Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

48 results about "Explosive forming" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Explosive forming is a metalworking technique in which an explosive charge is used instead of a punch or press. It can be used on materials for which a press setup would be prohibitively large or require an unreasonably high pressure, and is generally much cheaper than building a large enough and sufficiently high-pressure press; on the other hand, it is unavoidably an individual job production process, producing one product at a time and with a long setup time.

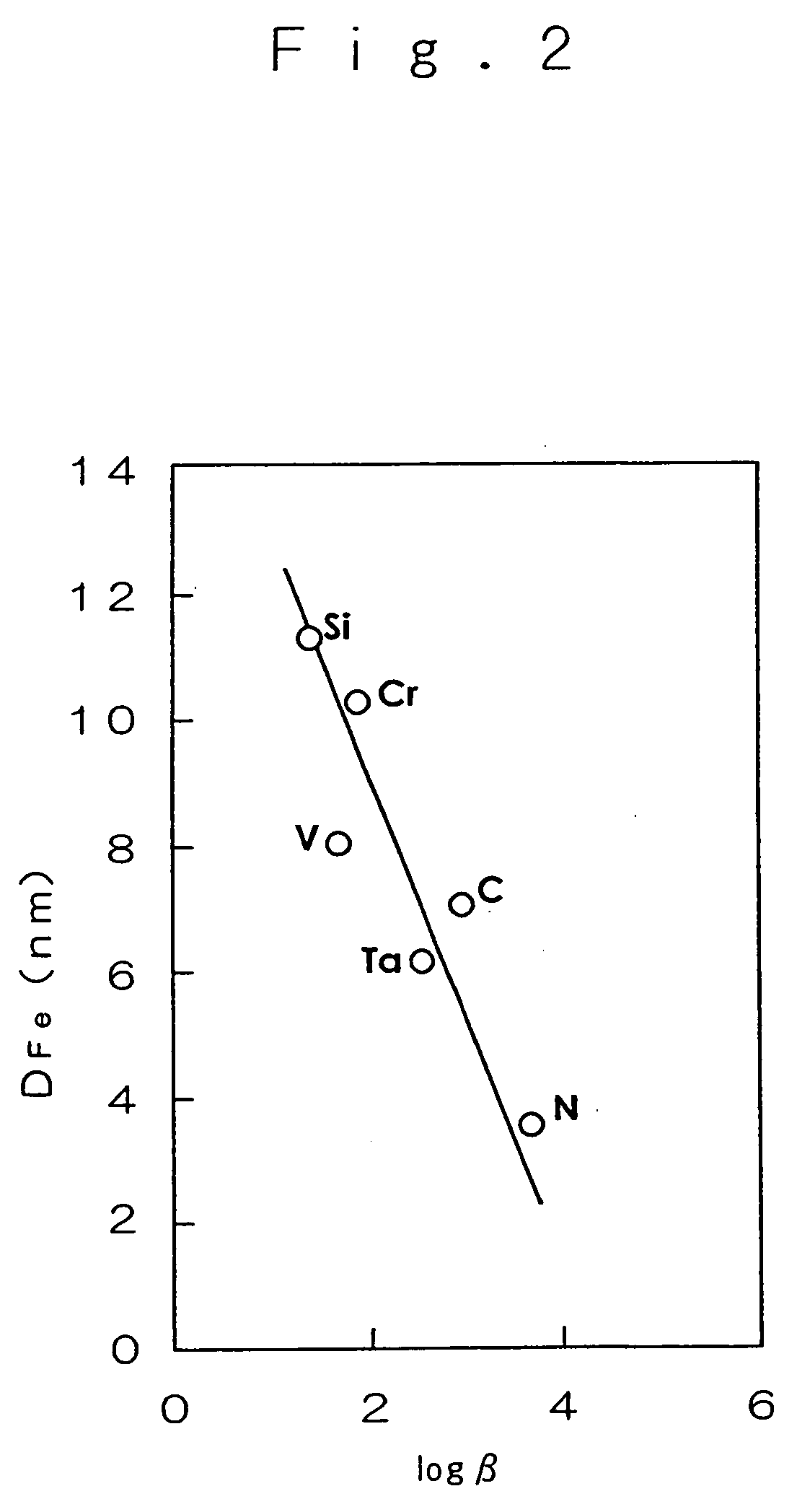

Nano-crystal austenitic metal bulk material having high hardness, high strength and toughness, and method for production thereof

InactiveUS20060127266A1Easy to prepareUltra-fine crystal grain structureTransportation and packagingMetal-working apparatusBorideExplosive forming

The invention provides a high hard, strength and tough nano-crystal metal bulk material and a preparation process thereof. The metal bulk material comprises an aggregate of metal nano-crystal grains, wherein an oxide, nitride, carbide, boride or the like of a metal or semimetal exists as a crystal grain growth inhibitor between and / or in the nano-crystal grains. The respective fine powders of nano-metal bulk material-forming components are mechanically alloyed (MA), using a ball mill or the like, thereby preparing nano-metal powders. Then, hot forming-by-sintering treatment such as spark plasma sintering, extrusion and rolling or explosive forming is applied to the powders to obtain a high hard, strength and tough nano-crystal metal bulk material.

Owner:NANO TECH INST

Tenacious metallic nano-crystalline bulk material with high hardness and high strength, and its manufacturing method

InactiveCN1685071AEasy to manufactureApplicable to solidification forming processTransportation and packagingMetal-working apparatusBorideExplosive forming

The invention provides a high hard, strength and tough nano-crystal metal bulk material and a preparation process thereof. The metal bulk material comprises an aggregate of metal nano-crystal grains, wherein an oxide, nitride, carbide, boride or the like of a metal or semimetal exists as a crystal grain growth inhibitor between and / or in the nano-crystal grains. The respective fine powders of nano-metal bulk material-forming components are mechanically alloyed (MA), using a ball mill or the like, thereby preparing nano-metal powders. Then, hot forming-by-sintering treatment such as spark plasma sintering, extrusion and rolling or explosive forming is applied to the powders to obtain a high hard, strength and tough nano-crystal metal bulk material.

Owner:NANO TECH INST

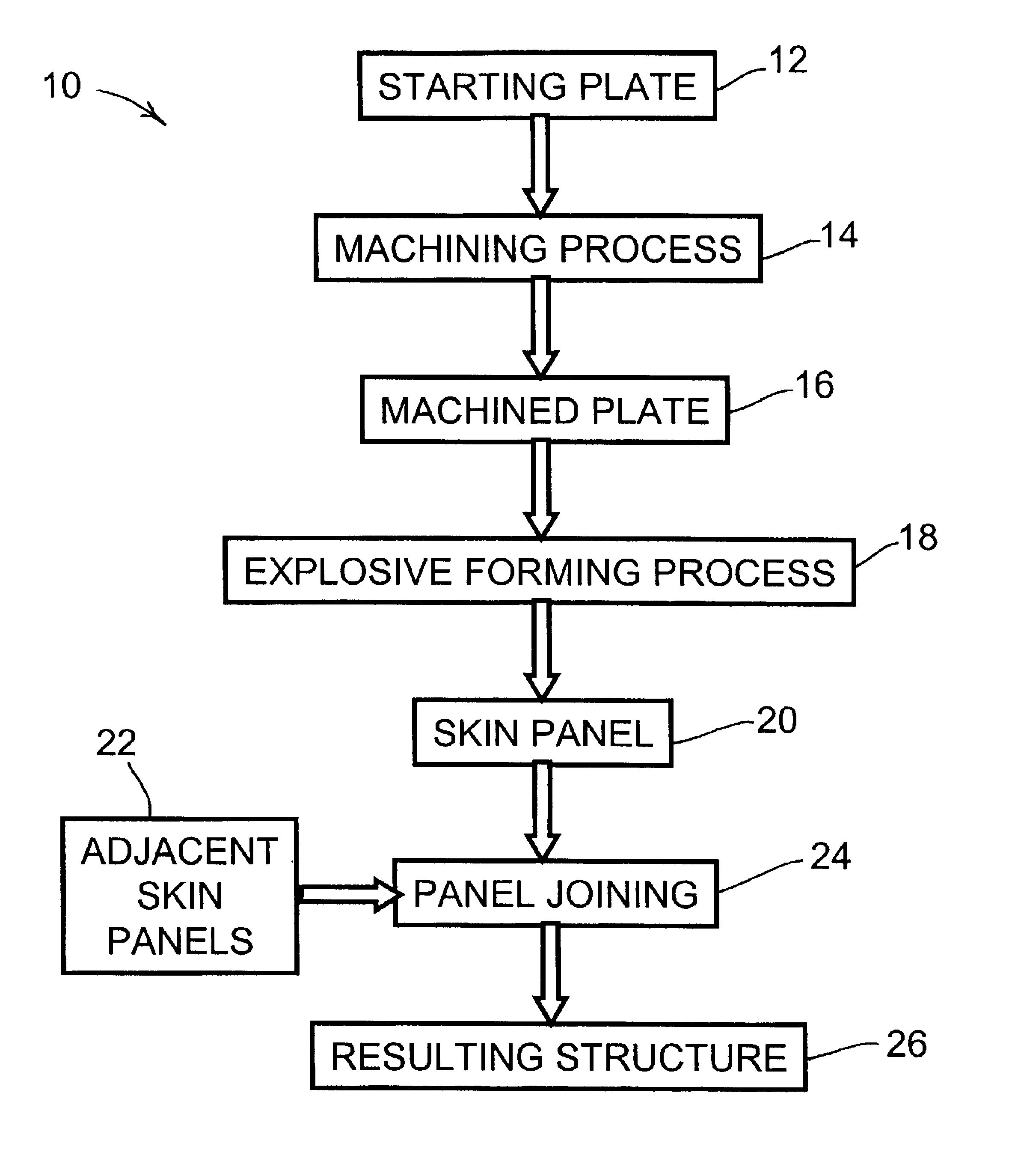

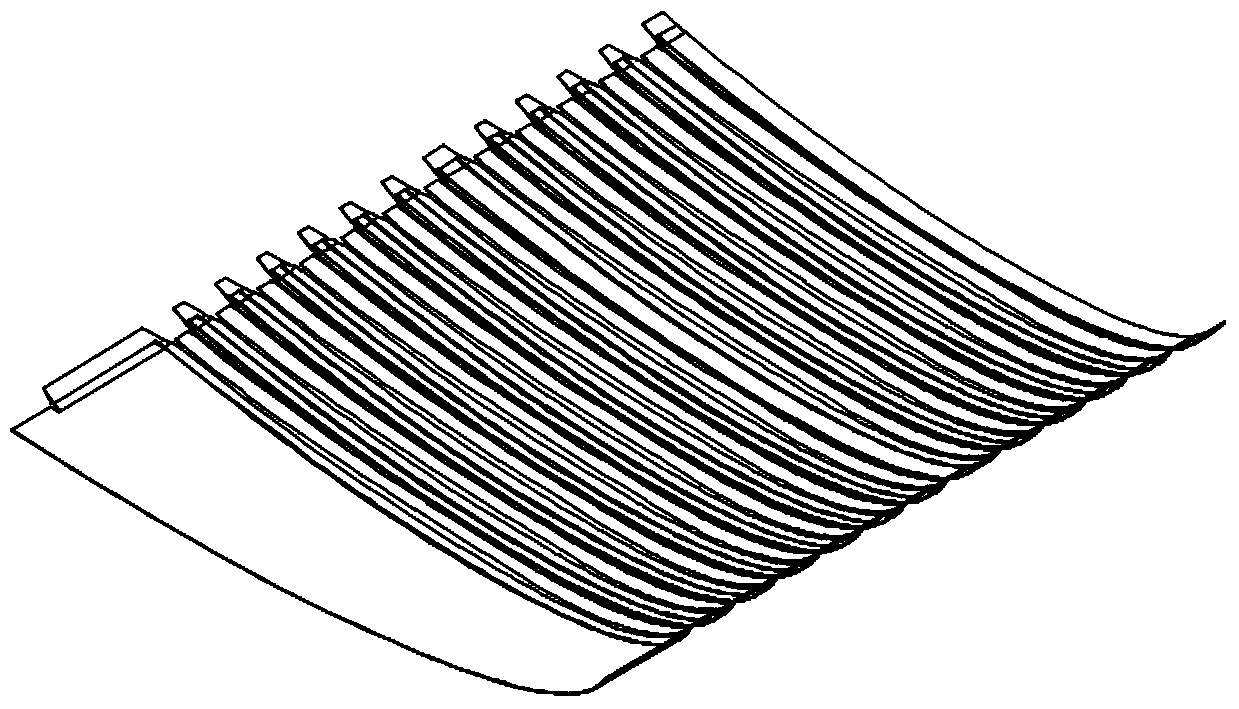

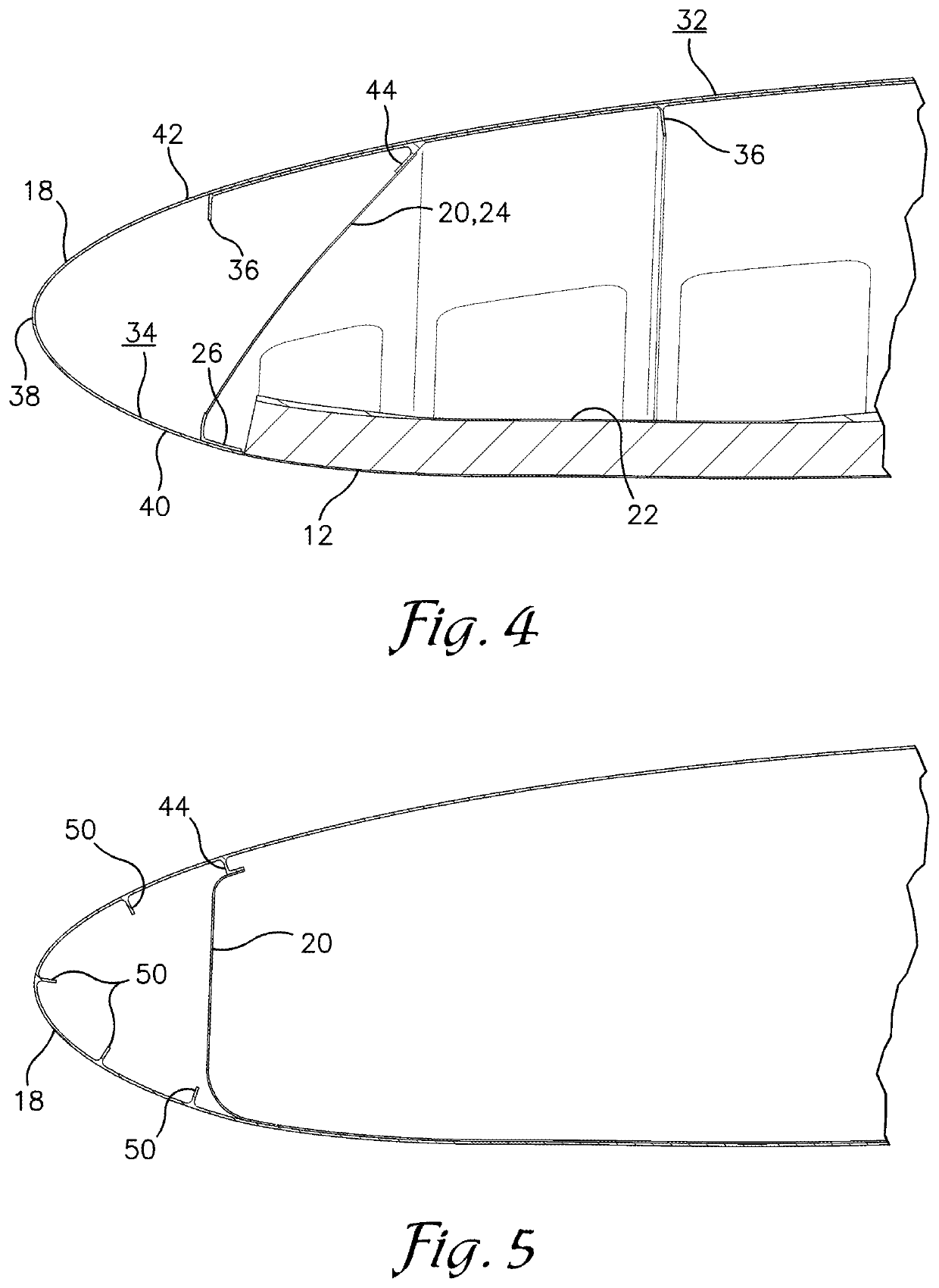

Methods of making integrally stiffened axial load carrying skin panels for primary aircraft structure and fuel tank structures

Methods for making skin panels suitable for use in aircraft structures and fuel tank structures, such as fuselages and reusable launch vehicle propellant tanks. A first method includes the following steps: machining a starting plate to a final part geometry; and explosive forming the machined plate to at least one of a uniaxial curvature and a biaxial curvature. A second method includes the following steps: explosive forming a starting plate to at least one of a uniaxial curvature and a biaxial curvature; and machining the curved plate to a final part geometry. Accordingly, the invention enables making integrally stiffened unitized axial load carrying skin panels that are either uniaxially or biaxially curved.

Owner:THE BOEING CO

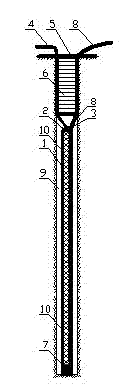

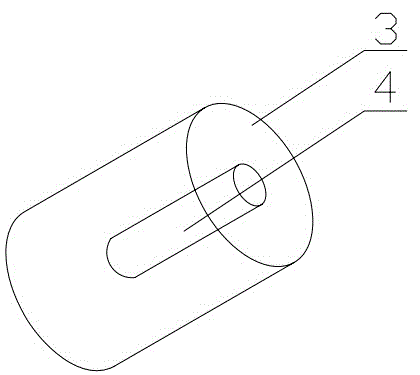

Loading method suitable for field mixed loading of explosive and tool used for method

The invention relates to a loading method suitable for field mixed loading of explosive and a tool used for the method. The loading method suitable for the field mixed loading of the explosive comprises the following steps: 1) putting constituted detonated explosive into an explosive forming bag, introducing a detonating fuse connected with the detonated explosive out of the explosive forming bag, and binding a load bearing rope with a load bearing belt of the explosive forming bag; 2) enabling an explosive conveying hose to extend into the bottom of the explosive forming bag from an explosive conveying hole of the explosive forming bag, and fixing the rope and a detonating fuse on the hole of a blasthole by a load bearing rod after the explosive forming bag is taken into place; and 3) starting a mixed loading truck for the explosive, injecting the explosive into the explosive forming bag, removing an antistatic locating rod out of the blasthole when the length of an injected explosive section reaches the requirement of a user, and taking out the explosive conveying hose after the explosive loading amount reaches a designed volume to finish the explosive loading operation of the position. The loading method suitable for the field mixed loading of the explosive can be widely used for loading a fracture rock blasthole and an air interval outline blasthole under various conditions that explosive mixed loading is adopted for ground drilling and blasting, such as mines, traffic, hydroelectric power and the like.

Owner:GUANGDONG HONGDA BLASTING +1

Bidirectional pressing liquid-charging forming method for large-size thin-wall complex characteristic panel

ActiveCN103846331AGive full play to plasticityUniform wall thickness distributionReduction rateEngineering

The invention relates to a bidirectional pressing liquid-charging forming method for a large-size thin-wall complex characteristic panel. The method comprises the following steps: coating lubricating oil on a single side of a thin-wall panel, thereby performing lubricating treatment; bulging the panel after being lubricated in advance in a pre-forming mould, thereby forming the rough shape of parts; reversely shaping the pre-formed panel in a shaping mould, thereby forming small circular bead features; cutting off addendum surfaces of the parts, thereby finally forming the parts. According to the bidirectional pressing liquid-charging forming method for the large-size thin-wall complex characteristic panel provided by the invention, the plasticity of the panel is fully utilized, the wall thickness reduction rate of the parts is effectively controlled and the panel parts with any complex shallow characteristics can be formed. Compared with the explosive forming of the traditional similar parts manufacturing method, the bidirectional pressing liquid-charging forming method has the advantages of high efficiency, low cost, convenience and safety in operation, high precision of formed parts, no manual repairing, and the like.

Owner:BEIHANG UNIV

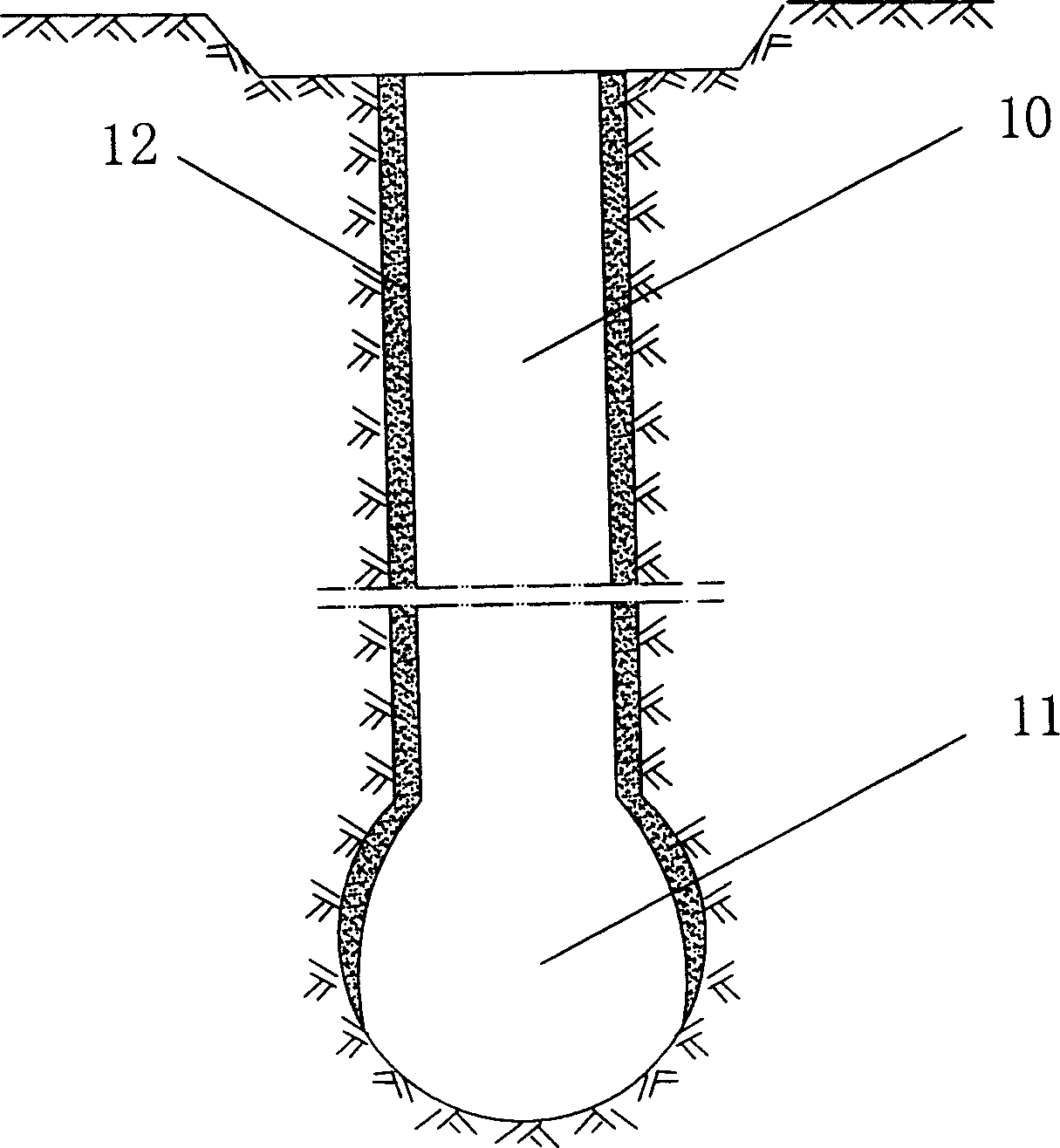

Explosion-enlarging stake construction process

InactiveCN1884712AHigh compression rangeImprove the compaction effectBulkheads/pilesExplosive formingSoil horizon

