Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

63results about How to "Less micro defects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

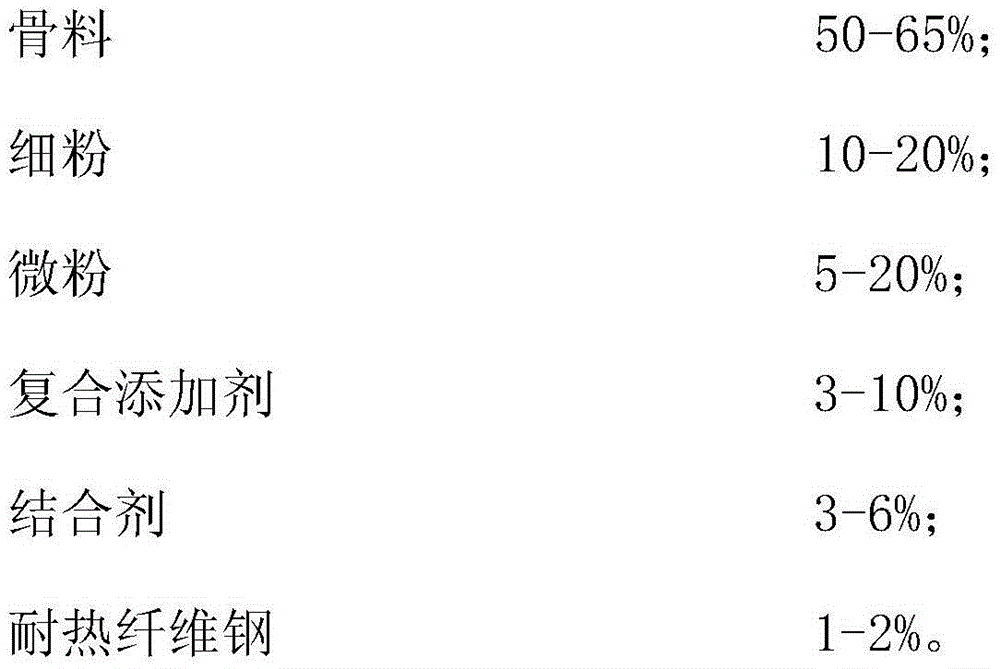

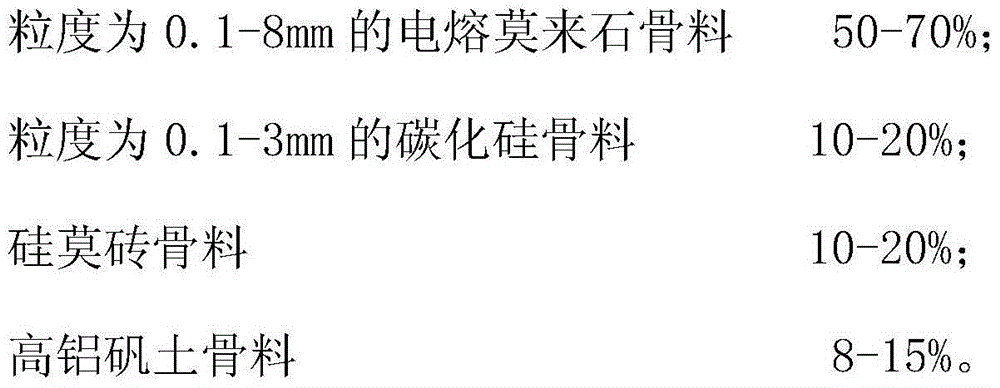

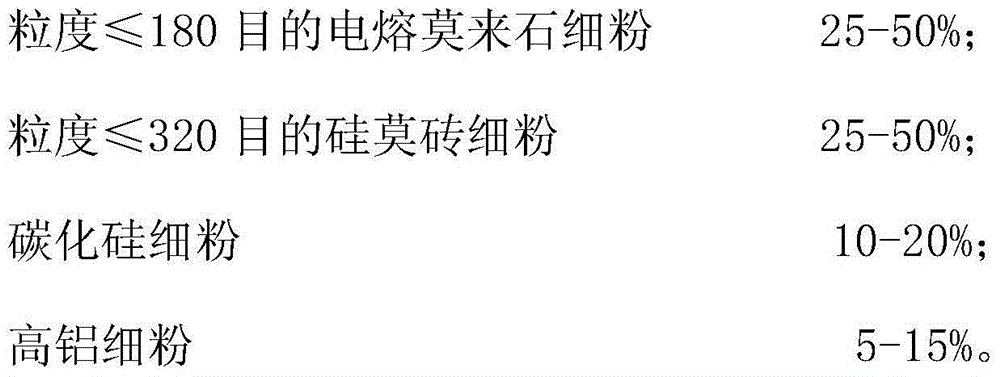

Silicon carbide mullite wear-resisting casting material

The invention discloses a silicon carbide mullite wear-resisting casting material which comprises the following components in percentage by mass: 50-65% of aggregate, 10-20% of refined powder, 5-20% of micro powder, 3-10% of a composite additive, 3-6% of a binding agent and 1-2% of thermal resisting fiber steel. As mullite aggregate and silicon carbide aggregate are adopted as the aggregate, the casting material has properties of good temperature resistance, scouring resistance, erosion resistance and thermal shock resistance; as the silicon dioxide micro powder and the activated aluminum oxide micro powder are introduced and the ratio of the silicon dioxide micro powder to the activated aluminum oxide micro powder is adjusted, the high-temperature strength, the wear-resistance and the corrosion resistance of the material are greatly improved; a waste material, namely, silicon-mullite bricks, is utilized, so that the energy is saved, the emission is reduced, the high-temperature application property of the casting material is improved, and through addition of organic and inorganic composite additives, the high-temperature application property of the casting material is improved.

