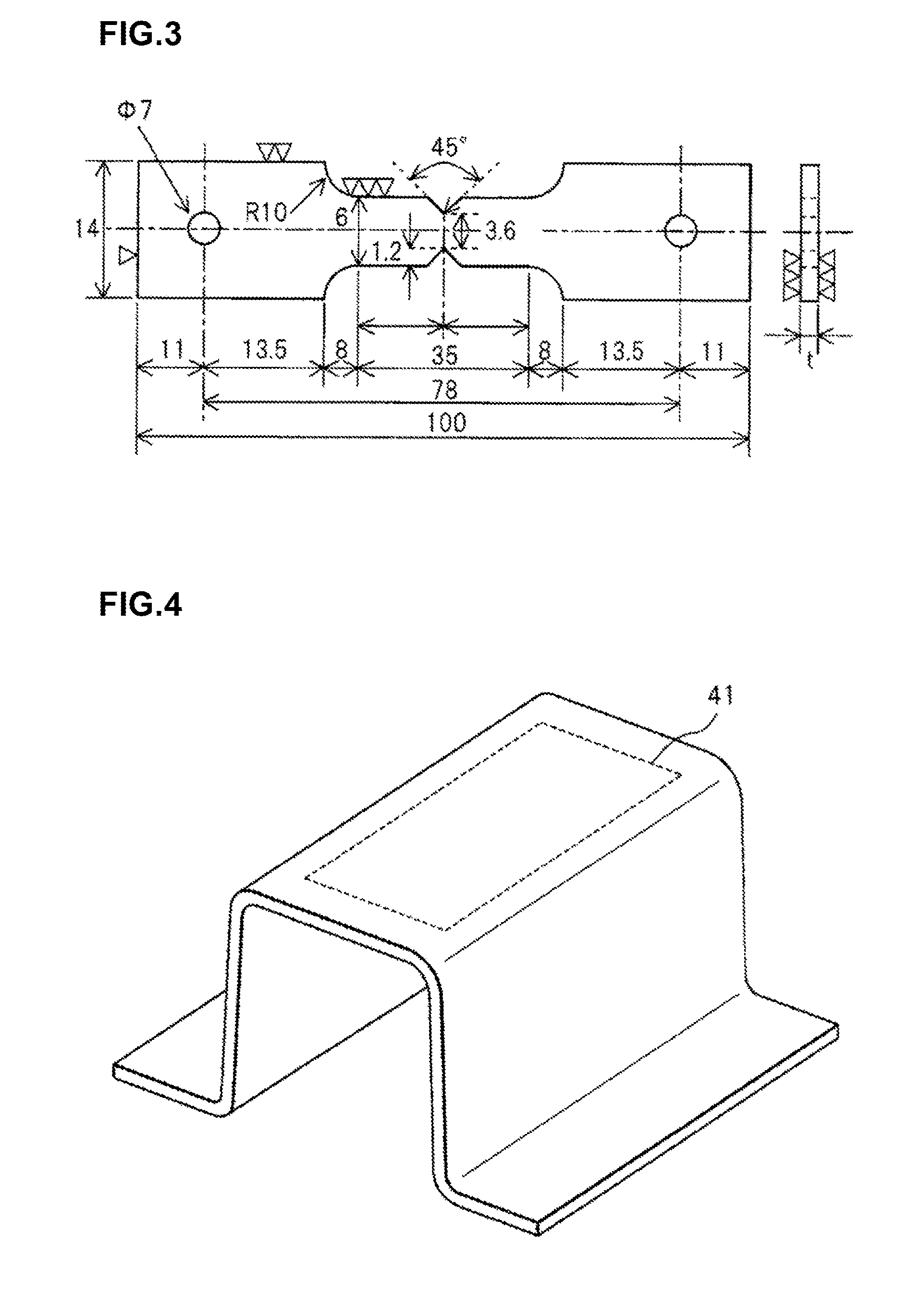

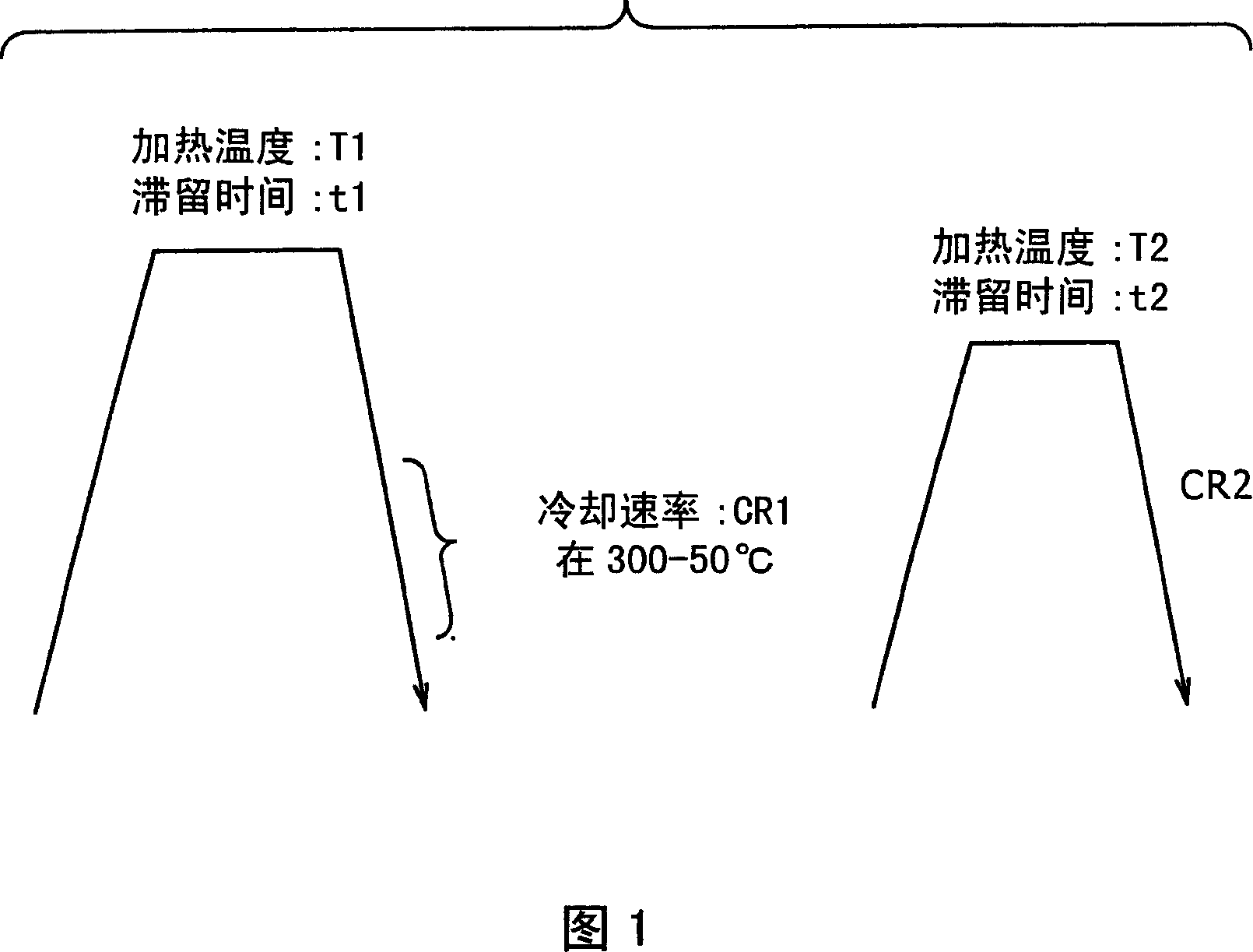

High-strength parts and a method for producing them can be provided, where such parts exhibit hydrogen embrittlement resistance and strength after high-temperature forming. For example, the atmosphere in a heating furnace can contain less than about 10% hydrogen and / or have a dew point of about 30° C. or less. The amount of hydrogen penetrating a steel sheet during heating can thereby be reduced. After forming, quench hardening in a die assembly and post-working can be performed. Post-working can include shearing followed by re-shearing or compression forming; punching with a cutting blade having a continuously reduced base width; punching with a tool having a curved blade and a protrusion at the tip of the cutting blade, where the curved blade may include a shoulder portion of given radius and / or angle; fusion cutting; etc. Tensile residual stresses after punching can be reduced and resistance to hydrogen embrittlement can be improved.

