Test device and method for explosive forming of metal slotted pipe

A technology of explosive forming and experimental device, applied in the direction of material explosiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

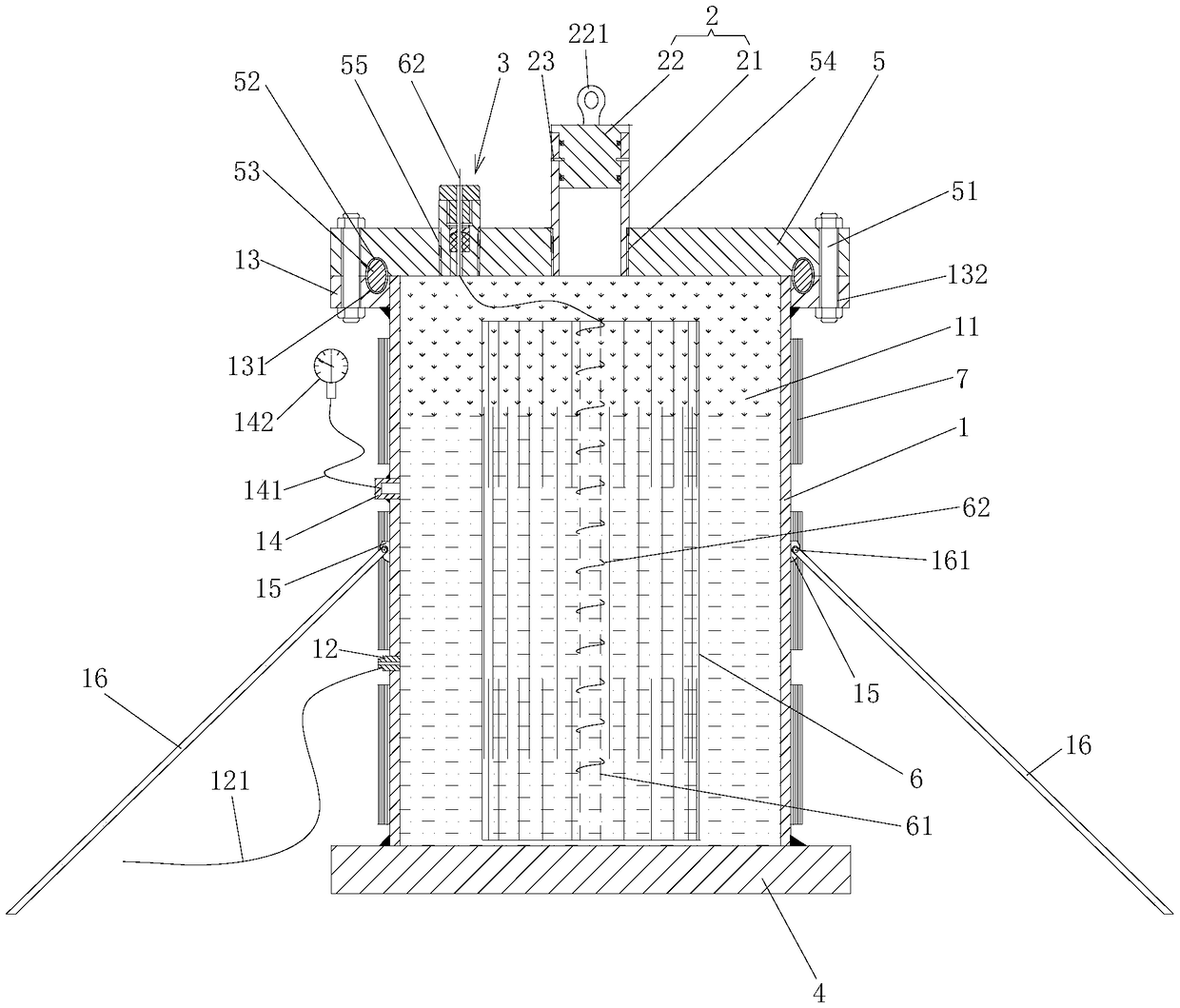

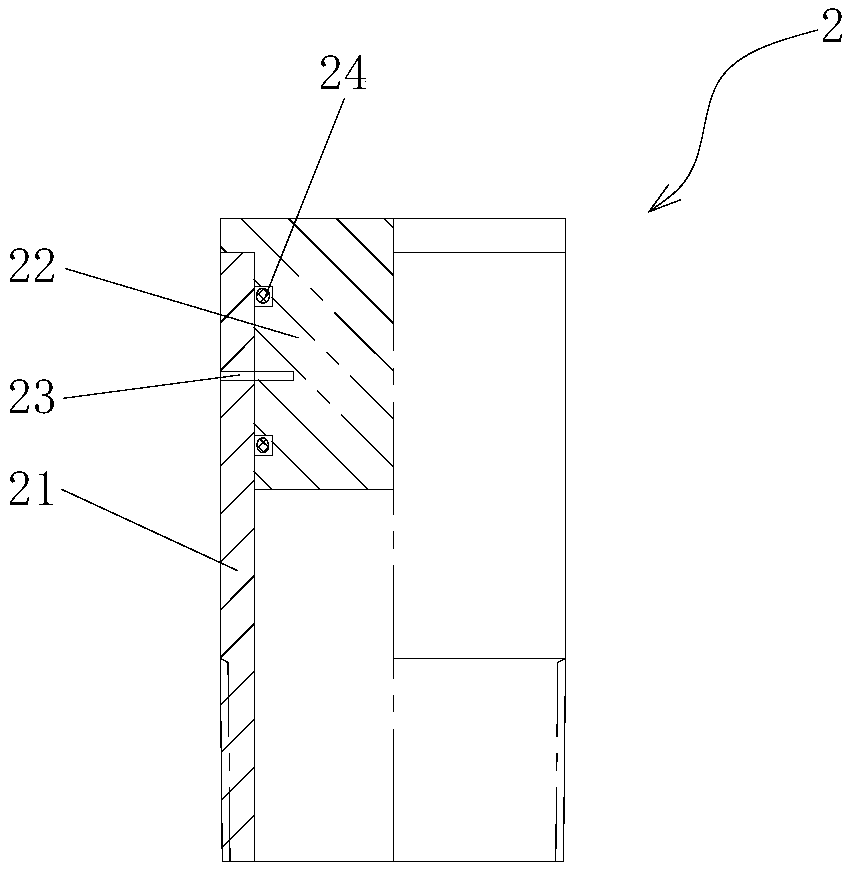

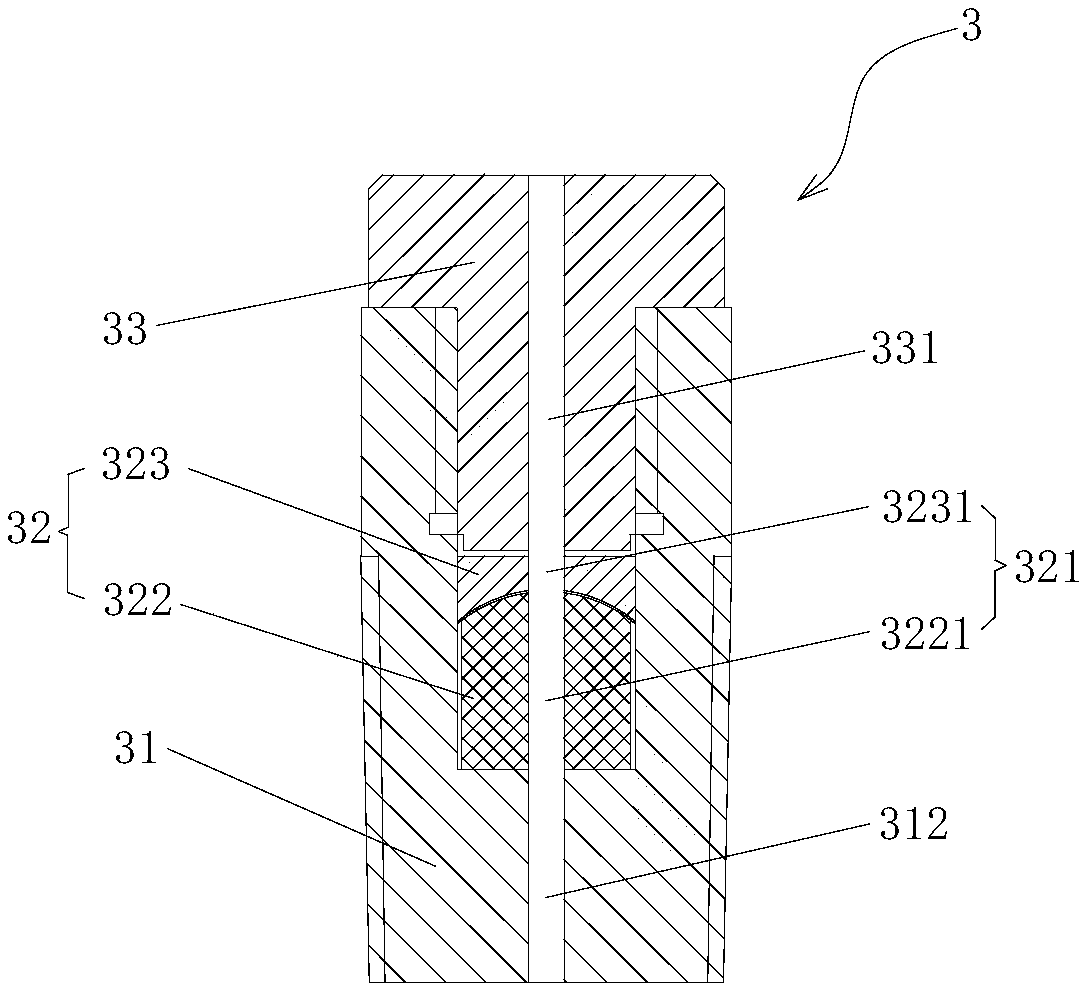

[0040] Such as figure 1 As shown, the present invention provides a metal slotted pipe explosive forming experiment device, comprising a target cylinder 1, a pressure relief valve 2 and a detonating cord sealing sleeve 3, wherein: the lower end of the target cylinder 1 is sealed and connected with a bottom flange 4, Its upper end is detachably sealed with a top flange 5, the target cylinder 1 has an inner cavity 11 capable of accommodating the metal