Owner:CHINA UNIV OF MINING & TECH

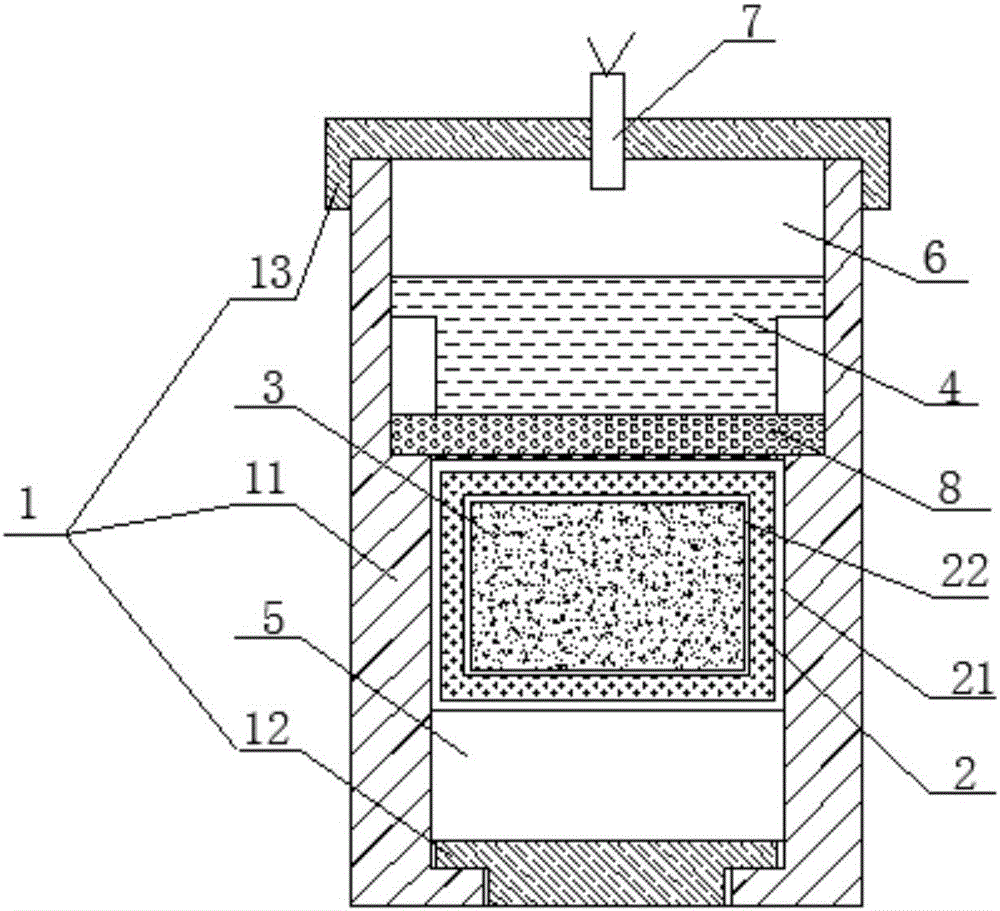

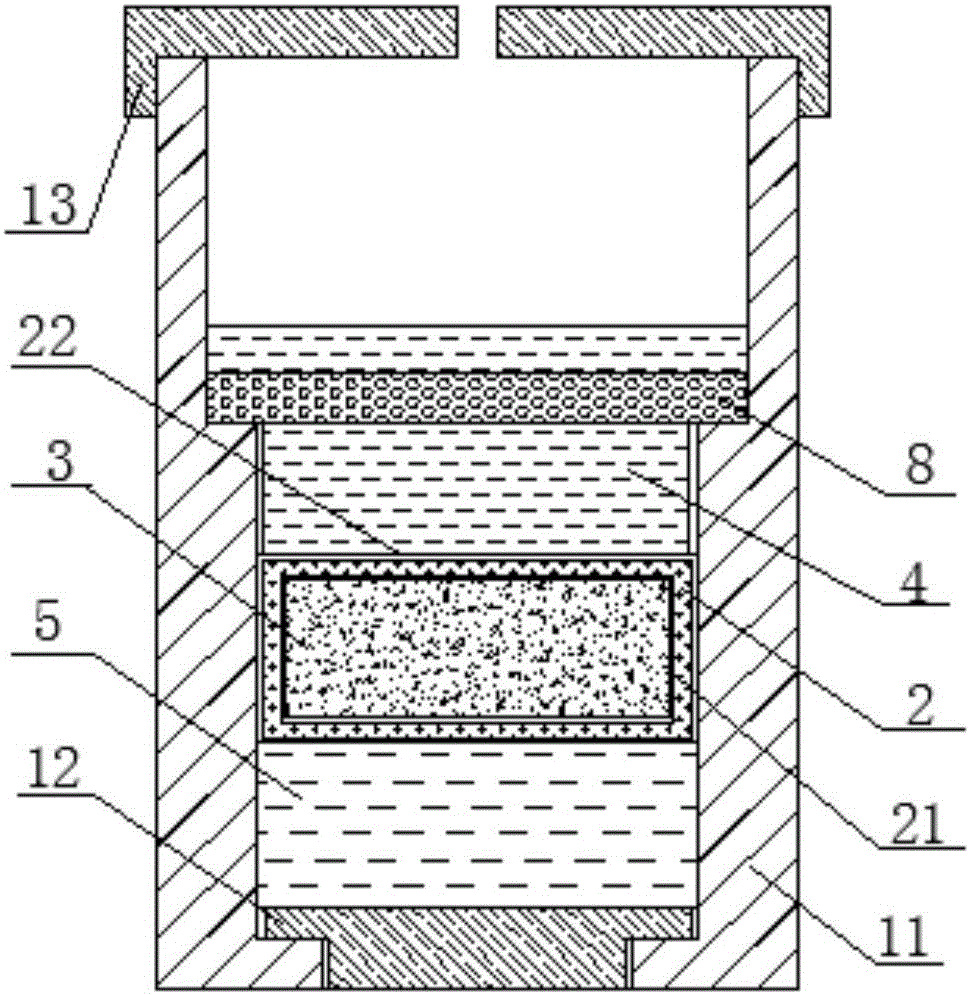

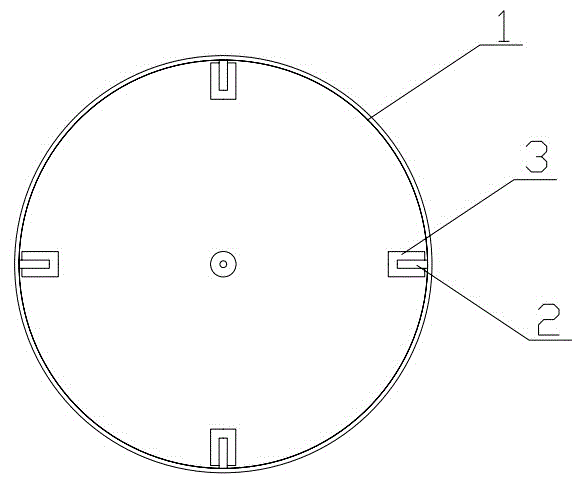

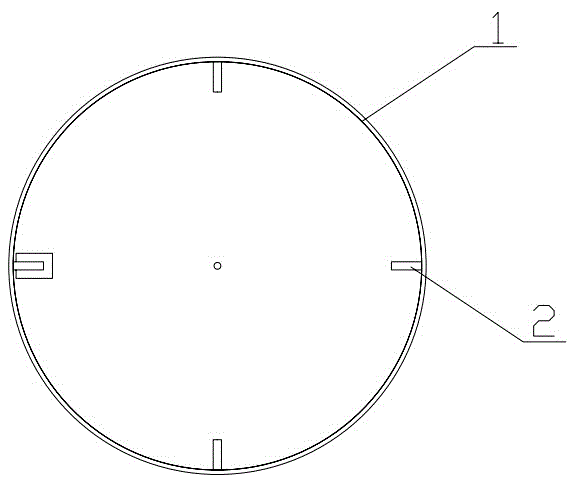

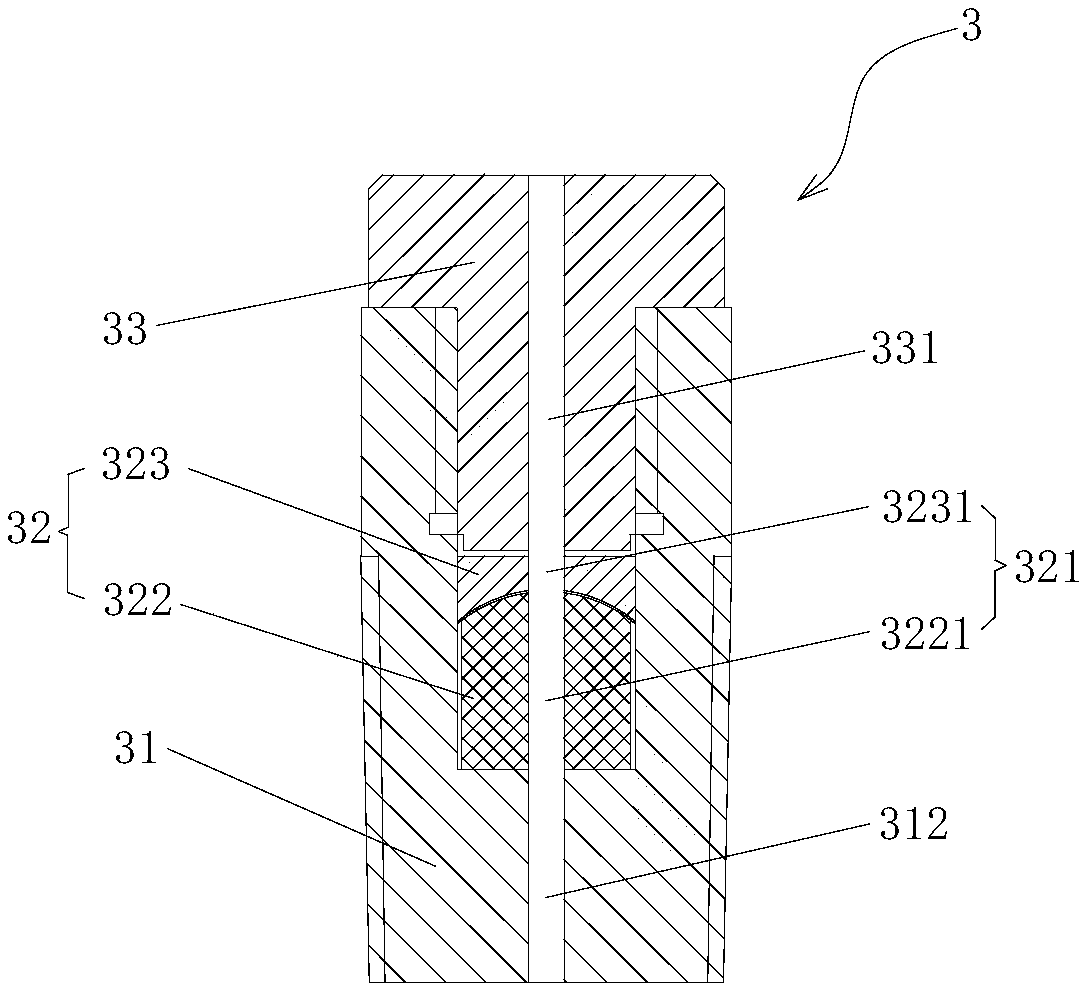

Explosive forming mold of active compound material

The invention relates to the field of explosive forming, in particular to an explosive forming mold of an active compound material. The explosive forming mold comprises a hard mold, a soft mold, a compression molding part and an explosion part, wherein the hard mold is provided with a hollow cavity; the soft mold is located in the hard mold and is provided with a cavity used for wrapping the active compound material; the compression molding part and the explosion part are located in the hard mold; under the acting force of the explosion part, the compression molding part exerts pressure on the soft mold, and achieves compression molding of the active compound material. Through the explosive forming mold of the active compound material, a method of combining the hard mold and the soft mold is adopted for compression molding of the active compound material, not only is the sealing effect of the mold improved, but also the shape of the molded active compound material is easy to control, and waste of materials is reduced.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Process for preparing nano-diamond black powder by virtue of detonation

InactiveCN102910626AImprove qualityImprove performanceDiamondNanotechnologyDetonationExplosive Agents

The invention relates to a process for preparing nano-diamond black powder by virtue of detonation, and belongs to the technical field of preparation of nano-diamond black powder. According to the process, due to the improvement of the explosive forming process, a spherical explosive ball which takes initiating explosive columns as initiating points is prepared by using a spherical mold, the initiating explosive columns are uniformly distributed and embedded on the surface of the spherical explosive ball, 4-20 initiating points which are uniformly distributed on the surface of the spherical explosive ball are formed by cavities on the initiating explosive columns, so that the final nano-diamond black powder prepared by detonation has the advantages that the quality is high, the performance is good, the particle size distribution is uniform, the dispersion is easy, the subsequent treatment process is simple, and the yield of the nano diamond can be improved.

