Mechanical-thermal coupled NiMnGa single crystal-contained twin crystal eliminating method

A thermally coupled, single crystal technology, applied in single crystal growth, single crystal growth, chemical instruments and methods, etc., can solve problems such as difficult to achieve detwining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A method for removing twins in NiMnGa single crystals by using force-thermal coupling to obtain anisotropic magnets, comprising the steps of:

[0027] Step 1: Preparation of NiMnGa Rods

[0028] Put Ni, Mn, and Ga with a purity of 99.99% in the vacuum electric arc furnace in the order of Mn, Ga, and Ni in the order of the target composition ratio from bottom to top, and add an additional 2% of the mass of Mn to make up for the burning loss; Vacuum to 2~5×10 -3 Pa, filled with argon to 0.3~0.7×10 5 Pa, the NiMnGa master alloy is obtained after repeated smelting for 3 to 5 times, and then cast into NiMnGa rods. In this example, press the Ni 53 mn 25 Ga 22 Prepare the master alloy with the target ingredients; then put the master alloy in the vacuum electric arc furnace, adjust the vacuum degree of the vacuum chamber to 4×10-3Pa, fill it with argon gas to 0.7×105Pa, perform repeated melting for 5 times, and then cast Ni 53 mn 25 Ga 22 bar.

[0029] The second step:...

Embodiment 2

[0043] A method for removing twins in NiMnGa single crystals by using force-thermal coupling to obtain anisotropic magnets, comprising the steps of:

[0044] The first step and the second step are the same as in Embodiment 1, so the description is omitted here.

