High-speed impact pressing method for metal powder

A metal powder, high-speed impact technology, applied in the field of high-speed impact pressing of metal powder, can solve the problems of difficult energy control and poor safety, and achieve the effects of small energy loss, short pressing time and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

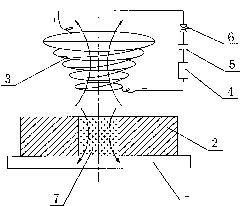

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0014] A high-speed impact pressing method for metal powder, comprising the following steps:

[0015] (1), a mold 2 made of a non-magnetic material is arranged on the substrate 1, and a cavity is set on the mold 2;

[0016] (2), the tower-shaped coil 3 is fixed on the top of the mold 2 in such a way that the top is wide and the bottom is narrow. overlap;

[0017] (3), current-limiting resistor 4, high-voltage energy storage capacitor 5 and three-electrode switch 6 are connected in series to form a discharge circuit, then the discharge circuit is connected in series on the tower coil 3, and the discharge high voltage of the discharge circuit is set to be Above DC2KV;

[0018] (4) Fill the metal powder 7 in the mold cavity of the mold 2, then discharge the tower coil 3, and the pulsed magnetic field generated by the tower coil 3 directly acts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com