Owner:长兴兴鹰新型耐火建材有限公司

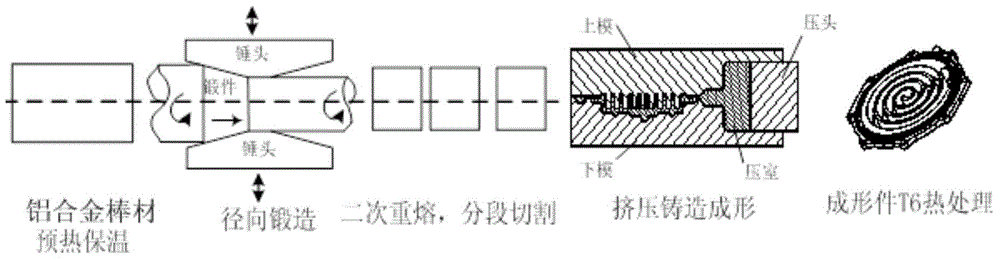

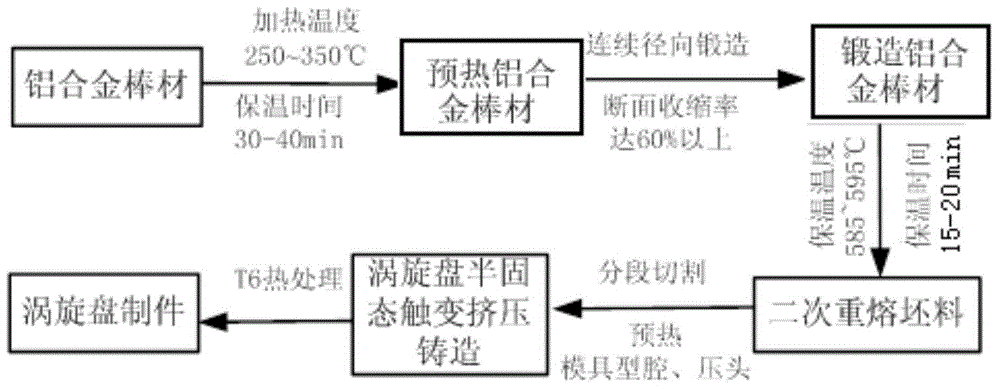

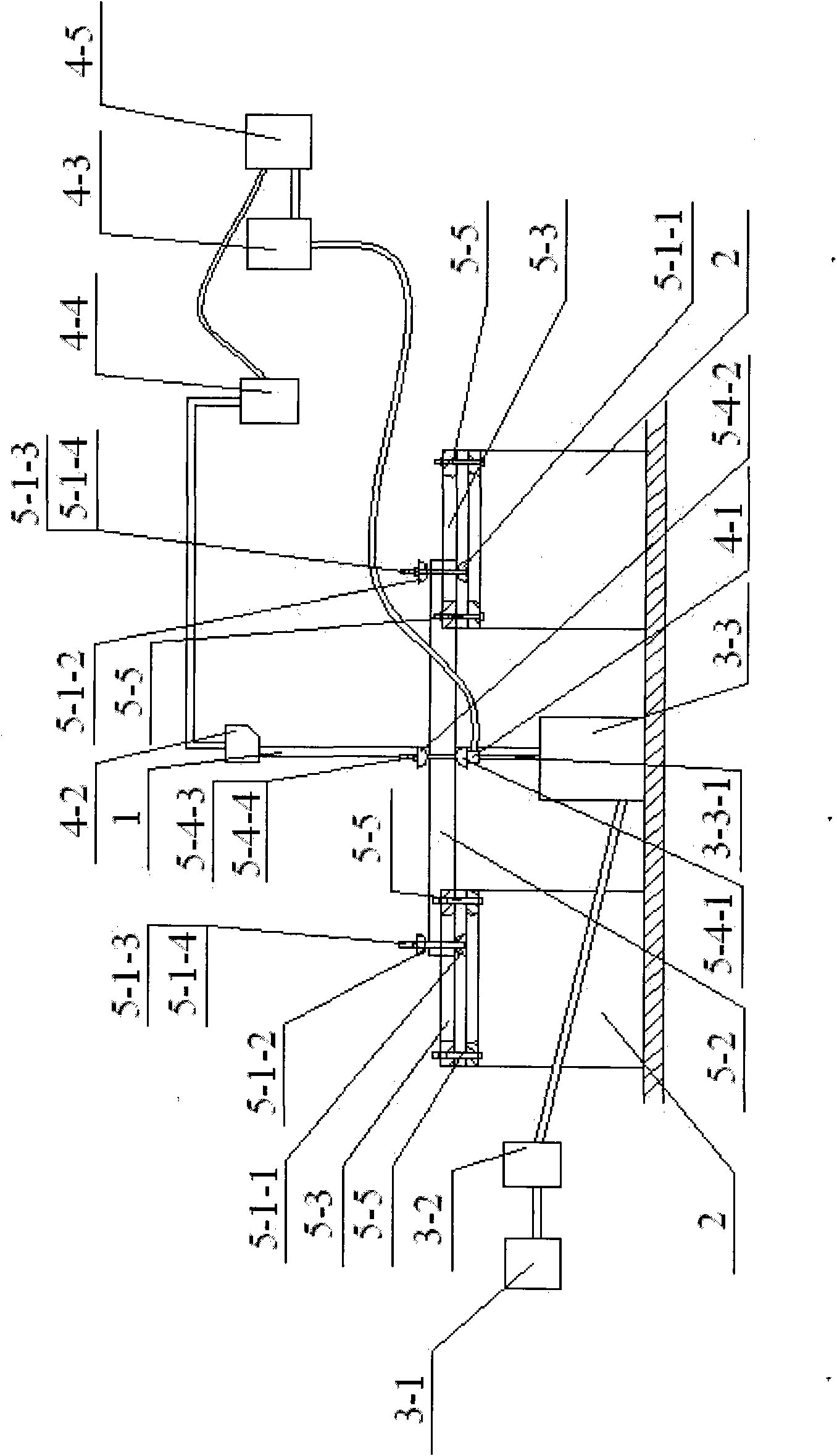

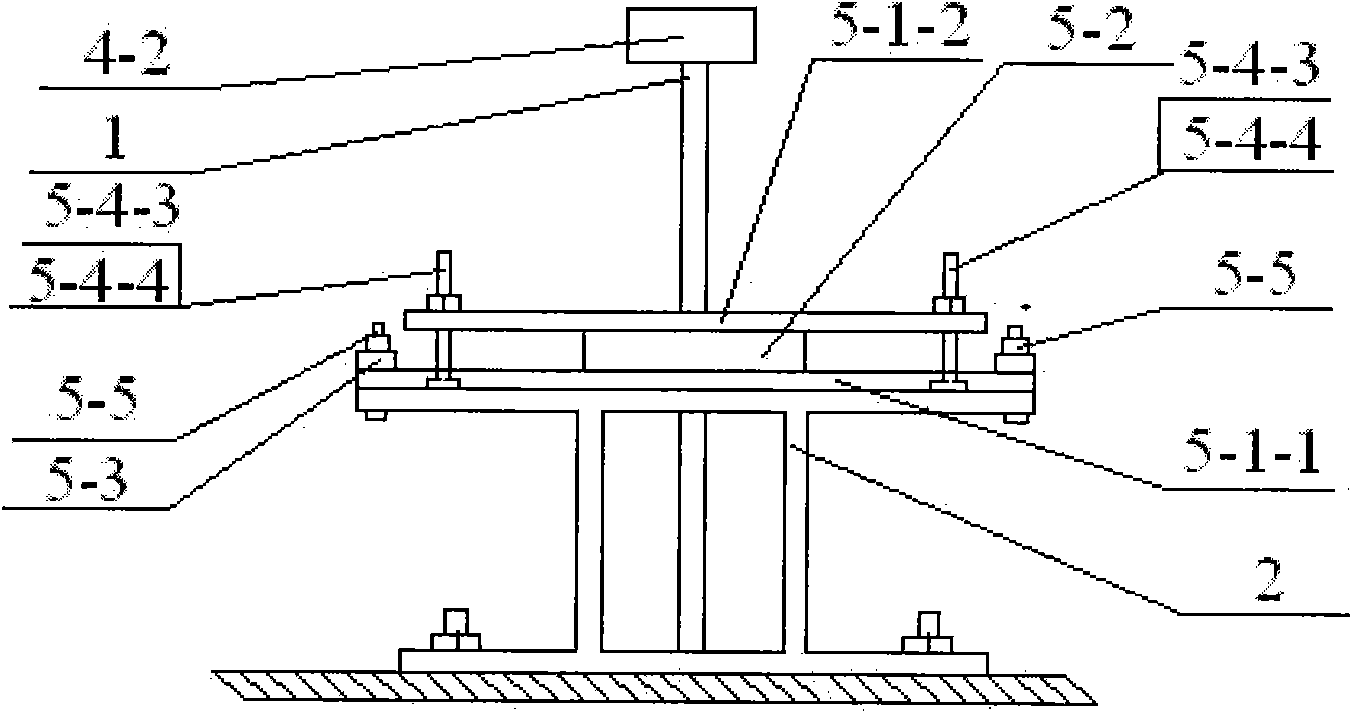

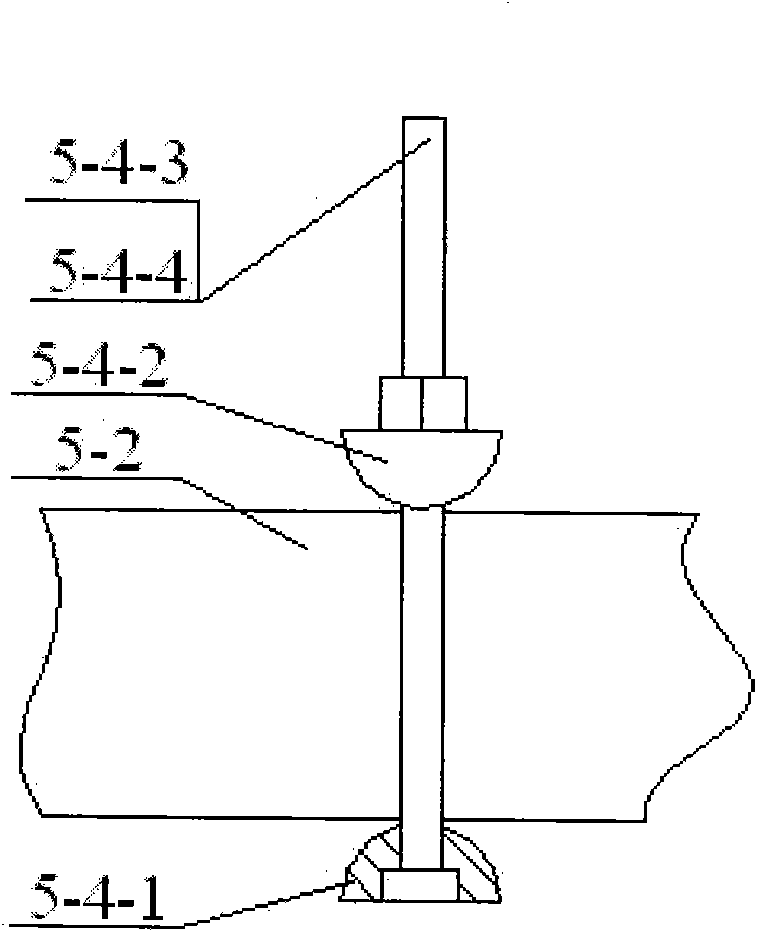

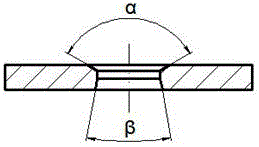

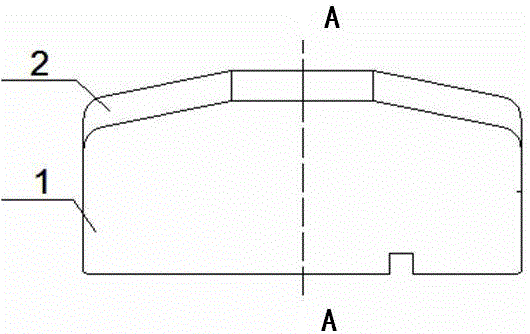

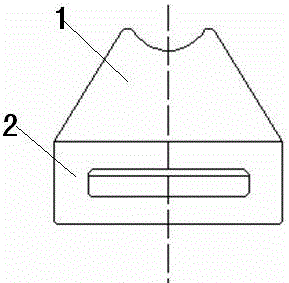

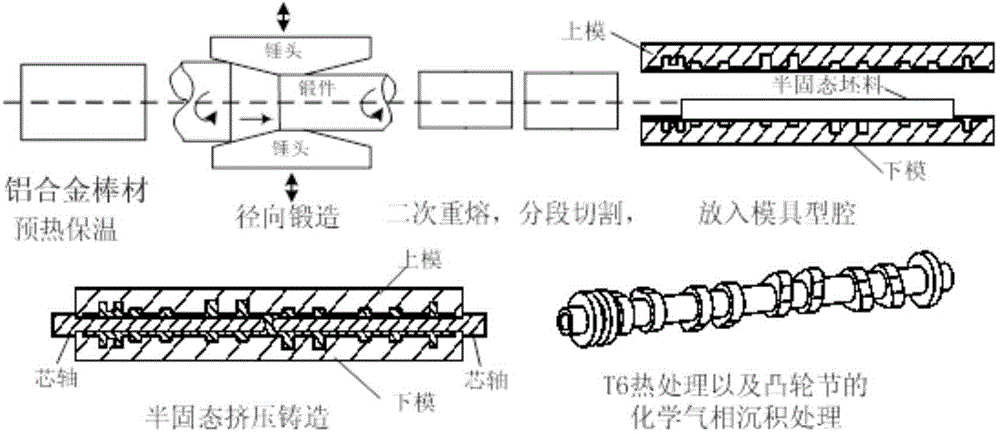

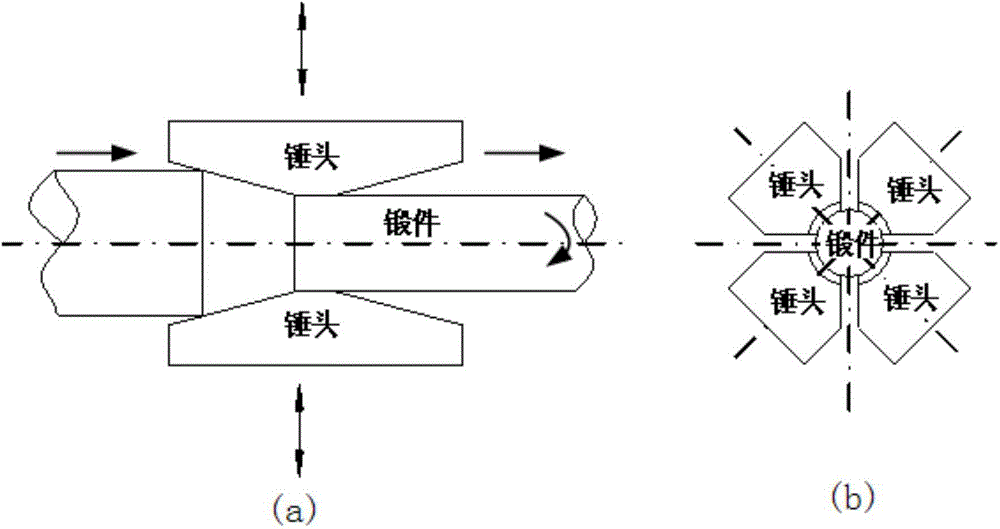

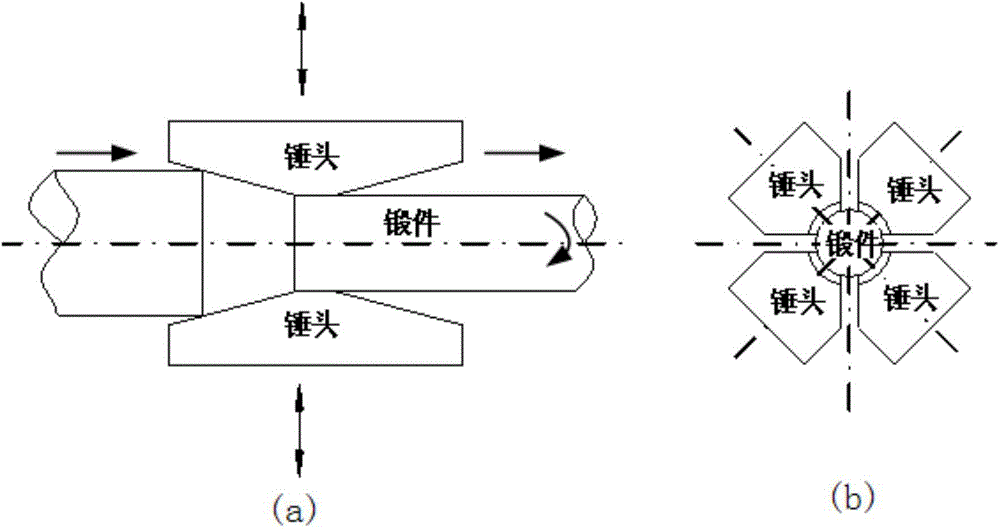

Process for preparing semi-solid state aluminum alloy scroll plate by radial forging strain induction method

InactiveCN104561852AAvoid uneven defectsReduce plastic forming forceIncreasing energy efficiencySemi solidInduction method

The invention discloses a process for preparing a semi-solid state aluminum alloy scroll plate by a radial forging strain induction method. The method comprises the following steps: pre-heating an aluminum alloy rods at first; performing radial forging on the aluminum alloy rods; performing secondary remelting on blanks subjected to radial forging; performing extrusion casting on the aluminum alloy scroll plate; performing T6 heat treatment on the aluminum alloy scroll plate acquired by extrusion casting in a semi-solid state to increase the mechanical property. According to the process, the aluminum alloy semi-solid state blanks which are uniform and free of microdefect are prepared and are subjected to extrusion casting to form a scroll plate workpiece with less microdefects and high mechanical performance, and the process is simple and easy to operate.

Owner:XI AN JIAOTONG UNIV

Silicon carbide fused mullite wear-resistant castable

The invention discloses a silicon carbide mullite wear-resisting casting material which comprises the following components in percentage by mass: 50-65% of aggregate, 10-20% of refined powder, 5-20% of micro powder, 3-10% of a composite additive, 3-6% of a binding agent and 1-2% of thermal resisting fiber steel. As mullite aggregate and silicon carbide aggregate are adopted as the aggregate, the casting material has properties of good temperature resistance, scouring resistance, erosion resistance and thermal shock resistance; as the silicon dioxide micro powder and the activated aluminum oxide micro powder are introduced and the ratio of the silicon dioxide micro powder to the activated aluminum oxide micro powder is adjusted, the high-temperature strength, the wear-resistance and the corrosion resistance of the material are greatly improved; a waste material, namely, silicon-mullite bricks, is utilized, so that the energy is saved, the emission is reduced, the high-temperature application property of the casting material is improved, and through addition of organic and inorganic composite additives, the high-temperature application property of the casting material is improved.

Owner:长兴兴鹰新型耐火建材有限公司

High-durability damping concrete and preparation method thereof

The invention discloses a high-durability damping concrete and a preparation method thereof, and relates to several concretes and a preparation method thereof. The invention solves the problems of low damping capability and poor durability of the conventional concrete structure material per se. The high-durability damping concrete is prepared by stirring and mixing cements, rubber powder, water, medium sand, stones, and adding fibers and silicon powder. In the invention, c the loss factors of the high-durability damping concrete are improved by about 80-200 percent compared with that of pain concrete under the condition of different frequencies. After maintenance for 28 days, the concrete prepared by using the method has chloridion-resistant permeability and carbonizing-resistant capability both superior to that of blank concretes.

