Method for preparing micro-nano copper through multi-axial compression, twisting and combined extrusion

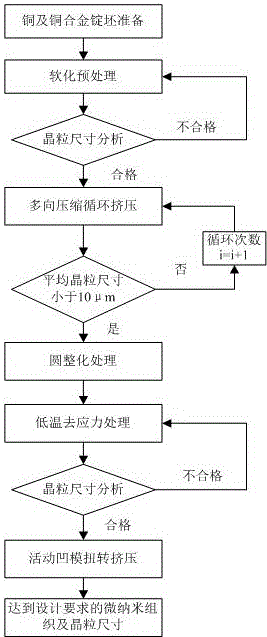

A multi-directional compression and composite extrusion technology is applied in the field of multi-directional compression torsional composite extrusion to prepare micro-nano copper, which can solve the problems of high strength, poor plasticity and high cost of ultra-fine-grained materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

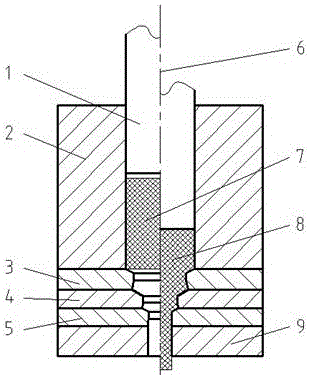

Method used

Image

Examples

Embodiment 1

[0024] (1) Select a Φ65mm pure copper bar, after forging a pure copper ingot with a length, width and height of 108mm×65mm×60mm, and then perform annealing treatment at a temperature of 400°C, and cool to room temperature with the furnace after a holding time of 2.0h.

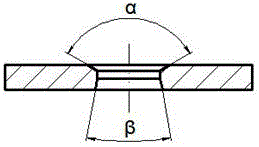

[0025] (2) Design and manufacture a mold cavity with a certain ratio of length, width and height. First, perform upsetting and compression along the height direction of the ingot, that is, the highest axial direction, until the cavity is filled; then turn the billet 90°, along the length direction, that is, the highest axis Perform upsetting and compression in the axial direction until the cavity is filled; then turn the billet 90°, and perform upsetting and compression along the width direction, that is, the highest axial direction, until the cavity is filled; extrude 16 times in this way, and the average grain size is measured by sampling. The particle size is 4 μm.

[0026] (3) After the shape of the billet ...

Embodiment 2

[0031] (1) Select Φ85mm copper-zinc alloy bar, after forging and processing a copper-zinc alloy ingot with a length, width and height of 152mm×85mm×80mm, and then perform annealing treatment at a temperature of 400°C, and cool to room temperature with the furnace after a holding time of 2.0h.

[0032] (2) Design and manufacture a mold cavity with a certain ratio of length, width and height. First, perform upsetting and compression along the height direction of the ingot, that is, the highest axial direction, until the cavity is filled; then turn the billet 90°, along the length direction, that is, the highest axis Perform upsetting and compression in the axial direction until the cavity is filled; then turn the billet 90°, and perform upsetting and compression along the width direction, that is, the highest axial direction, until the cavity is filled; extrude 18 times in this way, and the average grain size is measured by sampling. The particle size is 7 μm.

[0033] (3) After...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com