Owner:成都天成鑫钻纳米科技股份有限公司

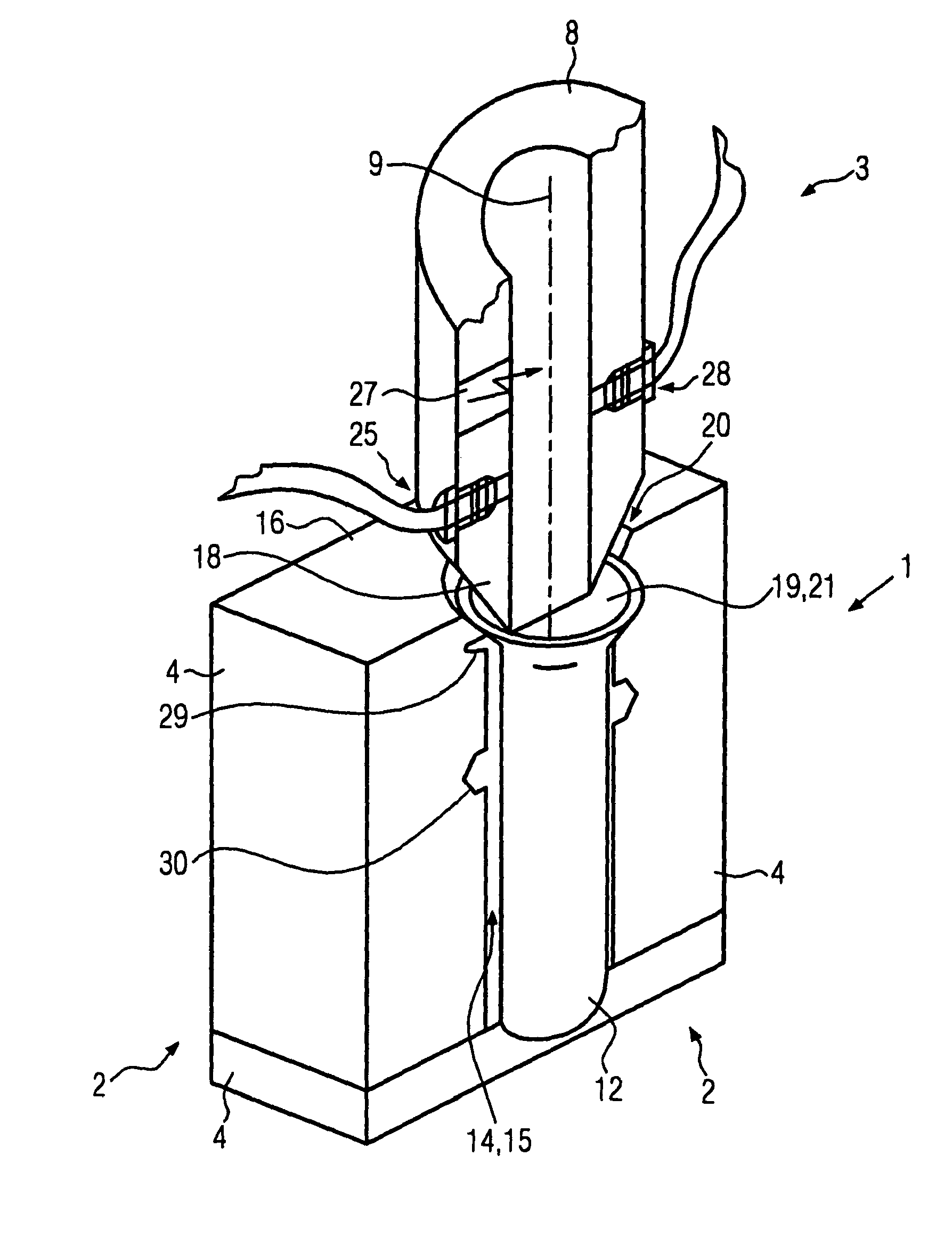

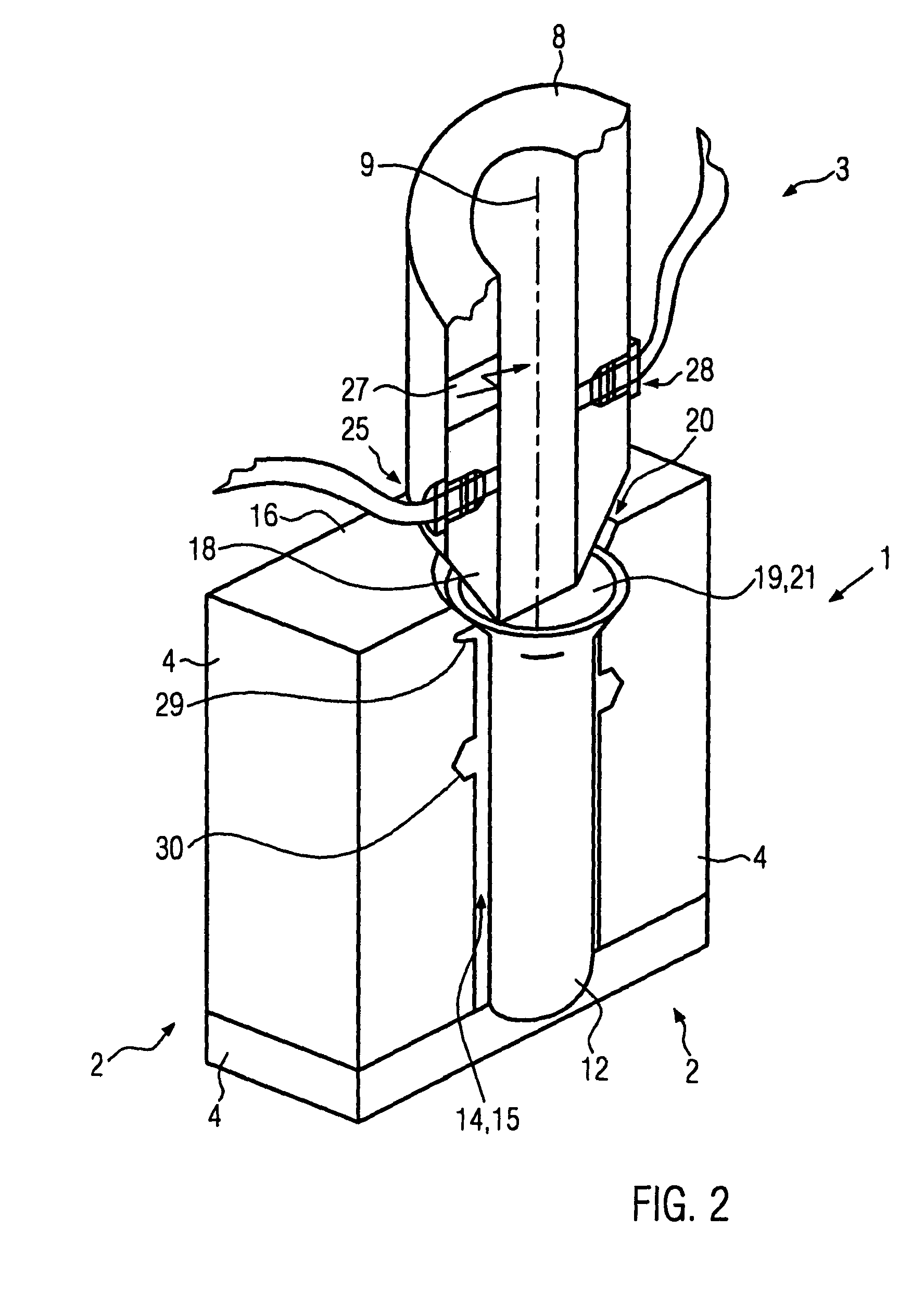

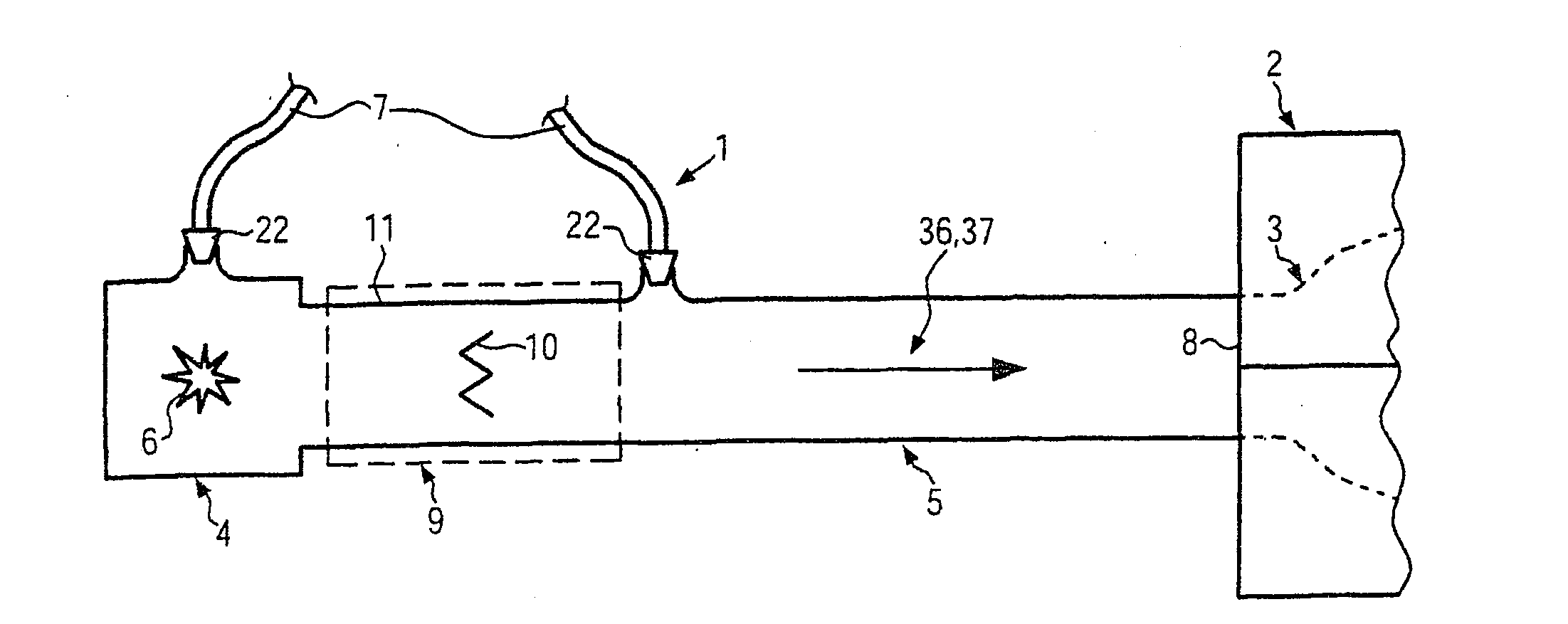

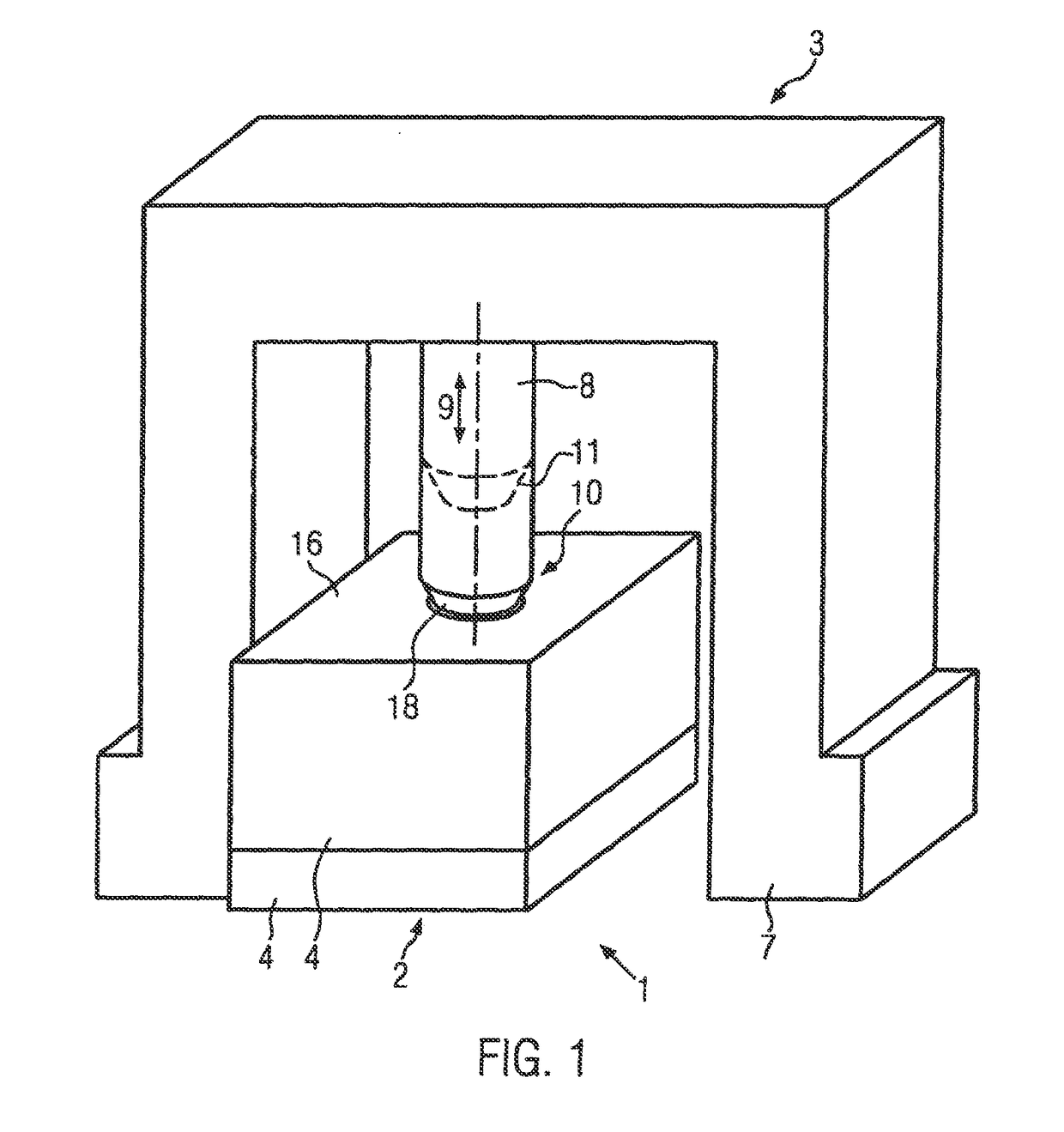

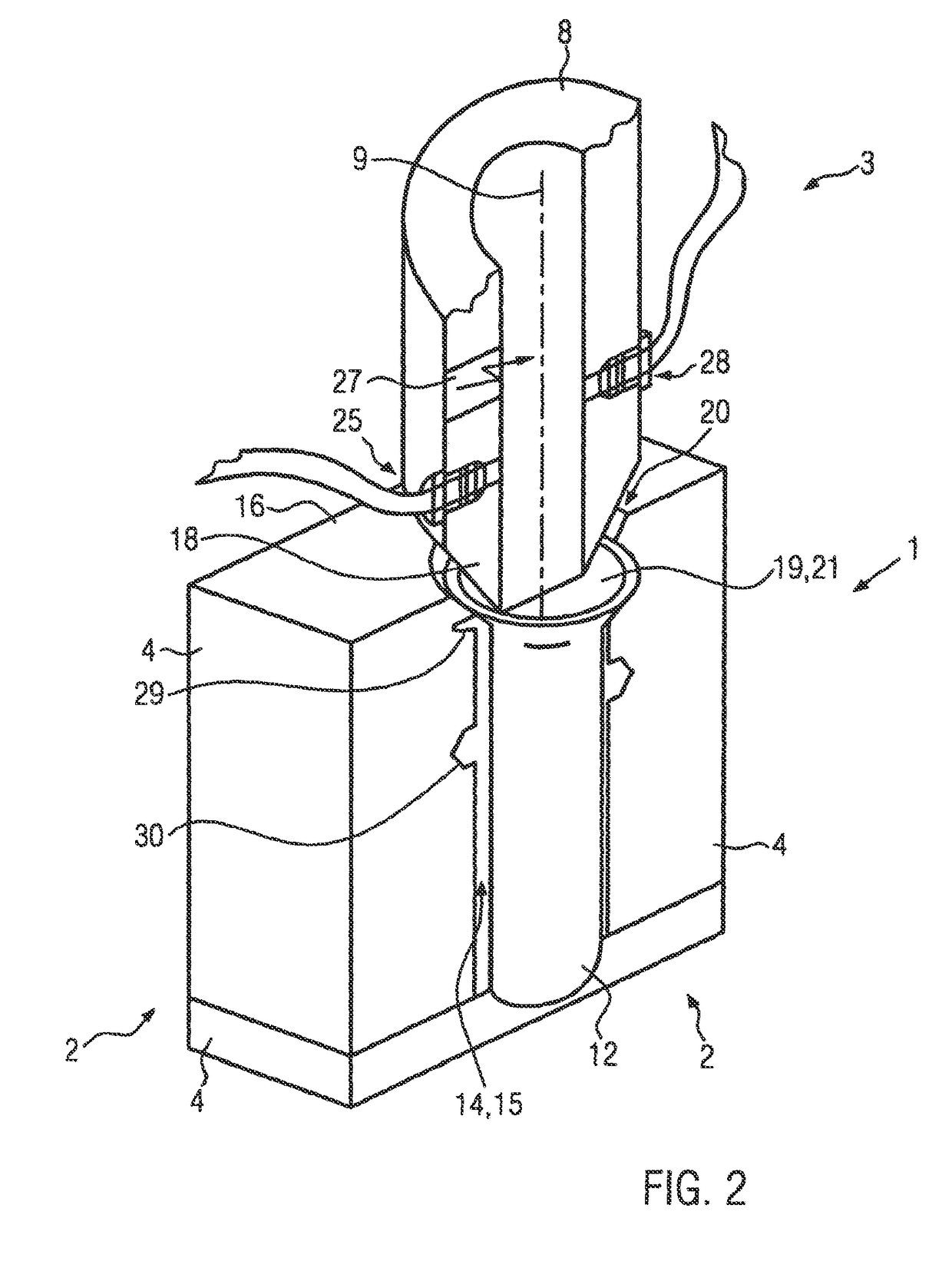

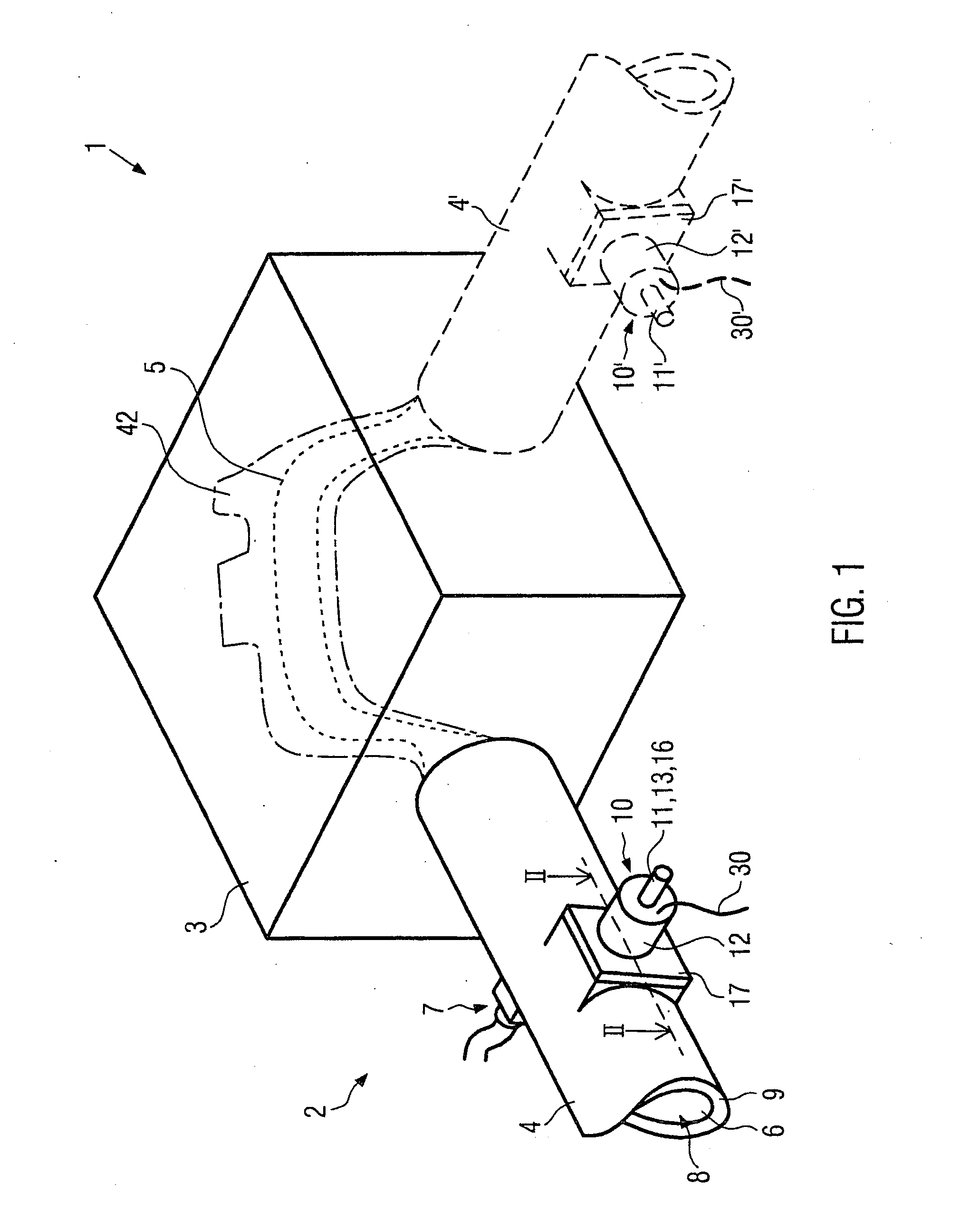

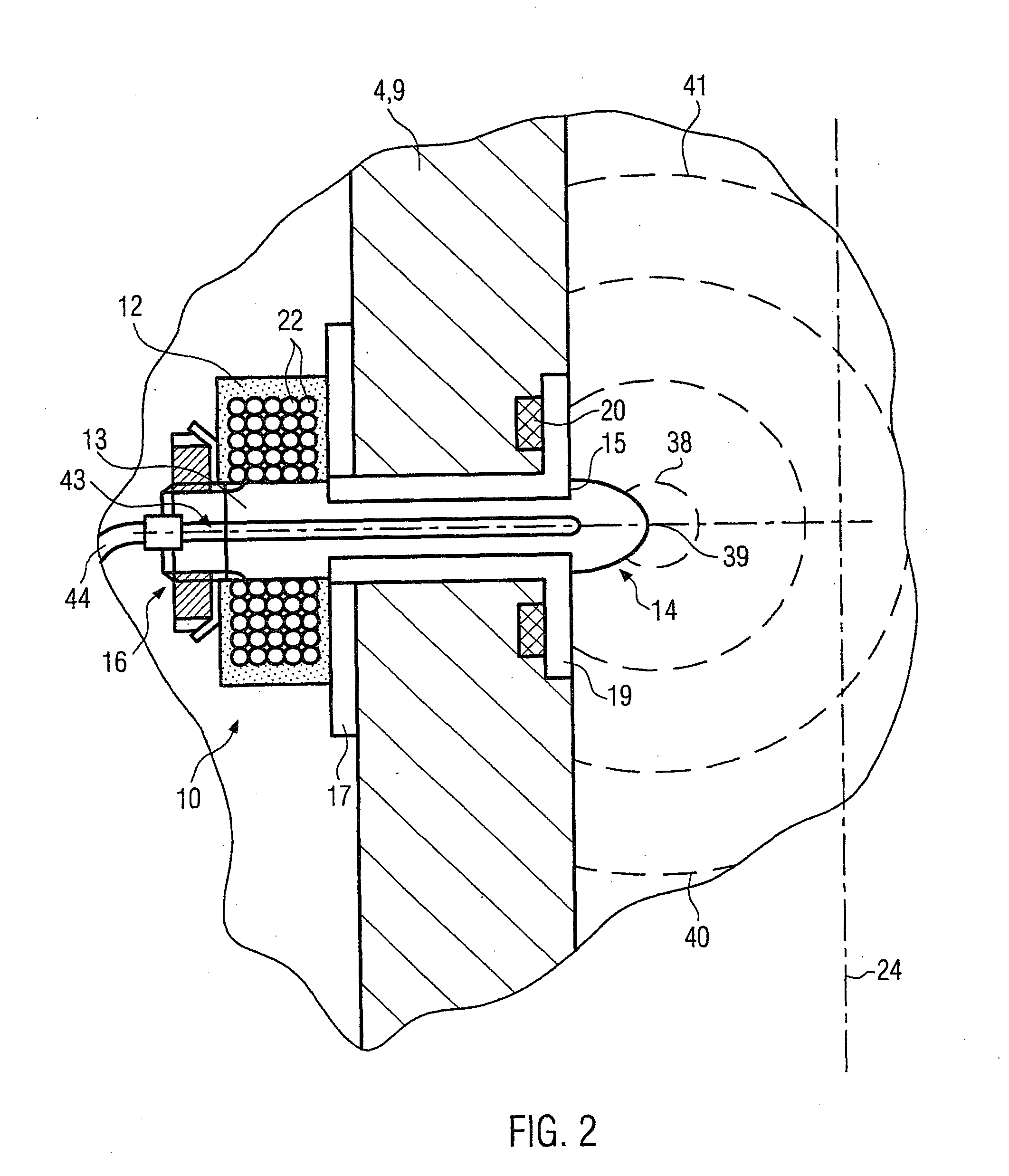

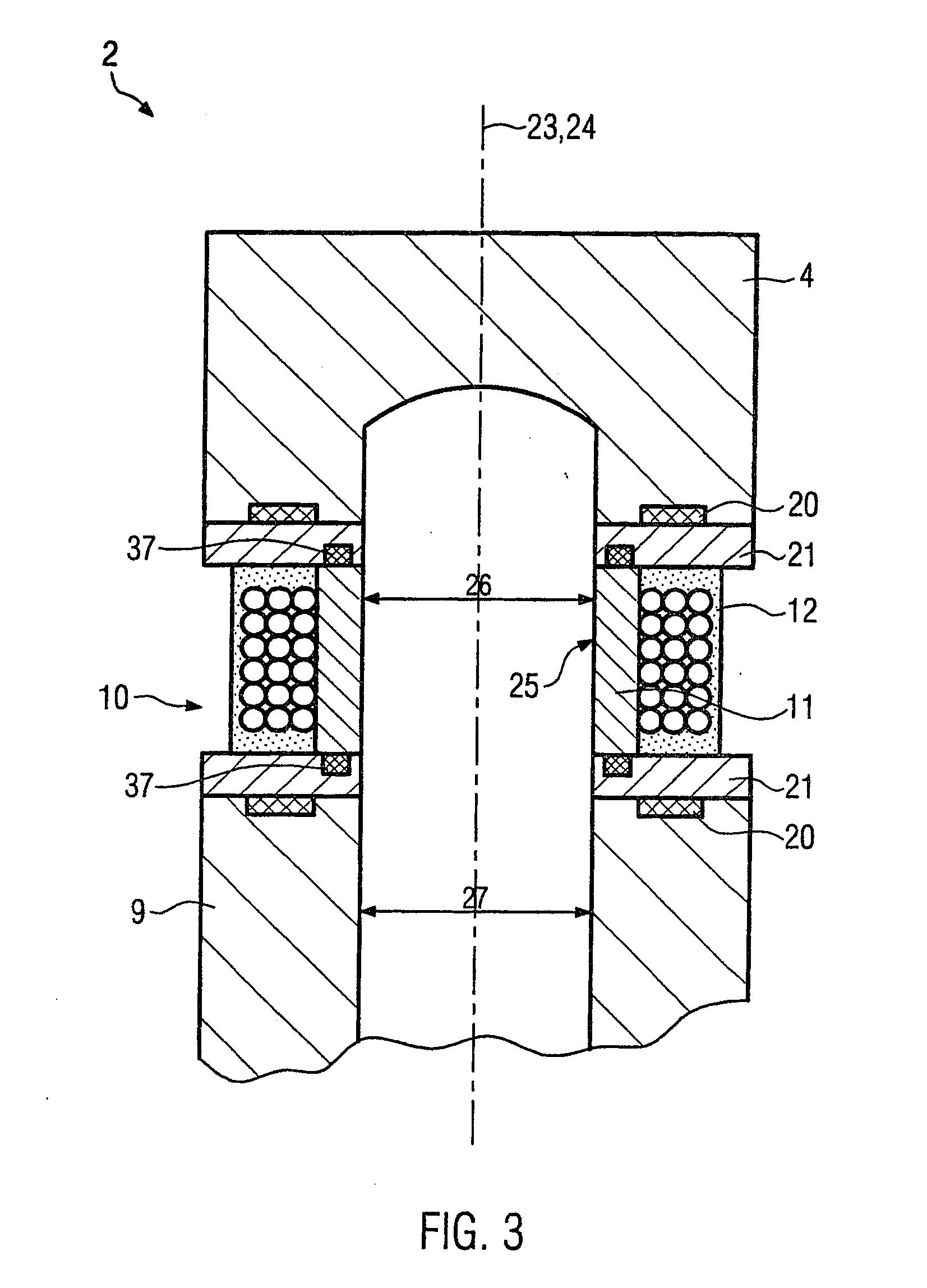

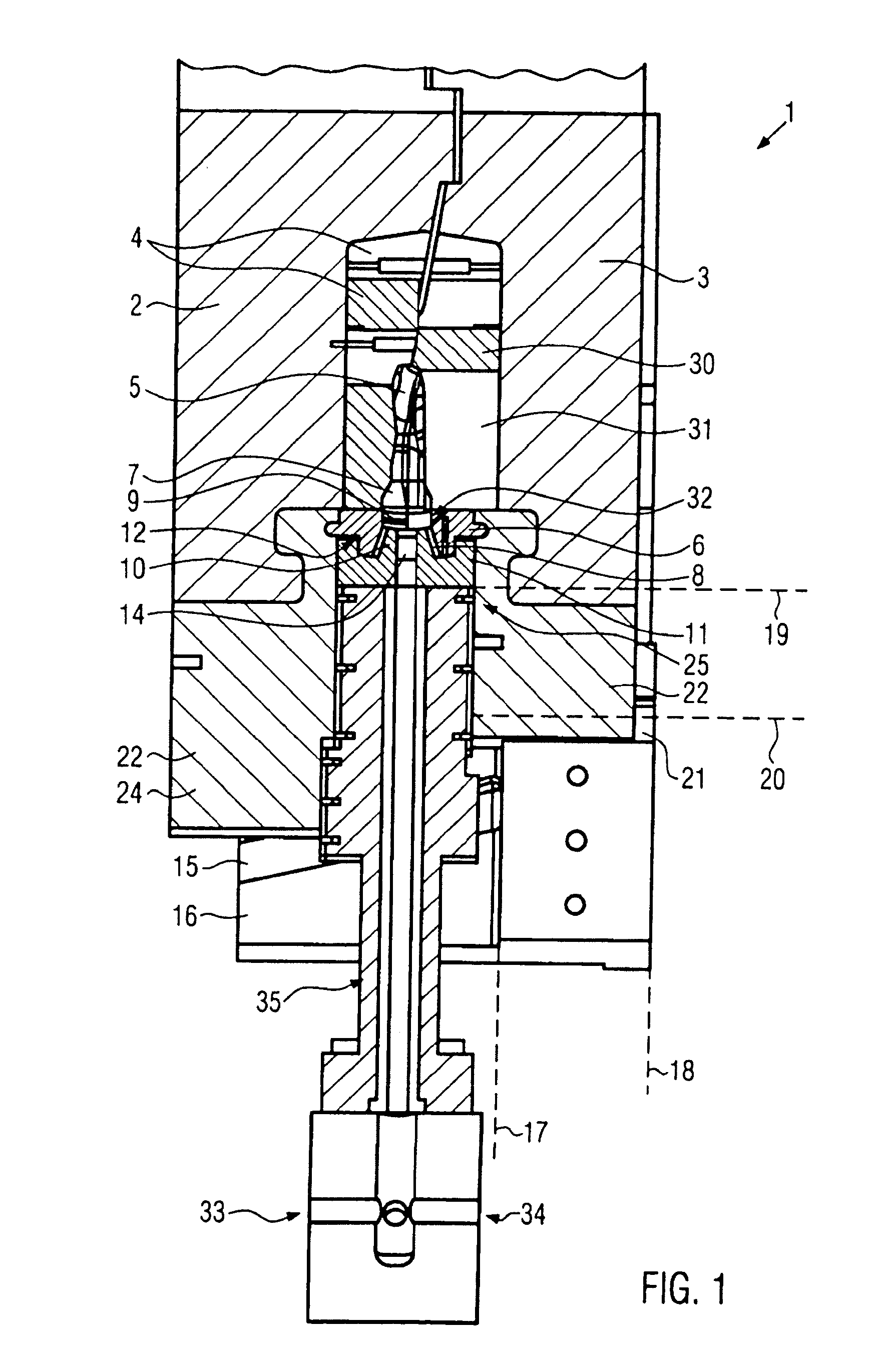

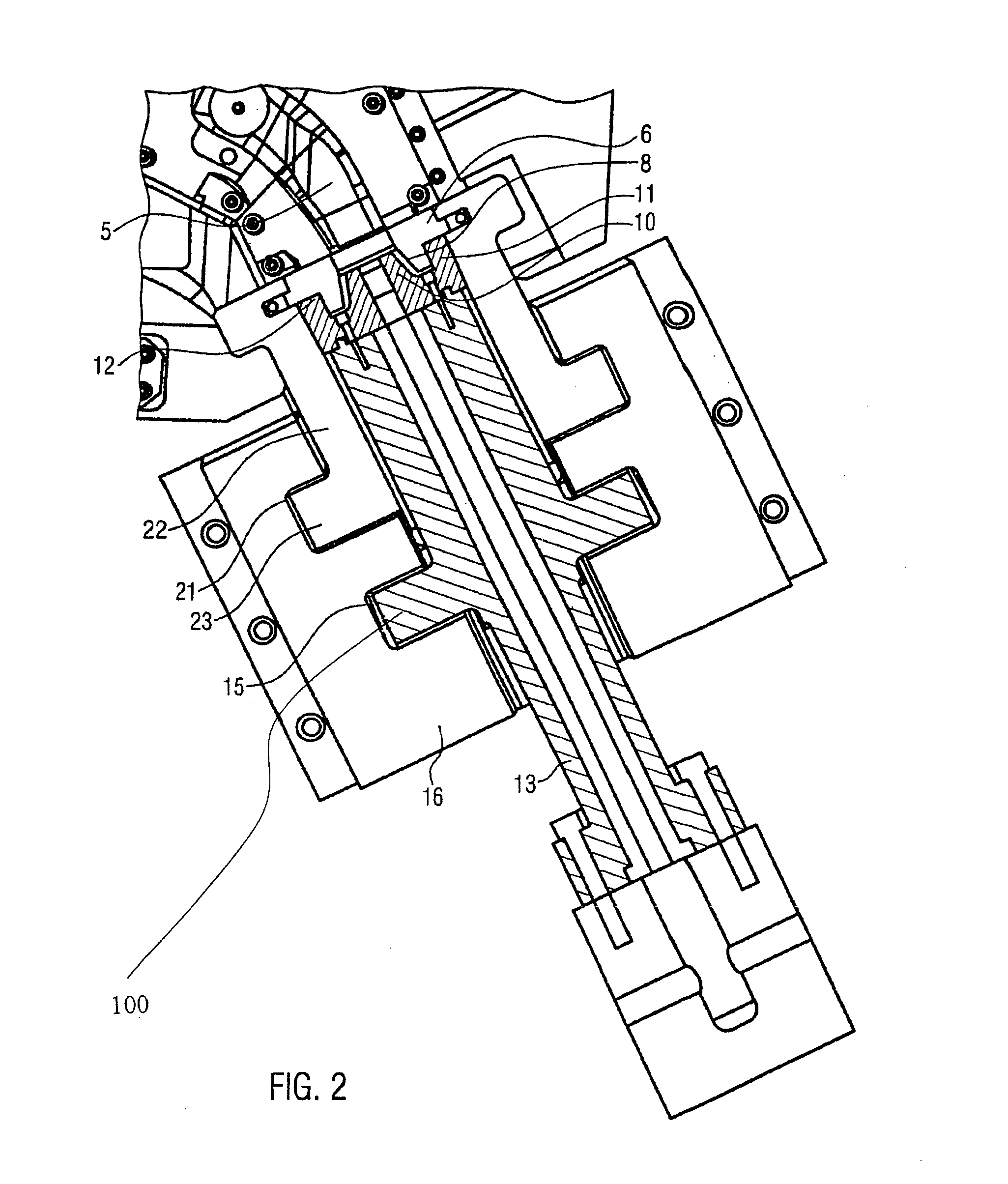

Device for explosive forming

ActiveUS8713982B2Easy to useGood detonationForging press detailsForging press drivesDetonationExplosive Agents

The invention relates to a device for explosive forming of workpieces, comprising an ignition chamber and an ignition mechanism, wherein an explosive agent can be ignited at an ignition location in the ignition chamber using the ignition mechanism, and an ignition chamber outlet is provided, to be improved such that the ignition mechanism has a longer service life. The aim is achieved by a device wherein an impact breaker is provided in the propagation path (37) of the detonation wave.

