High-life composite grid suitable for lead storage battery and preparation method of high-life composite grid

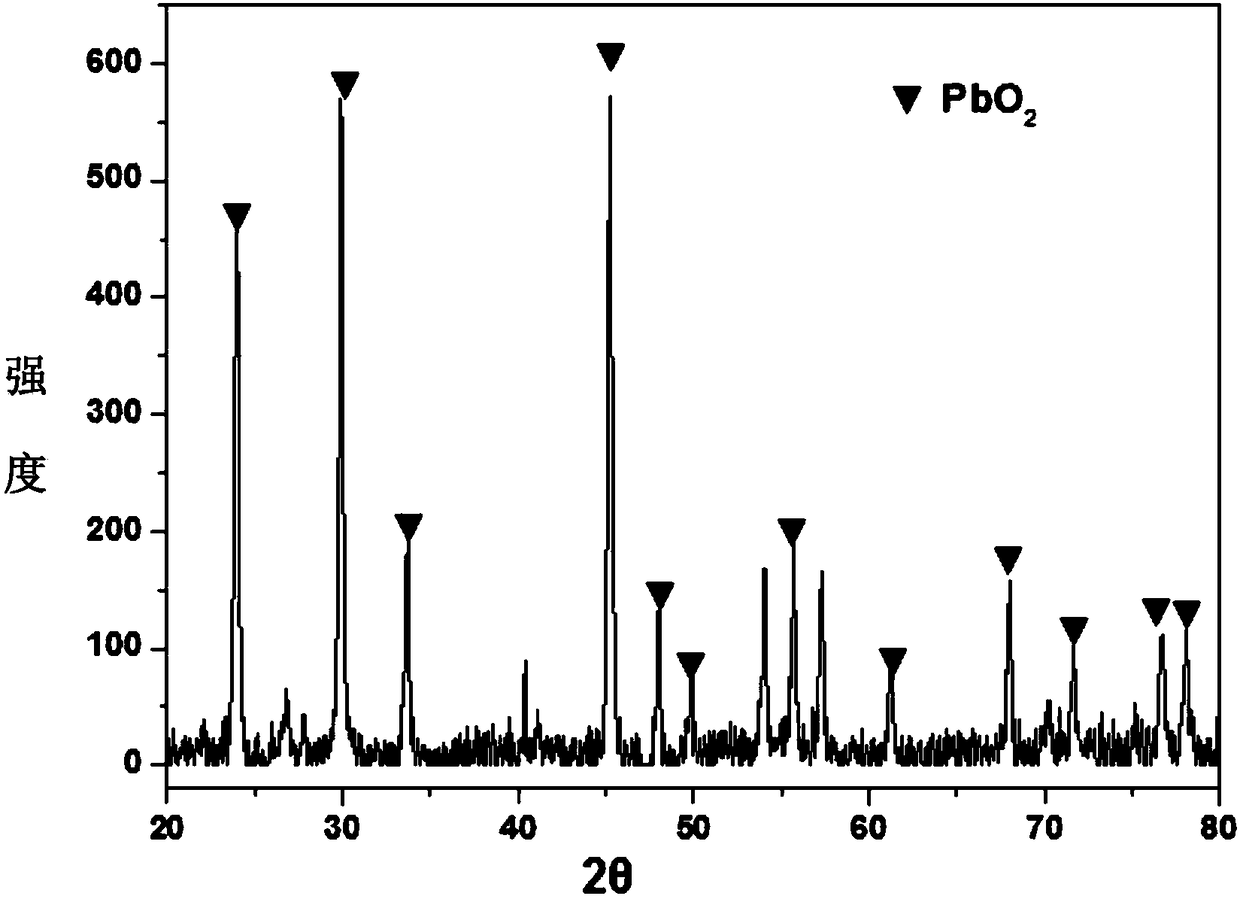

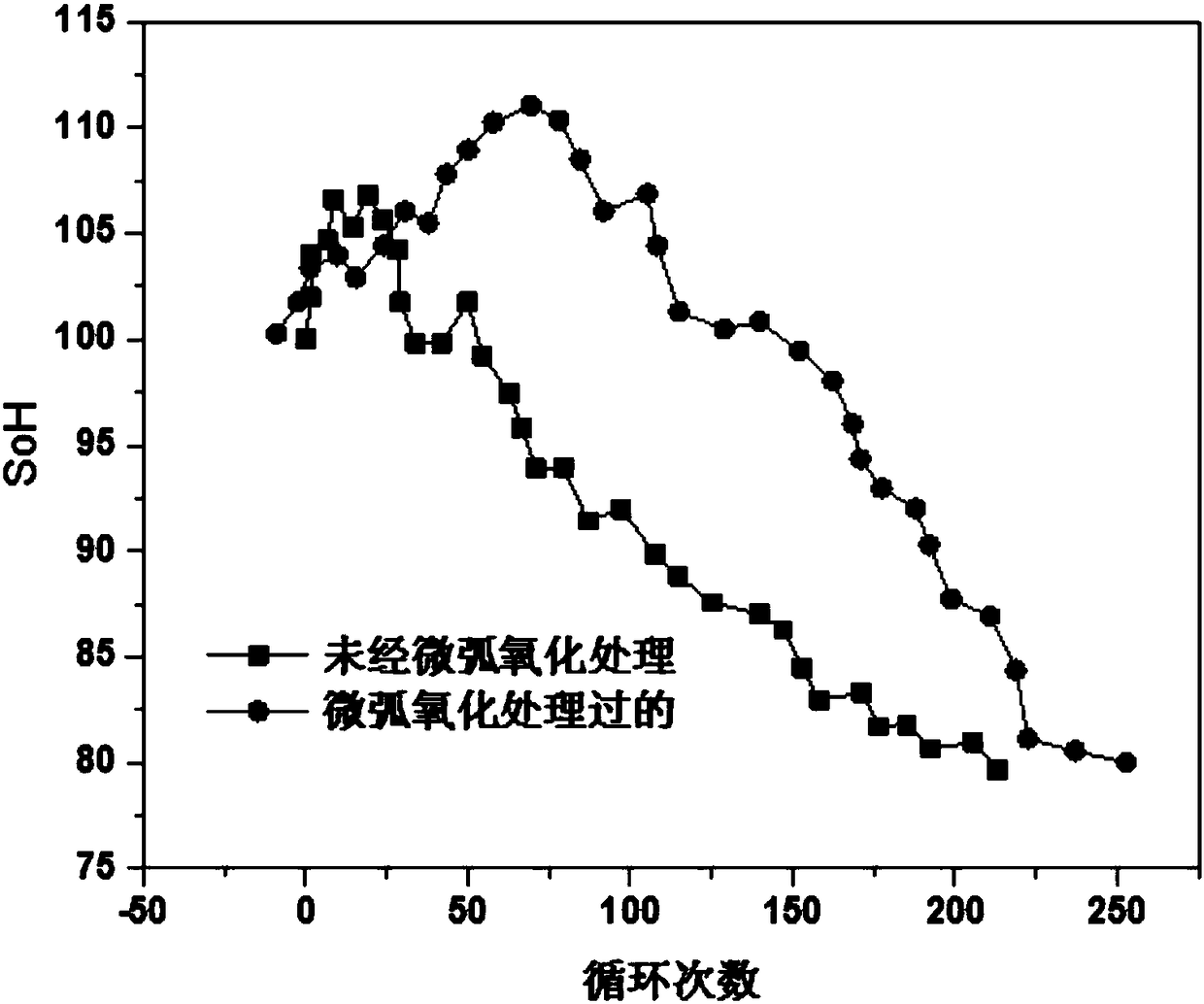

A lead-acid battery and composite board technology, applied in battery electrodes, circuits, electrolytic coatings, etc., can solve the problems of non-corrosion resistance and short service life, and achieve the effects of prolonging service life, improving battery life and reducing microscopic defects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Electrochemical pretreatment: use the grid as the anode, and the stainless steel sheet as the cathode, immerse in a mixed solution of 0.1mol / L sodium hydroxide and 0.05mol / L sodium phosphate, use constant current mode, and the current density is 3.5Adm -2 , the processing time is 100s.

[0030] (2) Micro-arc oxidation: use the grid obtained in the previous step as the anode, and the lead plate as the cathode, and immerse it in a mixed solution of 1.6mol / L sulfuric acid and 0.9mol / L phosphoric acid, and use the composite pulse control method to carry out micro-arc oxidation. Its control parameters are: the positive oxidation termination voltage is 50V, the negative termination voltage is 45V, the oxidation time is 10min, and the current density is 2.5A / dm 2 , the frequency is 300Hz, the positive duty cycle is 30%, and the negative duty cycle is 15%.

[0031] (3) Post-treatment: the grid after the oxidation in the previous step is washed with alkali, washed with wate...

Embodiment 2

[0038] (1) Electrochemical pretreatment: use the grid as the anode and the stainless steel sheet as the cathode, immerse in a mixed solution of 0.2mol / L sodium hydroxide and 0.05mol / L sodium phosphate, use constant current mode, and the current density is 4Adm -2 , the processing time is 80s.