Owner:NIPPON STEEL CORP

High-strength part and process for producing the same

Owner:NIPPON STEEL CORP

Microwave sintering and heat treatment method for preparing high-performance tungsten-based high-density alloy

A microwave sintering and heat treatment method for preparing high-performance tungsten-based high-density alloy comprises the following steps: preparing a powder compact by a traditional powder metallurgy method, putting the compact in a microwave high-temperature furnace with atmosphere protection and a vacuum pump, controlling the atmosphere in the furnace chamber to be reducing atmosphere at a heating phase below 1200 DEG C; sintering the product at low vacuum at a high-temperature phase of 1200-1400 DEG C, and vacuumizing the furnace to obtain a high vacuum of 10-2 Pa at a cooling phase after sintering. The obtained alloy has a uniform fine grain structure, and high mechanical properties. The invention adopts low vacuum at the sintering phase, and adopts high vacuum at the cooling phase, which allow the hydrogen content of the alloy to be reduced, and effectively avoid the hydrogen embrittlement phenomenon. Additionally, the tungsten-based high-density alloy is prepared by microwave sintering technology and equipment, which is rapid, high-efficient, simple, and low in cost; the tungsten-based high-density alloy is prepared by microwave sintering-heat treatment technology; theprocess is easy to control; the technology is mature, and is applicable to industrial production.

