Silicon carbide mullite wear-resisting casting material

A mullite and castable technology, applied in the field of silicon carbide fused mullite wear-resistant castables, can solve the problems of chemical erosion, large amount of dust, heavy alkaline components, etc., to improve high-temperature service performance and save energy. The effect of resource and consumption saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

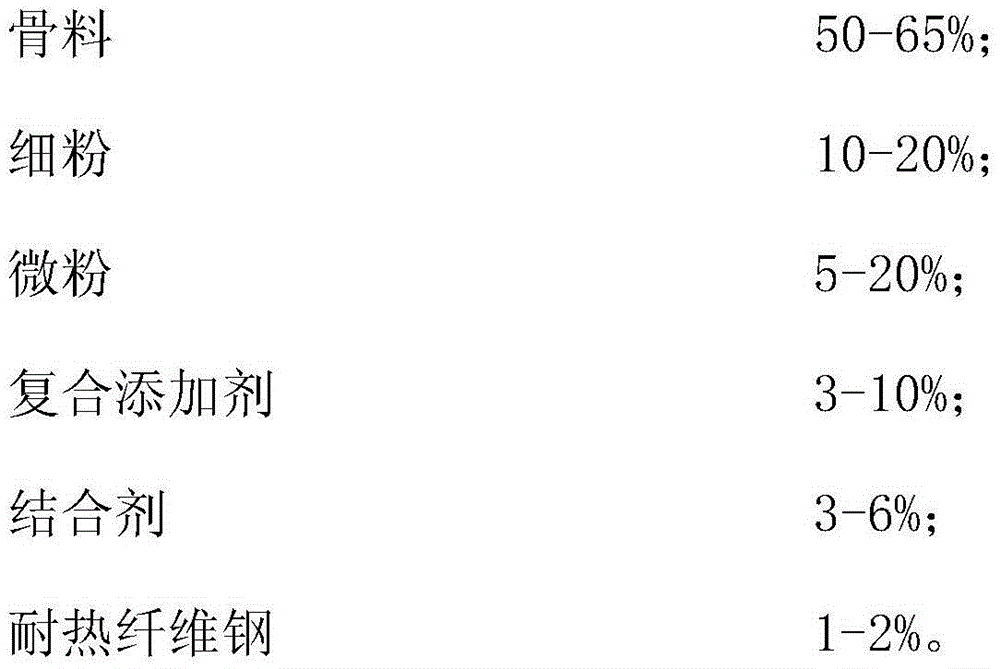

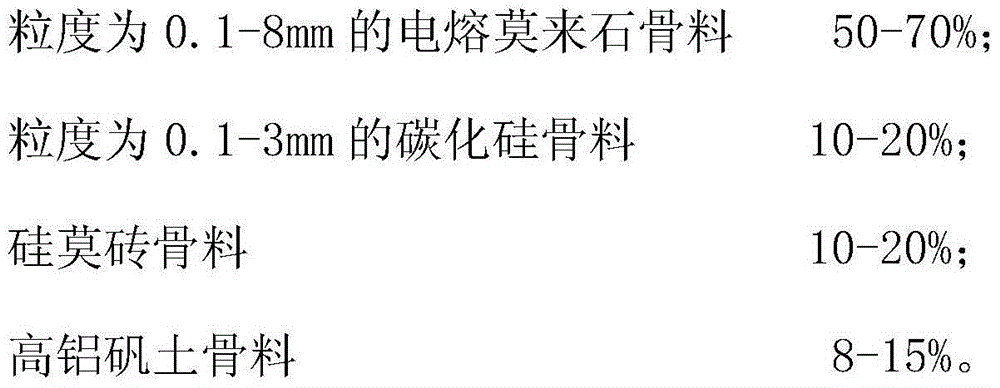

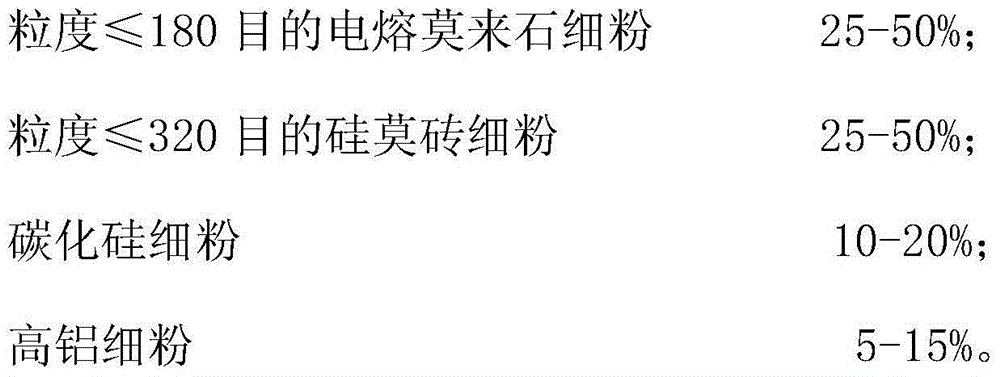

[0032] Silicon carbide fused mullite wear-resistant castable includes the following components and the mass percentage of each component is: aggregate 50%, fine powder 20%, micropowder 12%, compound additive 10%, binder 6%, Hot fiber steel 2%, preferably, the castable is only composed of aggregates, fine powder, micropowder, composite additives, binders and heat-resistant fiber steel, and one part of the aggregate includes electrofusion with a particle size of 0.1-8mm. 50% mullite aggregate, 20% silicon carbide aggregate with a particle size of 0.1-3mm, 20% silicon mullite brick aggregate and 10% high alumina bauxite aggregate, one fine powder includes electrofusion with particle size ≤180 mesh 30% mullite fine powder, 55% fine silica mullite powder with particle size ≤320 mesh and 15% fine silicon carbide powder, the fine powder is a combination of silicon dioxide fine powder and activated alumina fine powder, or the fine powder is dioxide The combination of silicon micropowd...

Embodiment 2