Owner:MAGNA INTERNATIONAL INC

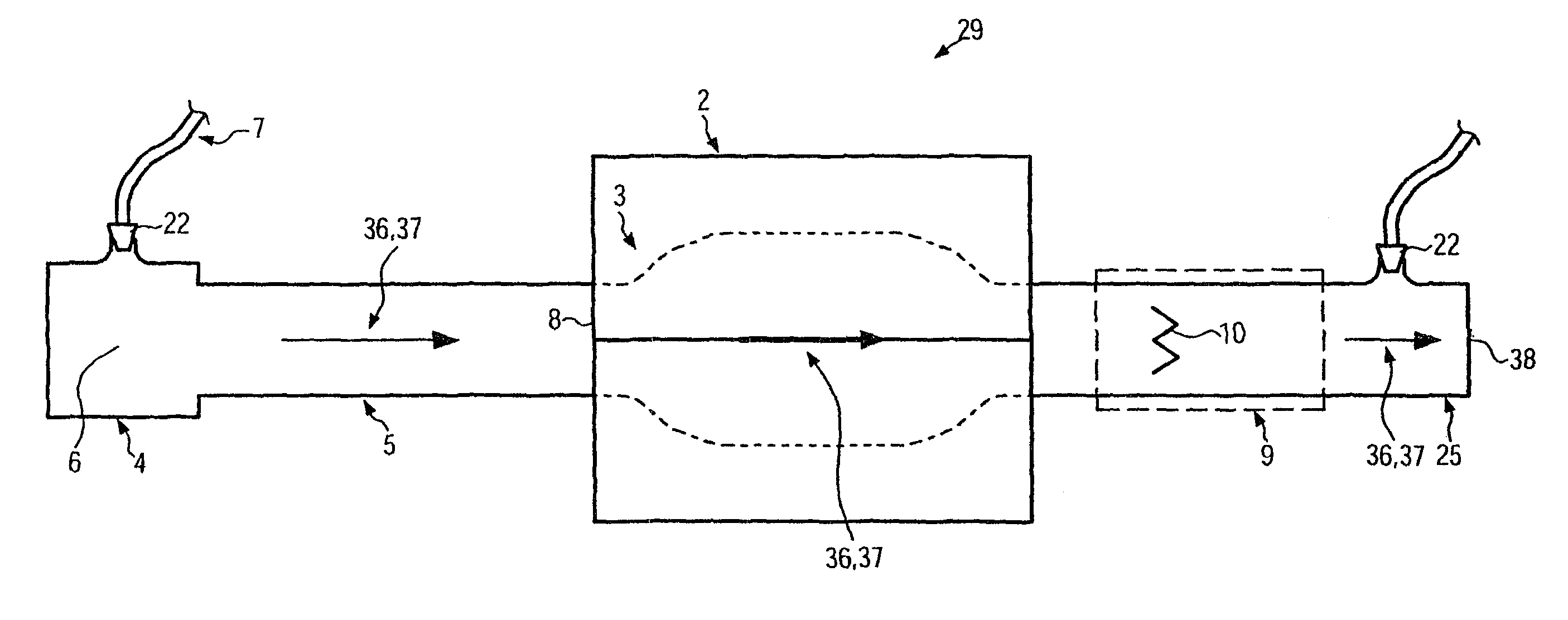

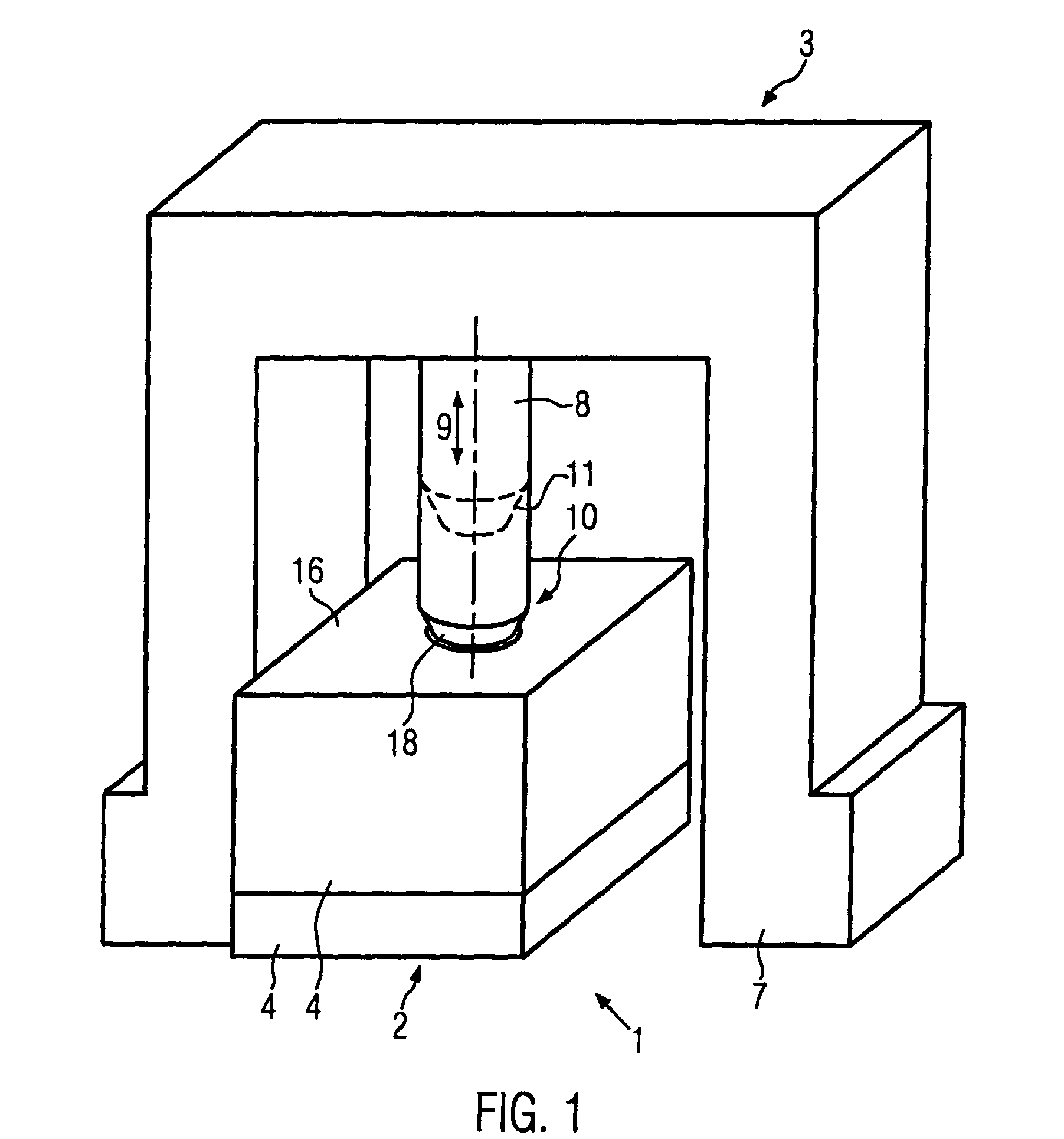

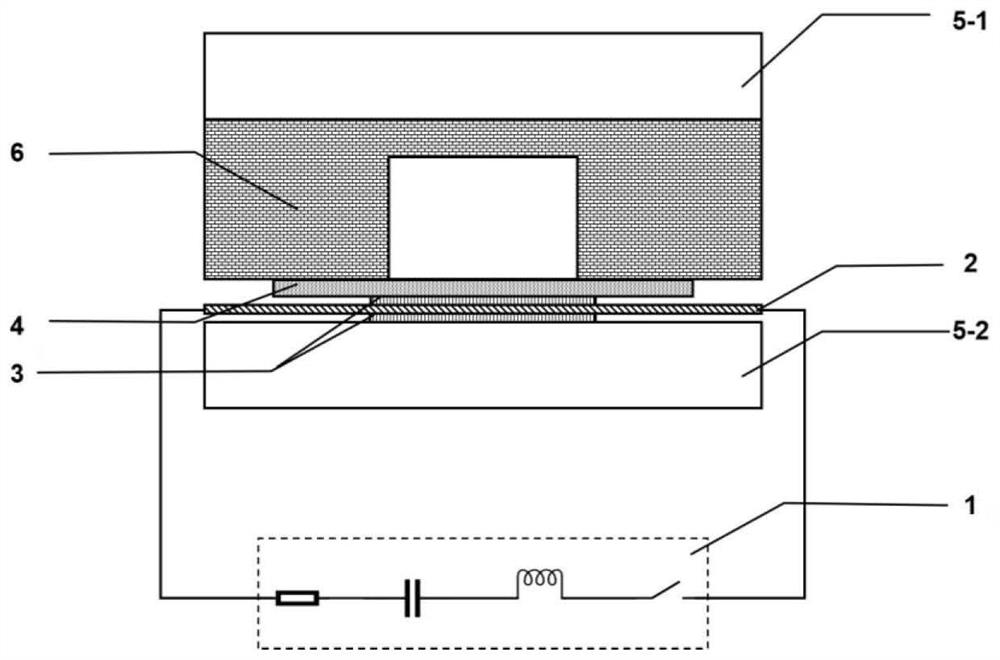

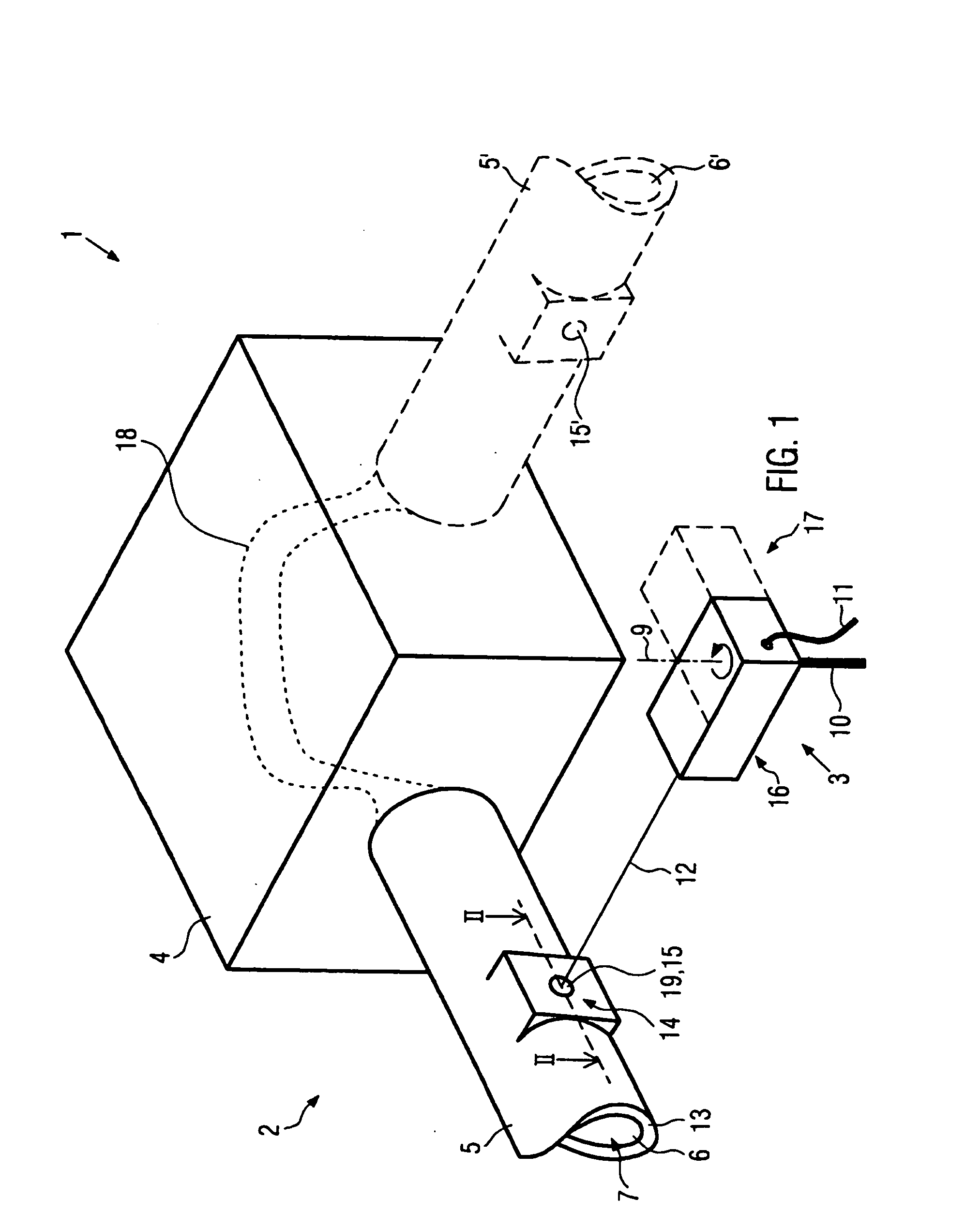

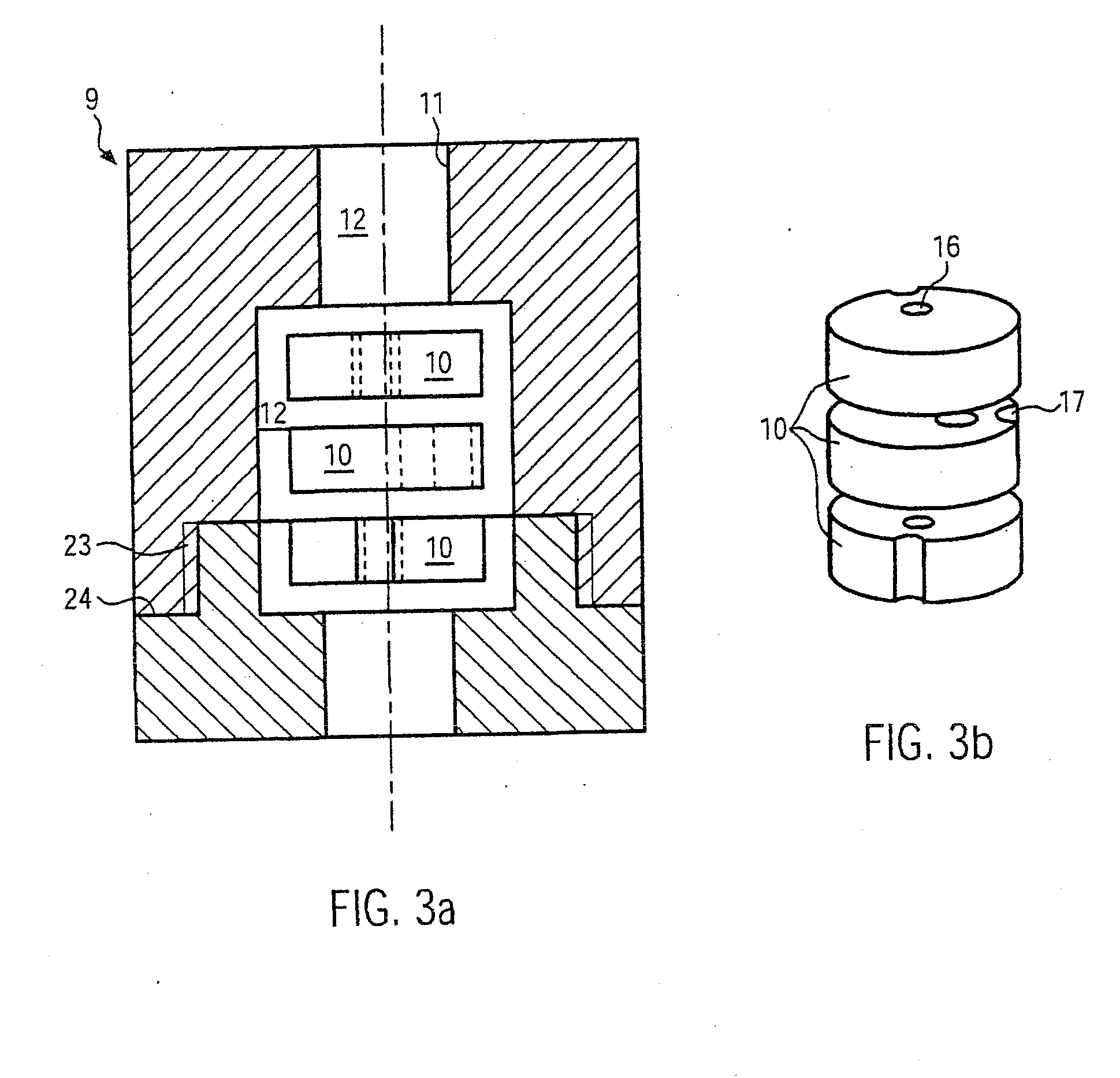

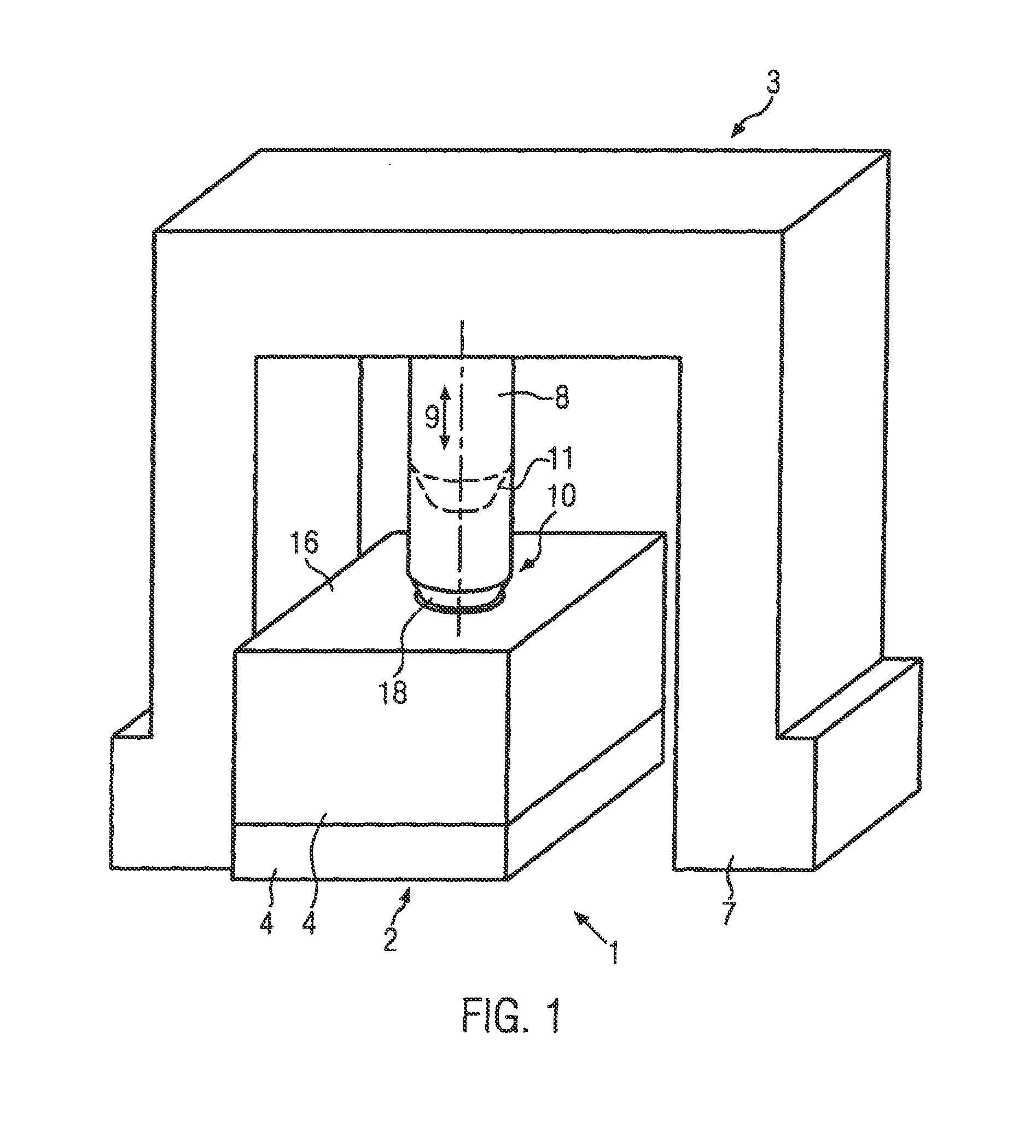

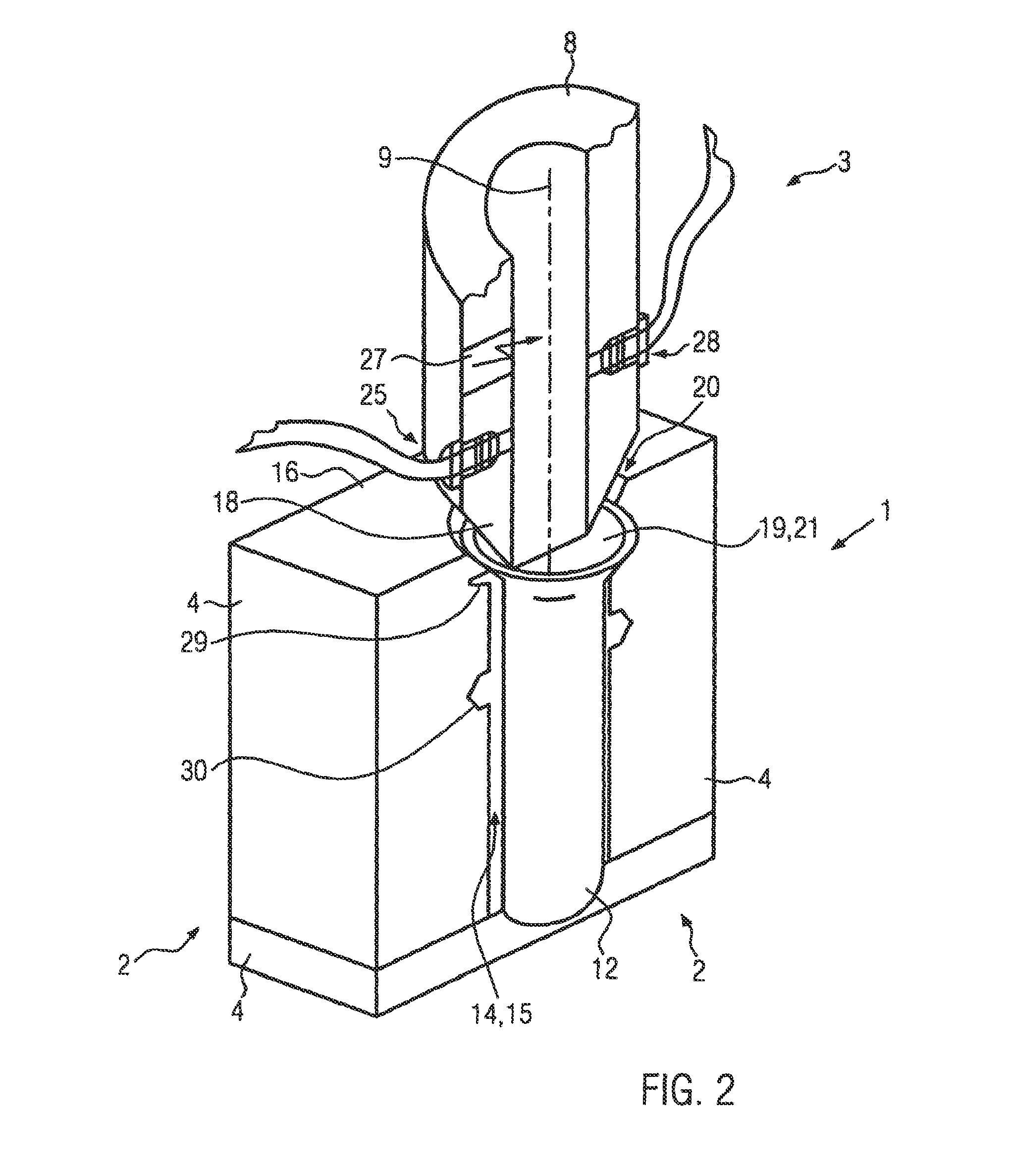

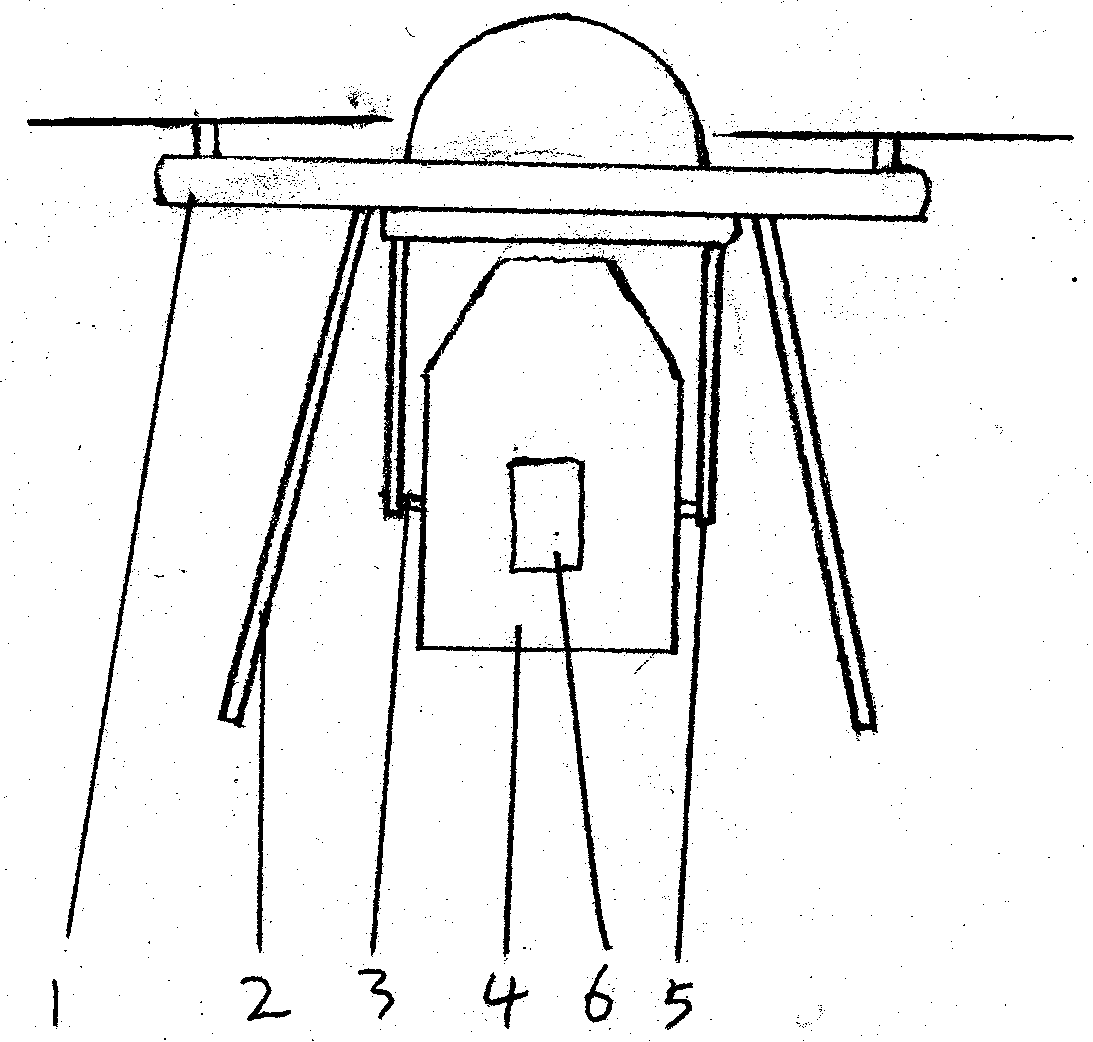

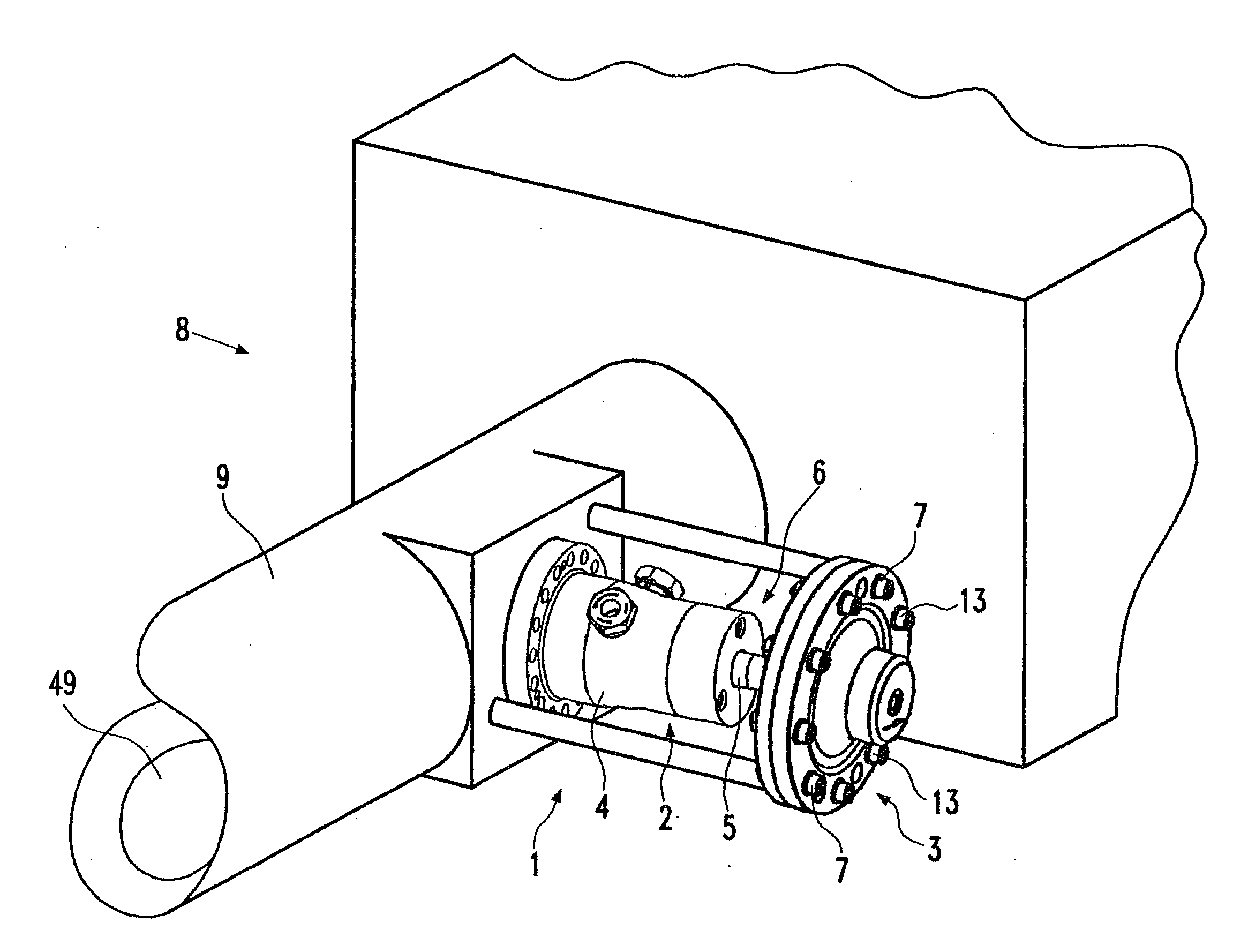

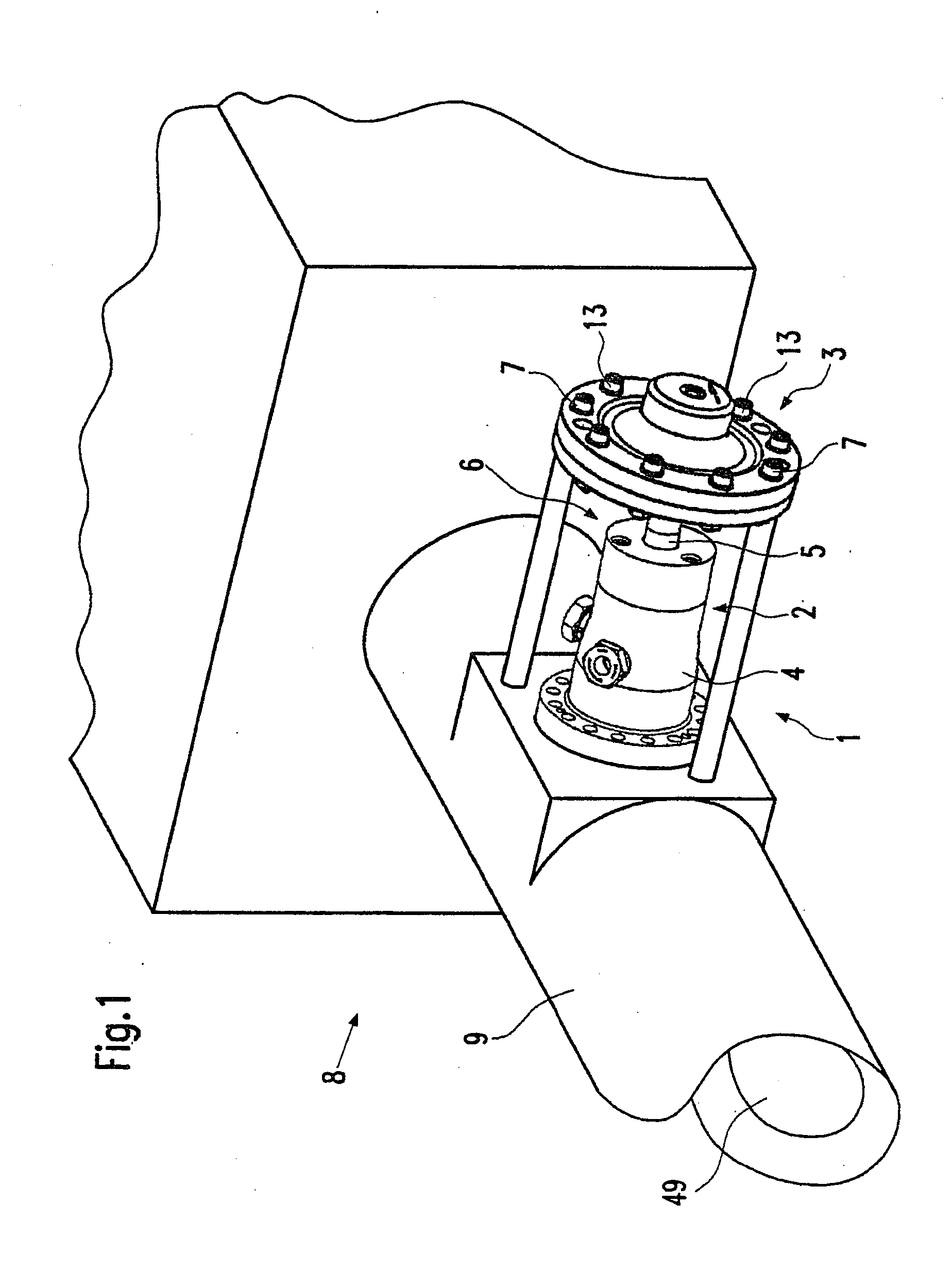

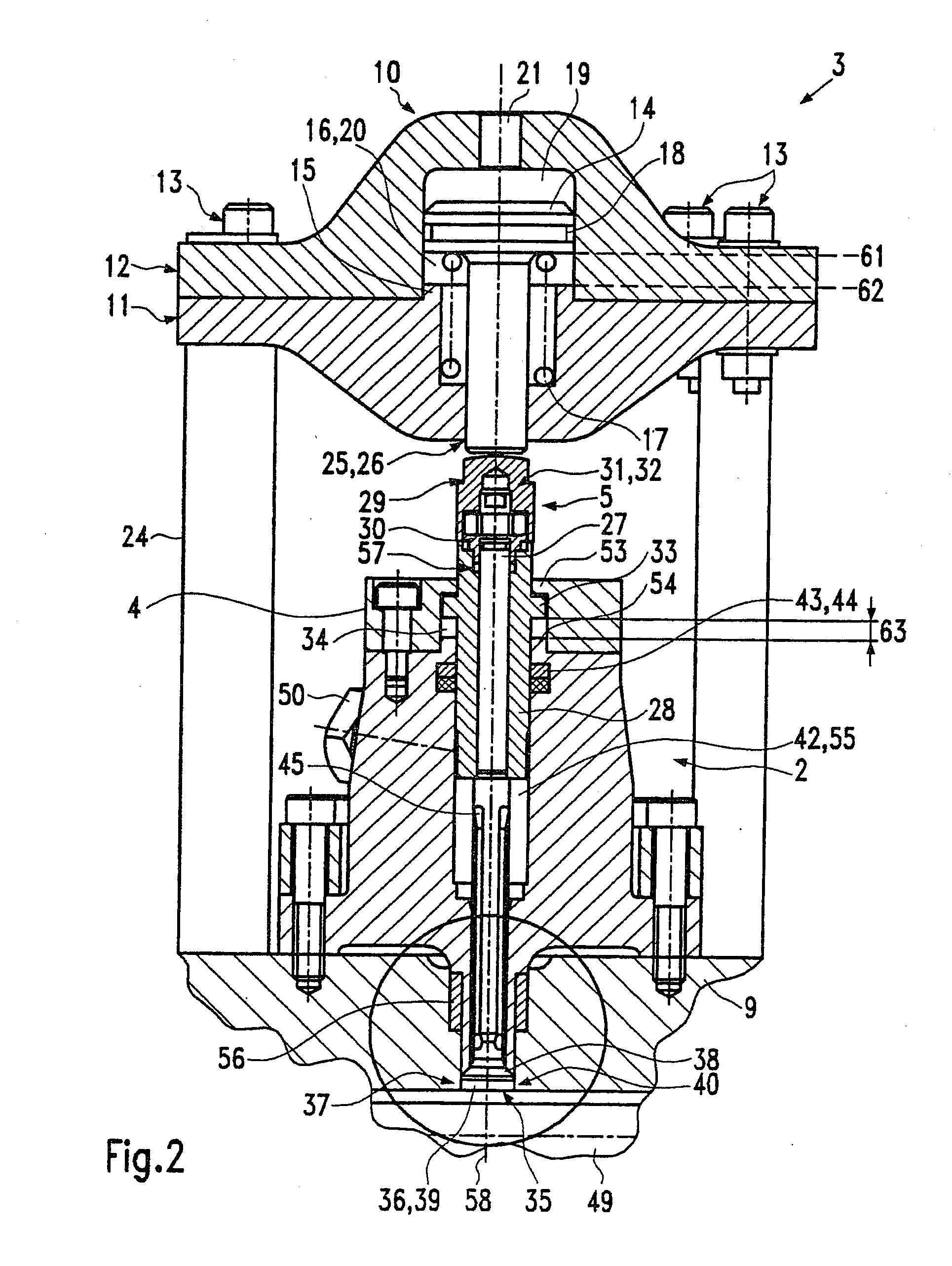

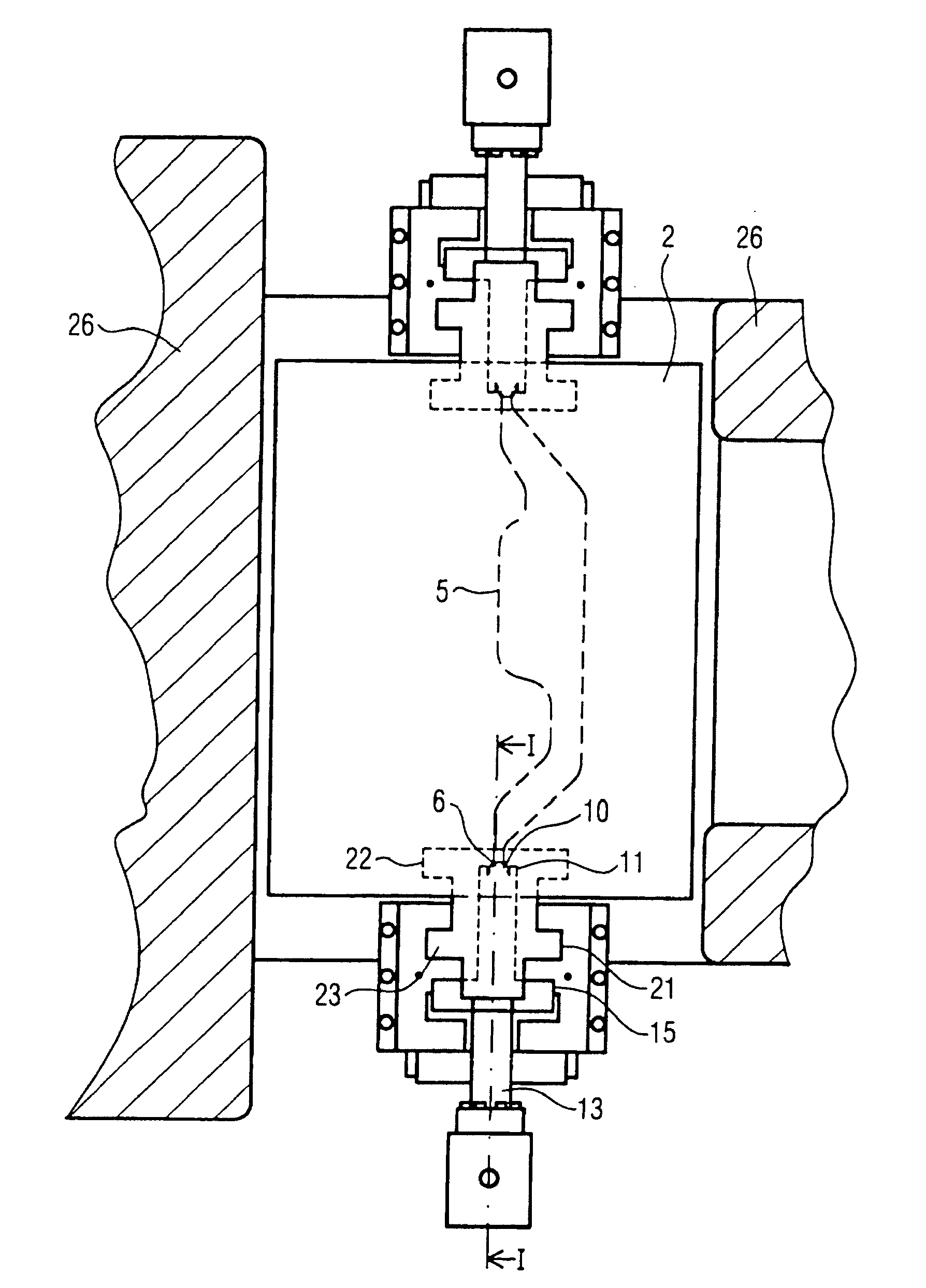

Method and mould arrangement for explosion forming

The invention is intended to improve a tool arrangement and method for explosive forming of a workpiece by means of gas explosion, in which the workpiece is arranged in a intake area of a molding tool, wherein the intake area is at least partially filled with liquid and the explosion is triggered by means of ignition of an explosive gas mixture, to the effect that the tool arrangement and the method are suitable and simplified for mass production. This object is solved by means of a tool arrangement and a method for explosive forming of a workpiece by means of gas explosion, in which the workpiece is arranged in a intake area of a molding tool, wherein the intake area is at least partially filled with liquid and the explosion is triggered by means of ignition of an explosive gas mixture, in which the explosive gas mixture is provided at least partially above the surface of the liquid before the ignition.

Owner:MAGNA INTERNATIONAL INC

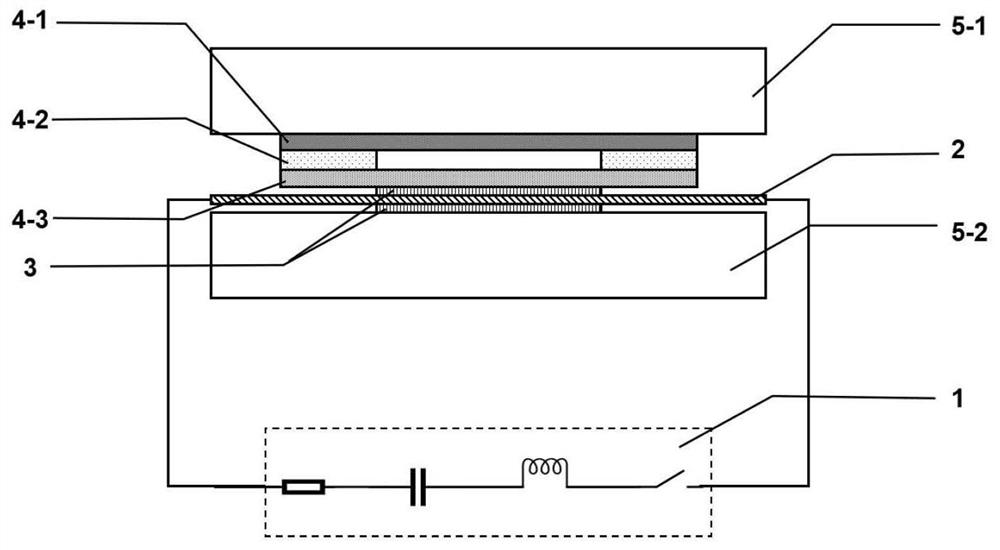

Device and method for forming workpiece by utilizing electrified explosive shock waves of metal foil

The invention provides a device and a method for forming a workpiece by utilizing electrified explosive shock waves of a metal foil. The method comprises the following steps: connecting the metal foil with a pulse power supply system to form a closed loop; putting metal foil is in a liquid environment; enabling the liquid in the liquid environment to be subjected to oxidation-reduction reaction with the metal foil; arranging a metal workpiece to be processed on the metal foil; enabling the metal workpiece to be machined to be partially located in the liquid environment, insulating the metal workpiece to be machined and the metal foil, thereby guaranteeing that liquid does not conduct electricity between the metal foil and the metal workpiece to be machined; introducing pulse current into the metal foil through the pulse power supply system, enabling the metal foil to explode under the action of the pulse current to generate violent shock waves, and enabling the metal foil and liquid in the liquid environment to be subjected to an oxidation-reduction reaction in the explosion process to release a large amount of energy; and under the action of the shock waves and the energy, enabling the metal workpiece to be machined to generate mechanical response to be machined and formed. The energy utilization rate in the explosive forming process of the metal foil is increased.

