Process for preparing semisolid steel blank by using radial forging strain induction method

A technology of radial forging and strain induction, which is applied in the field of preparing steel semi-solid blanks by radial forging strain induction method, which can solve the problems that do not involve the preparation of high-melting point ferrous semi-solid blanks, serious mechanical stirrers, difficult semi-solid blanks, etc. , to achieve the effect of easy operation, low cost and good formability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings.

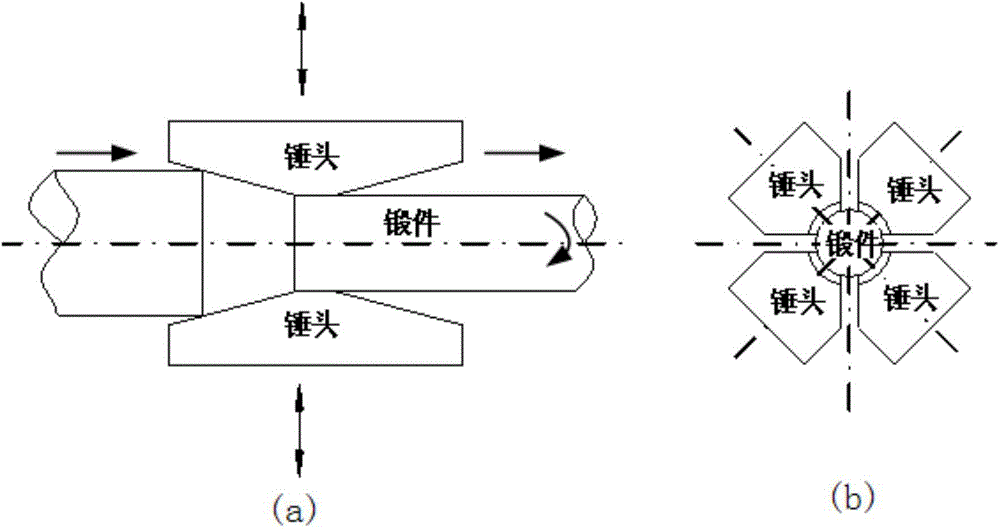

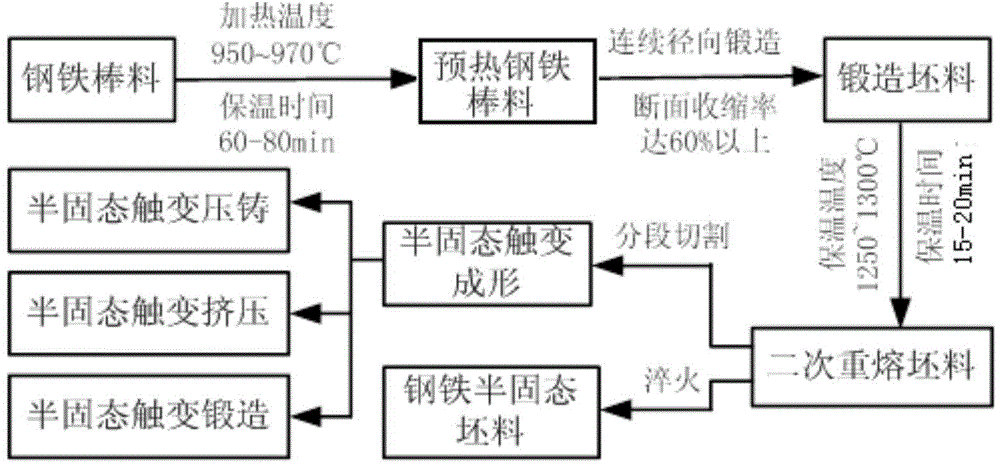

[0018] refer to figure 1 and figure 2 , taking the 45# steel bar of Φ120mm as an example, a process for preparing semi-solid steel blanks by radial forging strain induction method, including the following steps:

[0019] 1) Preheat the steel bar, heat the Φ120mm steel bar to 950-970°C with the electric furnace, and then carry out the heat preservation treatment for 60-80 minutes to ensure that the whole billet is heated through; the specific heat preservation time for bars with different diameters is 0.5D~0.7D minutes, D is the diameter of the bar;

[0020] 2) Carry out radial forging on the steel bar. The preheated steel bar is taken out by the manipulator of the radial forging machine and sent axially by clamping and rotating. The four hammerheads of the radial forging machine are symmetrically distributed around the blank, Carry out high-frequency reciprocatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com