[0035] Silicon carbide fused mullite wear-resistant castable includes the following components and the mass percentage of each component is: aggregate 65%, fine powder 10%, micropowder 18%, compound additive 3%, binder 3%, Hot fiber steel 1%, preferably, the castable is only composed of aggregates, fine powder, micropowder, composite additives, binders and heat-resistant fiber steel, wherein, one part of the aggregate includes electrofusion with a particle size of 0.1-8mm. 70% mullite aggregate, 10% silicon carbide aggregate with a particle size of 0.1-3mm, 10% silicon mullite brick aggregate, 10% high alumina bauxite aggregate, one fine powder includes electrofusion with particle size ≤180 mesh 55% fine mullite powder, 30% fine silica mullite powder and 15% fine silicon carbide powder with a particle size of ≤320 mesh. The discarded silica mullite bricks that are replaced are broken and obtained, and the micropowder is a combination of silica micropowder and activated alumina...

Embodiment 3

[0037] Silicon carbide fused mullite wear-resistant castable includes the following components and the mass percentage of each component is: aggregate 58%, fine powder 15%, micropowder 15%, compound additive 6%, binder 4%, Hot fiber steel 2%, preferably, the castable is only composed of aggregates, fine powder, micropowder, composite additives, binders and heat-resistant fiber steel, and one part of the aggregate includes electrofusion with a particle size of 0.1-8mm. 60% mullite aggregate, 15% silicon carbide aggregate with a particle size of 0.1-3mm, 15% silicon mullite brick aggregate, and 10% high alumina bauxite aggregate. One fine powder includes electrofusion with a particle size of ≤180 mesh 40% mullite fine powder, 40% fine silica mullite powder with particle size ≤320 mesh and 20% fine silicon carbide powder. Said silica mullite brick aggregate and silica mullite fine powder are dismantled during maintenance and replacement through cement rotary kiln. The discarded s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com