Owner:HUAZHONG UNIV OF SCI & TECH

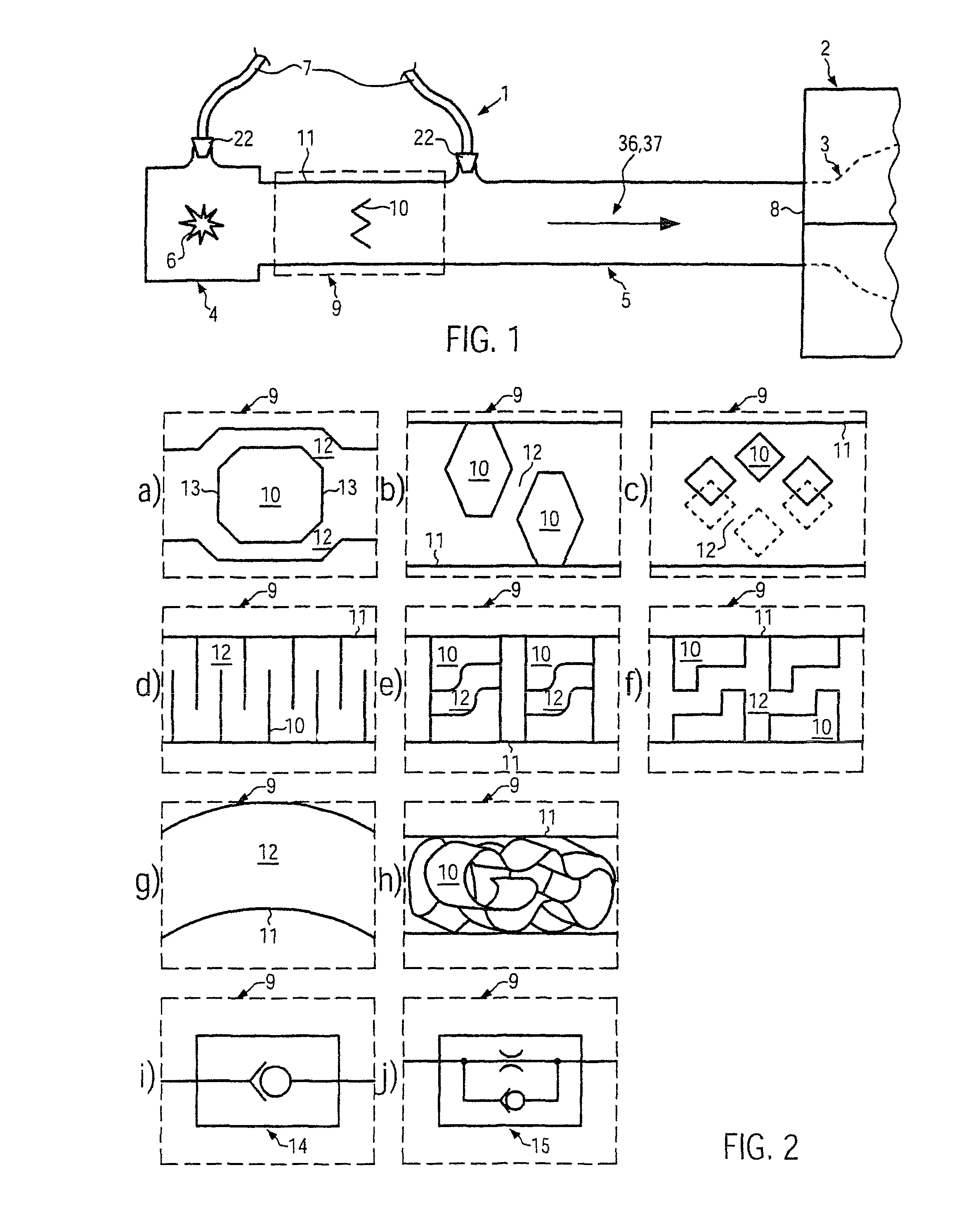

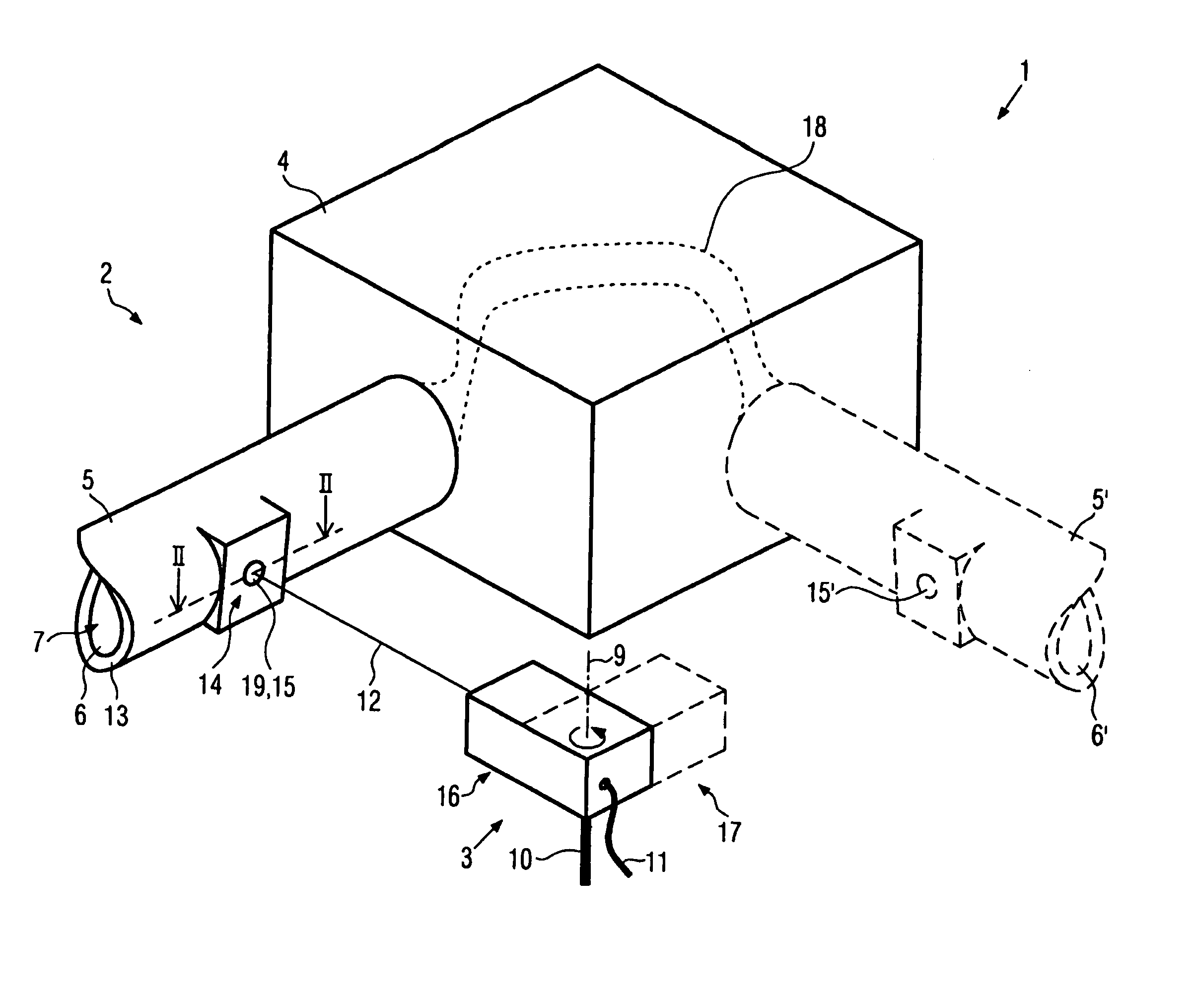

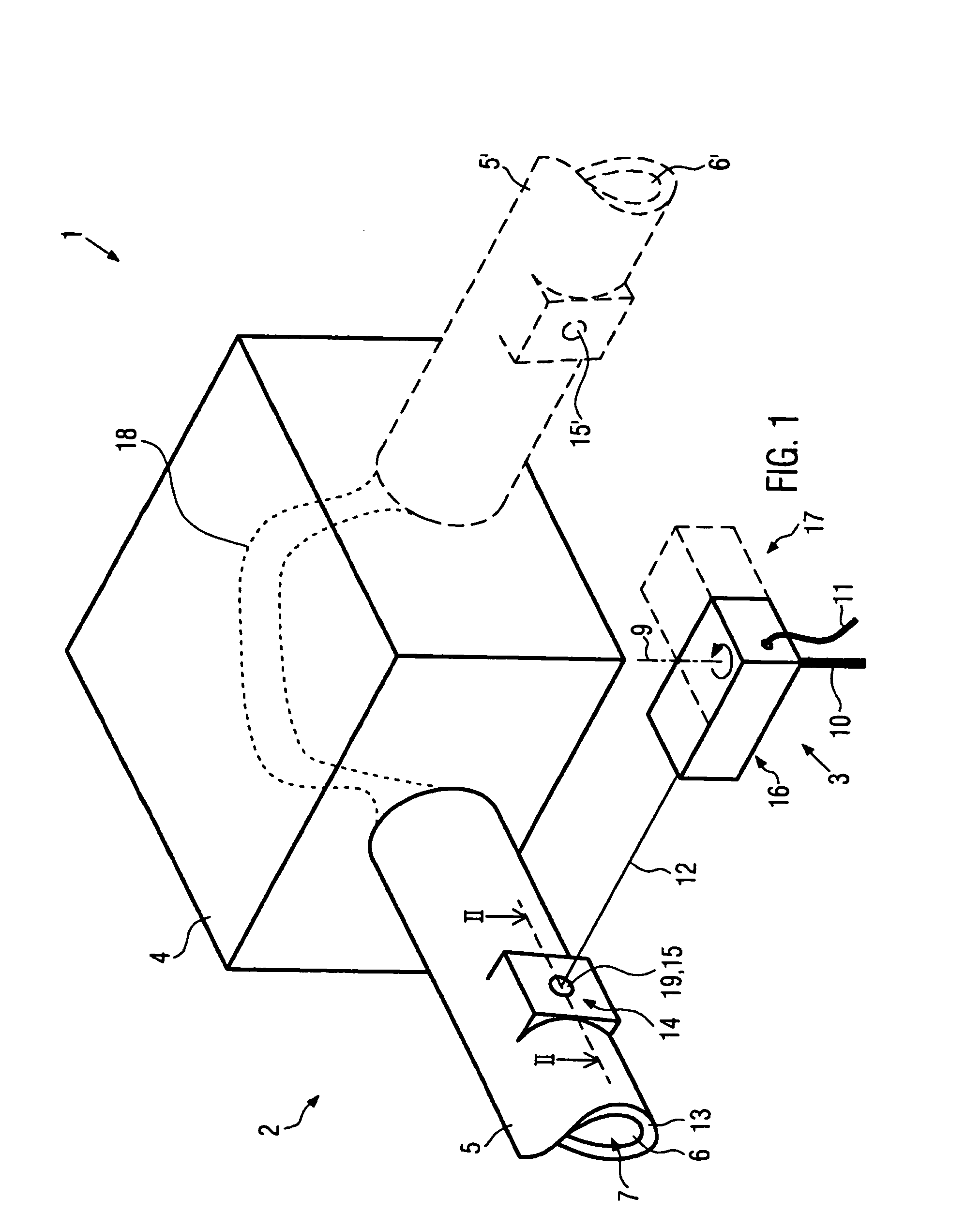

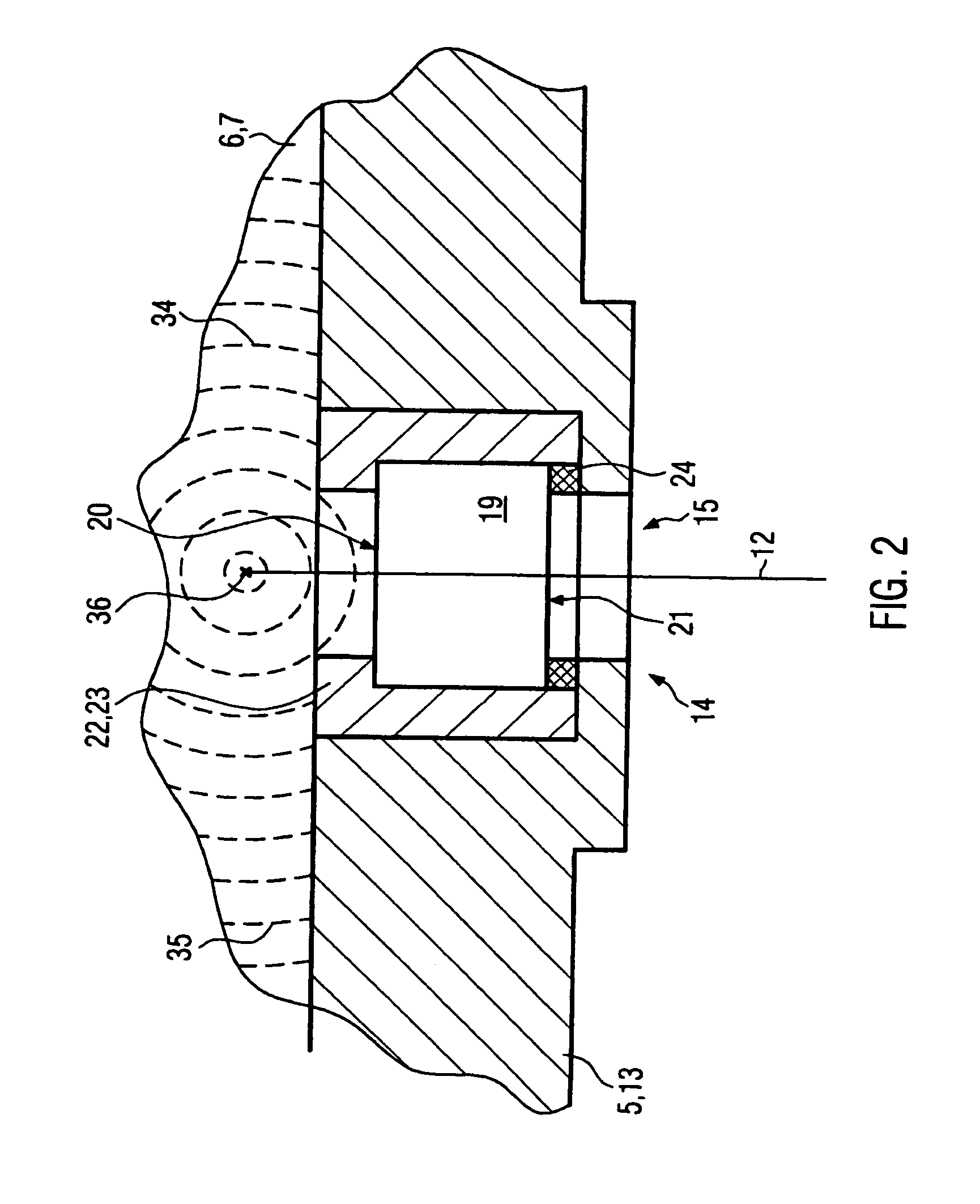

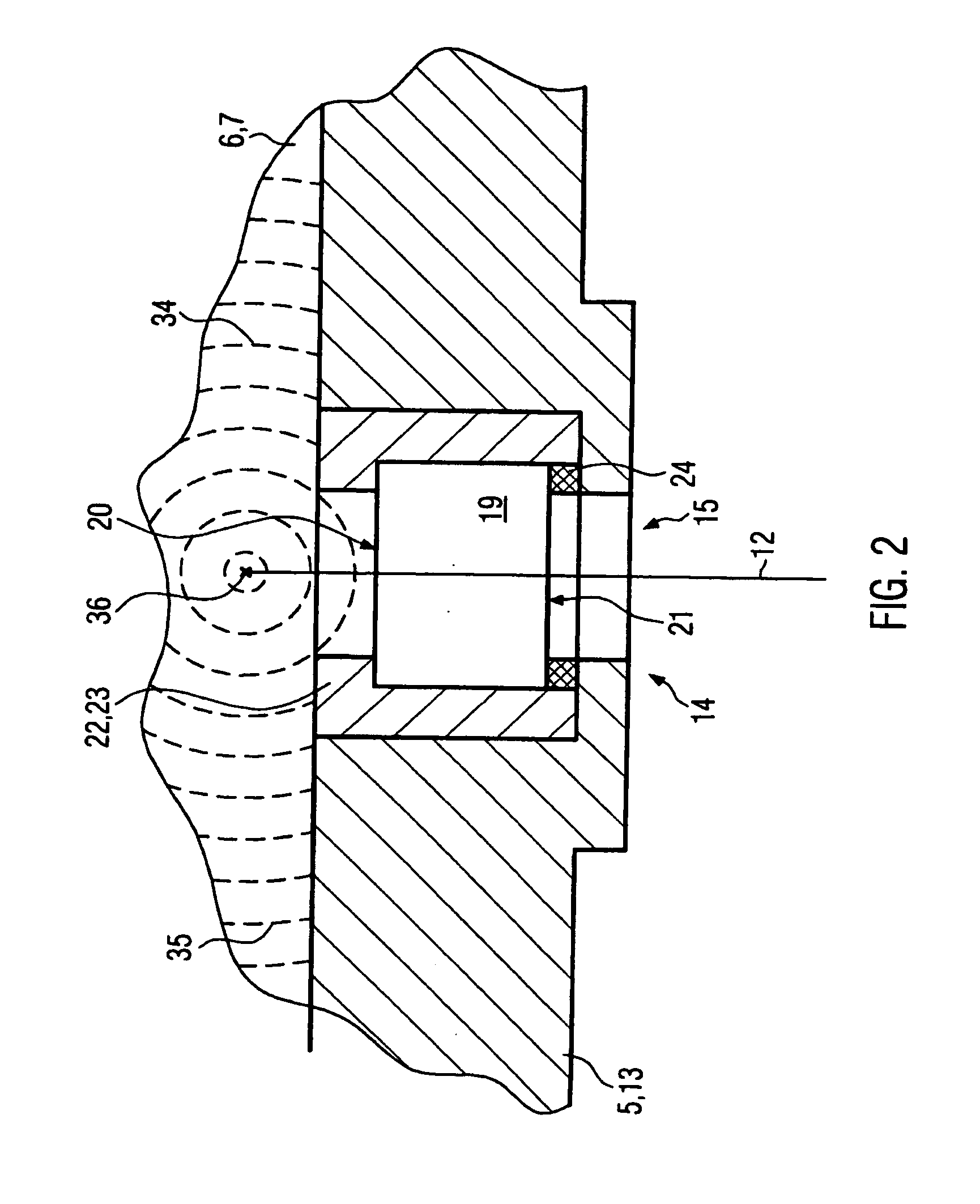

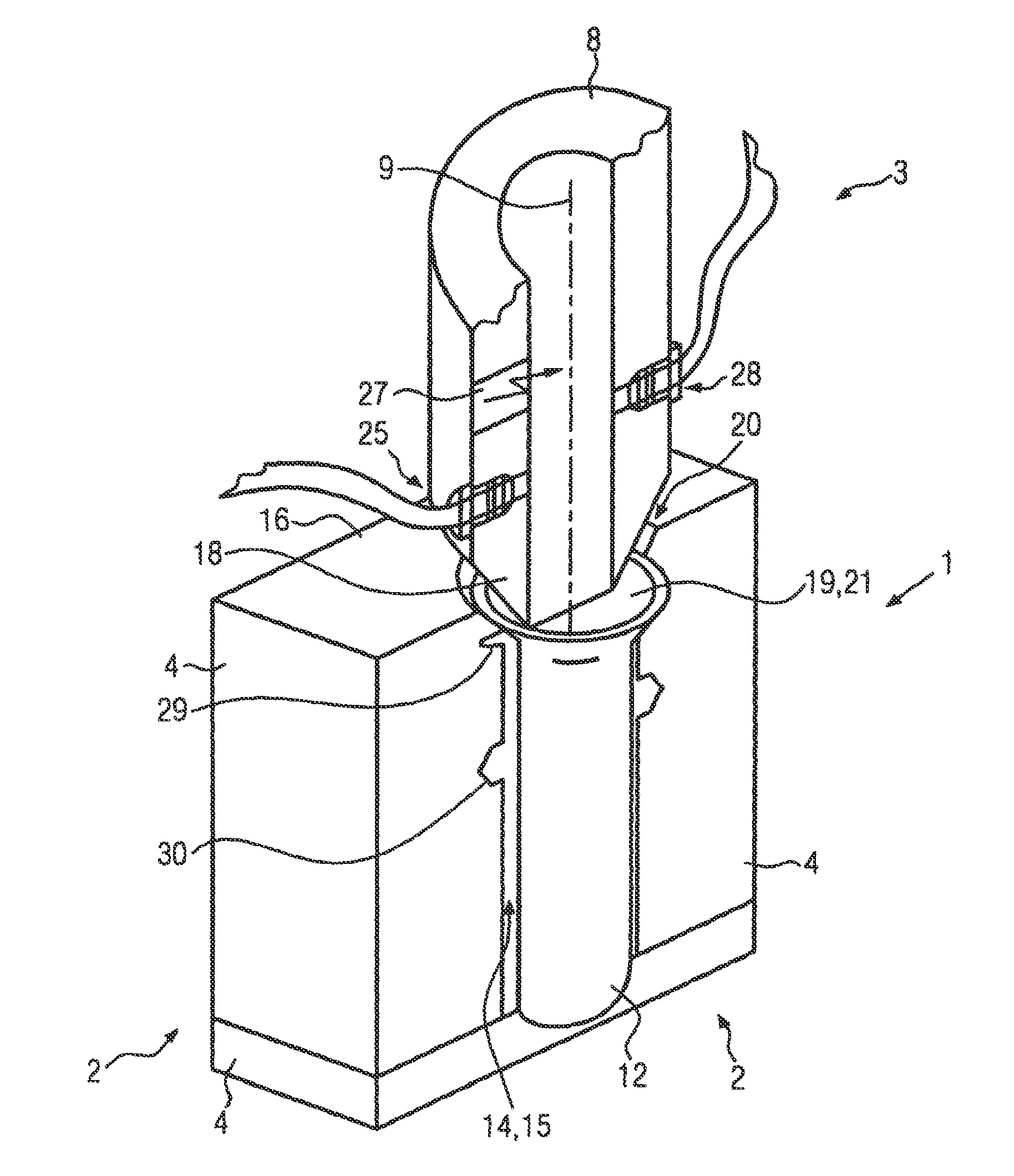

Method and device for explosion forming

ActiveUS8252210B2Easy to operateMost precise possible ignition of the explosiveExplosive working-up apparatusElectric/magnetic/electromagnetic heatingEngineeringExplosive forming

With the invention, a method and a device for explosive forming of work pieces, in which at least one work piece is arranged in at least one die and there deformed by means of an explosive to be ignited, is to be improved, in that an ignition mechanism that is technically easy to handle is produced with the shortest possible setup times, which permits the most precise possible ignition of the explosive with time-repeatable accuracy. This task is solved by a method and device, in which at least one work piece is arranged in at least one die and deformed there by means of an explosive being ignited, in which the explosive is ignited by means of at least one energy beam.

Owner:COSMA ENG EURO AG

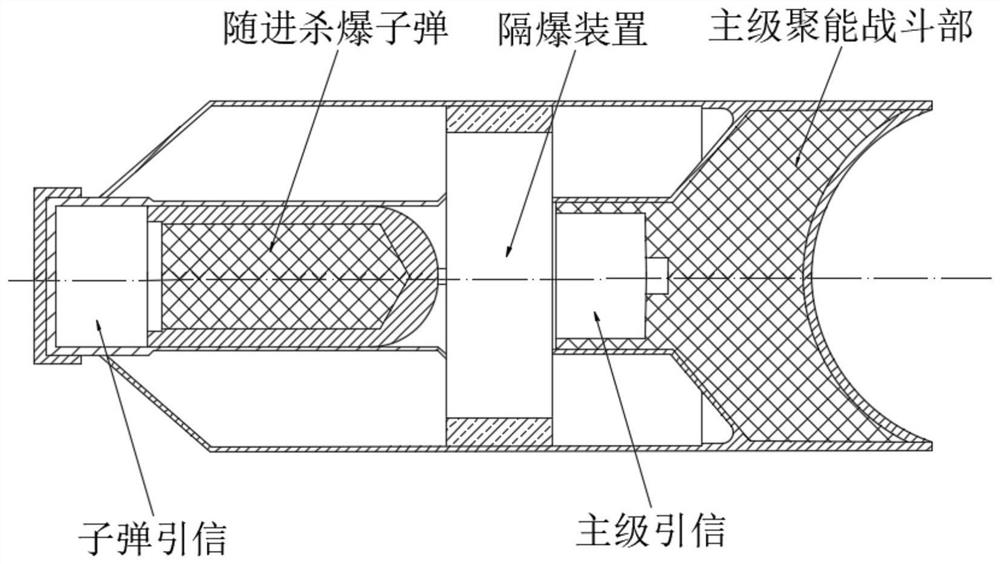

Single-stage shaped charge structure capable of forming penetrating and blasting time sequence combined effect

ActiveCN113513949AReduce complexitySimple structureAmmunition projectilesProjectilesChemical reactionShaped charge

The invention discloses a single-stage shaped charge structure capable of forming a penetrating and blasting time sequence combined effect. Under the action of low-detonation-velocity charge and the control of a segment-shaped structure, an active shaped charge liner forms a trailing explosive forming bullet EFP, the trailing explosive active EFP is also activated in the forming process, a violent chemical reaction occurs during macroscopic flight, meanwhile, under the action of high-detonation-velocity charge and the control of a cone and circular truncated cone structure, the metal shaped charge liner forms high-speed precursor metal rod flow, and the trailing explosive active EFP flies forwards, so that a series-connection detonation penetration body composed of the precursor metal rod flow and the trailing explosive active EFP is formed, thus, the precursor metal rod flow firstly conducts penetration on a target through kinetic energy and forms a pre-perforated hole, the trailing explosive active EFP enters the interior of the target, then the trailing explosive active EFP is utilized to generate a violent deflagration reaction inside the interior of the target, an aftereffect damage enhancement effect is caused, and therefore the penetration depth and the aftereffect effect are both considered.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Method and device for explosion forming

ActiveUS20100207287A1Easy to operateMost precise possible ignition of the explosiveExplosive working-up apparatusElectric/magnetic/electromagnetic heatingExplosive AgentsEngineering