Owner:CENT SOUTH UNIV

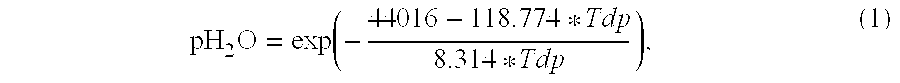

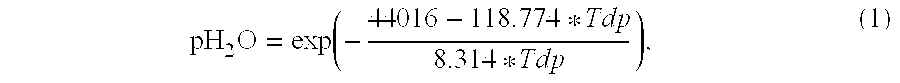

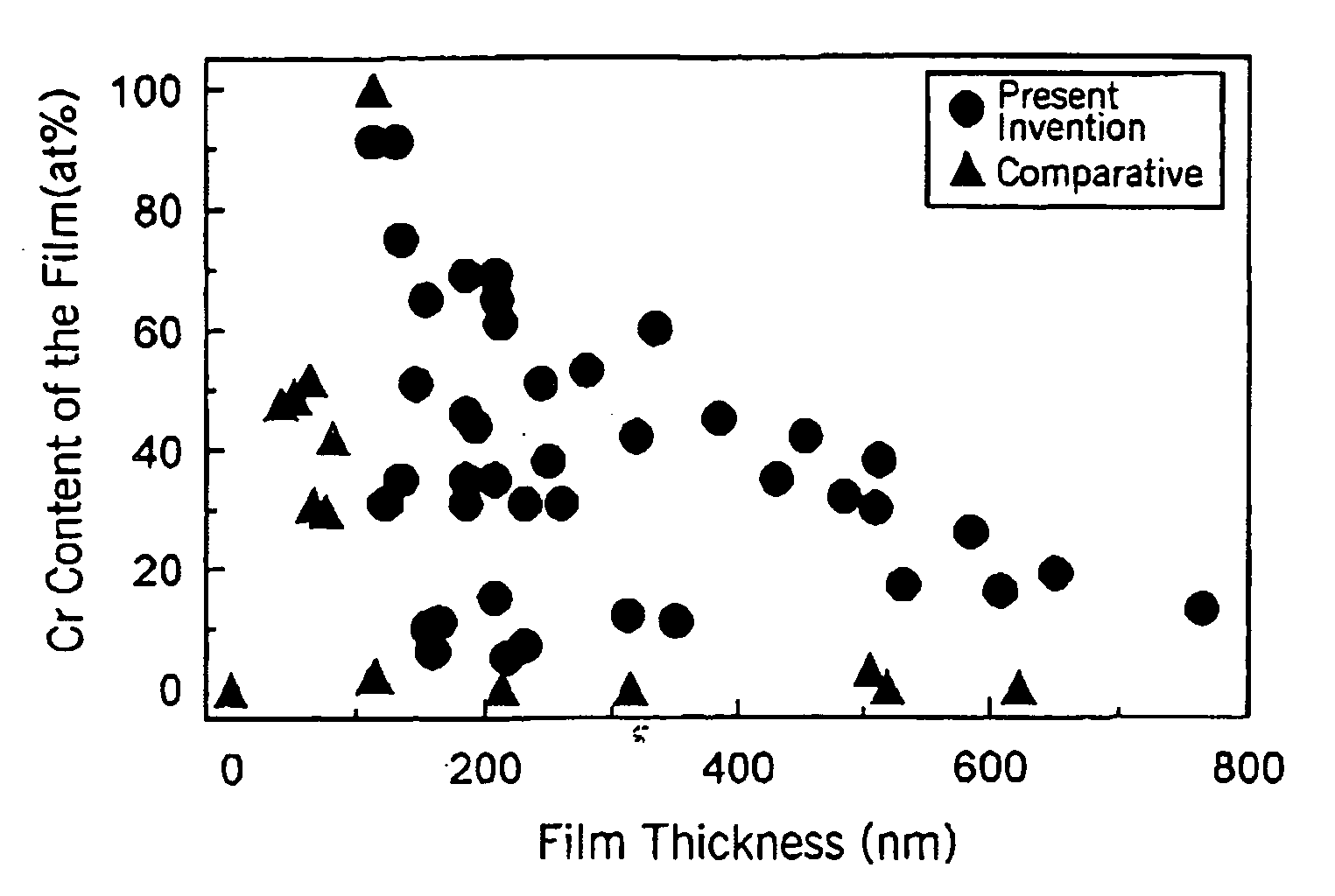

Steel and component of structural equipment for use in a hydrogen gas environment, and a method for the manufacture thereof