Owner:刘铁军

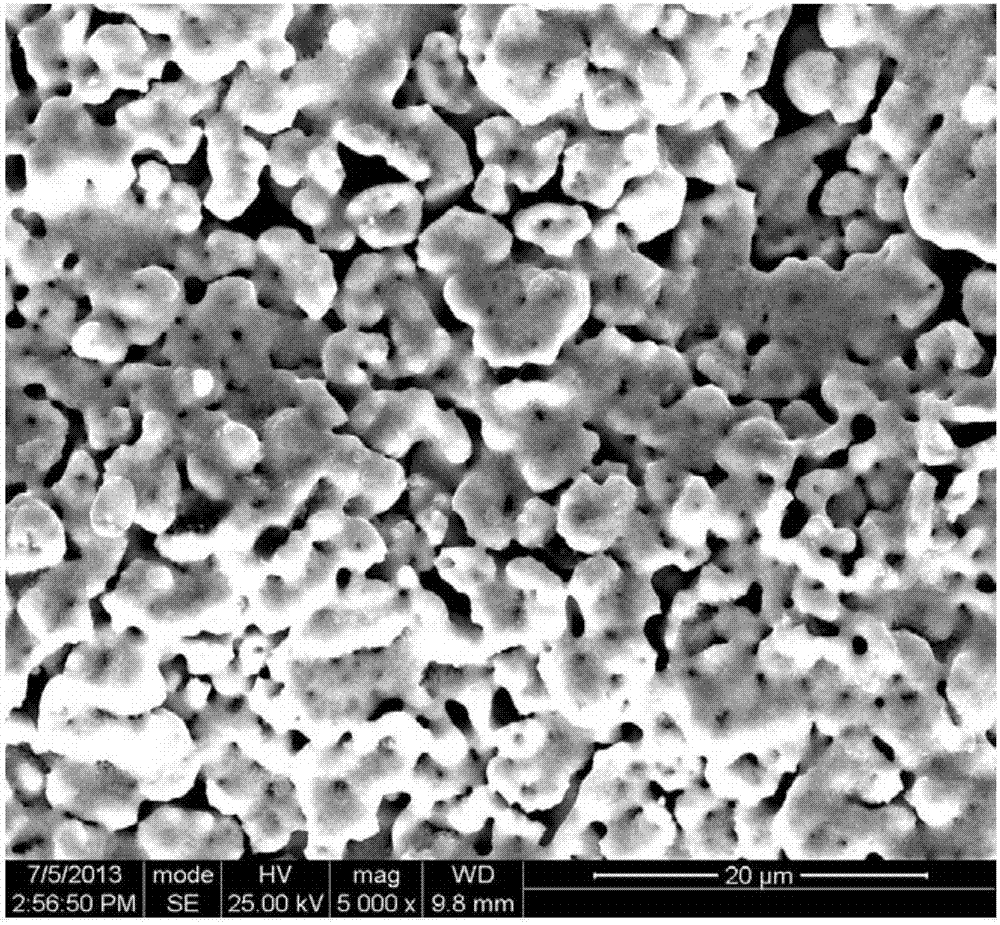

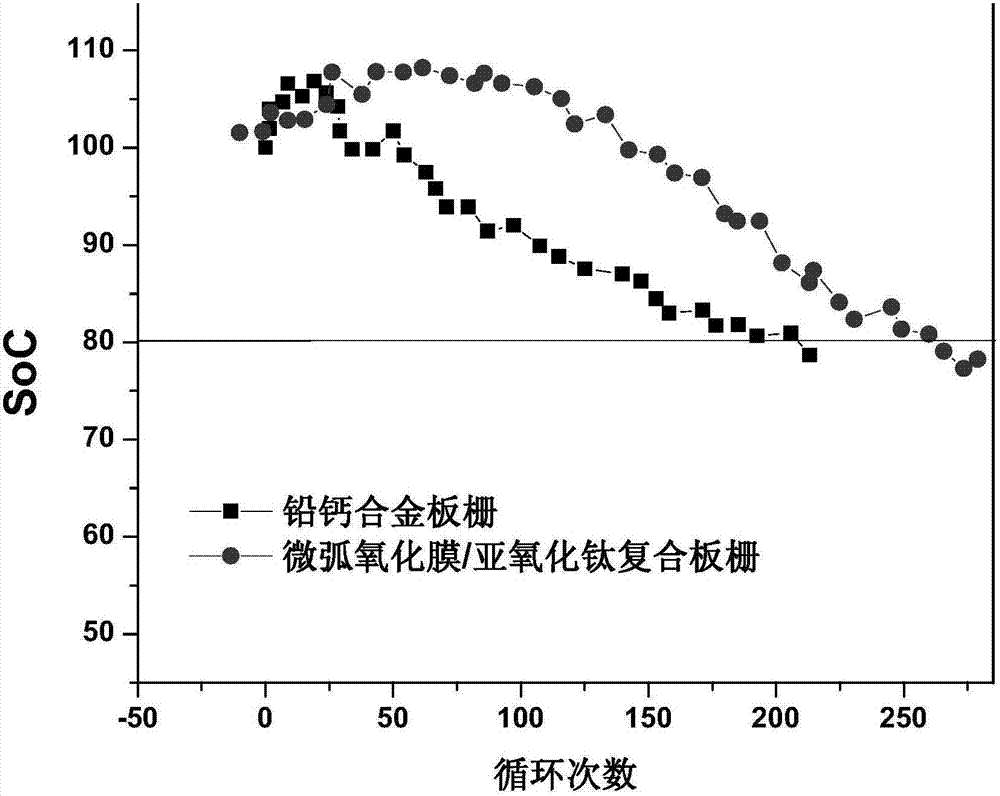

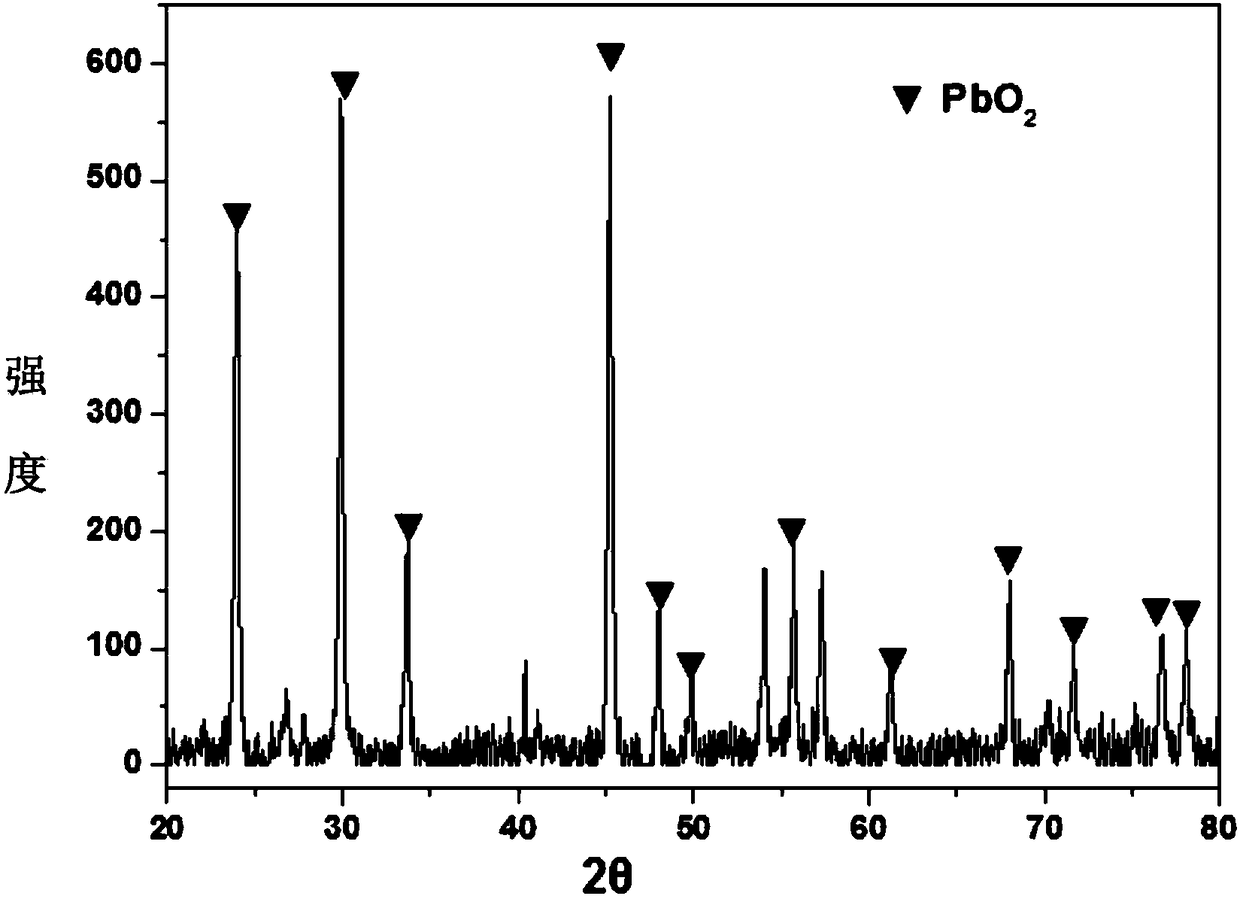

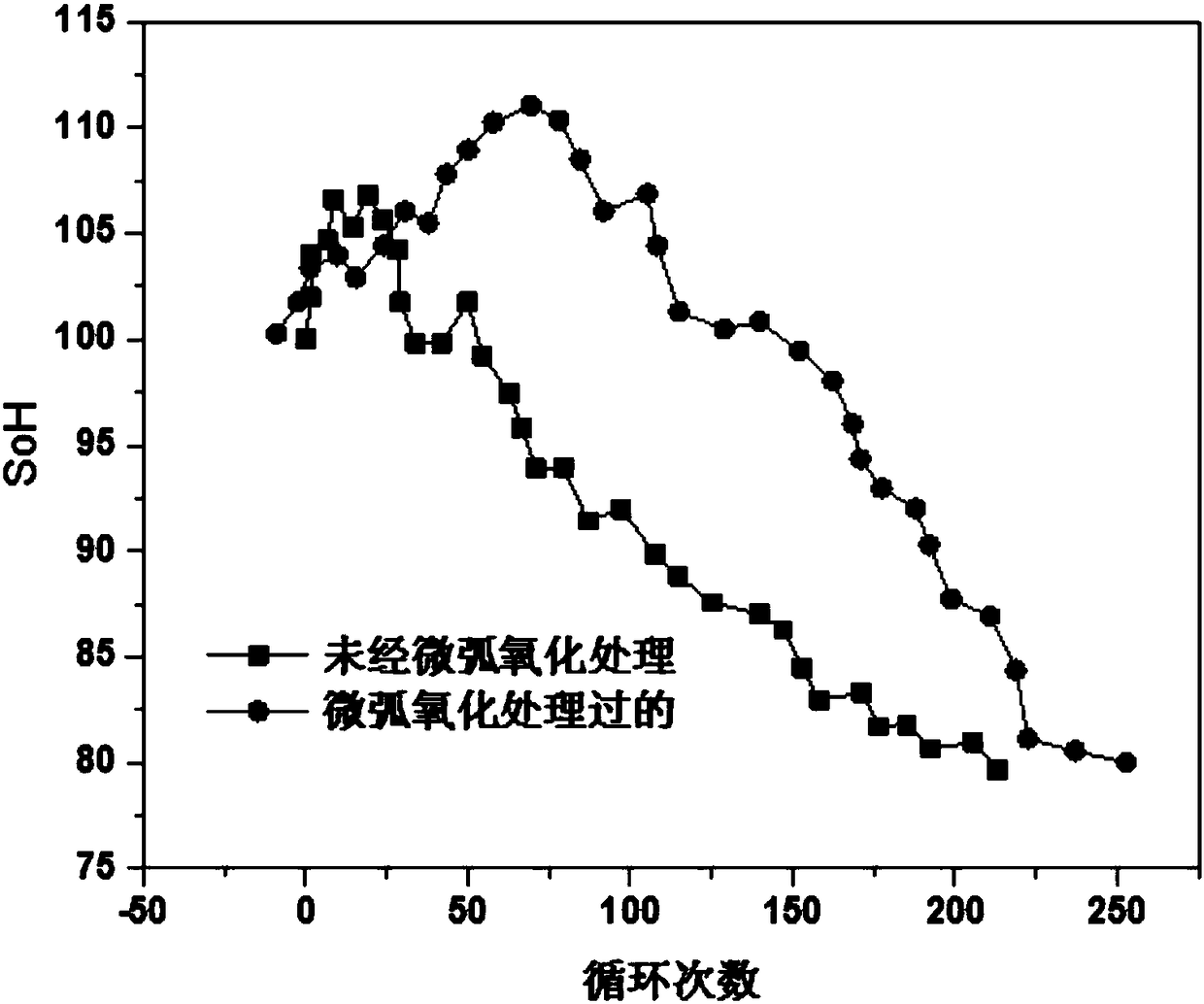

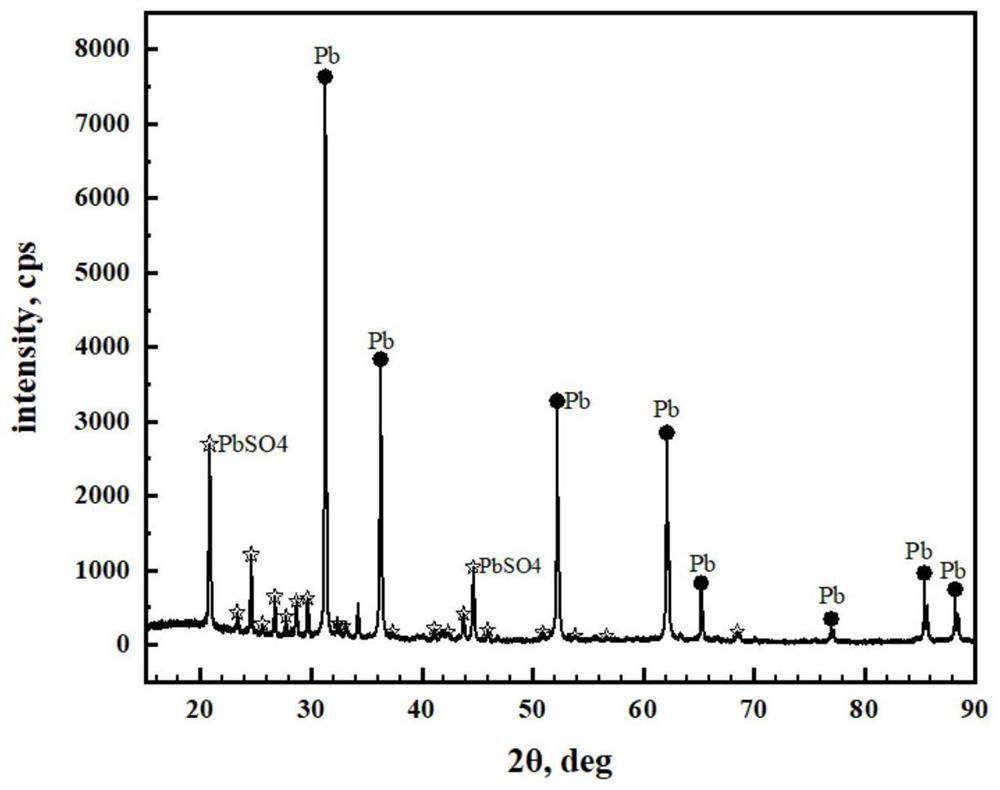

Lead storage battery grid with composite coating and preparation method of lead storage battery grid

ActiveCN107190303ALess micro defectsImprove bindingAnodisationElectrolytic inorganic material coatingComposite gridPre treatment

The invention discloses a lead storage battery grid with a composite coating and a preparation method of the lead storage battery grid and belongs to the field of chemical power sources and composites. The preparation method comprises the steps of pretreatment, electrochemical oxidation and cathode electrodeposition. According to the lead storage battery grid with the composite coating and the preparation method of the lead storage battery grid, a lead alloy grid serves as a substrate, a compact lead dioxide oxidation film is formed on the surface of lead alloy through an electrochemical oxidation method, metallurgy level combination is achieved between the film layer and the substrate, contact electroconductivity of the grid is fully ensured, and the protection performance of the lead alloy substrate is also enhanced effectively. Then titanium oxide is deposited on the surface of the lead dioxide oxidation film through a cathode electrodeposition method. On the one hand, holes of the oxidation film are filled with part of titanium oxide, so that compactness of the lead dioxide oxidation film is enhanced; and one the other hand, the titanium oxide has good electrochemical performance, so that the comprehensive performance of the composite grid is promoted. Through the composite coating prepared on the surface of the lead alloy grid, on the premise that the electroconductivity of the grid is ensured, corrosion resistance of the grid is improved substantially, and service life of the grid is prolonged.

Owner:TIANNENG BATTERY GROUP +1

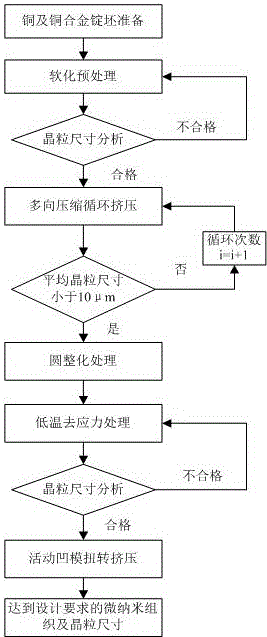

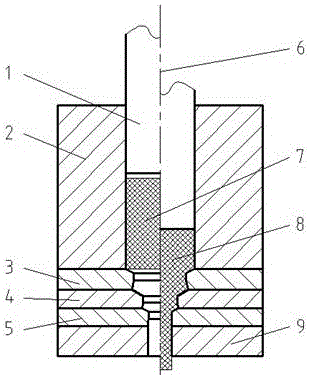

Method for preparing micro-nano copper through multi-axial compression, twisting and combined extrusion

The invention discloses a method for preparing micro-nano copper through multi-axial compression, twisting and combined extrusion. The method comprises the following steps: (1) carrying out softening pre-treatment on a copper ingot blank; (2) carrying out multi-axial compression circulating extrusion on the blank obtained by the step (1) to generate great plastic deformation of the blank; fining the size of a crystal grain to obtain a sub-micron grade; (3) carrying out rounding treatment on the blank obtained by the step (2) to obtain a designed blank shape size; (4) carrying out destressing annealing treatment on the blank obtained by the step (3); (5) carrying out movable concave die twisting and extrusion on the blank obtained by the step (4), so as to generate multi-grade forward extrusion and compression neck deformation of the blank, and fining the size of the crystal grain to obtain a micro-nano grade; (6) carrying out microstructure sampling analysis on the blank obtained by the step (5) so as to guarantee tissue performance of the prepared micro-nano copper. The method provided by the invention can be applied to preparation of ultrafine crystals including pure copper, brass, white brass and the like and micro-nano materials.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

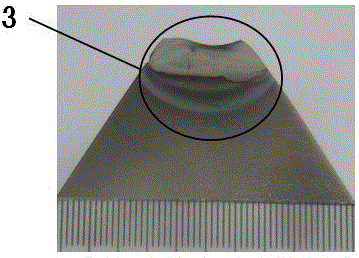

Preparation method for high-hardness hammer head for radial precision forging machine

InactiveCN105063491ADense tissueLess micro defectsMetallic material coating processesChemical compositionHardness

The invention discloses a preparation method for a high-hardness hammer head for a radial precision forging machine. The preparation method is characterized by comprising the following steps: forging a basal body which is made from 4Cr5MoSiV1 hot-forging mould steel comprising the following chemical components in percentage by weight: 0.32%-0.42% of C, 0.80%-1.20% of Si, less than or equal to 0.40% of Mn, 4.5%-5.5% of Cr, 1.0%-1.5% of Mo, 0.8%-1.0% of V and the balance of Fe; carrying out a forging process of heat-working mould steel with a forging ratio of 2.5-3.0 at a forging temperature of 750-800 DEG C; carrying out a forging piece annealing process: preserving the temperature for 1-4 hours at 860-890 DEG C, furnace-cooling to 50 DEG C, and carrying out air-cooling; carrying out basal body thermal treatment: carrying out a thermal treatment process of a 4Cr5MoSiV1 heat-working mould steel forging piece: carrying out oil quenching at 1000-1050 DEG C and carrying out tempering at 500-600 DEG C; carrying out basal body surface treatment: carrying out polishing and shot blasting treatment on a basal body working surface; carrying out laser cladding on the basal body working surface; carrying out mechanical processing and performance detecting on the forging piece, and warehousing the forging piece. The invention aims to provide the preparation method for the high-hardness hammer head, which is long in service life, for the radial precision forging machine.

Owner:NO 52 INST OF CHINA NORTH IND GRP CORP

CrB2 coating layer with high hardness and corrosion resistance on surface of stainless steel substrate and preparation method thereof

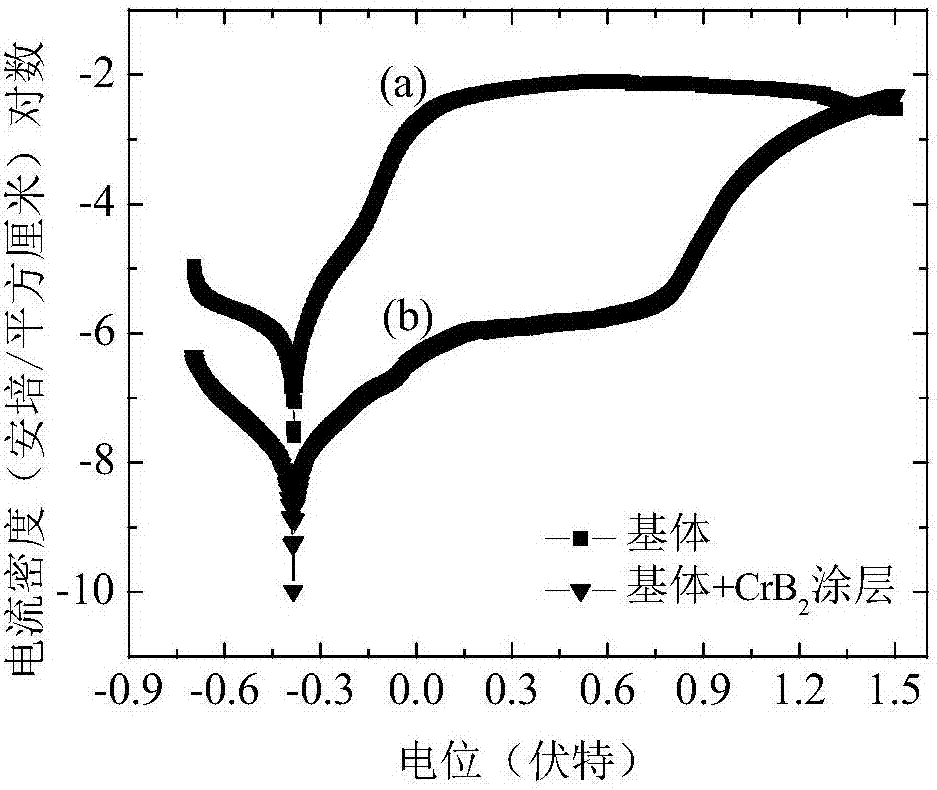

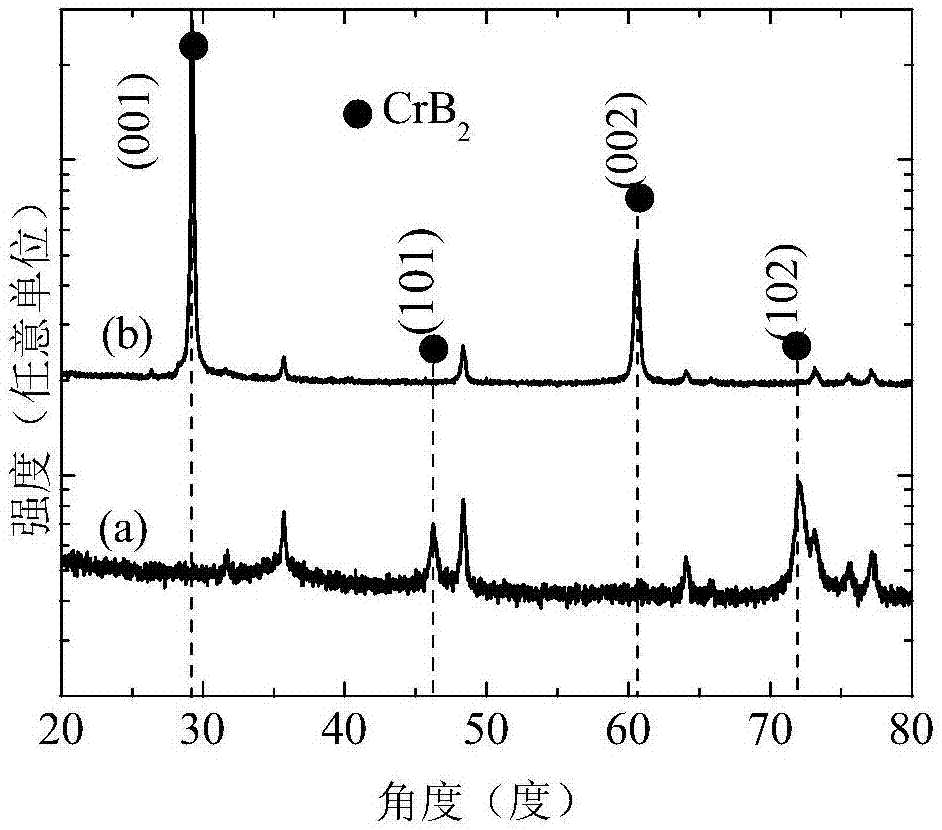

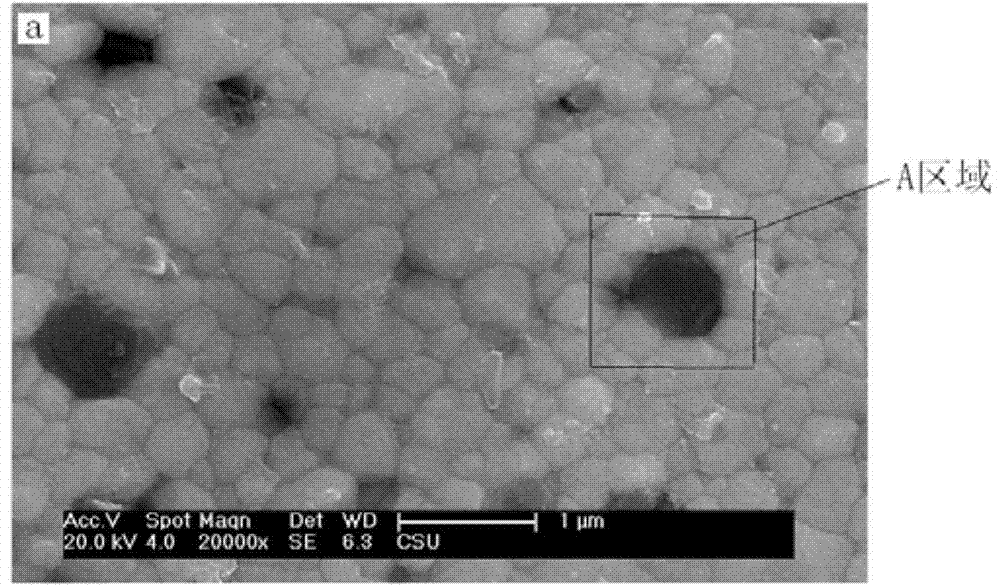

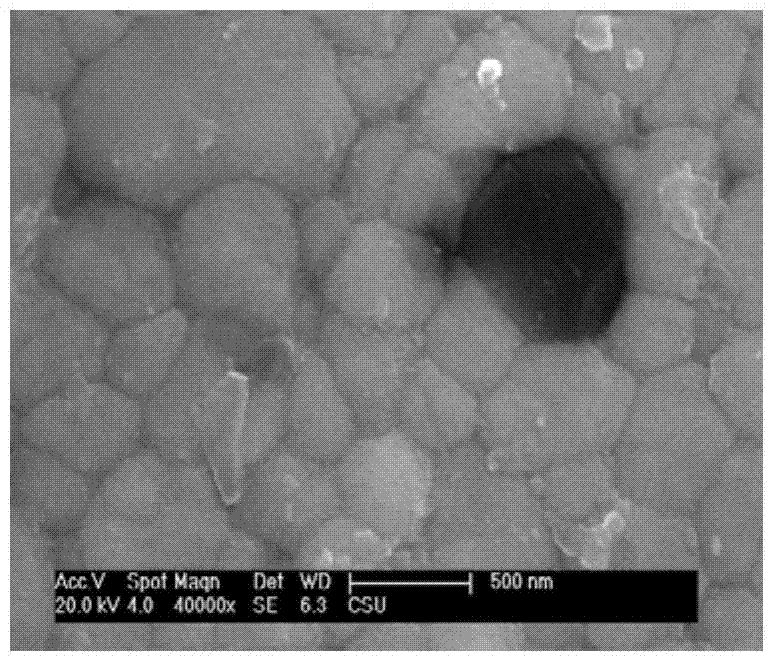

InactiveCN107313018AHigh hardness and compactnessExcellent wear and corrosion resistanceVacuum evaporation coatingSputtering coatingIonizationHigh-power impulse magnetron sputtering

The invention discloses a CrB2 coating layer with high hardness and corrosion resistance on the surface of a stainless steel substrate. The coating layer uses a nanometer columnar crystal CrB2 as a main phase structure; and the CrB2 coating layer contains (001) and (002) two types of crystal orientations, wherein (001) is preferentially selected. Experiments prove that the hardness of the coating layer can reach 42-50 GPa; the corrosion speed of matrix is greatly decelerated in simulation of artificial seawater; and the corrosion resistance is excellent. In addition, the invention further provides a method for preparing the coating layer; a high-power pulse magnetron sputtering method is adopted; a Cr-B compound target is used; the Cr-B coating layer with specific phase structure and crystal structure is obtained through adjusting high-power pulse power supply parameters; and the method has such characteristics as high metal ionization rate, low cost, simplicity and easiness in control.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Zirconium oxide composite ceramic and preparation method thereof

ActiveCN104261822ASolve the problem of performance degradationHigh hardnessComposite ceramicHigh intensity

The invention relates to zirconium oxide composite ceramic and a preparation method thereof, particularly relates to high-toughness and high-hardness composite ceramic and a preparation method thereof and belongs to the technical field of composite ceramic. The zirconium oxide composite ceramic comprises the following components in percentage by mass: 90.0-96.5% of ZrO2, 3.0-9.5% of TiB2 and less than or equal to 1% of other unavoidable impurities. By virtue of the method in which coating the surfaces of nano-TiO2 powder and nano-B2O3 powder with a layer of carbon and in situ synthesizing TiB2, the zirconium oxide composite ceramic with high toughness and high hardness is obtained. The preparation process is simple and the obtained high-hardness zirconium oxide composite ceramic can be used in partial application field of hard alloys and has broad application development prospects.