With the invention, a method and a device for explosive forming of work pieces, in which at least one work piece is arranged in at least one die and there deformed by means of an explosive to be ignited, is to be improved, in that an ignition mechanism that is technically easy to handle is produced with the shortest possible setup times, which permits the most precise possible ignition of the explosive with time-repeatable accuracy. This task is solved by a method and device, in which at least one work piece is arranged in at least one die and deformed there by means of an explosive being ignited, in which the explosive is ignited by means of at least one energy beam.

Owner:COSMA ENG EURO AG

Device for explosive forming

The invention relates to a device for explosive forming of workpieces, comprising an ignition chamber and an ignition mechanism, wherein an explosive agent can be ignited at an ignition location in the ignition chamber using the ignition mechanism, and an ignition chamber outlet is provided, to be improved such that the ignition mechanism has a longer service life. The aim is achieved by a device wherein an impact breaker is provided in the propagation path (37) of the detonation wave.

Owner:MAGNA INTERNATIONAL INC

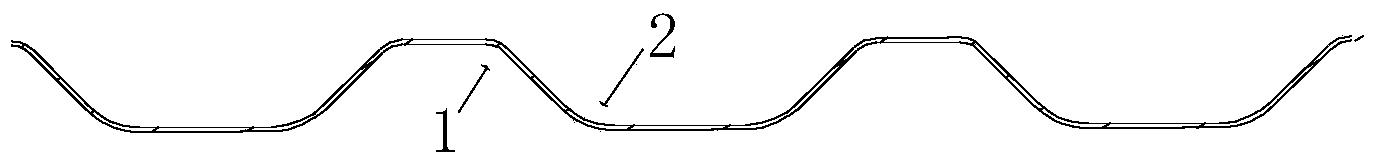

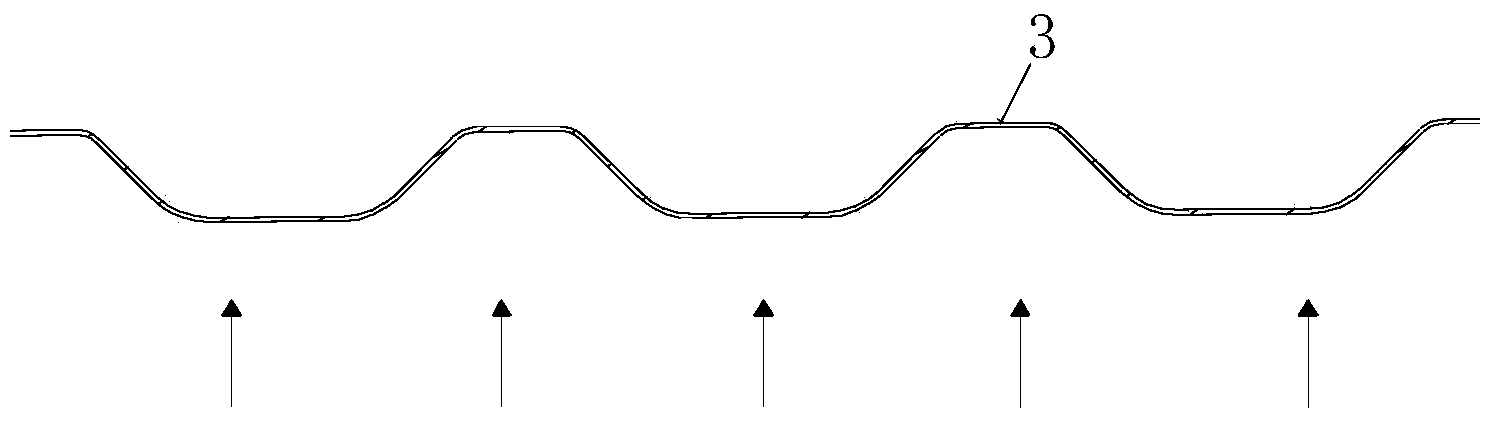

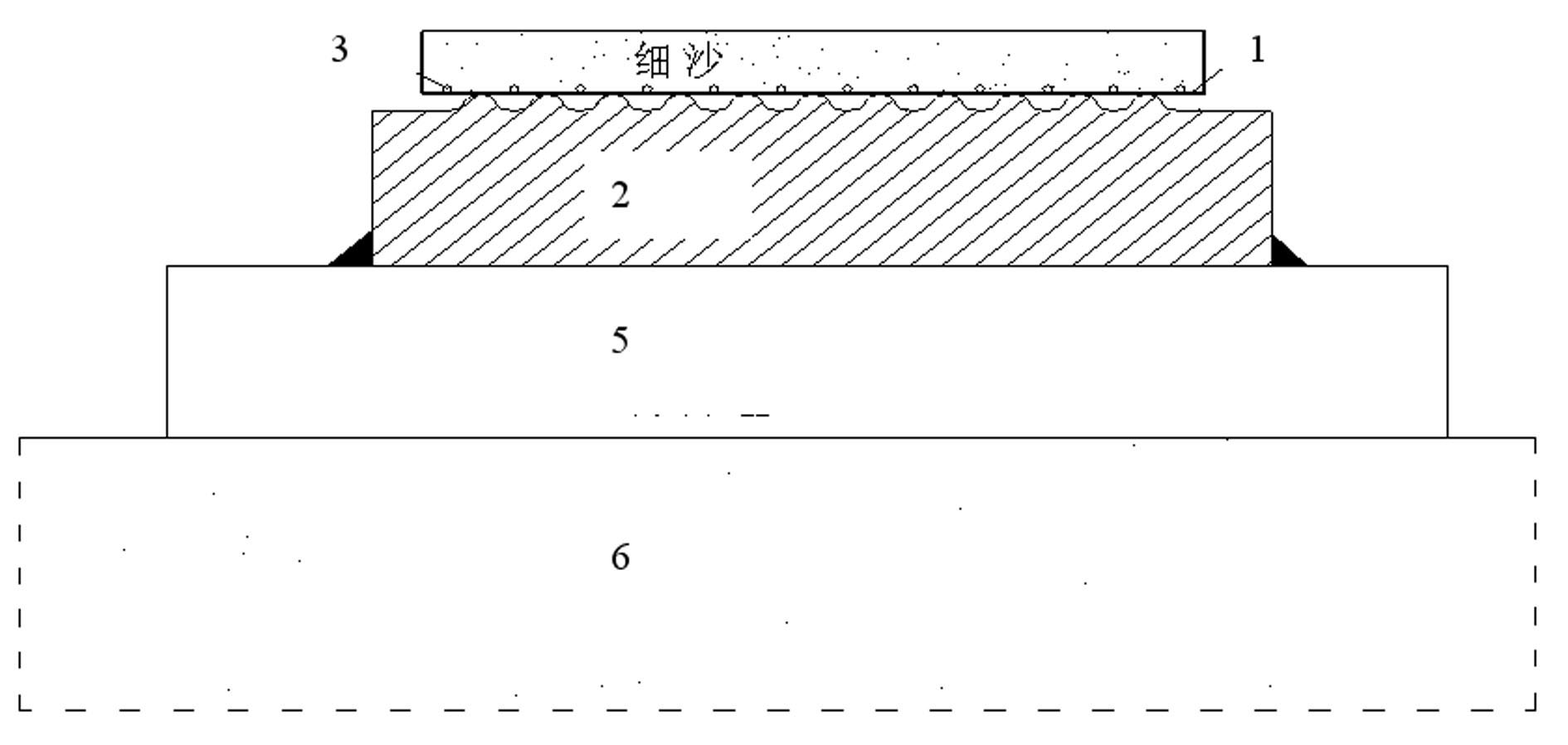

Explosive forming method of arc-wave titanium anode plate

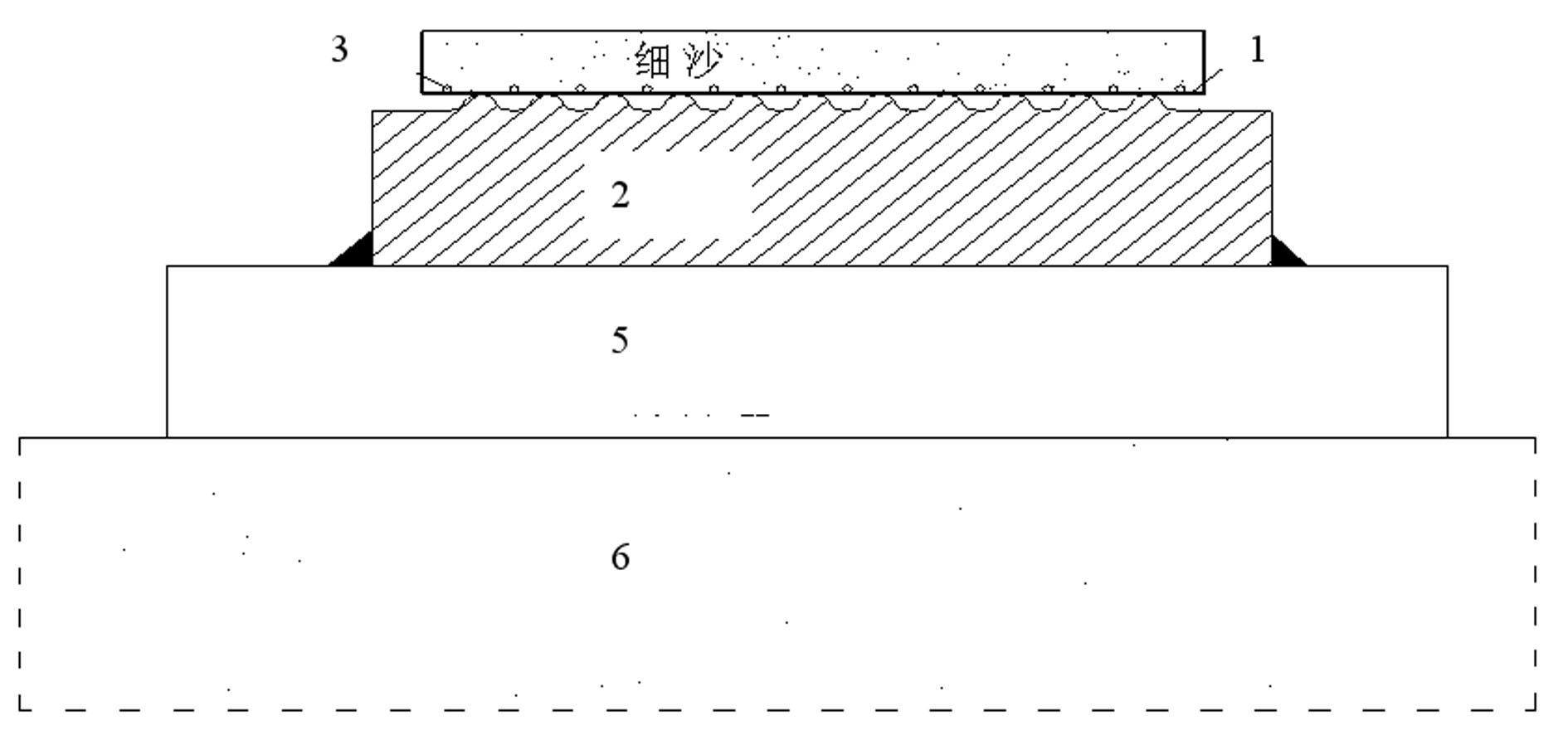

The invention relates to an explosive forming method of an arc-wave titanium anode plate. The titanium anode plate is exploded to form an arc-wave-shaped titanium anode plate of which the cross section is distributed in a uniform arc-wave mode. The method comprises the following steps: arranging a uniform arc-wave-shaped die on the bottom of a titanium plate, and fixing an expansion tube blasting fuse at the center of a die groove on the surface of the titanium plate, wherein the blasting fuse is not shorter than the die groove; and uniformly spreading fine sand on the expansion tube blasting fuse and the titanium anode plate, and simultaneously igniting the expansion tube blasting fuse to form the arc waves of the titanium anode plate at the same time. In the invention, the arc-wave anode plate is processed by explosion; and the anode plate is formed under the explosive action of the blasting fuse distributed by being matched with the wave of the die, thereby increasing the strength of the wave plate and enhancing the service performance of the material. Meanwhile, the invention reduces the large-size pressing machine and other facilities, lowers the energy consumption, enhances the production efficiency and lowers the production cost.

Owner:黄山顺钛新材料科技有限公司

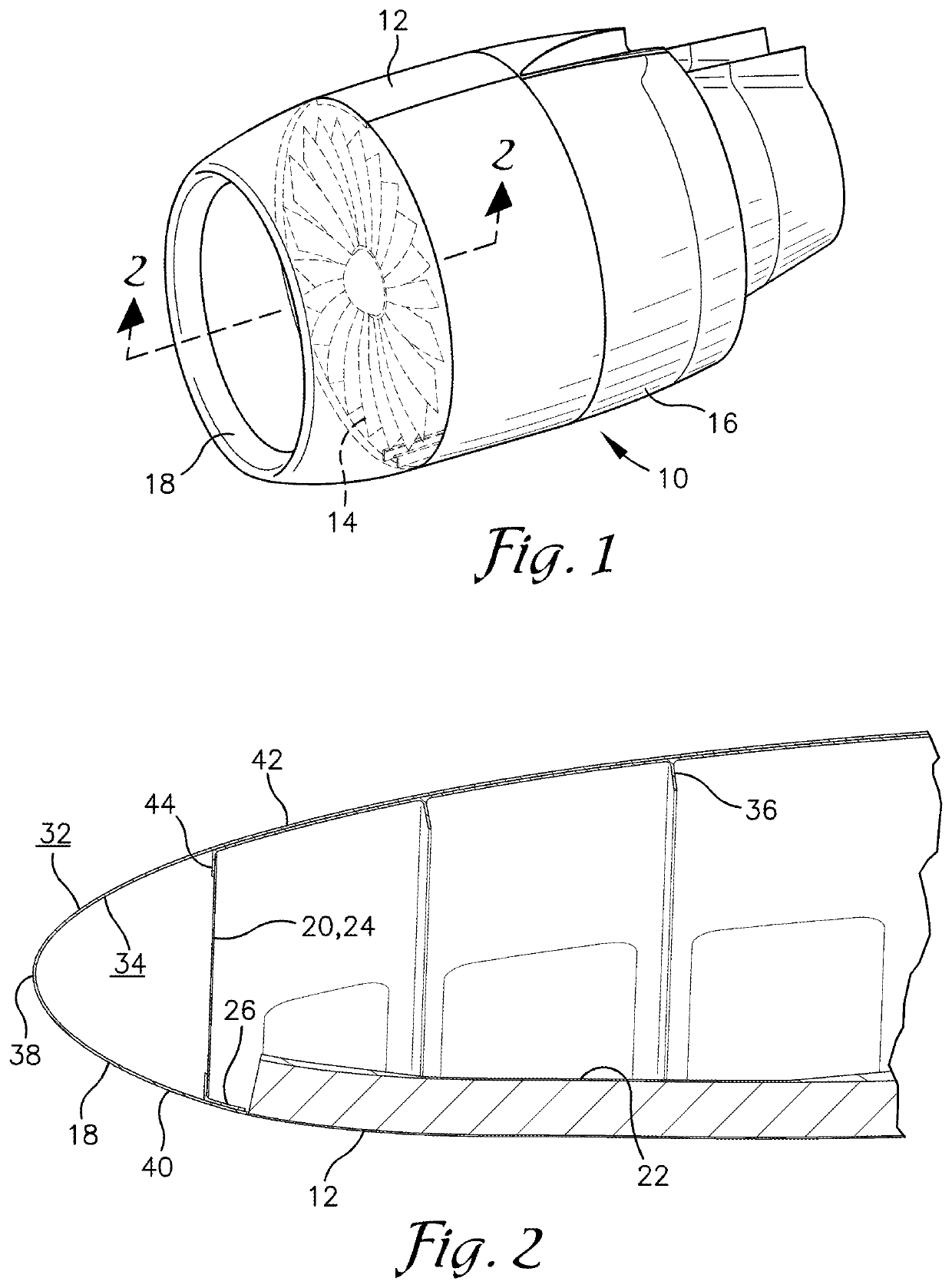

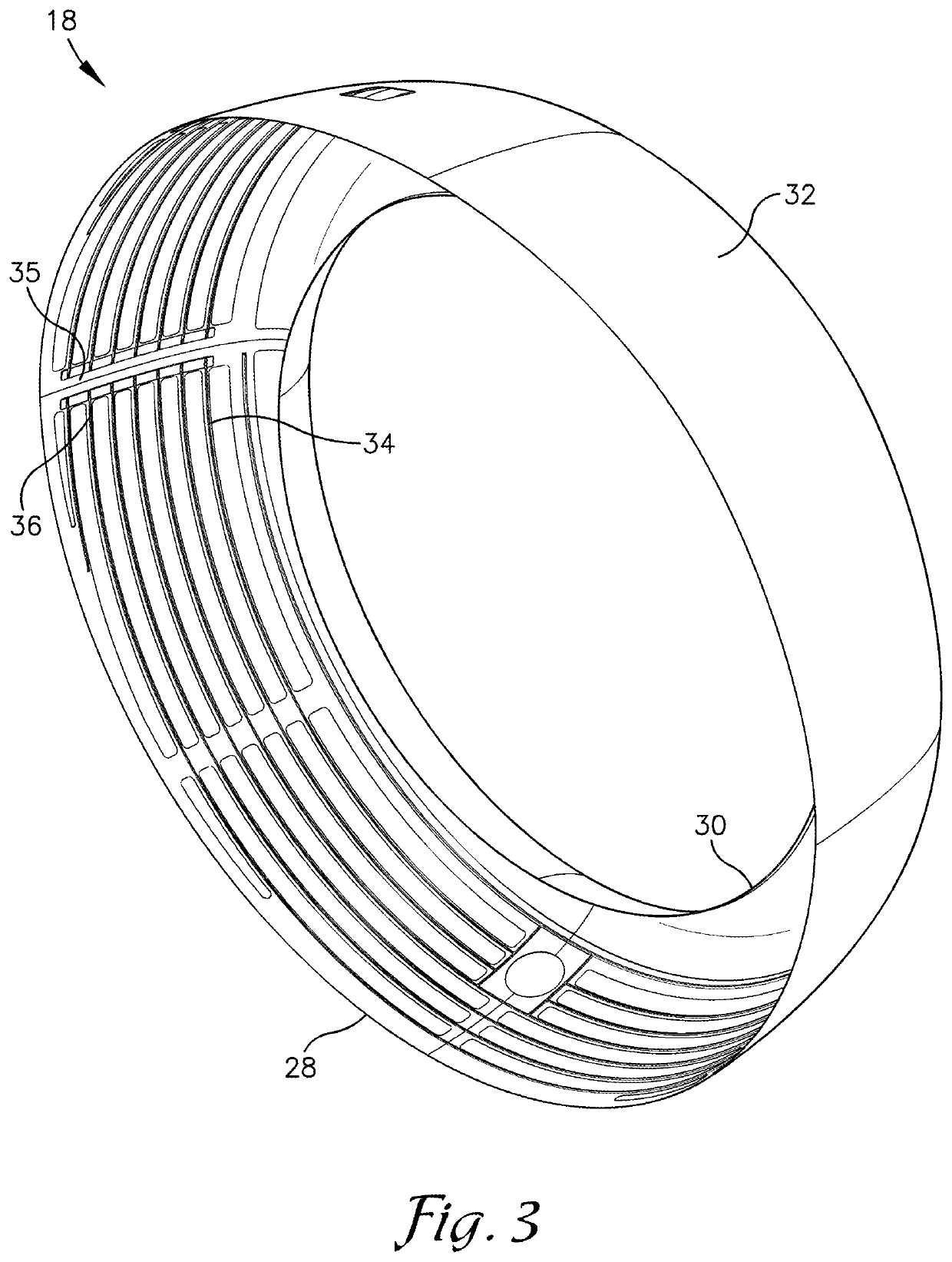

Monolithic lipskin and method of fabrication

An aircraft nacelle and method of fabricating a monolithic lipskin of the nacelle. The nacelle may include a fan cowl, a bulkhead, and the monolithic lipskin. The lipskin may be formed by spin-forming or explosive forming an annularly-shaped plate onto a mandrel, and machining or chemically-milling integrated stiffeners or other protrusions and attachment tabs into an inner mold line (IML) of the lipskin. The machining or chemical milling may occur before or after the spin-forming or explosive forming. The stiffeners may have a spiral or circumferential configuration. An attachment tab extending from the IML may attach to the bulkhead, such that an outer mold like (OML) of the lip-skin is not disrupted by mechanical fasteners attaching the lipskin to the bulkhead.