slotted pipe 6, and the target cylinder 1 is provided with a pressurized joint 12, the pressurized joint 12 It communicates with the inner cavity 11, and the outer wall of the target cylinder 1 is provided with a heating belt layer 7; the pressure relief valve 2 is sealed and connected to the top flange 5, and the pressure relief valve 2 is connected with the inner cavity 11 are connected; the detonating cord sealing sleeve 3 is sealed and connected on the top flange 5, the metal slotted pipe 6 is provided with a detonating mandrel ...

Embodiment approach 2

[0055] Such as Figure 1 to Figure 8 As shown, the present invention also provides an experimental method for explosive forming of metal slotted pipe, which is implemented by using the experimental device for explosive forming of metal slotted pipe described in Embodiment 1. The experimental method for explosive forming of metal slotted pipe includes the following steps :

[0056] Step S1: Place the metal slotted tube 6 with the detonating mandrel 61 in the inner cavity 11 of the target cylinder 1, inject liquid into the inner cavity 11, and guide the detonating mandrel 61 The detonating cord 62 passes through the target cylinder 1 from the detonating cord sealing sleeve 3, and seals the top flange 5 at the upper end of the target cylinder 1;

[0057] Step S2: Inject an inert gas into the inner cavity 11 of the target cylinder 1 through the pressurized joint 12;

[0058] Step S3: heating the heating belt layer 7;

[0059] Step S4: ignite the detonating cord 62, detonate the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com