Owner:CENT SOUTH UNIV +1

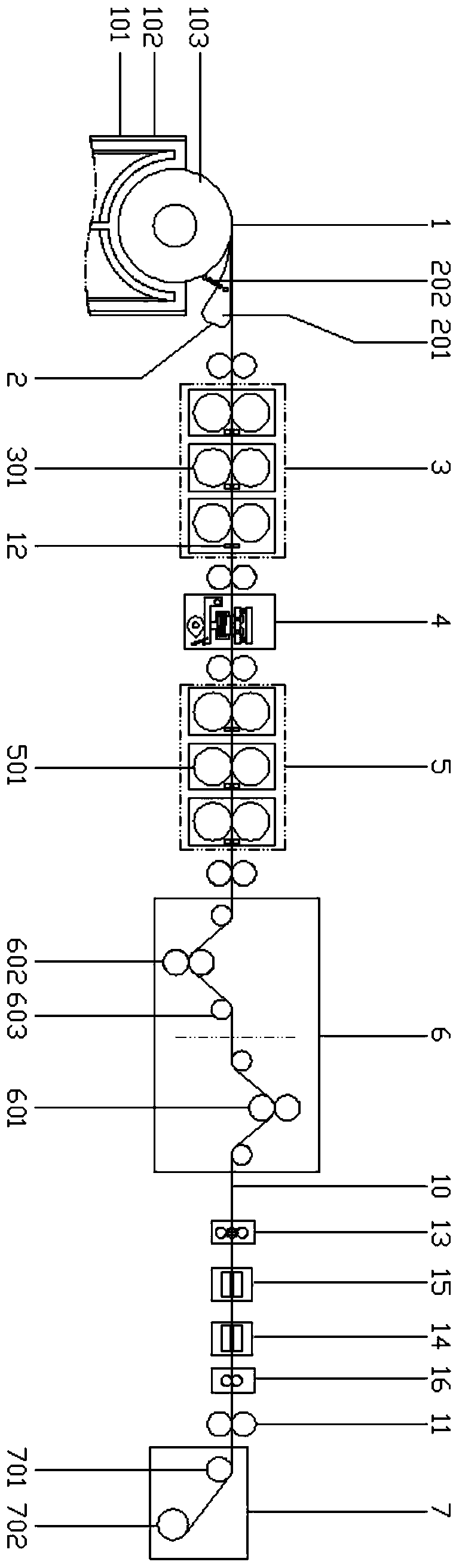

Electrolytic copper foil manufacturing equipment

ActiveCN109778246AHigh surface finishReasonable designPolishing machinesGrinding machine componentsSurface finishHigh density

The invention discloses electrolytic copper foil manufacturing equipment. The electrolytic copper foil manufacturing equipment comprises an electrolytic copper foil mechanism, a stripping mechanism, acoarse roll prepressing mechanism, a high-frequency stamping mechanism, a finish roll rolling mechanism, a polishing and grinding mechanism and a collection mechanism. The high-frequency stamping mechanism comprises an elastic rolling device used for being arranged on one side of copper foil and a high-frequency stamping device used for being arranged on the other side of the copper foil. The polishing and grinding mechanism comprises a front surface polishing and grinding device used for polishing and grinding the front surface of the copper foil and a back surface polishing and grinding device used for polishing and grinding the back surface of the copper foil. The electrolytic copper foil manufacturing equipment provided by the invention is novel in design and reasonable in structure.The electrolytic copper foil manufacturing equipment strips off the electrolyzed copper foil from a cathode electrolytic roll and then conducts prepressing, high-frequency stamping, rolling and polishing to obtain the copper foil with the small mall, high surface smoothness, fewer microdefects and high density. The obtained copper foil has excellent elongation and tensile strength, is suitable forlithium batteries and can improve through quality of the lithium batteries.

Owner:TAIXING SHENGDA COPPER IND CO LTD

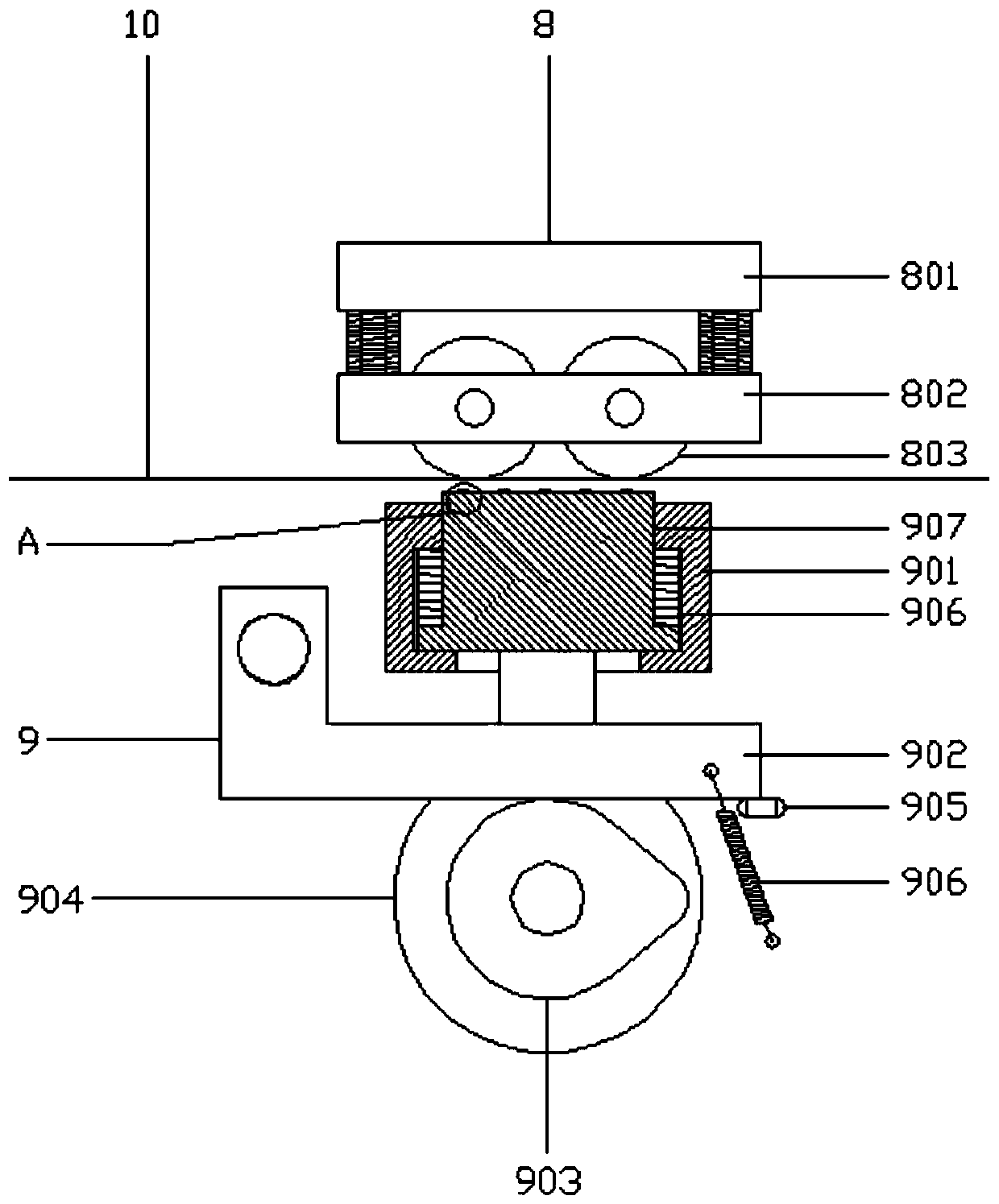

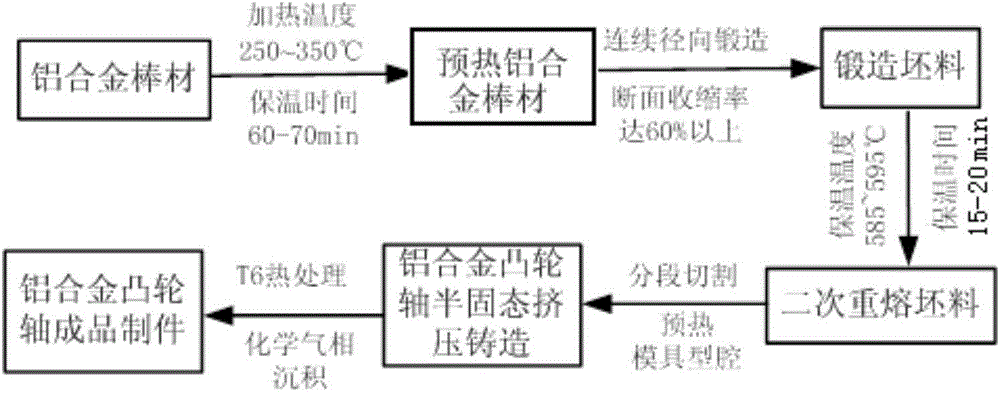

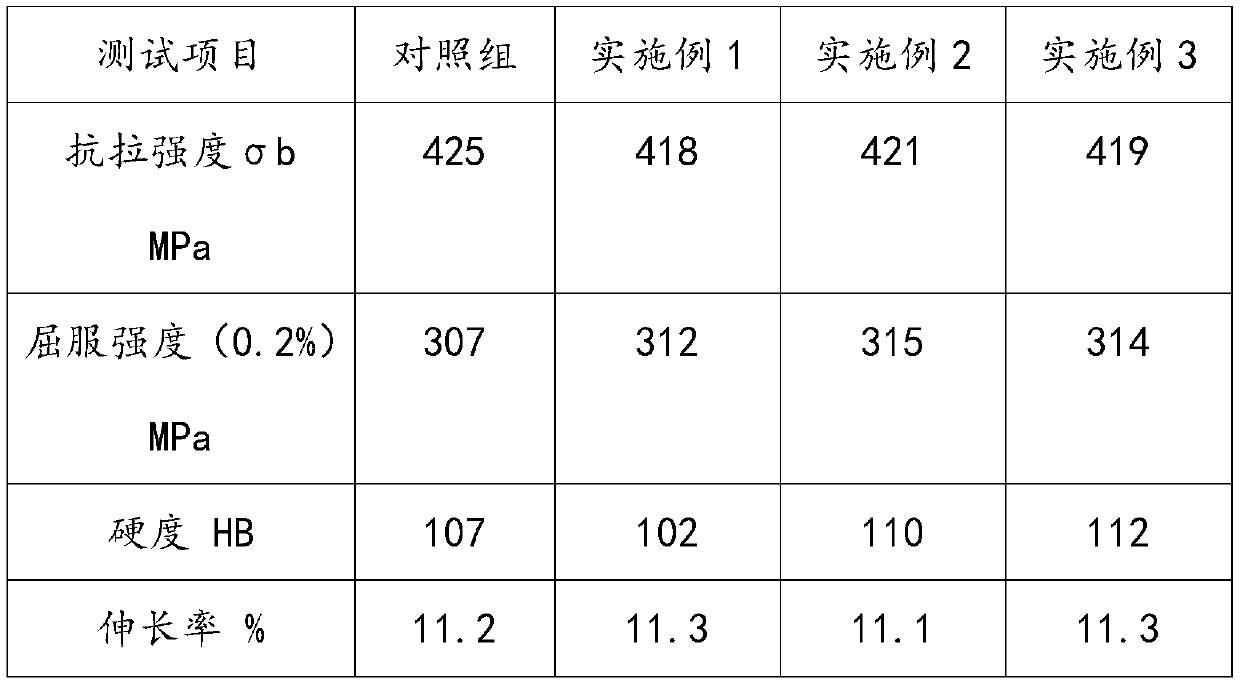

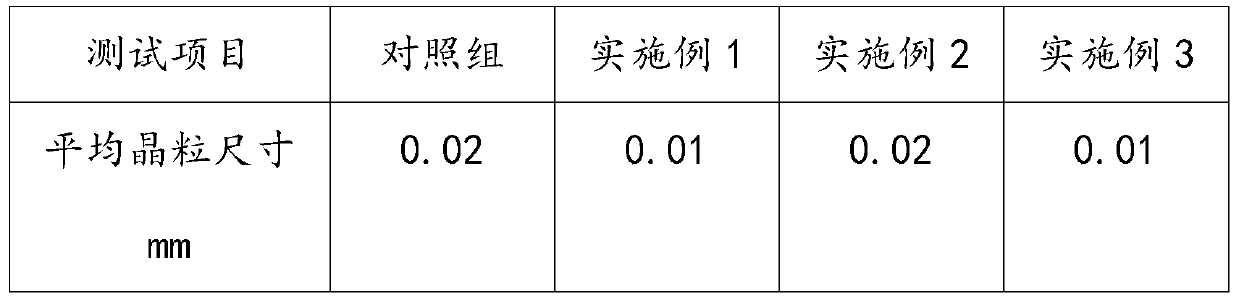

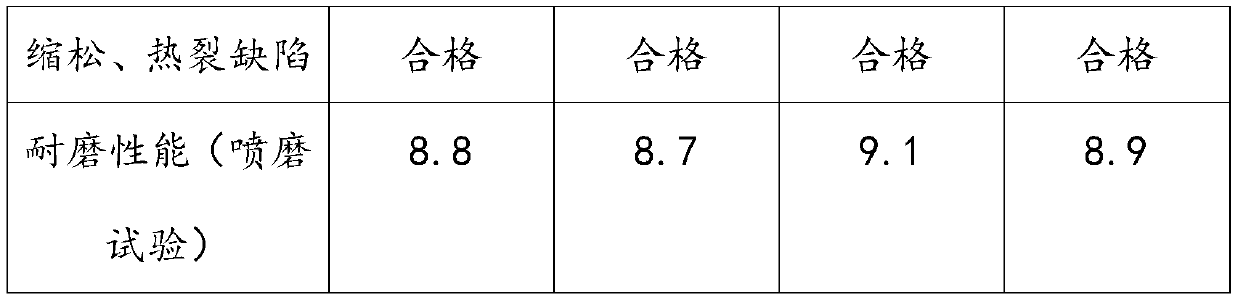

Semisolid process for manufacturing engine aluminum alloy cam shaft through radial forging strain provocation method

InactiveCN104624914AAvoid composition segregation and uneven microstructure defectsAvoid uneven defectsMetal-working apparatusEngine componentsMicro structureCam

Disclosed is a semisolid process for manufacturing an engine aluminum alloy cam shaft through a radial forging strain provocation method. Aluminum alloy rod materials are preheated and then forged in the radial direction, a blank is remelted again after radial forging, the aluminum alloy cam shaft is extruded and cast, and finally follow-up treatment is carried out on the aluminum alloy cam shaft in the radial direction. Through the process, the uniform aluminum alloy semisolid blank without micro defects can be manufactured, the aluminum alloy cam shaft which has a few micro structure defects and is good in mechanical performance can be formed, and the process is simple and easy to operate.

Owner:XI AN JIAOTONG UNIV

Method for manufacturing high-conductivity corrosion-resistant pure copper special cable

InactiveCN104575874AImprove conductivityIntegrity guaranteedCable/conductor manufactureMaterials processingCopper

The invention discloses a method for manufacturing a high-conductivity corrosion-resistant pure copper special cable, and belongs to the technical field of material processing. High-purity cathode electrolytic copper is adopted as a substrate of a wire, and the cable is formed through mixing and preheating, smelting, heat preservation, traction, wire drawing, crystallization, annealing and cooling and oxide layer plating treatment. The TR specification volume resistivity of the cable is smaller than or equal to 0.01707omega.cm<3>, and the tensile strength of the cable is more than 420 MPa. The method can meet the requirement of submarine cables for high-conductivity corrosion-resistant materials well, and can be used for the field requiring high-conductivity high-strength materials. The method has the advantages of being simple in process and low in cost.

