Process for preparing nano-diamond black powder by virtue of detonation

A nano-diamond and detonation technology is applied in the field of preparing nano-diamond black powder by detonation, which can solve the problems of low diamond content and achieve the effects of high content, high efficiency and high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A process for preparing nano-diamond black powder by detonation, including preparation of explosives, explosive molding, detonation preparation, and detonation preparation of nano-diamond black powder. The explosive molding is specifically:

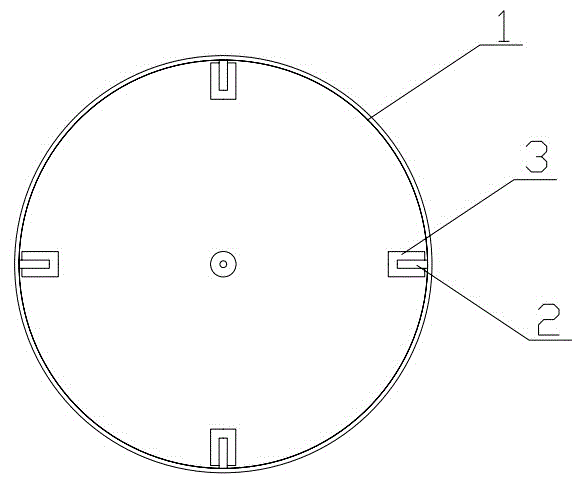

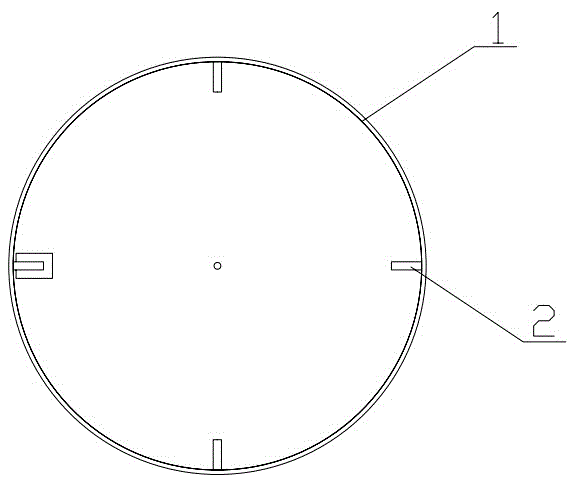

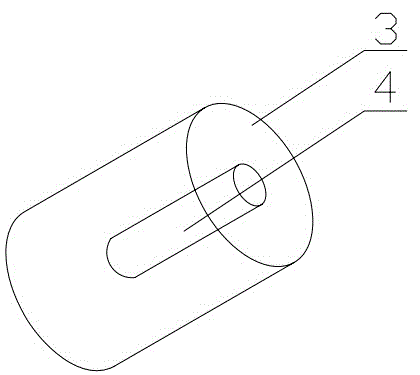

[0032] Pour the prepared Tihei explosive liquid into a hollow spherical mold 1; 4 to 20 protrusions 2 are evenly distributed on the inner surface of the spherical mold 1, and all of them point to the center of the spherical mold 1; the protrusions 2 are provided with priming charges 3, and the priming charges 3 are provided with a cavity 4 matching with the protrusions, and are sleeved on the protrusions 2; after the ladder black explosives fill the entire interior of the spherical mold 1, maintenance is carried out. Until it is completely cooled to room temperature, after the Tihei explosive liquid is solidified, the spherical mold 1 is removed to obtain a spherical explosive ball 5, the detonating powder column 3 is evenly distrib...

Embodiment 2

[0035] On the basis of embodiment 1:

[0036] The preparation of explosives specifically includes: heating the TNT explosive powder to completely melt it into a liquid state, then adding the RDX explosive powder, and stirring continuously to completely dissolve the TNT explosive powder into the TNT explosive liquid to obtain the TNT explosive liquid.

[0037] Preferably, the weight ratio of the TNT explosive powder to the RDX explosive powder is 40:30.

Embodiment 3

[0039] On the basis of embodiment 1:

[0040] The preparation of explosives specifically includes: heating the TNT explosive powder to completely melt it into a liquid state, then adding the RDX explosive powder, and stirring continuously to completely dissolve the TNT explosive powder into the TNT explosive liquid to obtain the TNT explosive liquid.

[0041] Preferably, the weight ratio of the TNT explosive powder and the RDX explosive powder is 70:60.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com