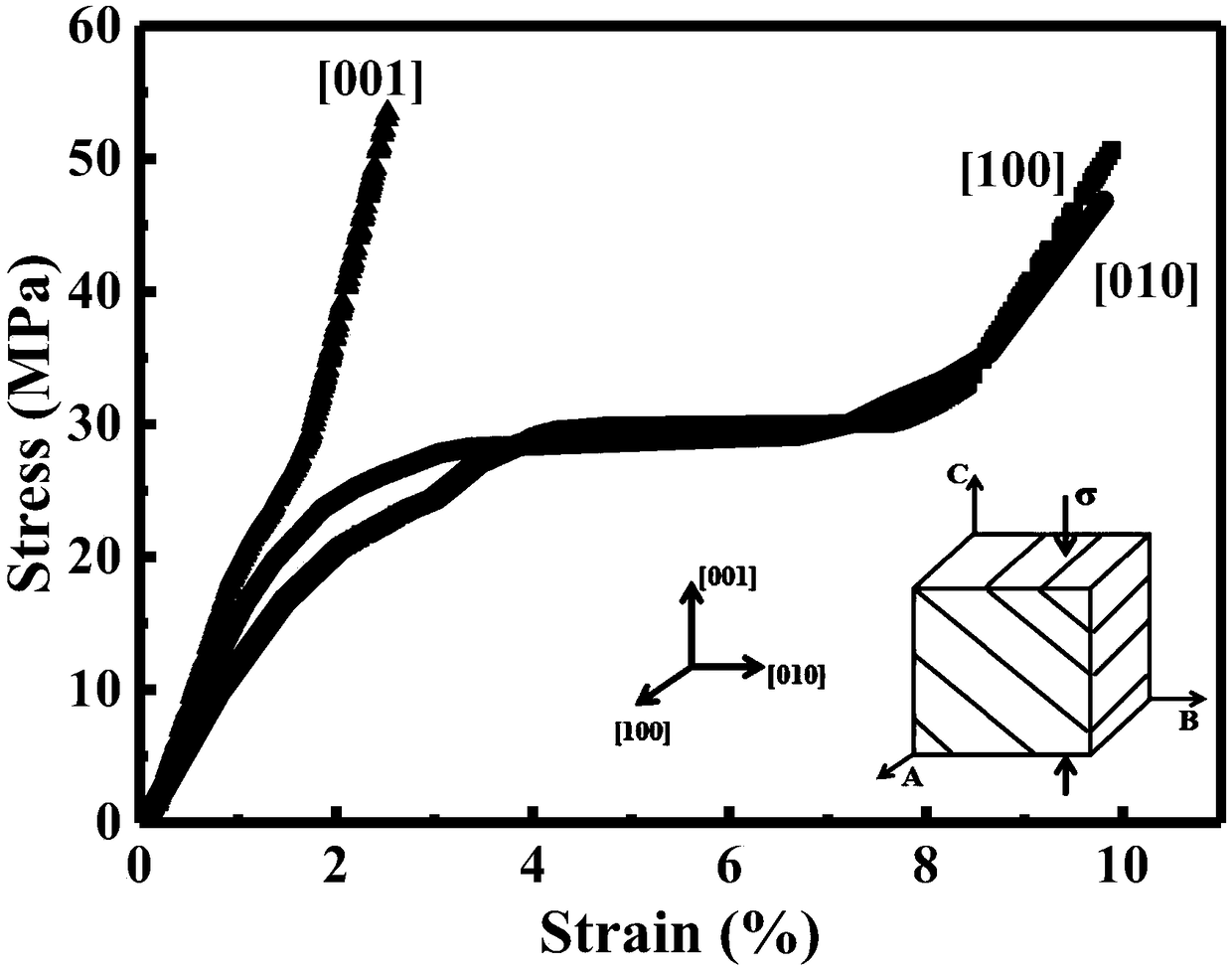

[0045] The third step: Mechanothermal coupling to eliminate NiMnGa twins

[0046] Place the NiMnGa single crystal obtained in the second step on a heating table and heat it above the austenite phase transition temperature; then perform Laue diffraction in the heated austenite state to determine the [100] direction of the crystal; wire cutting The cuboid sample, the longer direction is the [100] direction of the austenite phase; then the cuboid single crystal sample is placed in a self-designed heating furnace, and the mechanical-thermal coupling phase transformation is carried out using a SANS electronic universal testing machine to obtain De-twinned structure of NiMnGa alloy.

[0047] Processing conditions: first p...

Embodiment 3

[0051] The Ni53Mn25Ga22 multi-twin structure was obtained without mechanical-thermal coupling detwinning treatment for the [001] direction of the NiMnGa single crystal.

[0052] The first step and the second step are the same as in Embodiment 1, so the description is omitted here.

[0053] Step 3: Eliminate Ni without force-thermal coupling 53 mn 25 Ga 22 Twins in a single crystal

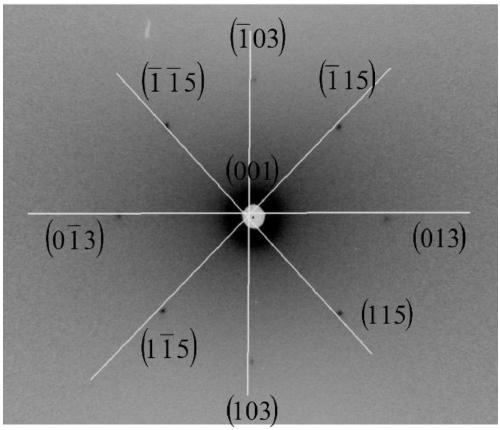

[0054] Measuring Ni 53 mn 25 Ga 22 The Laue diffraction spots on the alloy (001) surface, the diffraction pattern is multiple sets of spots, indicating that the structure has multiple twins, such as Figure 4 shown.