Owner:ANHUI CHUJIANG HIGH TECH ELECTRIC WIRE CO LTD

Process for producing electronic aluminium alloy from recycled aluminium

ActiveCN111020256AIncrease valueImprove ecological effectProcess efficiency improvementRefining (metallurgy)Ti element

The invention relates to the field of metallurgy, in particular to a process for producing electronic aluminium alloy from recycled aluminium. The process comprises the following steps of (1) smelting, (2) stirring and slagging off; (3) standing; (4) sampling analysis; (5) burdening; (6) degassing and refining; (7) alloy replenishing; (8) segregating modifier adding; (9) filtering and secondary sampling; and (10) ultrasonic casting. An aluminium alloy product comprises the following elements in percentage by mass: 0.3%-0.6% of Si, 0.5%-0.6% of Fe, 0.45%-1.32% of Mg, 0.12%-0.27% of Cu, 0.11%-0.13% of Mn, 0.10%-0.22% of Zn, 0.03%-0.13% of Cr, and the balance of Al and inevitable impurity elements. The recycled aluminium produced through the process can reach the performance index of the aluminium alloy for an electronic product, and has higher economy and higher environment-friendly value.

Owner:SHANDONG INNOVATION METAL TECH

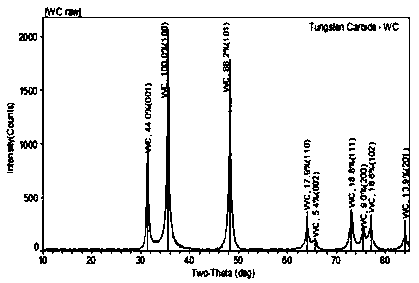

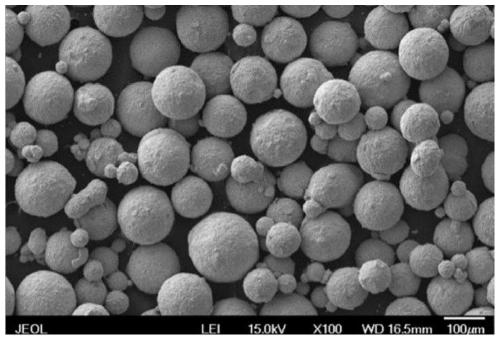

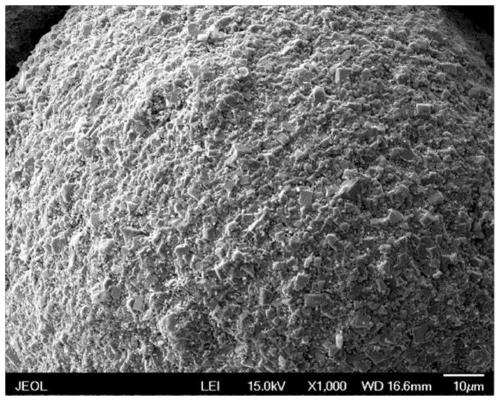

Powder material for 3D printing

ActiveCN110385430AHigh hardnessHigh strengthAdditive manufacturing apparatusIncreasing energy efficiencyWear resistantAlloy

The invention provides a powder material for 3D printing. The powder comprises a wear-resistant phase and a binding phase, wherein a mixture of sintered WC-Co hard alloy spherical particles and tungsten carbide particles serves as the wear-resistant phase, and Co-based alloy serves as the bonding phase. The weight percentage of the wear-resisting phase is 20-60%, the weight percentage of the bonding phase is 40-80%, the weight percentage of the sintered WC-Co hard alloy spherical particles is 5-15%, and the weight percentage of the coarse-grained or monocrystalline tungsten carbide particles is 15-45%. The failure period can be effectively avoided or delayed, and the wear resistance and working efficiency of the material are improved.

Owner:SEED TECH CORP LTD

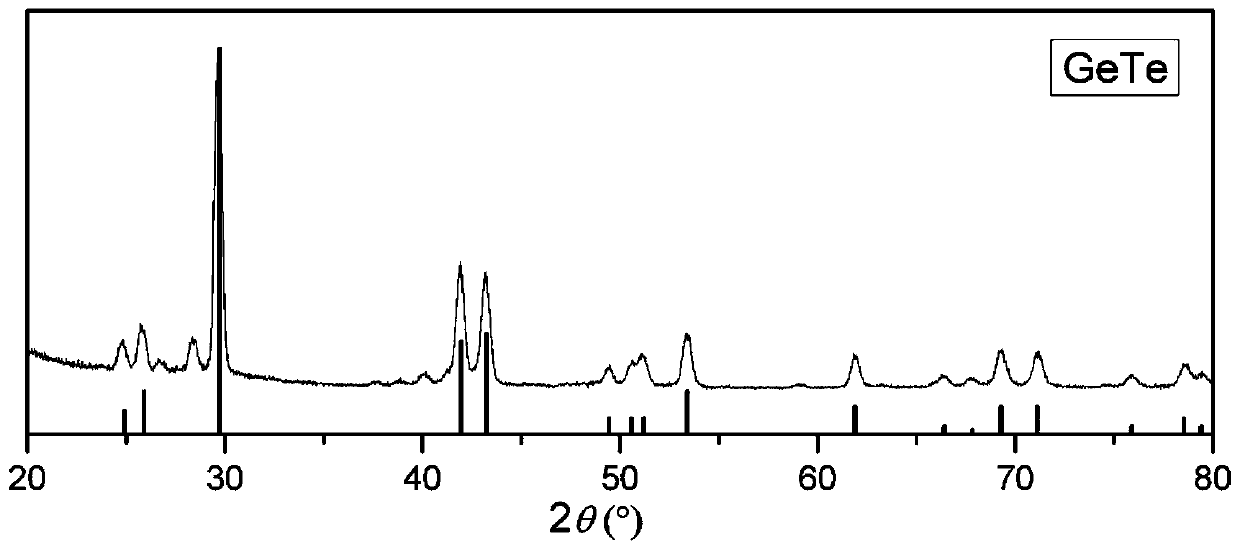

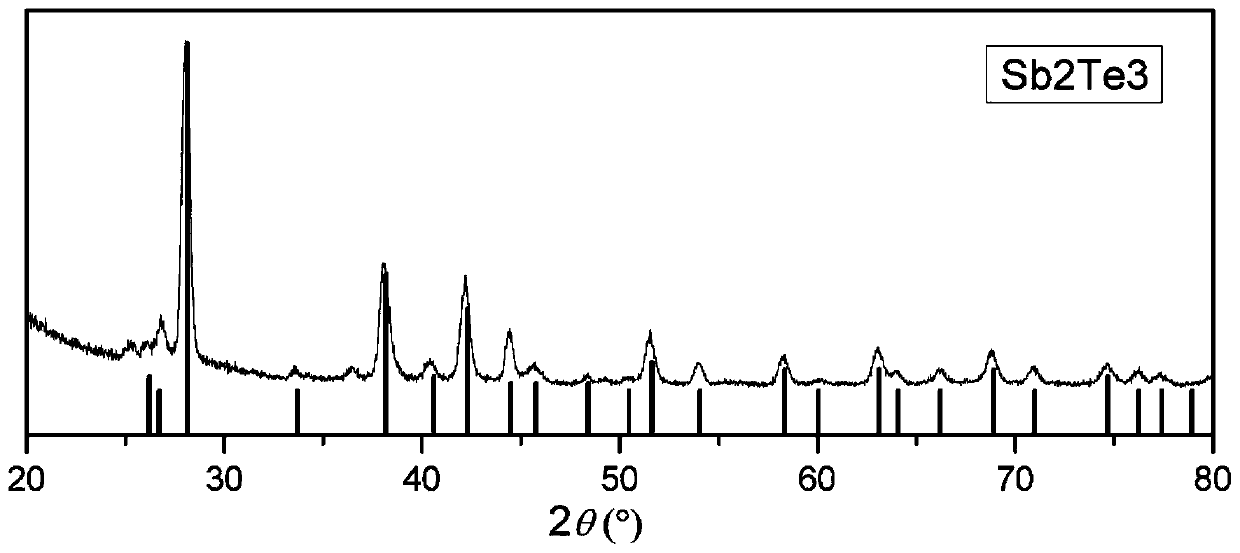

Preparation methods for germanium-antimony-tellurium powder and target material

InactiveCN110342473AHigh densityLess micro defectsVacuum evaporation coatingSputtering coatingBinary alloyTe element

The invention relates to a preparation method for germanium-antimony-tellurium powder. The method comprises the following steps: step 1, synthesizing a binary alloy; step 2, preparing powder by crushing; step 3, performing homogenization on a mixed material; and step 4, synthesizing the ternary alloy powder. The invention also provides a preparation method for a germanium-antimony-tellurium targetmaterial. According to the preparation methods for the germanium-antimony-tellurium alloy and target material provided by the invention, the prepared germanium-antimony-tellurium alloy has a yield ofgreater than 98%; and the prepared target material has a relative density of greater than 98%, purity of 4N or more, the high relative density, uniform components and less microdefects.

Owner:XIANDAO THIN FILM MATERIALS GUANGDONG CO LTD

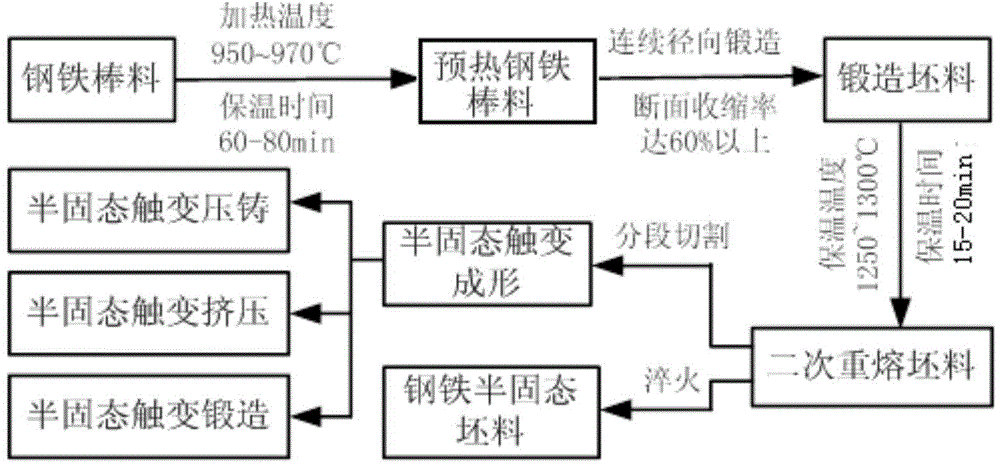

Process for manufacturing semi-solid steel cam shaft through radial forging strain induction method

InactiveCN104550838AUniform compositionFew ingredientsMetal-working apparatusTissue defectSemi solid

The invention discloses a process for manufacturing a semi-solid steel cam shaft through a radial forging strain induction method. The process comprises the following steps: preheating a steel bar material and preserving heat; radially forging the steel bar material; re-melting a radially-forged blank; performing extrusion casting on the steel cam shaft; performing subsequent treatment on the steel cam shaft. By adopting the process, steel semi-solid blanks which are uniform and free from micro-defects can be manufactured in batches, and the steel cam shaft which has less micro tissue defects, high mechanical performance and high wear resistance can be formed. The process flow is simple, and operation is easy.

Owner:XI AN JIAOTONG UNIV

Heat treatment process used for Cr12MoV steel casting die surface

ActiveCN106987685AReduce wear and tear costsLocal quenching deformation is smallFurnace typesHeat treatment furnacesLaser processingLaser quenching

The invention discloses a heat treatment process used for a Cr12MoV steel casting die surface. The heat treatment process comprises the following steps: preparing a sample; preparing a preparing a base used for balancing the self-cooling capacity of the die at all parts, wherein the upper end surface of the base is clung to the end surface of one side, back on to the die surface, of the die, and the base and the die form a part to be subjected to laser processing with an equal self-cooling capacity at all parts; performing laser quenching; performing 510 DEG C high-temperature tempering on the die for three times. According to the heat treatment process used for the Cr12MoV steel casting die surface, the steel material of the die surface is quickly heated by utilizing a focused laser beam, so that the steel material can generate phase deformation to form a martensite hardening layer, and the hardness requirement of the casting die surface is met.

Owner:芜湖创挚汽车科技有限公司

Process for preparing semisolid steel blank by using radial forging strain induction method

The invention discloses a process for preparing a semisolid steel blank by using a radial forging strain induction method. The process comprises the following steps: firstly, preheating a steel rod material, performing radial forging on the steel rod material, performing secondary remelting on the blank after radial forging, and finally preparing the semisolid steel blank. By adopting the process, semisolid steel blanks which are uniform in tissue and small in micro defect can be prepared in batch, and the process is simple in procedure and easy to operate.