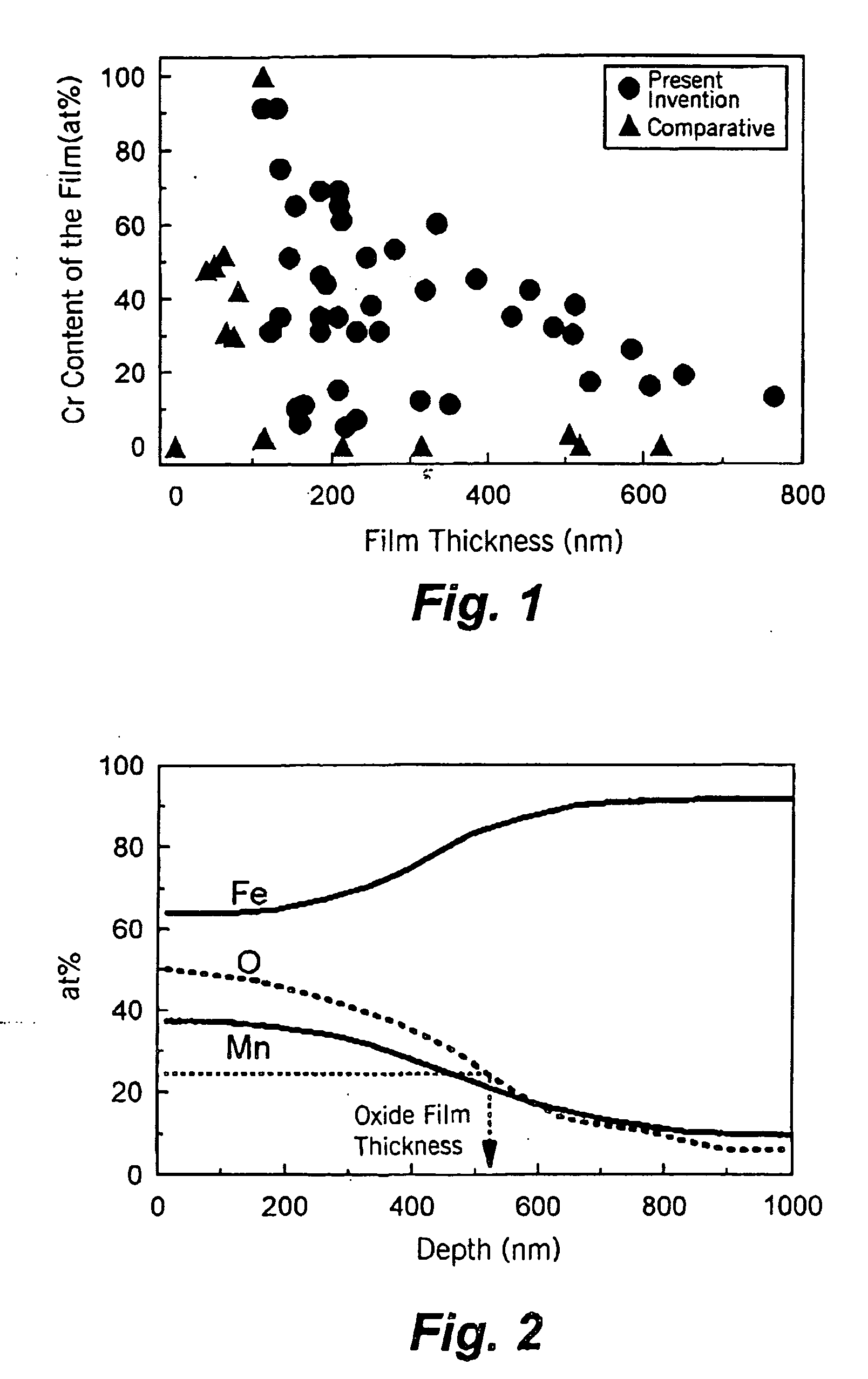

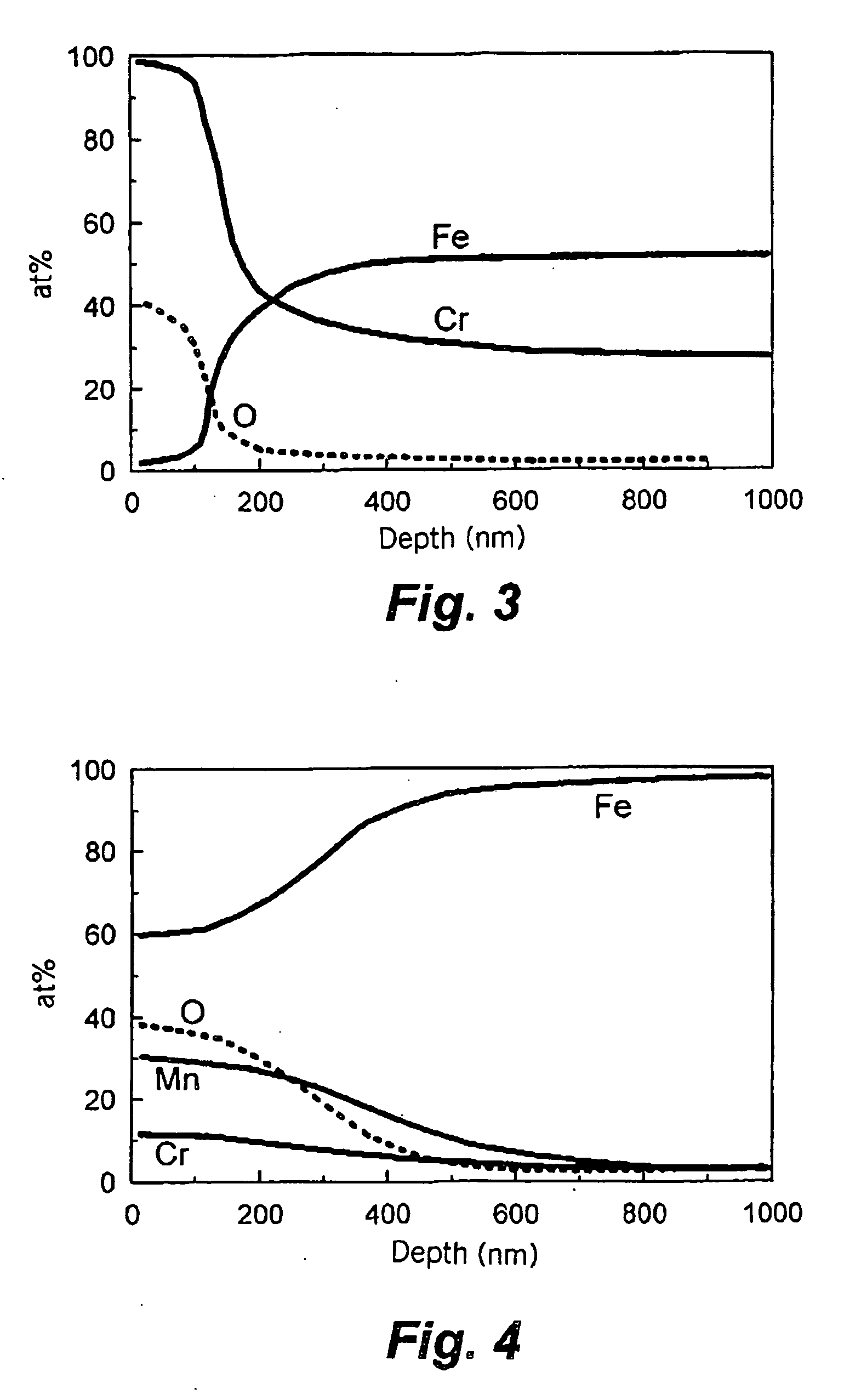

InactiveUS20060191600A1Decrease discharge and dissolving outPrevent penetrationSolid state diffusion coatingQuenching agentsWater vaporHydrogen atmosphere

