Pre-tensioning method prestress concrete anticorrosion pipe pile as well as manufacture method and application thereof

A concrete and prestressing technology, applied in sheet pile walls, reinforced molding, construction, etc., can solve problems affecting the durability of reinforced concrete, limited supply of sulfate-resistant cement, and inability to obtain anti-corrosion effects, etc., to achieve the benefit of alkaline Effects of protection, reduction of microscopic defects, improvement of penetration resistance and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

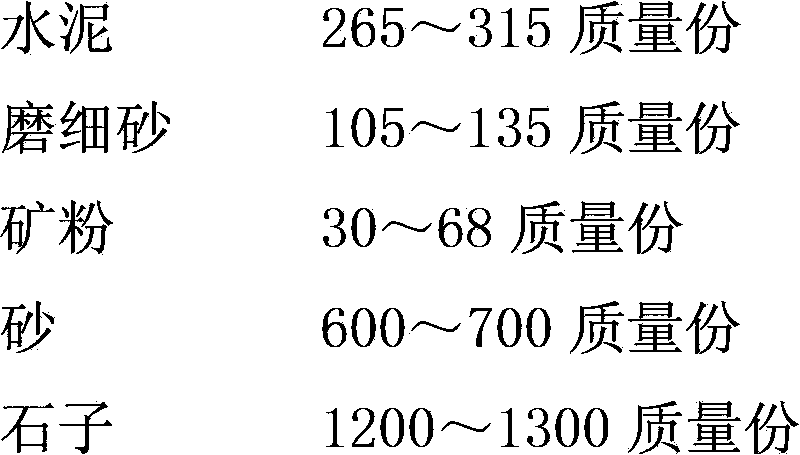

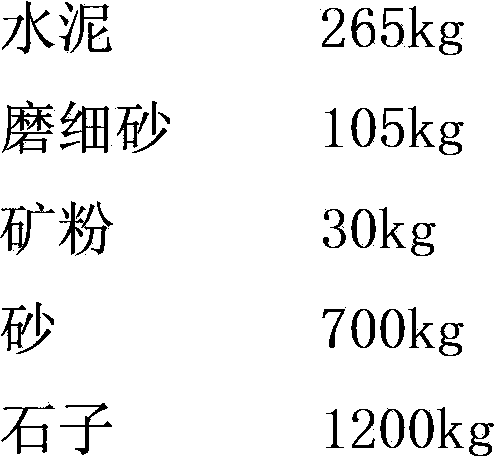

[0034] Pretensioned prestressed concrete anti-corrosion pipe pile, its raw materials and proportions are as follows:

[0035]

[0036] Among them, the combination of cement, finely ground sand and mineral powder is the cementitious material. And add 3.2kg of water reducer and 8kg of preservative, add 116kg of water. The cement is P.I52.5 cement with a specific surface area of 3500cm 2 / g, the mass percentage of tricalcium aluminate is 5.5%, and the 28-day mortar strength is greater than or equal to 57MPa. The mineral powder is S95 grade mineral powder, the 28-day activity index is greater than or equal to 95%, and the specific surface area is 4000cm 2 / g. The sand is medium-coarse sand with a fineness modulus of 2.8 to 3.2. The stones are continuously graded from 5 to 20mm, and the crushing index value is not more than 8%. The water reducing agent is a high-efficiency water reducing agent with a water reducing rate of 25%. The preservative is selected from the MS-60...

Embodiment 2

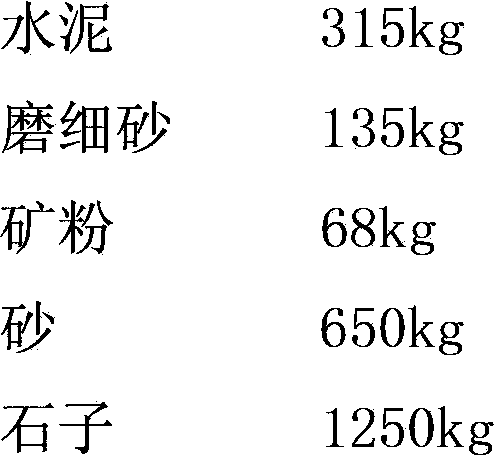

[0044] Pretensioned prestressed concrete anti-corrosion pipe pile, its raw materials and proportions are as follows:

[0045]

[0046] Among them, the combination of cement, finely ground sand and mineral powder is the cementitious material. Add 4kg of water reducer and 20kg of preservative, and add 150kg of water. The cement is P.I52.5 cement with a specific surface area of 3600cm 2 / g, the mass percentage of tricalcium aluminate is 5.5%, and the 28-day mortar strength is greater than or equal to 57MPa. The mineral powder is S95 grade mineral powder, the 28-day activity index is greater than or equal to 95%, and the specific surface area is 4300cm 2 / g. The sand is medium-coarse sand with a fineness modulus of 2.8 to 3.2. The stones are continuously graded from 5 to 20mm, and the crushing index value is not more than 8%. The water reducing agent is a high-efficiency water reducing agent with a water reducing rate of 28%. The preservative is selected from the MS-605...

Embodiment 3

[0054] Pretensioned prestressed concrete anti-corrosion pipe pile, its raw materials and proportions are as follows:

[0055]

[0056] Among them, the combination of cement, finely ground sand and mineral powder is the cementitious material. And add 3.7kg of water reducer and 15kg of preservatives, and add 133kg of water. The cement is P.I52.5 cement with a specific surface area of 3800cm 2 / g, the mass percentage of tricalcium aluminate is 5%, and the 28-day mortar strength is greater than or equal to 57MPa. The mineral powder is S95 grade mineral powder, the 28-day activity index is greater than or equal to 95%, and the specific surface area is 4500cm 2 / g. The sand is medium-coarse sand with a fineness modulus of 2.8 to 3.2. The stones are continuously graded from 5 to 20mm, and the crushing index value is not more than 8%. The water reducing agent is a high-efficiency water reducing agent, and the water reducing rate is 20%. The preservative is selected from the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com