Owner:XI AN JIAOTONG UNIV

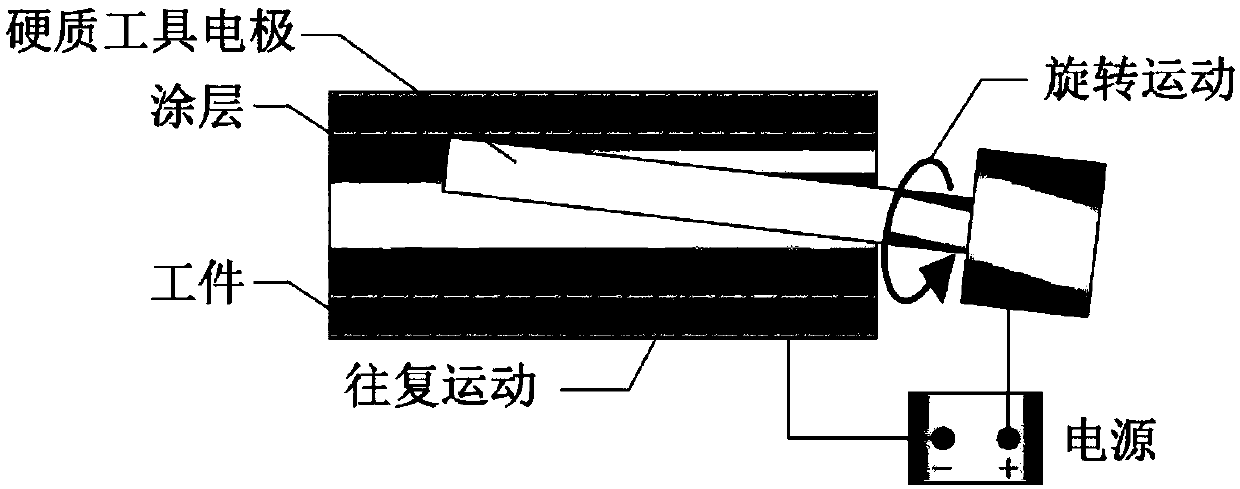

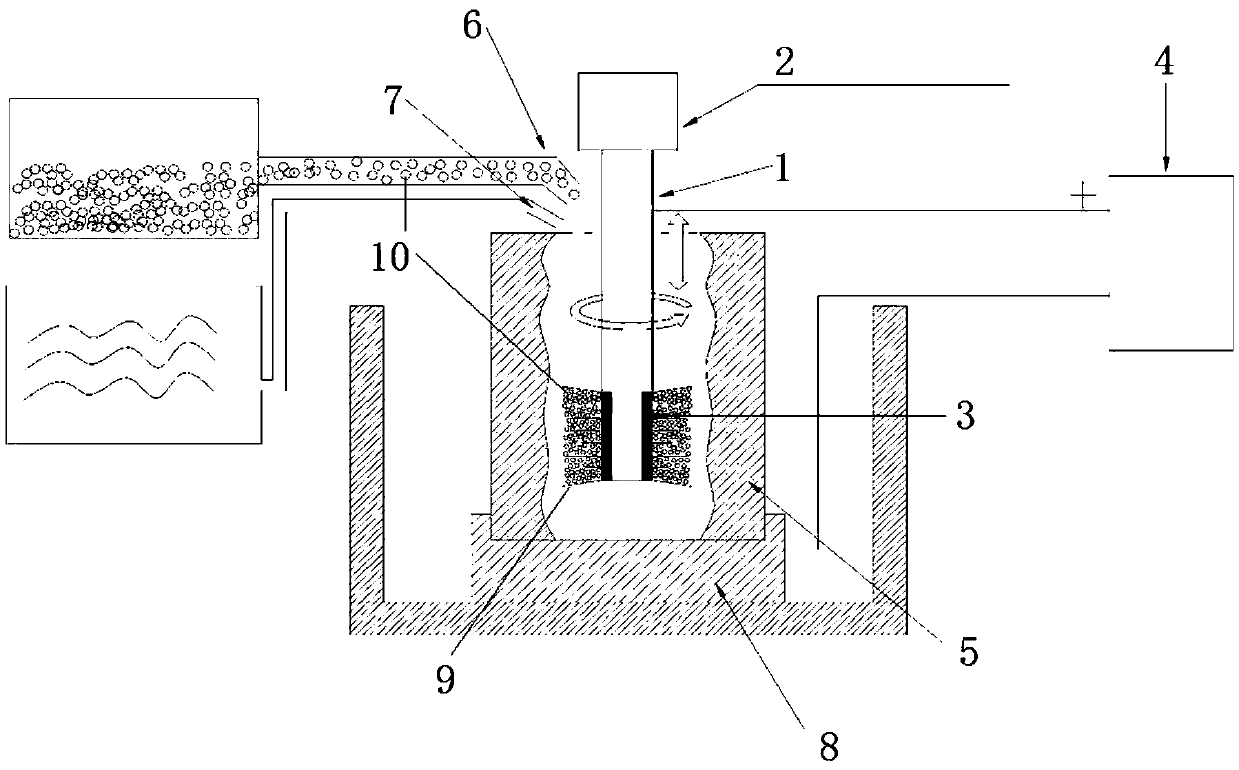

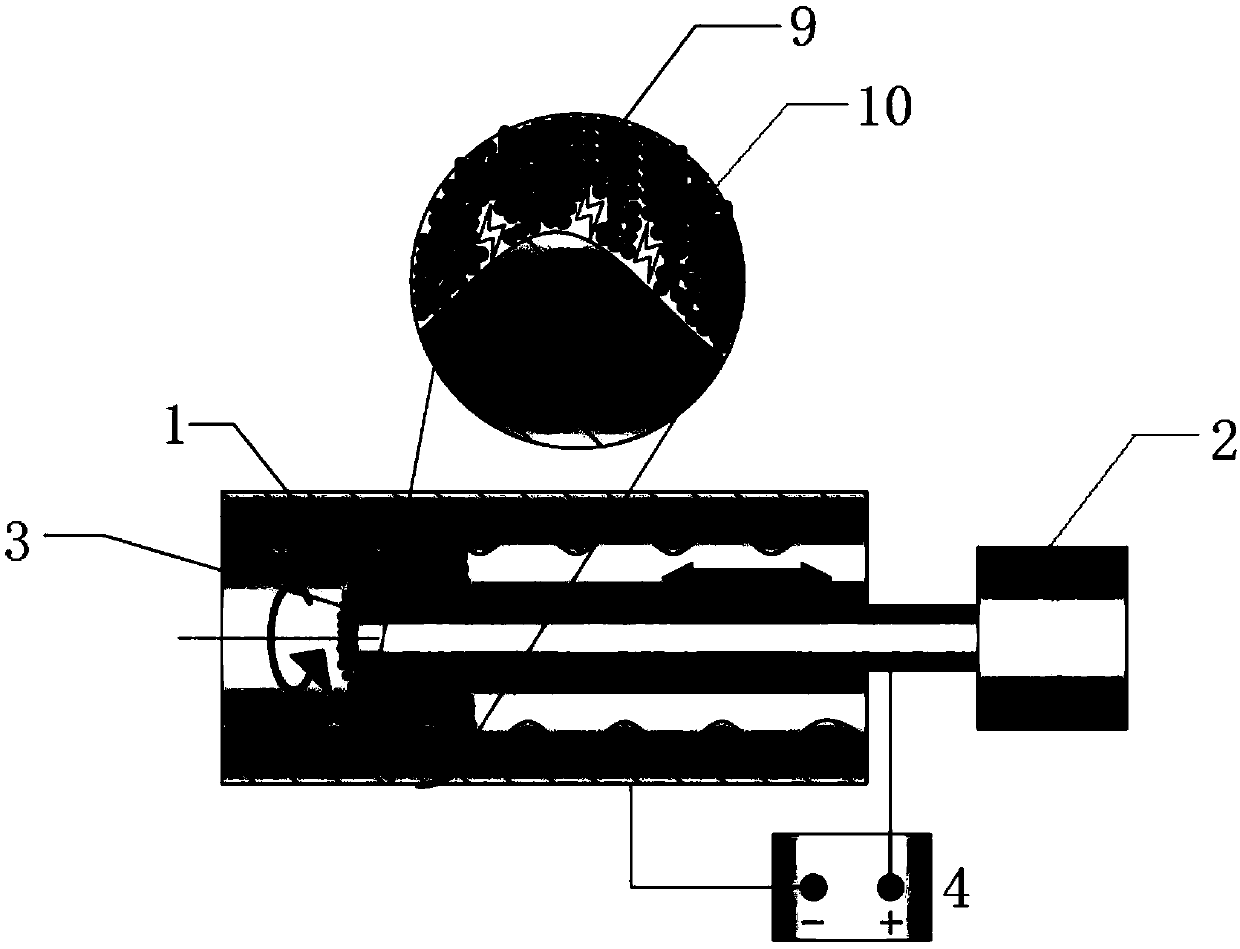

Electric spark deposition device

PendingCN109680277AEvenly distributedImprove uniformityMetallic material coating processesPipe fittingEngineering

The invention discloses an electric spark deposition device. Electromagnetism conducting powder is gathered at the second end of a tool electrode by an annular magnet or long-strip-shaped magnets which are in central symmetry, a flexible tool head is formed, and therefore the electromagnetism conducting powder can adapt to the shape of the inner wall of a long and thin pipe fitting by itself in the electric spark deposition process. In addition, the electric spark deposition device generates stable dynamic contact type discharge on the inner wall of the long and thin pipe fitting in the process that the electric spark deposition device and the inner wall of the long and thin pipe fitting conduct relative movement, and therefore the electric spark deposition device is suitable for conducting deposition on the various inner surfaces with the complex shapes, the distribution of discharge points in the deposition region in the process of the deposition on the inner wall of the long and thin pipe fitting can be more uniform, and the technical problem that due to the facts that in the process that a conventional hard tool electrode conducts discharge deposition on the inner wall of the long and thin pipe fitting, the fluctuation of the force of the contact between the hard tool electrode and the inner wall of the long and thin pipe fitting is high, and the dynamic contact is extremely unstable, an applicable coating cannot be obtained is solved.

Owner:GUANGDONG UNIV OF TECH

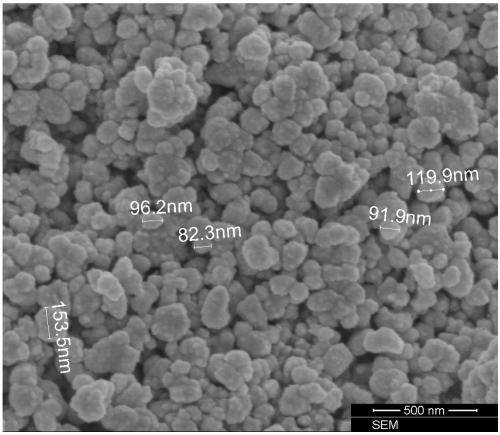

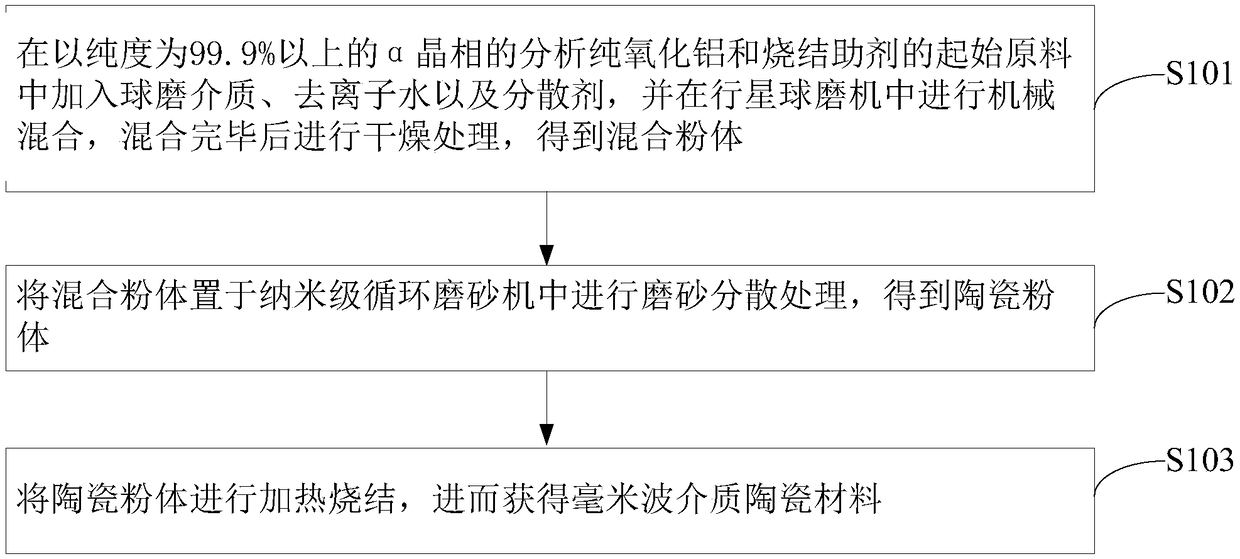

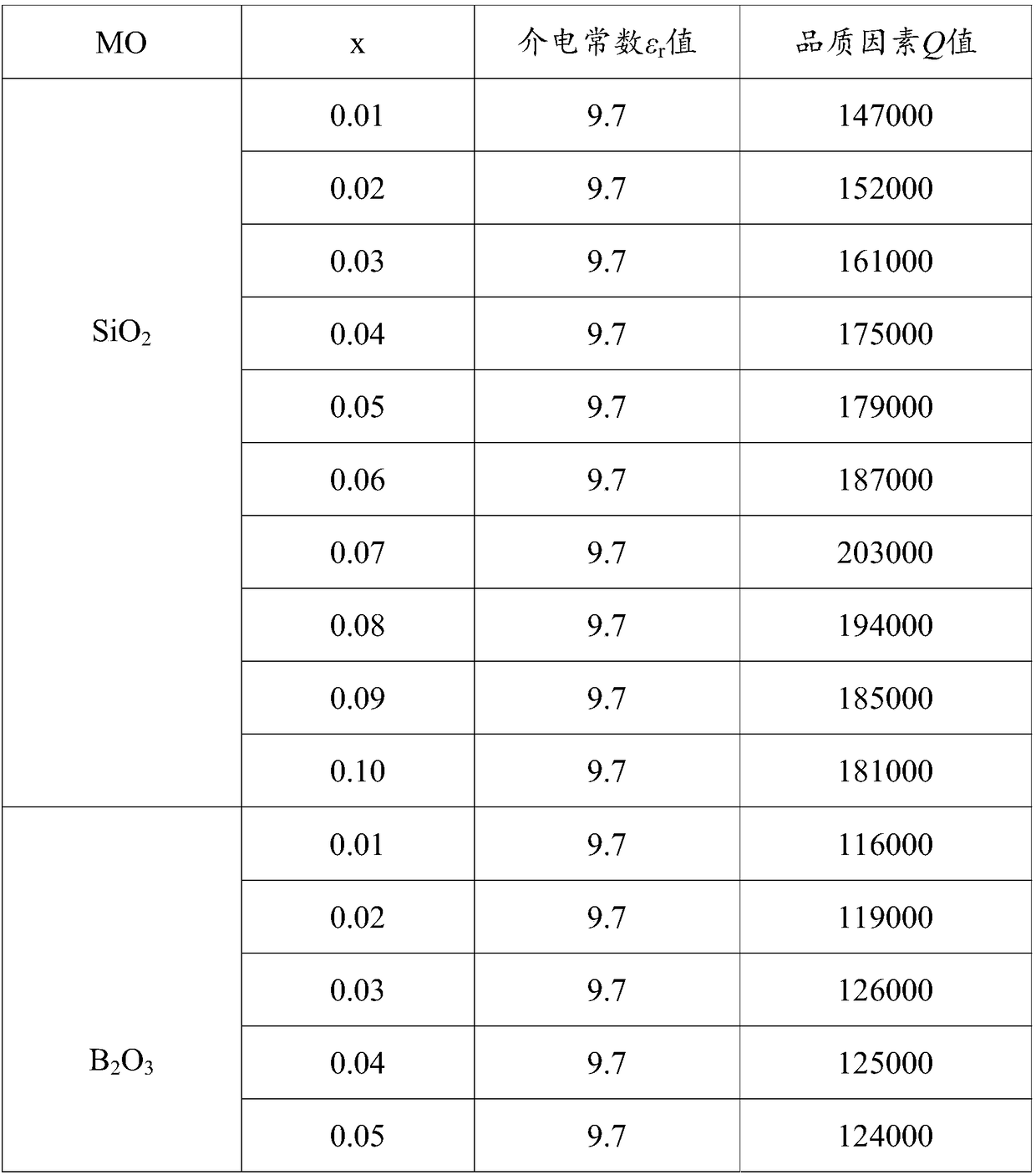

A dielectric ceramic material and a preparation method thereof

A dielectric ceramic material and a preparation method thereof, wherein a ball milling medium, a deionized water and a dispersing agent are added to a starting material of an analytically pure alpha-alumina and a sintering aid having a purity of 99.9% or more, and are mixed in a planetary ball mill. Mechanical mixing and drying are carried out to obtain a mixed powder, wherein the mass ratio of the starting material, the ball milling medium and the deionized water is 1:4:1.1 to 1.3, the ball milling time is 4 hours, and the diameter of the ball milling medium is 2-3mm; the mass percentage of the dispersing agent in the dielectric ceramic material is from three thousandths to six thousandths; the mixed powder is placed in a nano-scale circulating sander for sanding and dispersing treatmentto obtain the ceramic powder; the ceramic powder is subjected to heat sintering to further obtain the dielectric ceramic material.

Owner:ANHUI TATFOOK TECH CO LTD

High-life composite grid suitable for lead storage battery and preparation method of high-life composite grid

ActiveCN108258248ASolve corrosiveSolve the problem of longevityAnodisationElectrode carriers/collectorsLead dioxideAlloy

The invention discloses a high-life composite grid suitable for a lead storage battery and a preparation method of the high-life composite grid and belongs to the technical field of preparation of lead storage batteries. According to the high-life composite grid, a lead alloy grid is taken as a base material, and a compact micro-arc anodic oxide film is formed on the base material in situ by adopting a composite pulse oxidation technology in a mixed acid solution. The thickness of the micro-arc anodic oxide film is 5-20 microns, the main ingredient is lead dioxide, and metallurgical grade bonding between the film and a matrix is achieved, so that the contact conductivity of the grid is fully ensured, the protective performance of the lead alloy matrix is effectively strengthened, the service life of the grid is greatly prolonged and the maintenance cost of the lead storage battery is reduced. The composite grid disclosed by the invention is applied to the lead storage battery, so thatthe corrosion weight loss of a positive grid during the period of normal-temperature cycle life is smaller than 60% and the life of the battery is prolonged by over 15%.

Owner:TIANNENG BATTERY GROUP +1

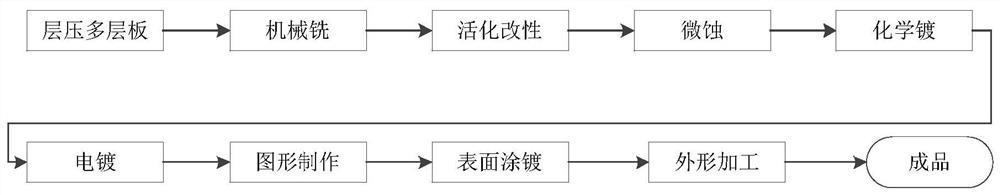

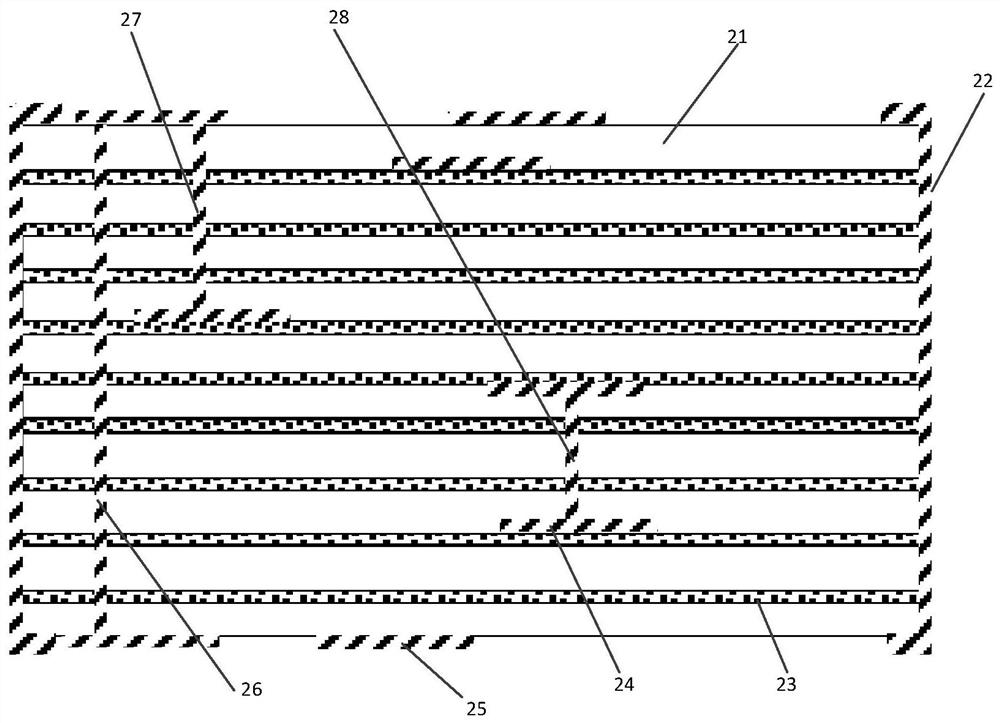

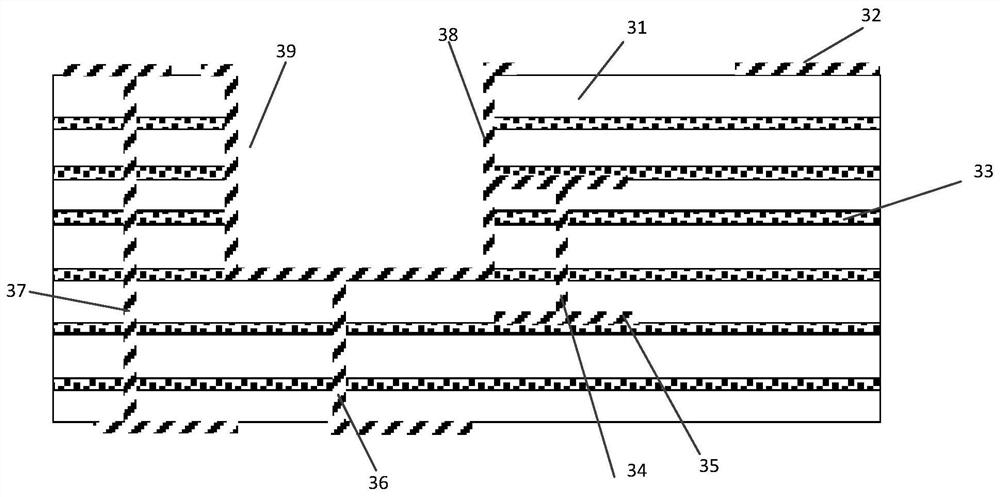

Multi-layer microstrip board processing method based on perovskite ceramic filling substrate

ActiveCN112384010AImprove consistencyLess micro defectsCircuit metal processingMultilayer circuit manufactureDielectric substrateElectroless plating