[0039] (2) Micro-arc oxidation: the grid obtained in the previous step is used as the anode, and the lead plate is used as the cathode. In a mixed solution of 1.8mol / L sulfuric acid and 1.1mol / L phosphoric acid, the compound pulse control method is used to carry out micro-arc oxidation. The control parameters are: the positive oxidation termination voltage is 80V, the negative termination voltage is 60V, the oxidation time is 20min, and the current density is 3.7A / dm 2, the frequency is 500Hz, the positive duty cycle is 40%, and the negative duty cycle is 30%.

[0040] (3) Post-treatment: the grid after the oxidation in the previous step is washed with alkali, washed with water to neut...

Embodiment 3

[0044] (1) Electrochemical pretreatment: use the grid as the anode, and the stainless steel sheet as the cathode, immerse in a mixed solution of 0.5mol / L sodium hydroxide and 0.01mol / L sodium phosphate, use constant current mode, and the current density is 5.5Adm -2 , the processing time is 30s.

[0045] (2) Micro-arc oxidation: the grid obtained in the previous step is used as an anode, and the lead plate is used as a cathode. In a mixed solution of 2.0mol / L sulfuric acid and 1.3mol / L phosphoric acid, the composite pulse control method is used to carry out micro-arc oxidation. The control parameters are: the positive oxidation termination voltage is 95V, the negative termination voltage is 75V, the oxidation time is 30min, and the current density is 4.2A / dm 2 , the frequency is 700Hz, the positive duty cycle is 50%, and the negative duty cycle is 30%.

[0046] (3) Post-treatment: the grid after the oxidation in the previous step is washed with alkali, washed with water to ne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com