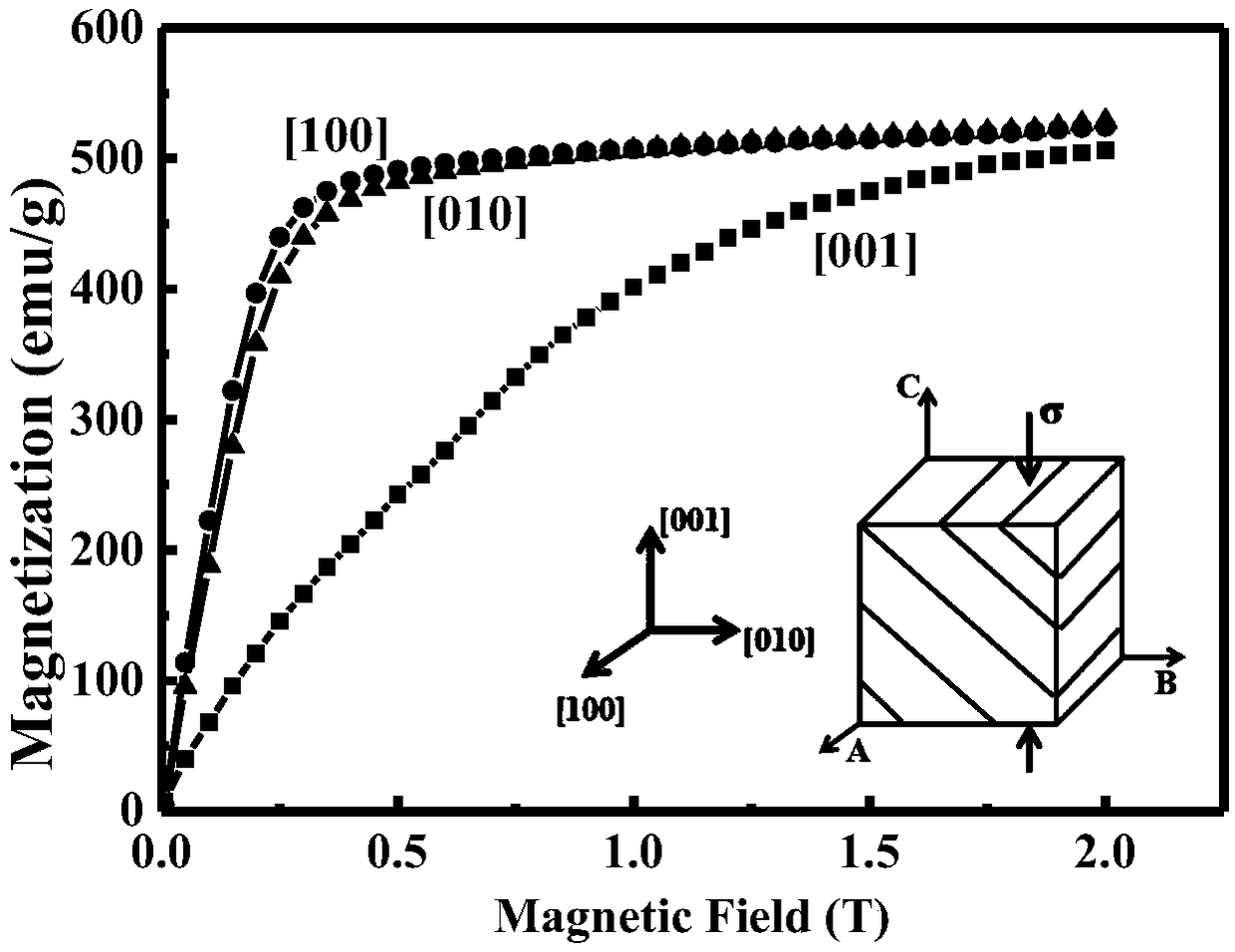

[0055] The above Ni 53 mn 25 Ga 22 Magnetization curve measurements for single crystals, such as Figure 5 As shown, respectively along the Ni 53 mn 25 Ga 22 The [001] direction, [100] direction and [010] direction of the alloy are gradually applied with a magnetic field, and the magnetization curves of the [001] direction, [100] direction and [010] direction are measure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com