A steel which does not suffer from hydrogen embrittlement contains 0.3-30% of Cr as the base material, and has an oxide film having a thickness of 100 nm or more formed on its surface. The oxide film contains at least two elements selected among Fe, Cr and Al in the form of oxides, respectively in an amount of 5 atom % or more. The oxide film is formed through single-step or two-step heating wherein the steel is heated in the atmosphere at 600-900° C. for not less than 3 minutes but not more than 2 hours if necessary, and then heated in a hydrogen atmosphere at 700-1200° C. for not less than 3 minutes but not more than 2 hours while controlling the water vapor partial pressure within the range from 10−8 to 10−1 MPa. The steel is adapted for use in hydrogen gas environments, such as a container or other hardware.

Owner:SUMITOMO METAL IND LTD

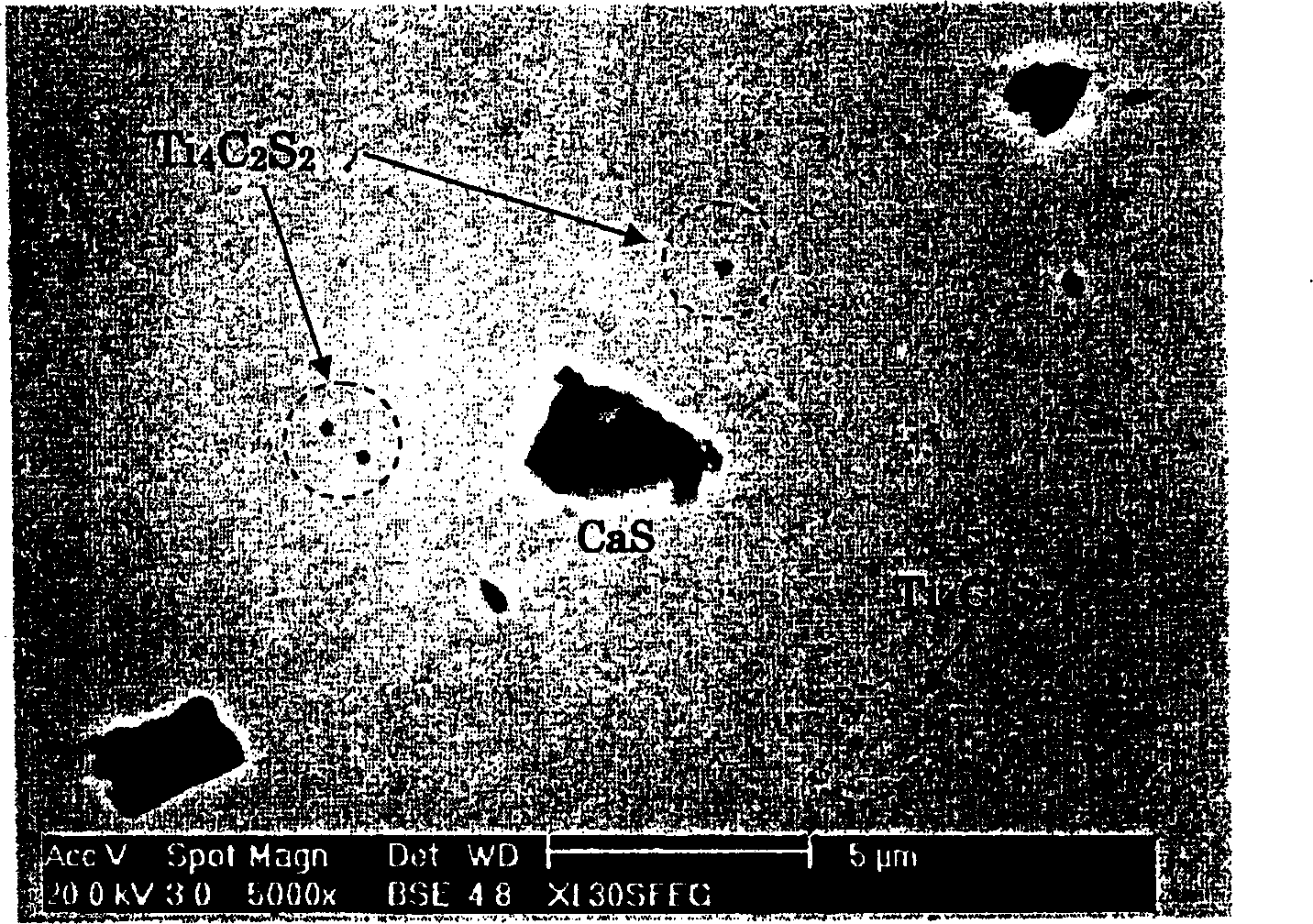

Steel sheet for hot stamping, method for production thereof, and hot stamping steel material

ActiveUS20150024237A1Improve hydrogen embrittlement resistanceEasy to practiceHot-dipping/immersion processesFurnace typesHot stampingChemical composition

A hot stamping steel material, which secures good hydrogen embrittlement resistance even when the steel sheet after hot stamping is subjected to processing leading to remaining of stress, such as piercing and which is easily practicable, wherein the steel sheet has the chemical composition of: C: 0.18 to 0.26%; Si: more than 0.02% and not more than 0.05%; Mn: 1.0 to 1.5%; P: 0.03% or less; S: 0.02% or less; Al: 0.001 to 0.5%; N: 0.1% or less; O: 0.001 to 0.02%; Cr: 0 to 2.0%; Mo: 0 to 1.0%; V: 0 to 0.5%; W: 0 to 0.5%; Ni: 0 to 5.0%; B: 0 to 0.01%; Ti: 0 to 0.5%; Nb: 0 to 0.5%; Cu: 0 to 1.0%; and balance: Fe and impurities, in terms of % by mass, the concentration of a Mn-containing inclusion is not less than 0.010% by mass and less than 0.25% by mass, and the number ratio of a Mn oxide to the inclusion having a maximum length of 1.0 to 4.0 μm is 10.0% or more.

Owner:NIPPON STEEL CORP

High strength spring steel wire with excellent coiling properties and hydrogen embrittlement resistance