The invention discloses a multi-layer microstrip board processing method based on a perovskite ceramic filling substrate, and belongs to the technical field of microwave printed circuit board manufacturing, and the method comprises the steps: obtaining the inner wall or shape side wall of a blind groove through mechanical milling, sequentially carrying out the activation modification and micro-etching of the inner wall or shape side wall of the blind groove, and then carrying out the chemical copper plating and electrocoppering thickening, and finally, performing surface coating and plating, and obtaining the final product through appearance machining. According to the invention, the problems of low side edge processing precision, poor hydrophilicity, difficult deposition of a copper layer, easy generation of holes and cracking of a copper plating layer, poor adhesion after deposition, easy shedding and low reliability of a dielectric substrate according to a traditional multilayer microstrip plate processing method due to change of the filler proportion and variety are effectively solved, the roughness of the copper plating layer is less than or equal to 20 [mu] m, and the yield is improved, the thickness of the copper plating layer can reach 20 microns or above, and 95% or above of the copper plating layer is complete, compact and free of cracks.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

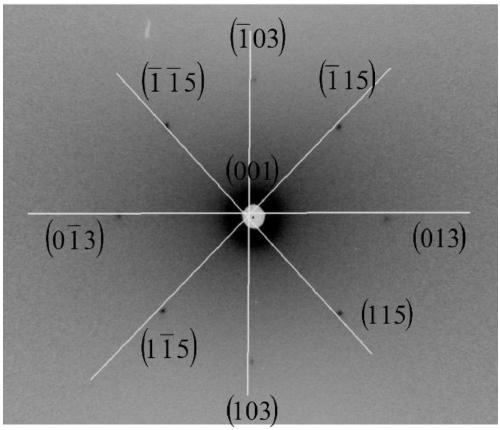

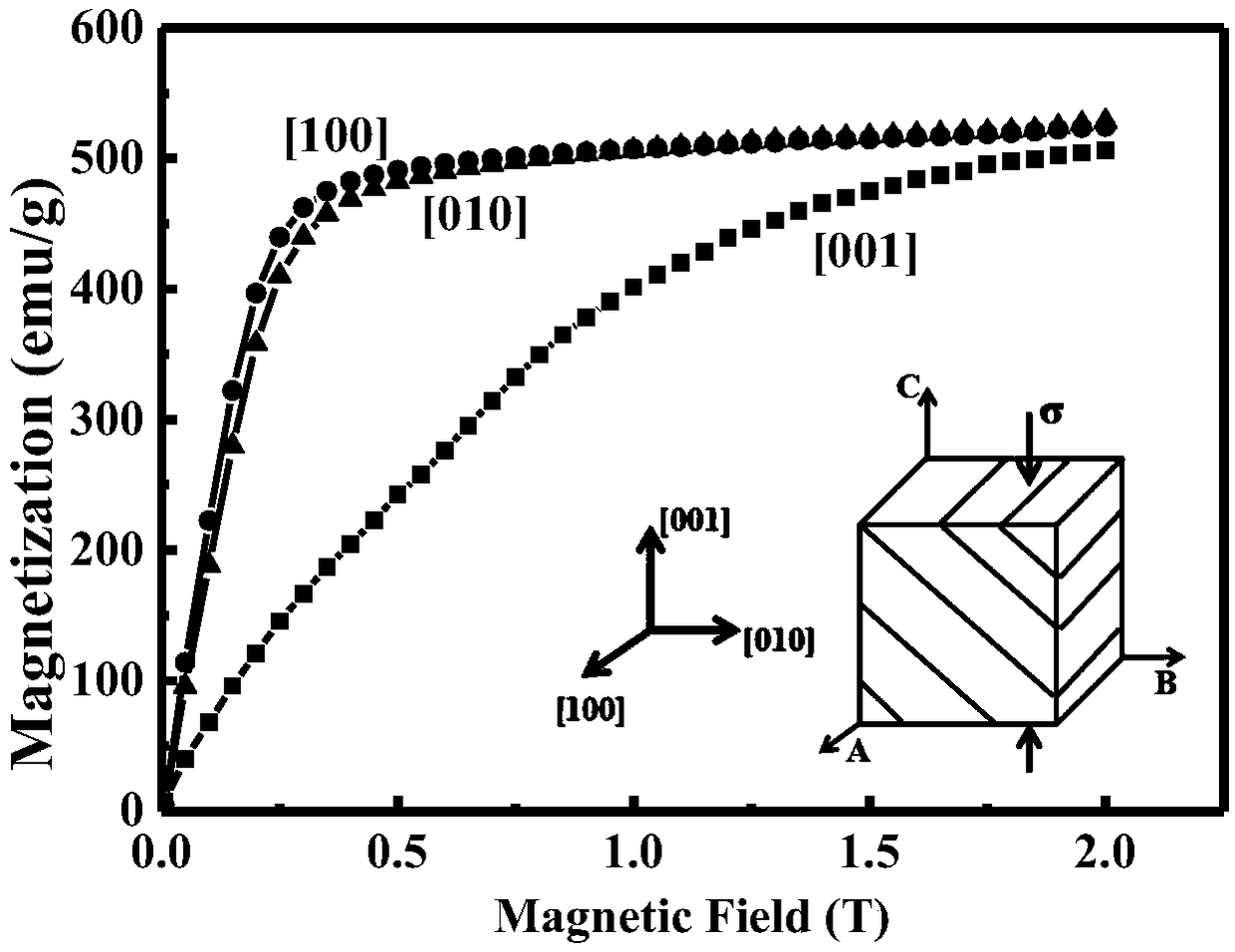

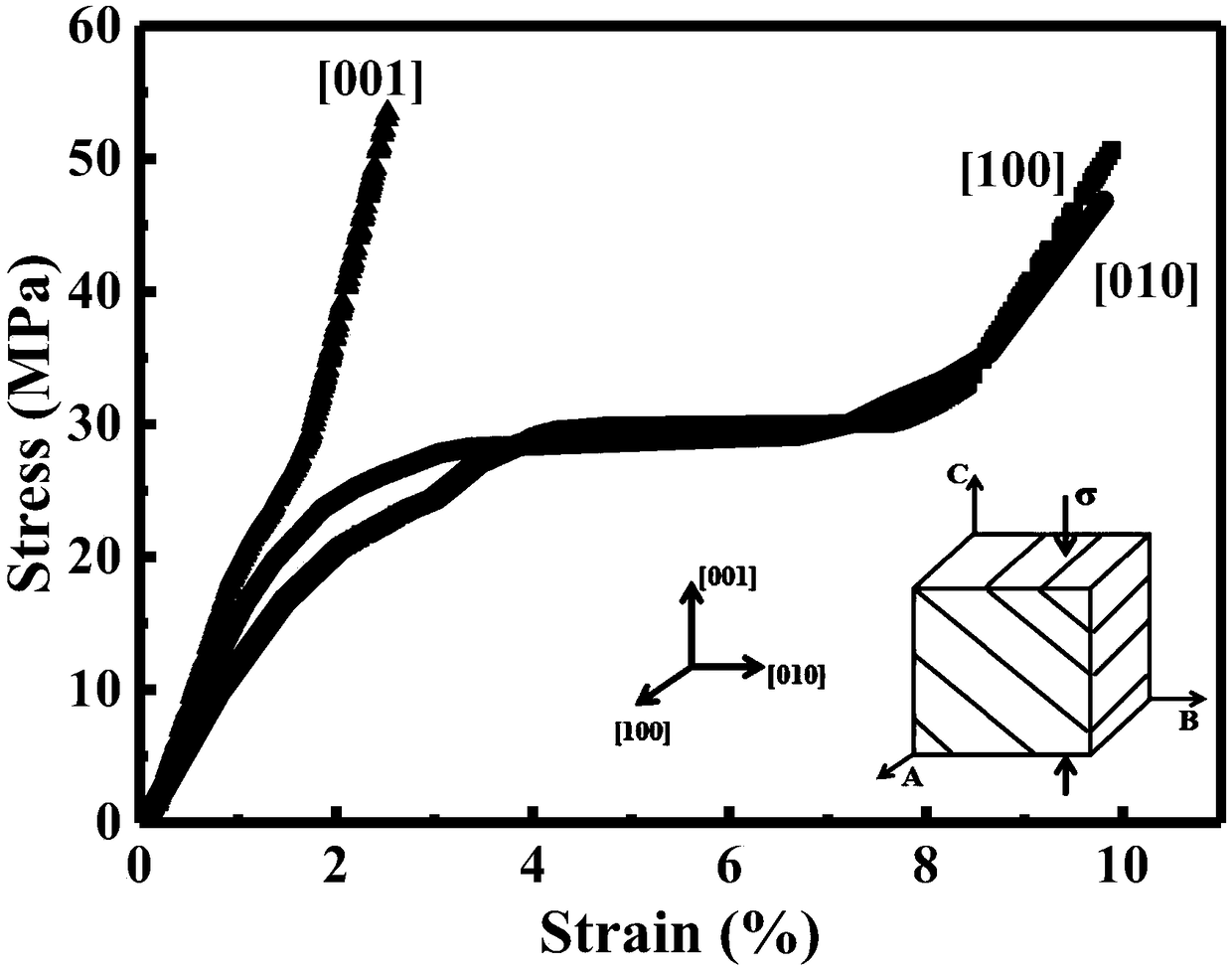

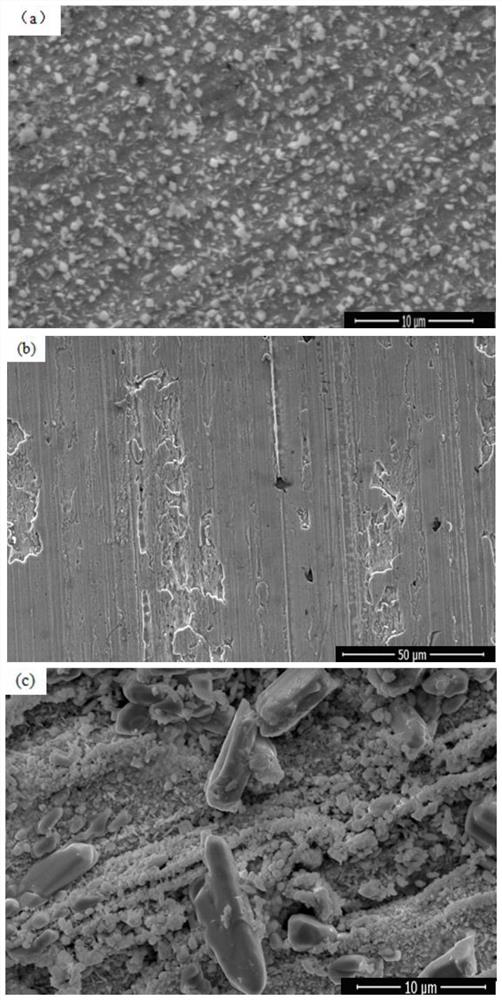

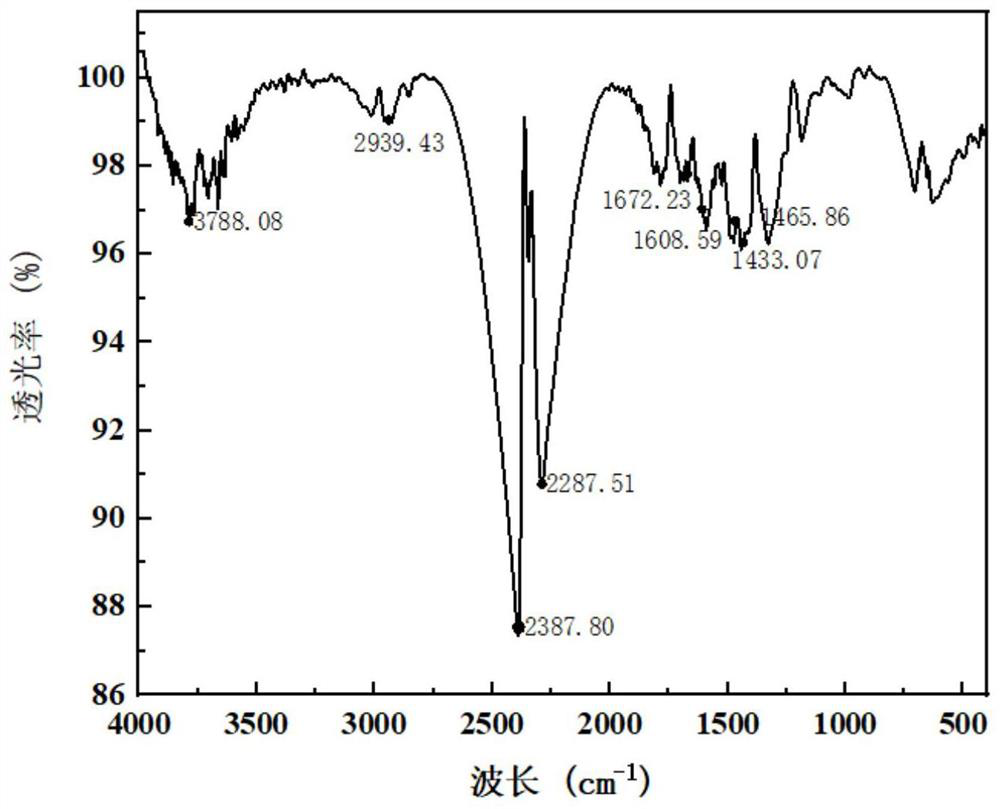

Mechanical-thermal coupled NiMnGa single crystal-contained twin crystal eliminating method

InactiveCN109371473AAvoid damageGuaranteed MagneticPolycrystalline material growthAfter-treatment detailsStress inducedCrystal twinning

The invention discloses a mechanical-thermal coupled NiMnGa single crystal-contained twin crystal eliminating method. The mechanical-thermal coupled NiMnGa single crystal-contained twin crystal eliminating method comprises heating NiMnGa single crystal to 150-200 DEG C and performing thermal preservation for 5-15 min, then exerting single axial tension in the [100] direction of the NiMnGa single crystal with the temperature unchanged, and under the action of the tension, eliminating the twin crystal in the T-type structural martensitic single crystal of NiMnGa alloy. The invention also discloses a NiMnGa twin crystal-removed structure prepared through the mechanical-thermal coupled NiMnGa single crystal-contained twin crystal eliminating method. The mechanical-thermal coupled NiMnGa singlecrystal-contained twin crystal eliminating method can effectively eliminate twin crystal in alloy to achieve single-variant structures, endow materials with anisotropic properties and further obtainrecoverable stress-induced and magnetic field-induced large deformation. Meanwhile, the mechanical-thermal coupled NiMnGa single crystal-contained twin crystal eliminating method is simple in processand capable of effectively avoiding damage of cracks produced during technical processes to the materials.

Owner:BEIHANG UNIV

Preparation method of material for high-strength and high-conductivity copper lead

ActiveCN104561865AImprove conductivityIntegrity guaranteedSingle bars/rods/wires/strips conductorsConductive materialMaterials processingCopper

The invention discloses a preparation method of a material for a high-strength and high-conductivity copper lead and belongs to the technical field of material processing. By taking high-purity electrolytic cathode copper as a base body, the lead is prepared by the following steps: mixing and preheating; smelting; insulating; pulling, wiredrawing and crystallizing; and annealing. The TR standard volume resistivity is less than or equal to 0.01707 ohm / cm<3> and the tensile strength reaches over 420MPa. The lead can better satisfy the performance requirement of leads in the electronic industrial field, can be further used for the field of high-conductivity and high-strength materials and has the advantages of simple process and low cost.

Owner:ANHUI CHUJIANG HIGH TECH ELECTRIC WIRE CO LTD

Preparation method of anti-corrosion composite coating on surface of lead alloy

The invention discloses a preparation method of an anti-corrosion composite coating on the surface of a lead alloy. The method comprises the following steps of degreasing and acidizing a lead alloy matrix, and forming a compact composite coating on the surface of the lead alloy by adopting an electrochemical deposition method, wherein electrolyte for electrochemical deposition comprises 5-30 mmol / L of ammonium cerous sulfate, 1-5 g / L of polyvinylpyrrolidone and 1-8 mol / L of sulfuric acid; and the process conditions of the electrochemical deposition are as follows: the temperature is 25-60 DEG C, the scanning cycle index is 50-300, the potential range is -0.9-2V, and the deposition time is 10-50 minutes. According to the method, a passive film formed on the surface of the lead alloy mainly comprises lead sulfate and is a composite film layer containing a small amount of cerium element and organic matter, the passive film is flat and compact, and the corrosion resistance of the lead alloy is effectively enhanced; and the method is simple in process and short in consumed time.

Owner:XIHUA UNIV

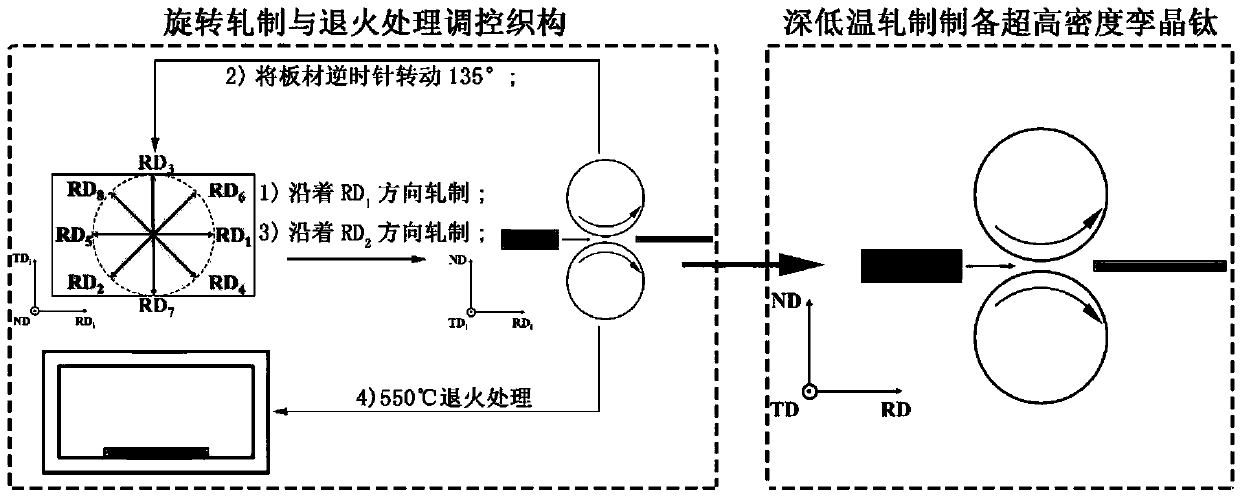

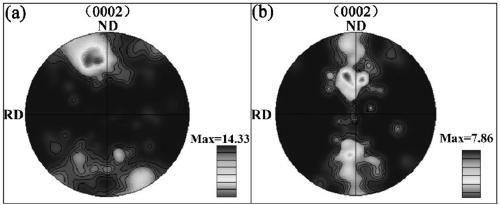

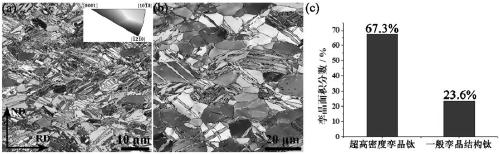

Ultrahigh-density twin titanium and preparation method thereof

The invention discloses ultrahigh-density twin titanium and a preparation method thereof. The method comprises three steps of rotary rolling, annealing treatment and cryogenic low-temperature cold rolling. The rotary rolling regulates and controls texture, so that a ultrahigh-strength texture titanium material with basal texture strength of 21.73 is obtained; the annealing treatment restores and eliminates microdefects and substructures, and reserves a high-strength texture with basal texture strength of 14.33; and the cryogenic low-temperature cold rolling deformation introduces an ultrahigh-density twin structure with a twin area fraction as high as 67.3% on the basis of the previous two procedures. The ultrahigh-density twin titanium prepared by the method has the yield strength of 850MPa or above and the tensile strength close to 1GP.

