Method for preparing aluminum oxide ceramic based on sinking type DLP photocuring 3D printing

A technology of alumina ceramics and 3D printing, which is applied in the direction of improving process efficiency, additive processing, and improving energy efficiency. And the effect of good physical properties, reducing serious scattering problems, and improving printing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

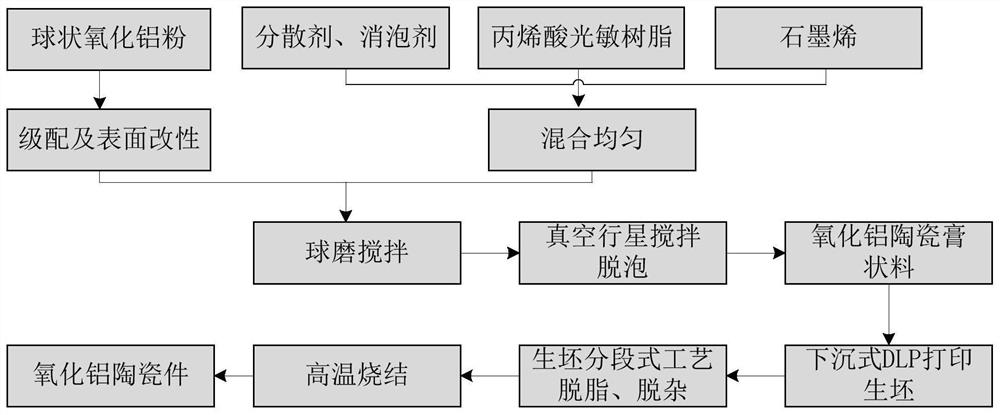

[0042] A method for preparing alumina ceramics based on sinking DLP photocuring 3D printing of the present invention, such as figure 1 shown, including the following steps:

[0043] S1. Preparation of light-cured alumina ceramic paste with high solid content, high stability and high molding precision:

[0044] (1) Take three kinds of α-spherical alumina powders with a particle size of 10 μm, 3 μm and 300 nm and add them to the ethanol solution according to the ratio of 40wt%, 50wt% and 10wt%, respectively. In this embodiment, the α-spherical alumina powder is 800g in total; α Spherical alumina powder mass meter, drop 2wt% dispersant KOS-110, after ultrasonic stirring and mixing for 2 hours, dry the mixture in a vacuum oven at 80°C for 24 hours to remove alcohol, and the dried alumina The powder is ground and pulverized and passed through an 80-mesh sieve to obtain α-spherical alumina powder after surface modification treatment.

[0045] (2) acrylic photosensitive resin is ad...

Embodiment 2

[0055] A method for preparing alumina ceramics based on sinking DLP light-curing 3D printing of the present invention comprises the following steps:

[0056] S1. Preparation of light-cured alumina ceramic paste with high solid content, high stability and high molding precision:

[0057] (1) Take three kinds of α-spherical alumina powders with particle diameters of 12 μm, 3 μm and 500 nm and add them to the ethanol solution according to the ratio of 55wt%, 25wt% and 20wt%, respectively. In this embodiment, the α-spherical alumina powders total 800g; α Spherical alumina powder mass meter, drop 3wt% dispersant BYK-111, after ultrasonic stirring and mixing for 3 hours, dry the mixture in a vacuum drying oven at 70°C for 30 hours to remove alcohol, and the dried alumina The powder is ground and crushed and passed through a 60-mesh sieve to obtain α-spherical alumina powder after surface modification treatment.

[0058] (2) Add acrylic photosensitive resin to the spherical ink tank...

Embodiment 3

[0068] A method for preparing alumina ceramics based on sinking DLP light-curing 3D printing of the present invention comprises the following steps:

[0069] S1. Preparation of light-cured alumina ceramic paste with high solid content, high stability and high molding precision:

[0070] (1) Take three kinds of α-spherical alumina powders with a particle size of 8 μm, 4 μm and 200 nm and add them to the ethanol solution according to the ratio of 65wt%, 27wt% and 8wt%, respectively. In this embodiment, the α-spherical alumina powder is 800g in total; α spherical alumina powder mass, drop 1.3wt% dispersant TEG-0685 and 0.8wt% dispersant oleic acid, after ultrasonic stirring and mixing for 3.5h, dry the mixture in a vacuum oven at 95°C After 20 hours to remove alcohol, the dried alumina powder was ground and crushed and passed through a 100-mesh sieve to obtain α-spherical alumina powder after surface modification.

[0071] (2) acrylic photosensitive resin is added in the spheric...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Microhardness | aaaaa | aaaaa |

| Microhardness | aaaaa | aaaaa |

| Microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com