Disclosed herein is a high strength spring steel wire with excellent coiling properties and hydrogen embrittlement resistance. The steel wire comprises, by mass, 0.4 to 0.60% of C, 1.7 to 2.5% of Si, 0.1 to 0.4% of Mn, 0.5 to 2.0% of Cr, 0.015% or less of P (exceeding 0%), 0.015% or less of S (exceeding 0%), 0.006% or less of N (exceeding 0%), 0.001 to 0.07% of Al, and the remainder being Fe and unavoidable impurities. The steel wire has a structure wherein prior austenite has an average grain size of 12 mum or less, and retained austenite exists in an amount of 1.0 to 8.0 vol. % with respect to a whole structure of the steel wire. The retained austenite has an average grain size of 300 nm or less and a maximum grain size of 800 nm or less. The steel has a tensile strength of 1,900 MPa or more.

Owner:KOBE STEEL LTD

Preparation method for producing diamond cutting line through steel wire magnetization

The invention discloses a preparation method for producing a diamond cutting line through steel wire magnetization. The method comprises the following steps: carrying out chemical nickel-plating treatment on diamond micro-powder so as to metalize the surface of the diamond micro-powder; removing a brass layer of a copper wire the surface of which is plated by brass in an alkali solution; preplating copper in a cyanide-free alkali copper plating solution; magnetizing the steel wire with pre-plated copper by magnetizing with a sintered neodymium iron boron strong magnet; in the process of sanding and electric-plating, attaching the diamond micro-powder which is dispersed in the solution and the surface is metalized to the surface of the steel wire under a magnetic field and the stirring function, and compositely depositing on the surface of the steel wire together with the copper plated layer; and plating the outermost layer of the steel wire with nickel. The electric-plated diamond cutting line is subjected to thermal treatment so as to demagnetize and eliminate the hydrogen embrittlement. The copper plated layer is adopted in pre-plating, sanding and electric-plating, so that the cost of the plated layer is lowered, the time needed for plating plated layers of the same thickness is also reduced, the production efficiency is improved, and meanwhile the uniform distribution of the diamond micro-powder on the surface of the steel wire is realized in sanding and electric-plating.

Owner:江苏聚成金刚石科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com