Owner:NANJING UNIV OF SCI & TECH

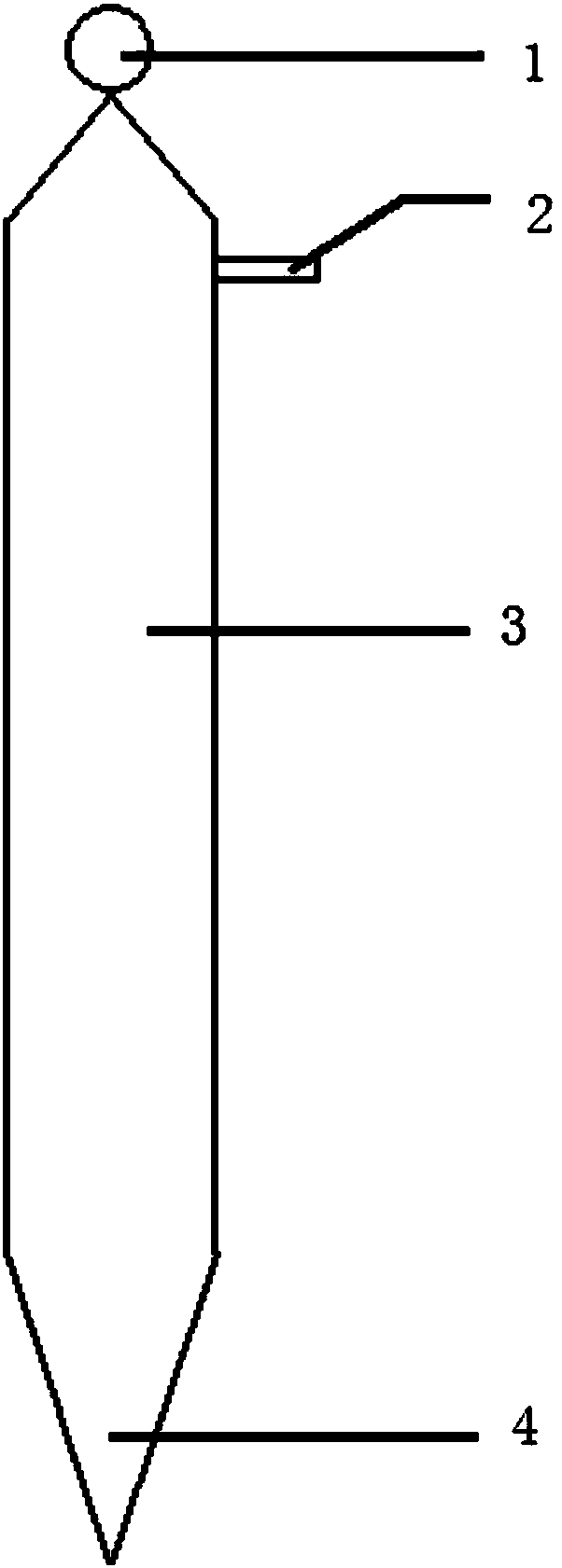

Pre-tensioning method prestress concrete anticorrosion pipe pile as well as manufacture method and application thereof

ActiveCN102718456BSmall loss of prestressIncreased durabilityShaping reinforcementsBulkheads/pilesPre stressPrestressed concrete

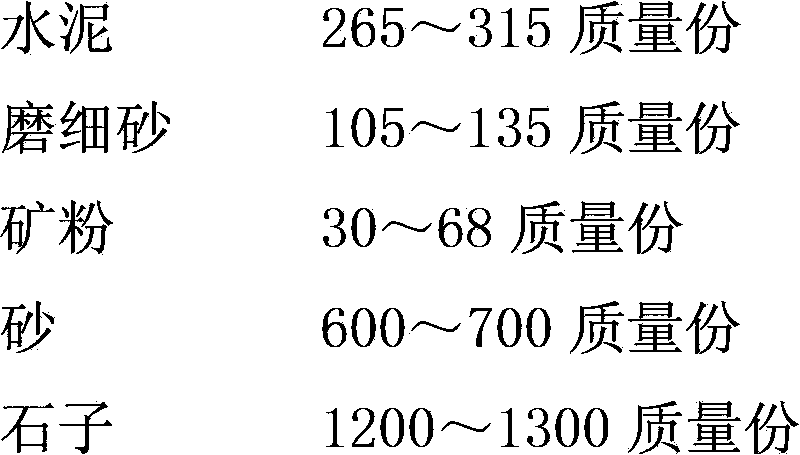

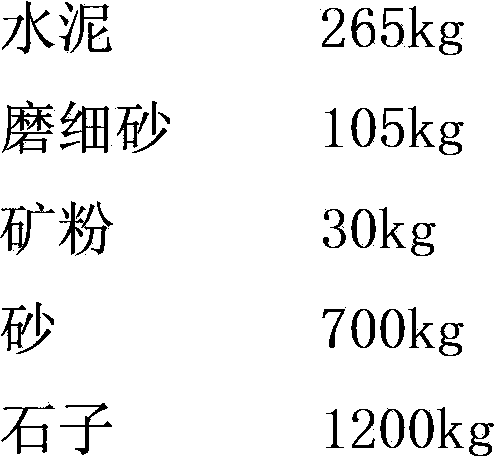

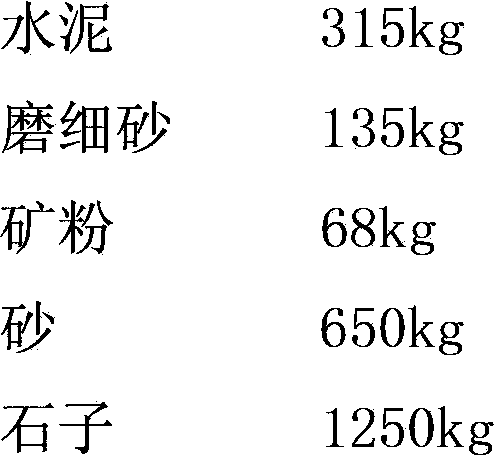

The invention discloses a pre-tensioning method prestress concrete anticorrosion pipe pile as well as a manufacture method and an application thereof. The pre-tensioning method prestress concrete anticorrosion pipe pile comprises the following raw materials in parts by weight: 265-315 parts by weight of cement, 105-135 parts by weight of levigated sand, 30-68 parts by weight of mineral powder, 600-700 parts by weight of sand and 1200-1300 parts by weight of stone, wherein the cement, the levigated sand and the mineral powder are combined into gelling material, the mass ratio of water and the gelling material is 29:100, and water reducing agent accounting for 0.8wt% of the gelling material and preservative accounting for 2-wt% of the gelling material are added. The pipe pile disclosed by the invention has a good anticorrosion performance, and can be applied to the strong-corrosion environment.

Owner:建华建材(莱阳)有限公司

Forging method of Cr18Mn18N steel forge piece and forge piece

The invention provides a forging method of a Cr18Mn18N steel forge piece and the forge piece and relates to the manufacturing field. The forging method of the Cr18Mn18N steel forge piece comprise the following steps of: heating a Cr18Mn18N steel ingot to a heating moulding temperature of 1190-1210 DEG C; carrying out heat preservation at the heating moulding temperature; carrying out repeated firing forging moulding; and then cooling. In the repeated firing forging moulding step, firing deformation during each firing is 10-20%, and final forging temperature is 850-950 DEG C. The forging method has the advantages that multiple steps coordinate with each other, so that the finally obtained forge piece is free of cracks on the surface, fibrous tissues of the forge piece are consistent with shape of the forge piece, and a metal streamline is complete; and defects are small, demands can be met, and machining dimension can be guaranteed.

Owner:PANGANG GROUP JIANGYOU CHANGCHENG SPECIAL STEEL

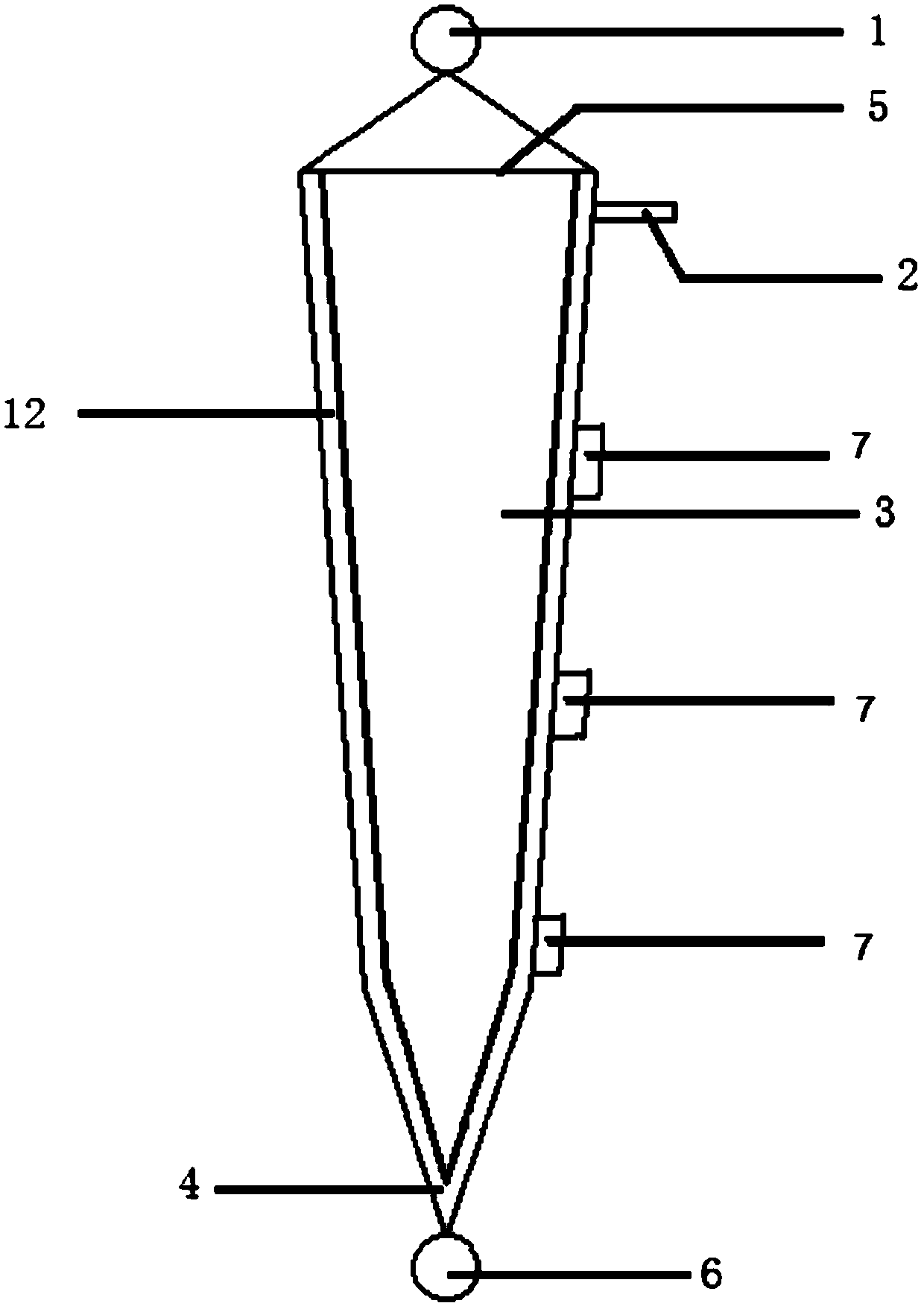

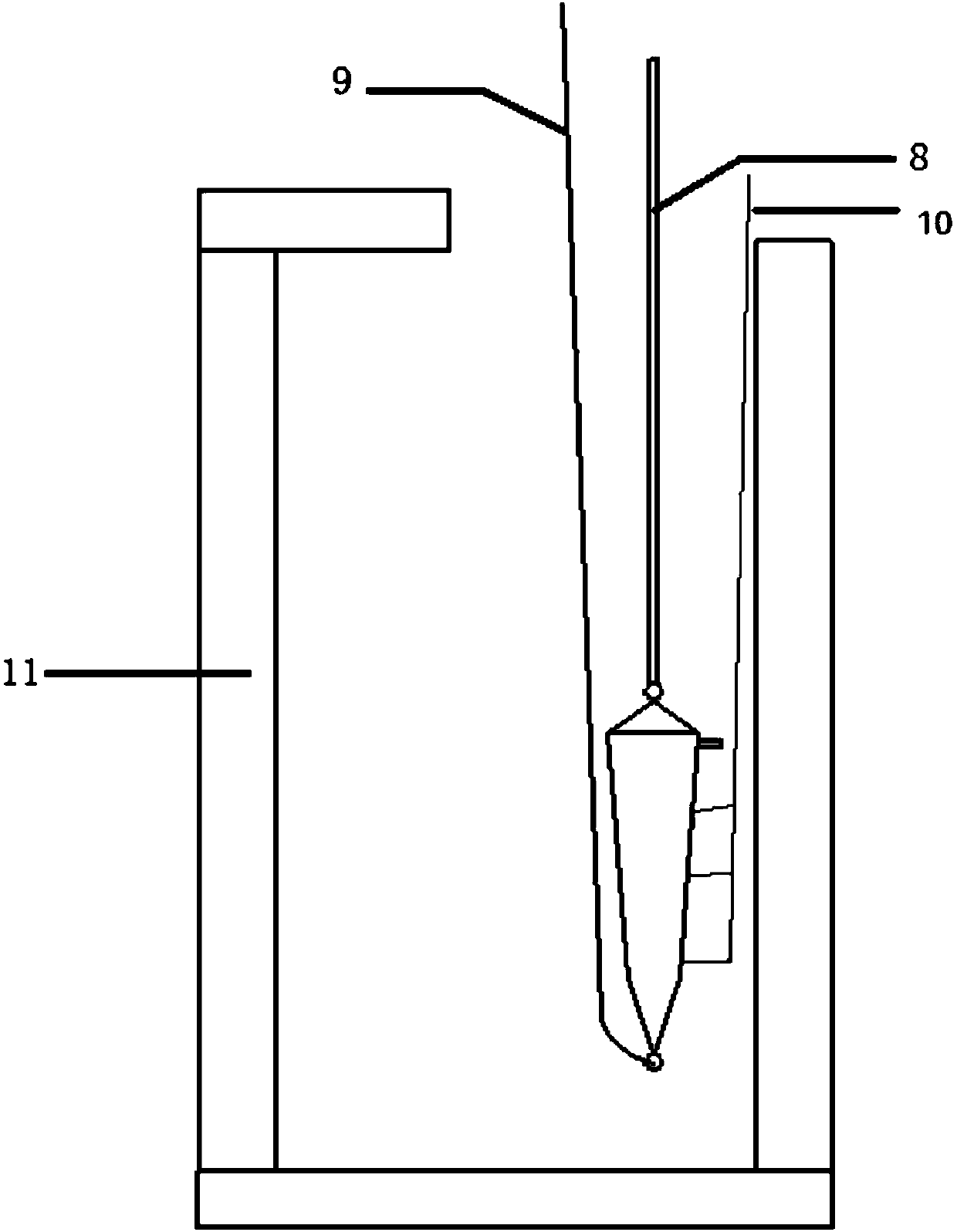

Method for reducing breakage rate of quartz tubes during preparation of scintillation single crystals

ActiveCN107675247AThere will be no ups and downsLess micro defectsPolycrystalline material growthVacuum evaporation coatingRoom temperatureScintillation crystals

The invention discloses a method for reducing the breakage rate of quartz tubes during the preparation of scintillation single crystals. The method comprises the following steps: drawing a quartz tubeinto a hetero-shaped quartz tube with a thick upper part and a thin lower part, coating the inner wall of the quartz tube with a film, mounting a strain gage on the outer wall of the quartz tube, controlling the growth speed of a single crystal through the feedback of strain amplitude, preventing the breakage of the quartz tube, inverting the hetero-shaped quartz tube after a crystal is formed, and taking out a scintillation crystal after the scintillation crystal is cooled to room temperature. The method has the advantages that the inner wall of the hetero-shaped quartz tube is coated with the film before a single crystal material is loaded, conglutination between the hetero-shaped quartz tube and the produced crystal can be avoided, complete separation of the produced crystal and the hetero-shaped quartz tube body is facilitated, the quartz tube can be prevented from directly extruding the crystal, the method is convenient for reducing micro defects of the crystal, the probability of self-absorption of the crystal is reduced, the cracking risk of the crystal is reduced, the internal performance of the scintillation crystal is obviously improved, in addition, after crystal growthand cooling after accomplished, the quartz tube is not required to be broken to take out the crystal, all that is needed is to open the quartz tube and pour out the crystal, and the quartz tube can be reused after being cleaned.

Owner:NORTHEASTERN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com