Owner:SPIRIT AEROSYSTEMS

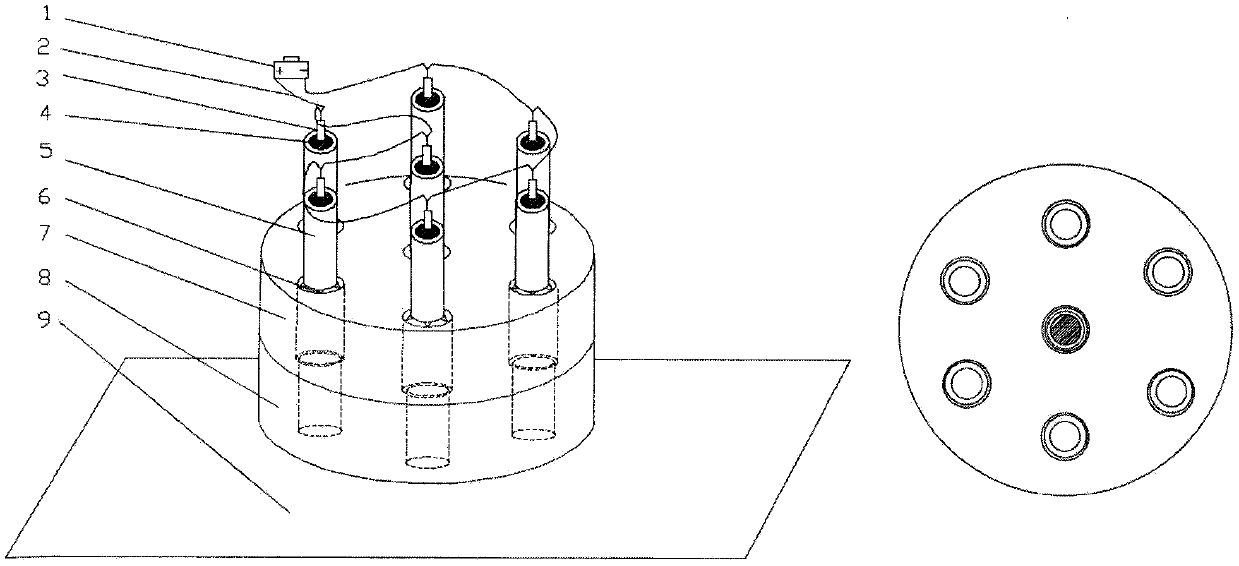

Multiple thin wall titanium tube and steel tube sheet hole simultaneous explosive welding composite tube sheet and method

InactiveCN110170731AAchieve weldingEnsure safetyNon-electric welding apparatusProduction rateDetonator

Provided are a multiple thin wall titanium tube and steel tube sheet hole simultaneous explosive welding composite tube sheet and a multiple thin wall titanium tube and steel tube sheet hole simultaneous explosive welding method. The multiple thin wall titanium tube and steel tube sheet hole simultaneous explosive welding method includes following steps: first, filling thin wall titanium tubes with explosives obtained through an optimized formula, wherein the wall thickness of the thin wall titanium tubes is 1-2mm, the optimized formula consists of components by weight part: 60-70 parts of theexplosives and the balance of ingredients composed of salt, perlite and saw powder, and the weight ratio of the salt, the perlite and the saw powder in the ingredients is 2:1:1; exposing unstable detonation ends out of two surfaces of a steel sheet separately by 2-10cm in explosive loading; secondly, controlling the distance between the outer wall of each thin wall titanium tube and the inner wall of each steel tube sheet hole as S=0.2*(delta+h), wherein the h is the thickness of titanium steel obtained after explosive forming, the delta is the diameter of the filling explosives, and the h isfar less than the delta; thirdly, using a series firing network for connecting all detonators, and controlling the length of a firing circuit within 200m. The multiple thin wall titanium tube and steel tube sheet hole simultaneous explosive welding method not only can guarantee safety of a heat exchanger, but also greatly prolongs use life of the heat exchanger, is high in production rate, can achieve welding forming of all tubes and tube sheets of the whole heat exchanger at a time.

Owner:ARMY ENG UNIV OF PLA

Flat-plate-shaped fusion casting explosive forming process design method

ActiveCN110256177AFlexible adjustmentWide coverageExplosive working-up apparatusExplosive formingProcess design

A flat-plate-shaped fusion casting explosive forming process design method is used for carrying out simulation design on a flat-plate-shaped fusion casting explosive casting and forming process unit and comprises the steps that A, a tool model is designed; step B, material parameters are acquired; c, a casting process is designed; and D, a forming process is designed. The method is suitable for abstract modeling and process design in the casting and forming processes of the flat-plate-shaped fused cast explosives of various sizes and specifications, wide in coverage and high in flexibility.

Owner:XIAN MODERN CHEM RES INST

Method And Mould Arrangement For Explosion Forming

ActiveUS20160089709A1Simple methodSuitable for massForging press detailsForging press drivesEngineeringGas explosion

The invention is intended to improve a method for explosive forming of a workpiece by means of gas explosion, in which the workpiece is arranged in a intake area of a moulding tool, wherein the intake area is at least partially filled with liquid and the explosion is triggered by ignition of an explosive gas mixture, to the effect that the method is suitable and simplified for mass production. This object is solved by a method for explosive forming of a workpiece by means of gas explosion, in which the workpiece is arranged in a intake area of a moulding tool, wherein the intake area is at least partially filled with liquid and the explosion is triggered by means of ignition of an explosive gas mixture, in which the explosive gas mixture is provided at least partially above the surface of the liquid before the ignition.

Owner:COSMA ENG EURO AG

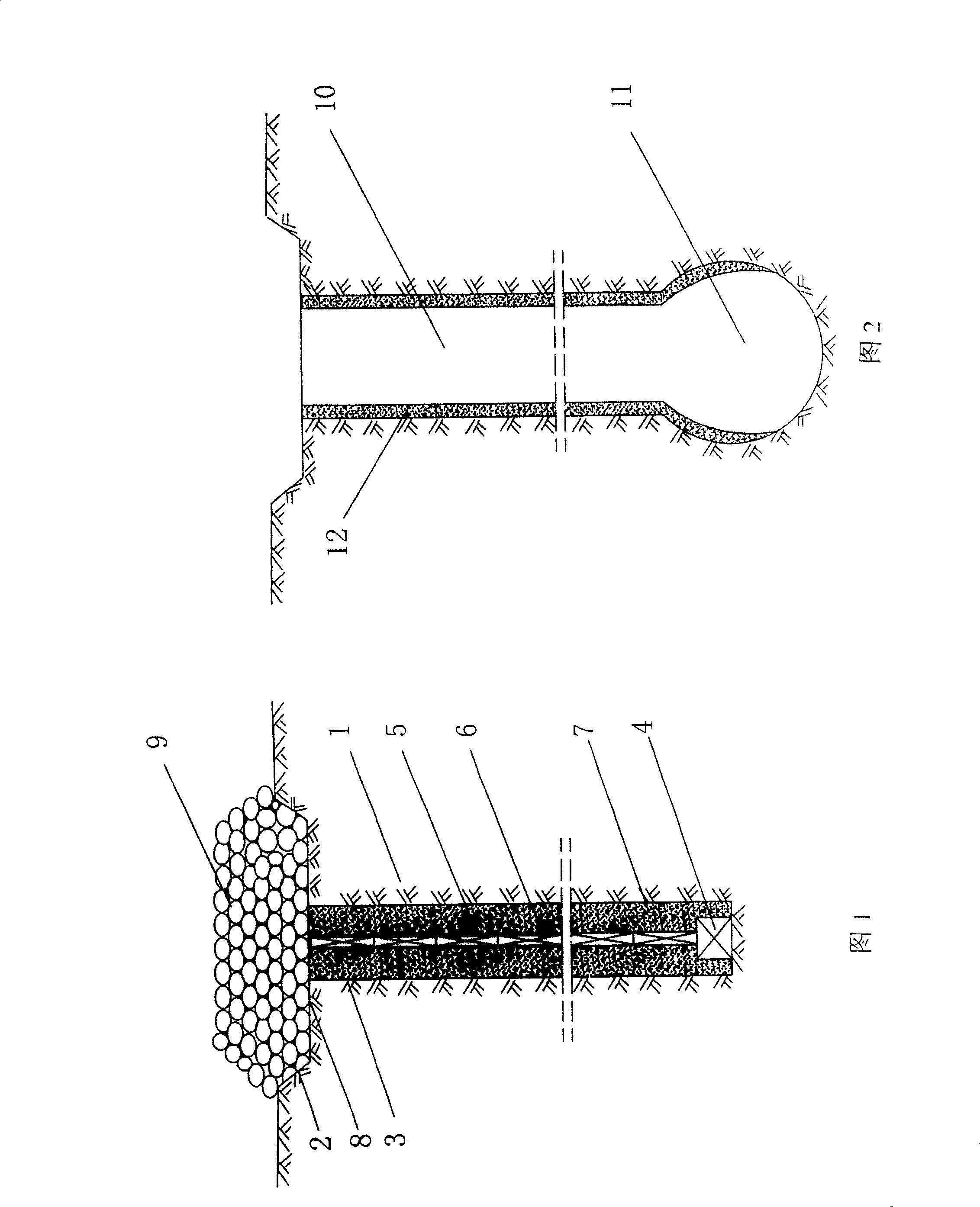

Application of Paste Emulsion Explosive and Explosive Forming Device of Titanium-aluminum Composite Plate

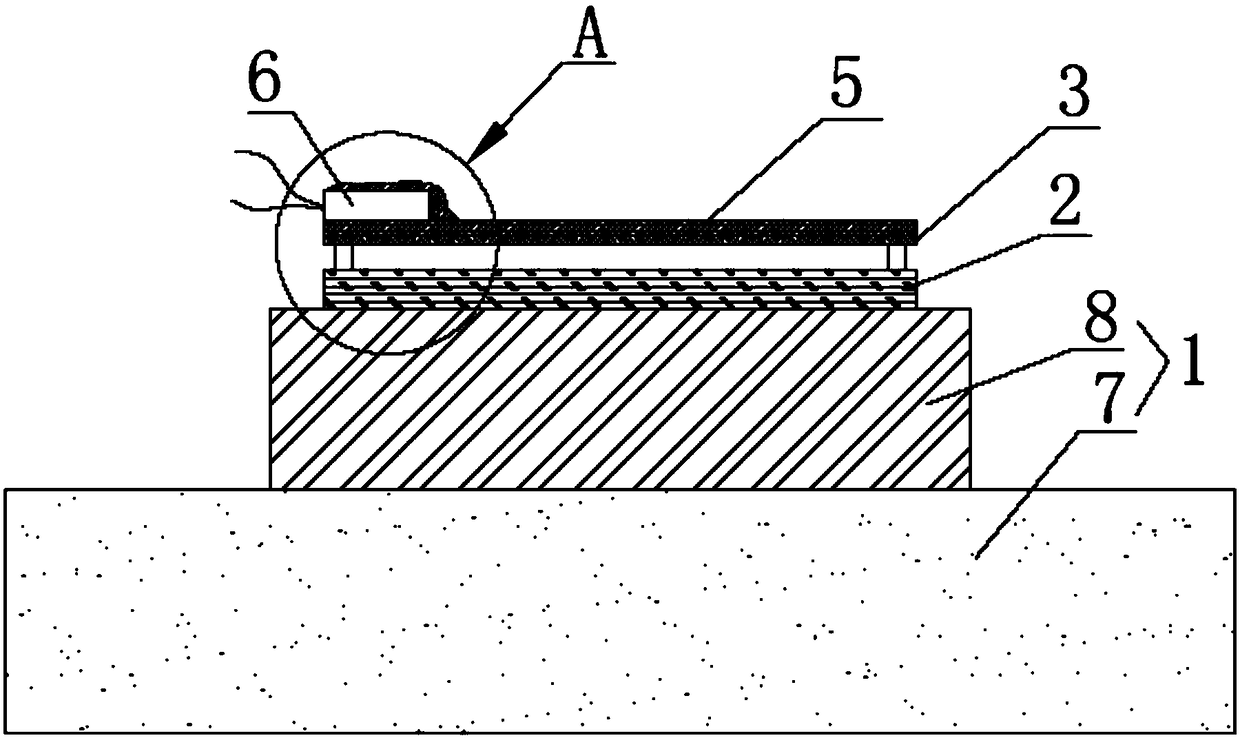

ActiveCN105750720BEasy to produceImprove performanceWelding/soldering/cutting articlesNon-electric welding apparatusDetonatorCompound a

The invention belongs to the field of titanium composite materials, provides a titanium-aluminum composite plate explosive molding device available for compounding a titanium plate with the thickness of less than 1 mm on an aluminum plate through explosive molding, and particularly provides use of a paste emulsion explosive in a titanium-aluminum composite plate explosive molding process. The device comprises a base, wherein a substrate is laid on the base; a compound plate is laid above the substrate; the substrate is the aluminum plate; the compound plate is the titanium plate; a support member is arranged between the aluminum plate and the titanium plate, so that a gap L is formed between the aluminum plate and the titanium plate; an explosive layer is laid on the titanium plate; a detonator is placed on the explosive layer; the titanium plate has the thickness of not greater than 0.2 mm; the explosive layer is a plate-like explosive layer formed by laying the paste emulsion explosive. The paste emulsion explosive is used in the composite plate explosive molding process, while the paste emulsion explosive can be laid on the titanium plate to form a plate-like explosive layer, so that the piercing, damage, deformation and the like for the titanium plate with the thickness of less than 1 mm due to explosion can be avoided effectively; a thinner titanium-aluminum composite plate can be obtained.

Owner:西藏高争民爆股份有限公司

Low-cost destruct type non-contact antitank unmanned aerial vehicle

PendingCN108082492ANot easy to exposeHas anti-tank capabilitiesMilitary adjustmentUncrewed vehicleEngineering

Owner:长沙深蓝未来智能技术有限公司

Method and mould arrangement for explosion forming

The invention is intended to improve a method for explosive forming of a workpiece by means of gas explosion, in which the workpiece is arranged in a intake area of a moulding tool, wherein the intake area is at least partially filled with liquid and the explosion is triggered by ignition of an explosive gas mixture, to the effect that the method is suitable and simplified for mass production. This object is solved by a method for explosive forming of a workpiece by means of gas explosion, in which the workpiece is arranged in a intake area of a moulding tool, wherein the intake area is at least partially filled with liquid and the explosion is triggered by means of ignition of an explosive gas mixture, in which the explosive gas mixture is provided at least partially above the surface of the liquid before the ignition.

Owner:COSMA ENG EURO AG

Test device and method for explosive forming of metal slotted pipe

The invention provides a test device and method for explosive forming of a metal slotted pipe. The test device comprises a target tube, a pressure relief valve and a detonating cord sealing sleeve; the lower end of the target tube is connected with a bottom flange in a sealed manner; the upper end of the target tube is detachably connected with a top flange in a sealed manner; the target tube comprises an inner cavity capable of accommodating the metal slotted pipe; a pressurizing joint is arranged on the target tube and communicates with the inner cavity; a heating band layer is arranged on the outer wall of the target tube; the pressure relief valve is connected onto the top flange in a sealed manner and communicates with the inner cavity; the detonating cord sealing sleeve is connectedonto the top flange in a sealed manner; a detonating mandrel is arranged inside the metal slotted pipe; and a detonating cord of the detonating mandrel can penetrates out of the target tube via the detonating cord sealing sleeve. By the aid of the test device and method for explosive forming of the metal slotted pipe, downhole conditions can be simulated relatively truly, and a test foundation canbe provided for explosive forming of the metal slotted pipe.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

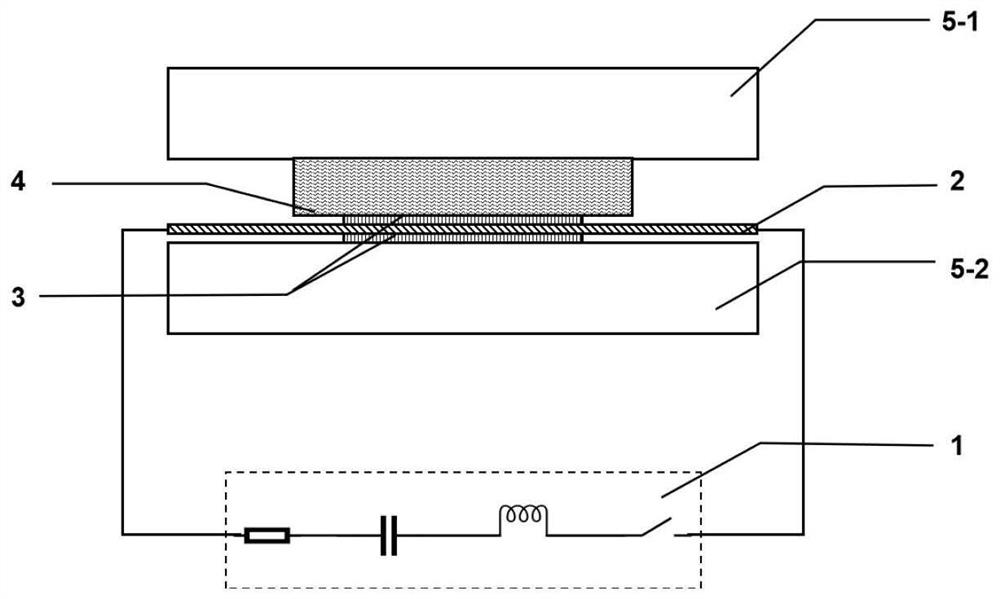

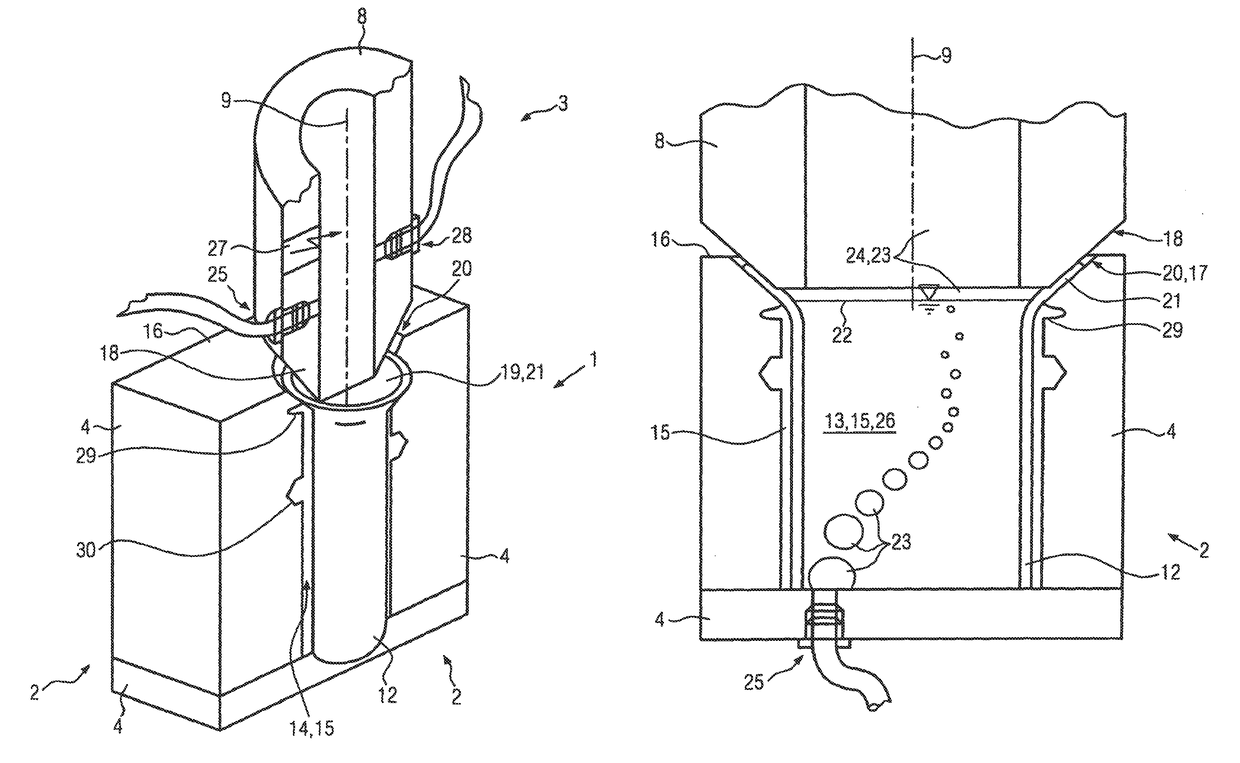

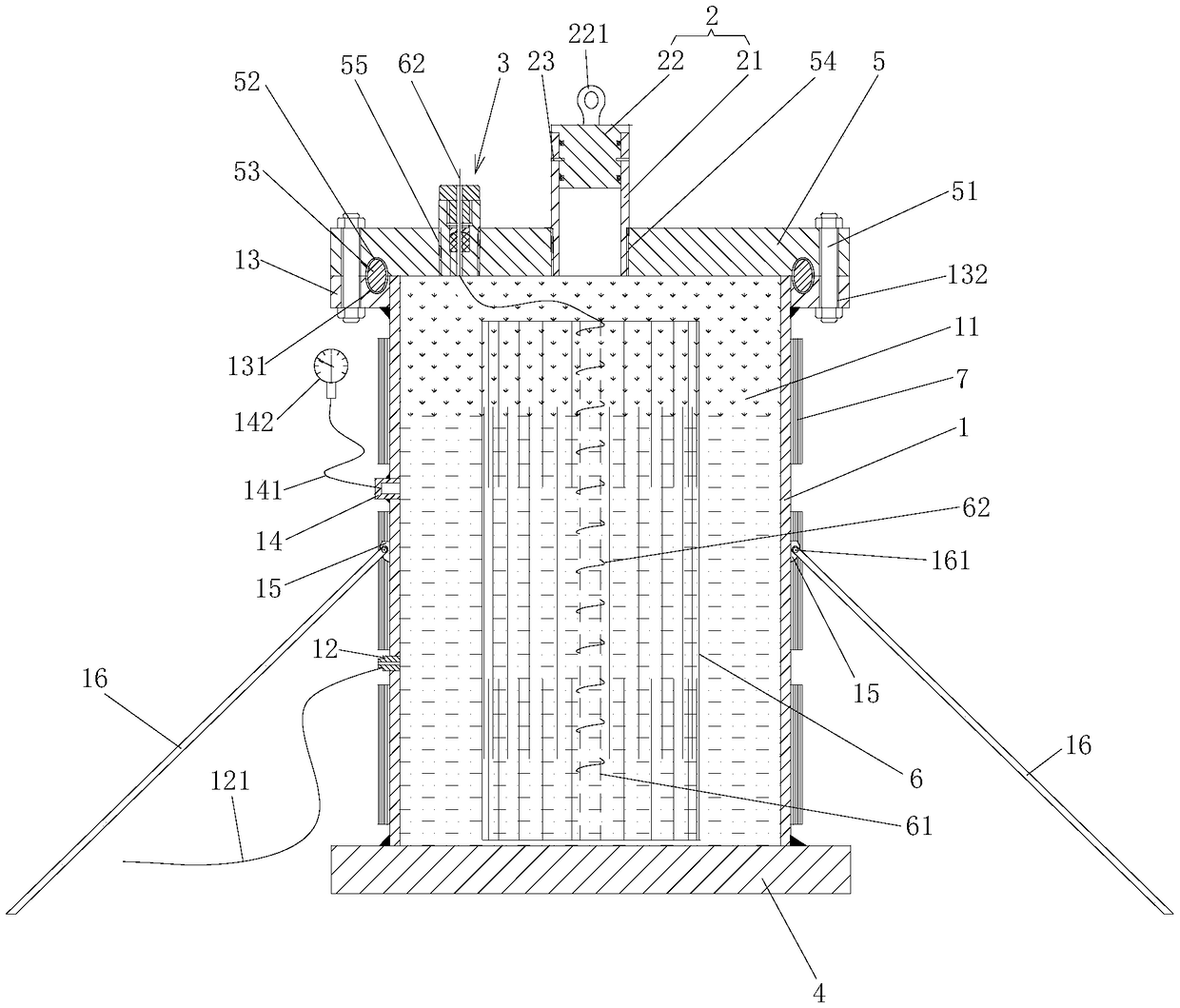

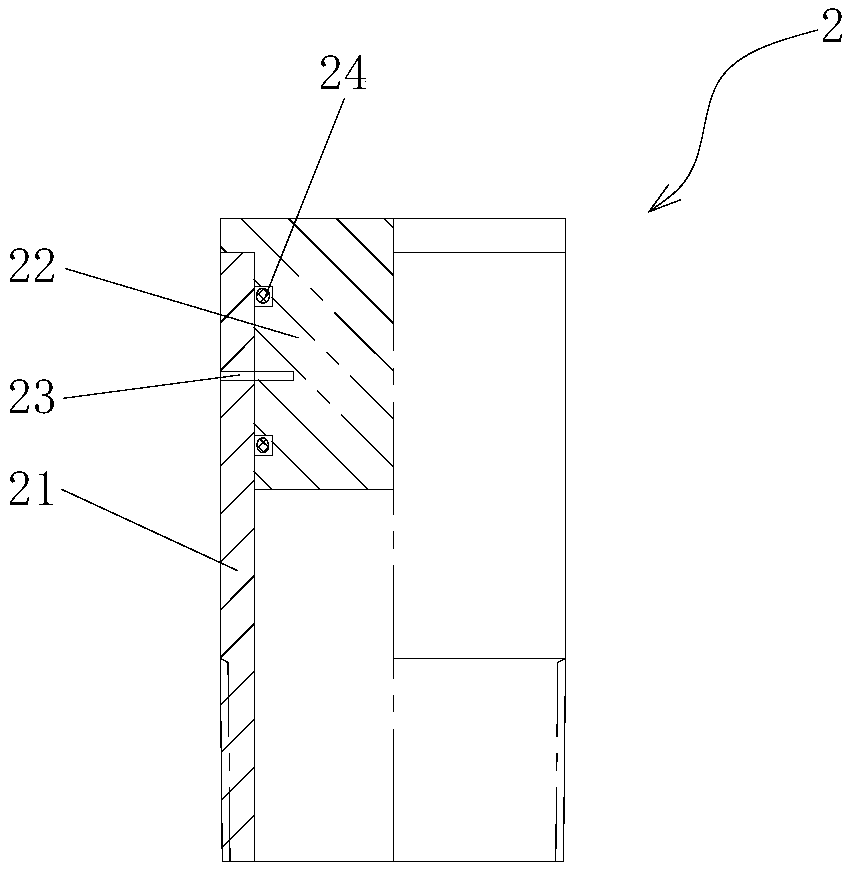

Device for supplying a fluid for explosion forming

ActiveUS20110180735A1Improve stabilityEasy to manufactureOperating means/releasing devices for valvesMetal-working apparatusEngineeringExplosive forming

With the invention, a device for fluid feed for explosive forming, which has a valve and an activating mechanism to activate the valve, is to be improved, so that the device permits both good filling of a die with fluid and good sealing during the explosive forming process in a technically simple design. This task is solved by a device for fluid feed for explosive forming that has a valve and an activating mechanism to activate the valve, in which the activating mechanism is arranged separate from the valve in an inactivated valve state.

Owner:COSMA ENG EURO AG

Method and device for explosion forming

ActiveUS20100175448A1Easy to controlGood predictability and reproduction accuracyShaping toolsBlastingExplosive AgentsExplosive forming

With the invention, a method and device for explosive forming of work pieces, in which at least one work piece is arranged in at least one die and deformed by means of an explosive to be ignited, is to be improved, in that an ignition mechanism that is technically simple to handle, is produced with the shortest possible setup time, which permits the most precise possible ignition of the explosive with time-repeatable accuracy. This task is solved by a method and device, in which at least one work piece is arranged in at least one die and deformed by means of an explosive to be ignited, in which the explosive is ignited by means of induction.

Owner:COSMA ENG EURO AG

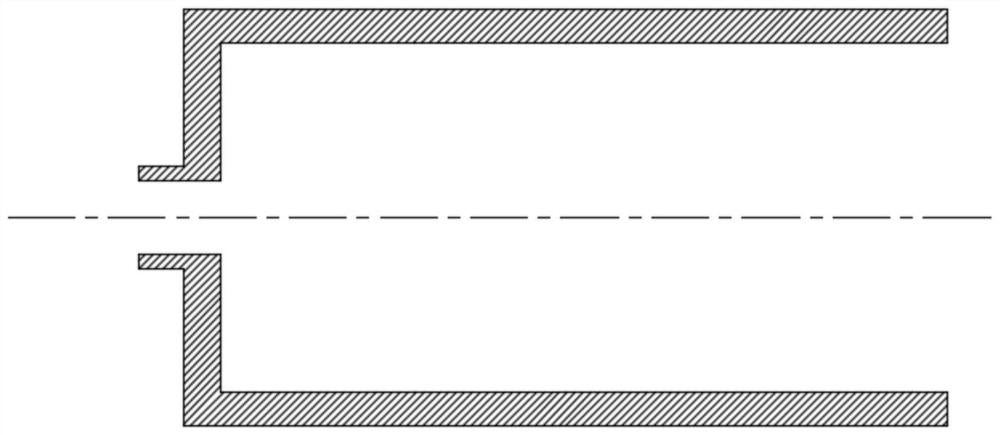

Device And Method For Explosive Forming

ActiveUS20120024029A1Short working hoursSimplifies and accelerates work piece changeMetal-working apparatusSpray nozzleEngineering

A device for explosive forming of a tubular work piece includes a multipart explosive forming die, which defines a forming area having an inner surface corresponding to a final shape of the tubular work piece and a nozzle arrangement disposed adjacent to the forming area. The device also includes a plug for forming a seal by simultaneously deforming an end of the work piece and clamping the deformed end between the plug and a facing surface of the nozzle arrangement. In this way, the work piece itself contributes to the sealing of an internal explosion space. With insertion of new work piece blanks, and introduction of the plug during each individual forming process, new seals are produced in a convenient manner during subsequent forming processes. The device supports a simplified handling approach and integrates several functions into one working step, resulting in a shorter cycle times and cost-effective industrial production.

Owner:COSMA ENG EURO AG

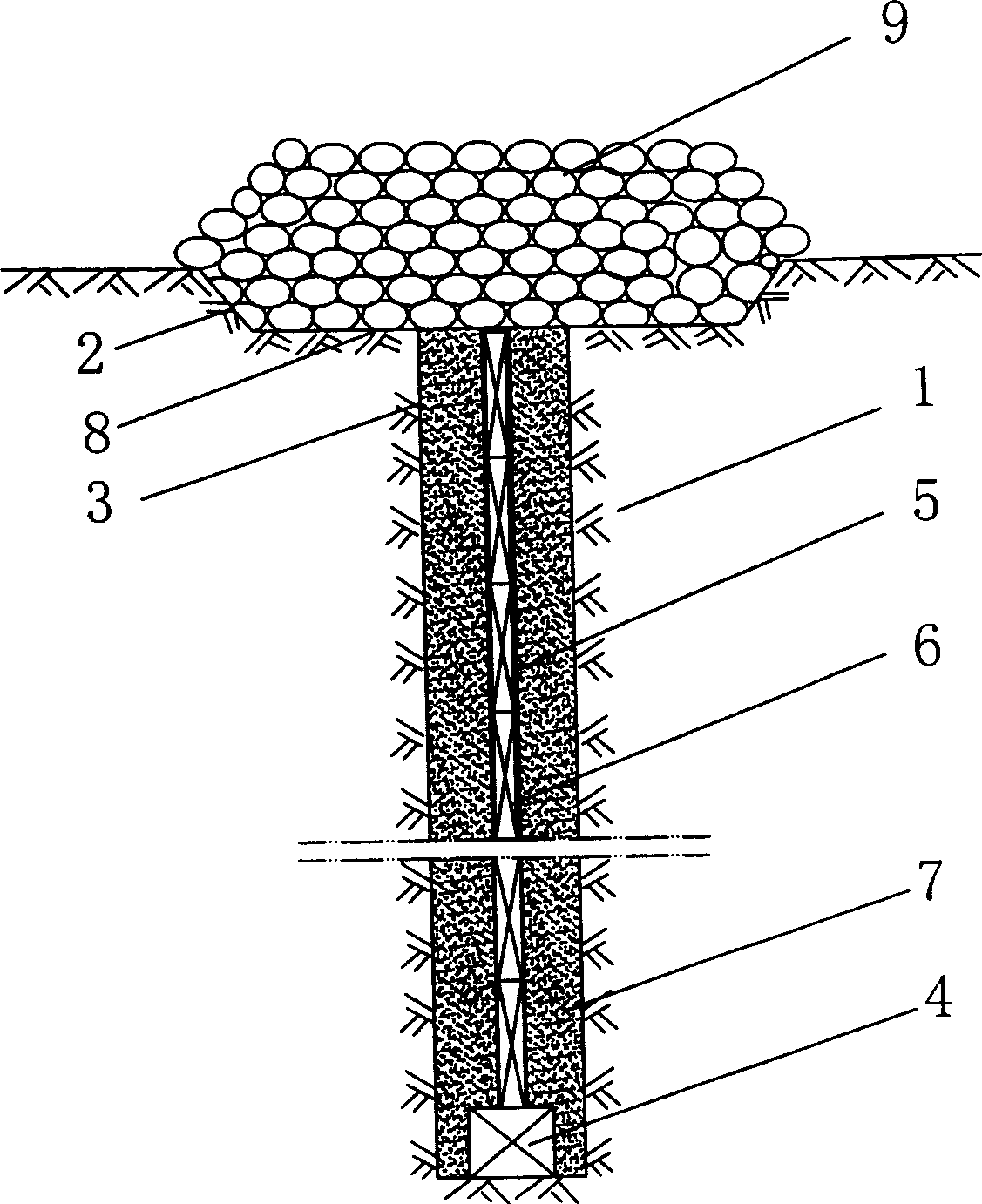

Explosion-enlarging stake construction process

InactiveCN100429353CHigh compression rangeImprove the compaction effectBulkheads/pilesExplosive formingSoil horizon

The invention relates to a method for constructing explosive-forming pile, which comprises: first, digging one horn well mouth at the soil; then at the center of well mouth, downwards drilling vertical tile hole to preset depth; arranging integrated drug pack into hole bottom; arranging sleeve at the center of borehole; filling bar drug pack into sleeve; filling mixed concrete or cement sand pulp between the borehole and sleeve; covering steel plate at the open of borehole; stacking carrier matter on the steel plate; exploding the drug pack and bar drug pack, after 3-8 hours when the filled concrete or cement sand pulp are poured, to form tile post and tile head with concrete protective layer; pouring concrete into tile head and tile post to form explosive-forming pile. The invention has simple process and better forming effect without reducing radius and sink hole.

Owner:CHINA UNIV OF MINING & TECH

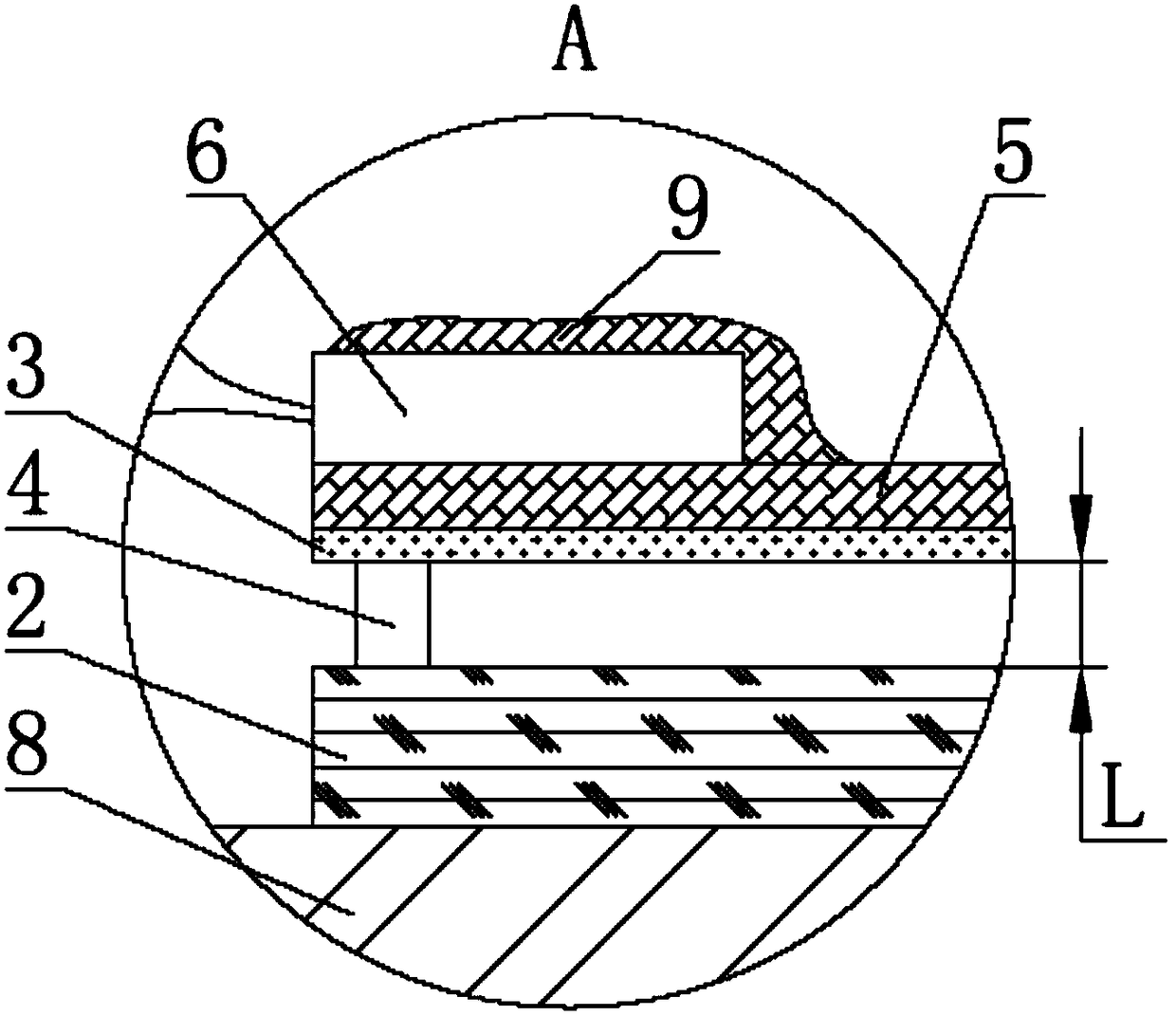

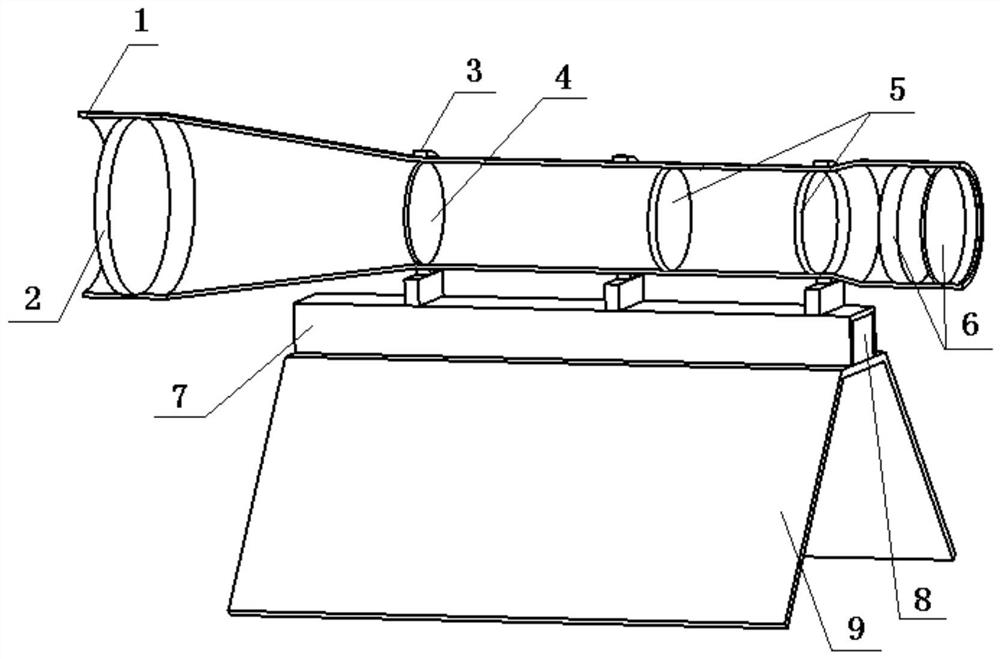

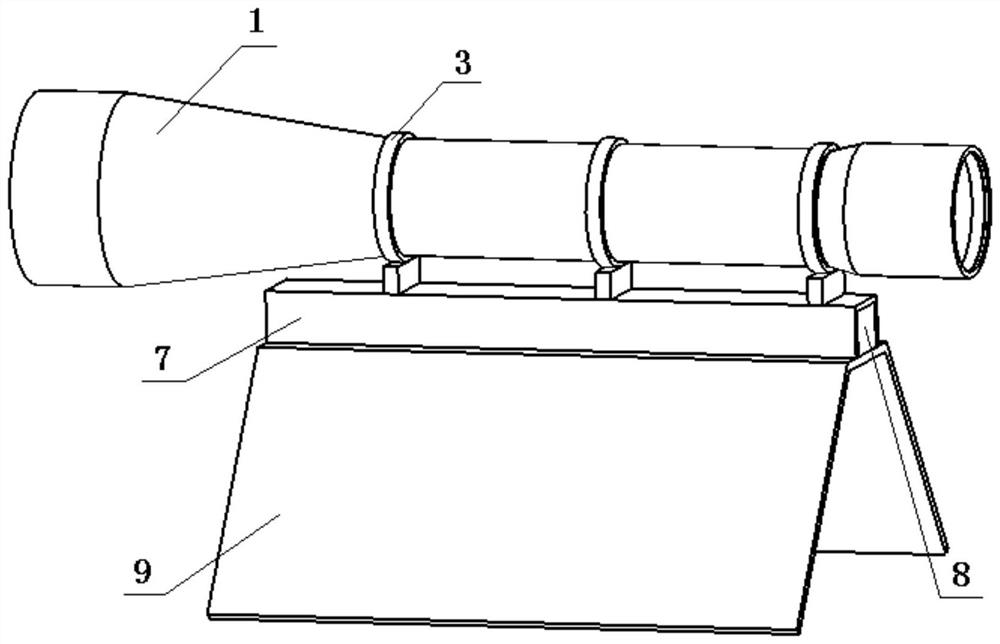

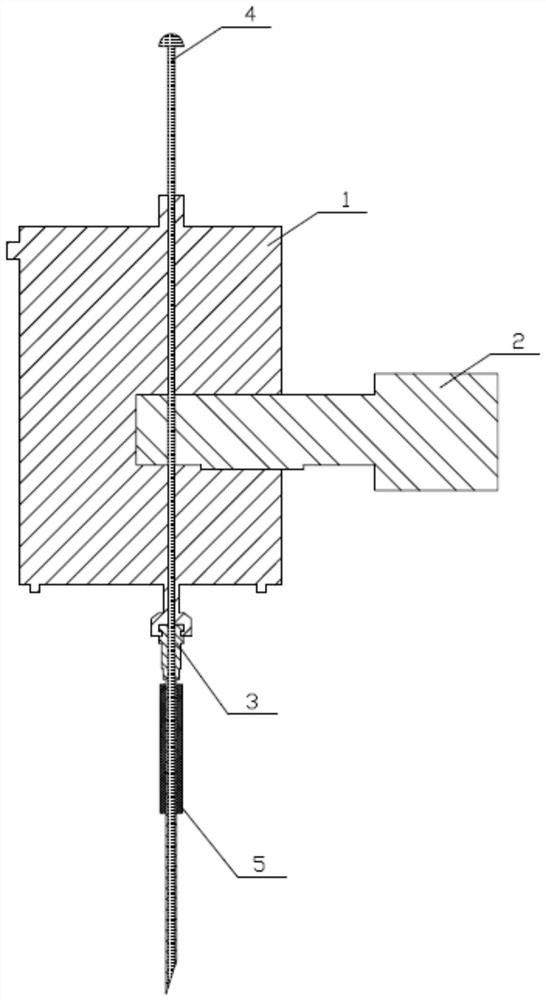

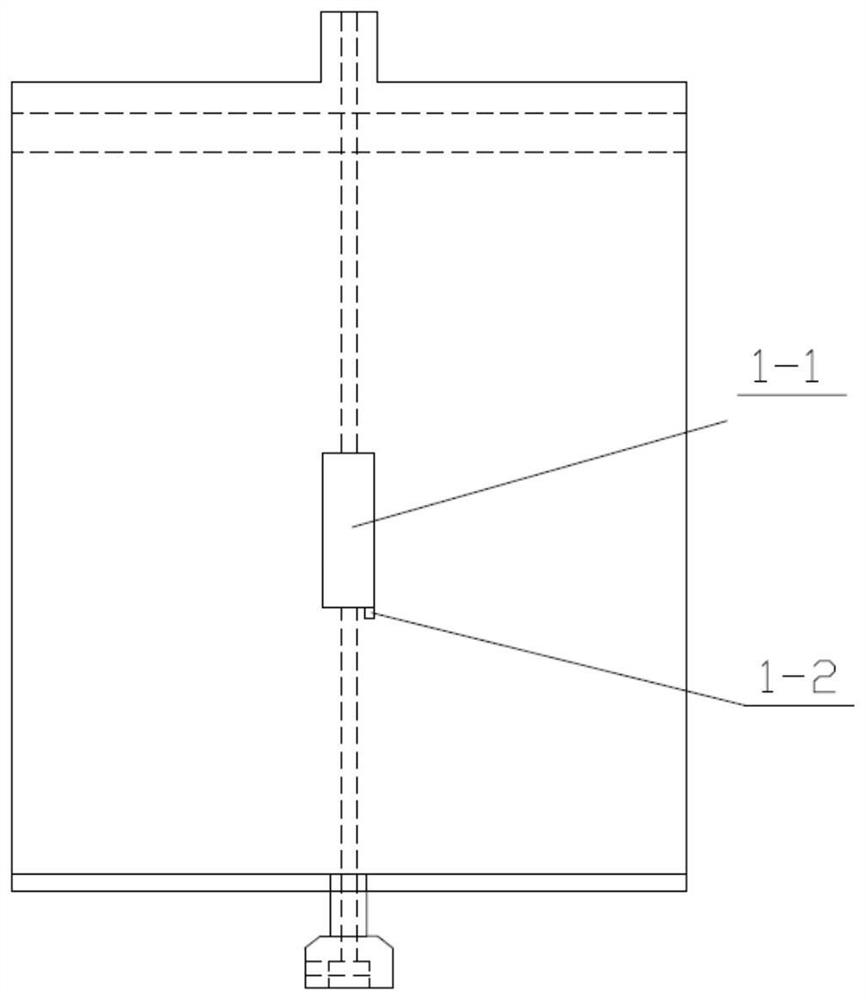

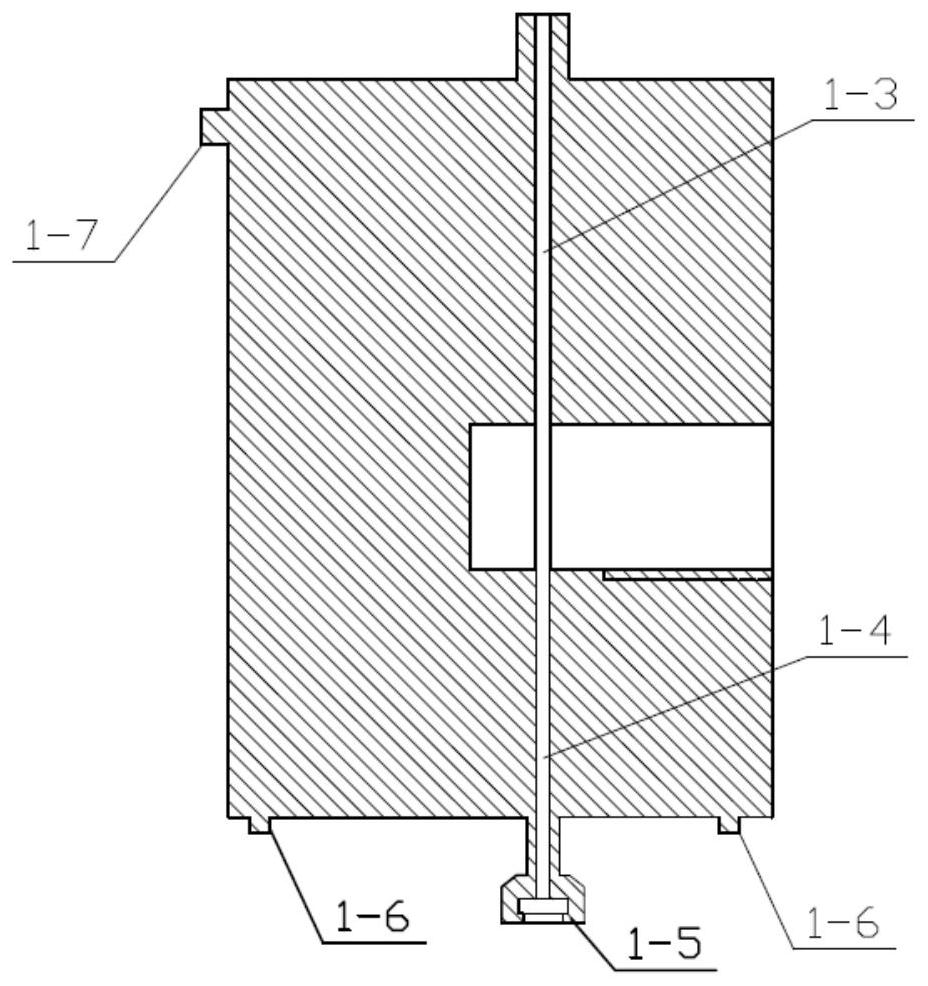

Aiming device for explosively formed projectile warhead

ActiveCN109186378BGuaranteed parallelPrecise aimingAmmunition testingSighting devicesEyepieceEngineering

Owner:XIAN MODERN CHEM RES INST

A composite explosive molding process

ActiveCN111454110BOrderly assemblyFlawlessExplosive working-up apparatusImplantation timeExplosive Agents

The invention discloses a composite explosive molding process. In order to solve the problem that the pouring explosives cannot realize the orderly assembly of particles, the invention adopts the method of mechanical implantation to implant oxidant, reducing agent particles or composite explosives into the mixed explosives to prepare high-energy pouring PBX explosives, pyrotechnics, and propellants Wait. While achieving the purpose of orderly assembly of particles, the invention solves the problem of air bubbles in mechanical implantation through a vacuum process; by controlling the implantation time, it ensures that there is no crack defect in the charge after implantation. The molding process disclosed by the invention is divided into five steps: determining the implantation time, preparing the implanted particles, preparing the matrix, implanting the particles, orderly assembling the particles, and curing at high temperature. The invention is mainly applied in the fields of explosives and explosives.

Owner:XIAN MODERN CHEM RES INST

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com