Nano-crystal austenitic metal bulk material having high hardness, high strength and toughness, and method for production thereof

a technology of austenitic metal and nanocrystal, which is applied in the field of high hardness, strength and toughness of nanocrystal metal bulk materials, can solve the problems of unable to obtain materials whose grain diameters are reduced down to the nano-size level, and can hardly be reduced down to the nano-order, and achieve the effect of ultra-fine crystal grain structur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

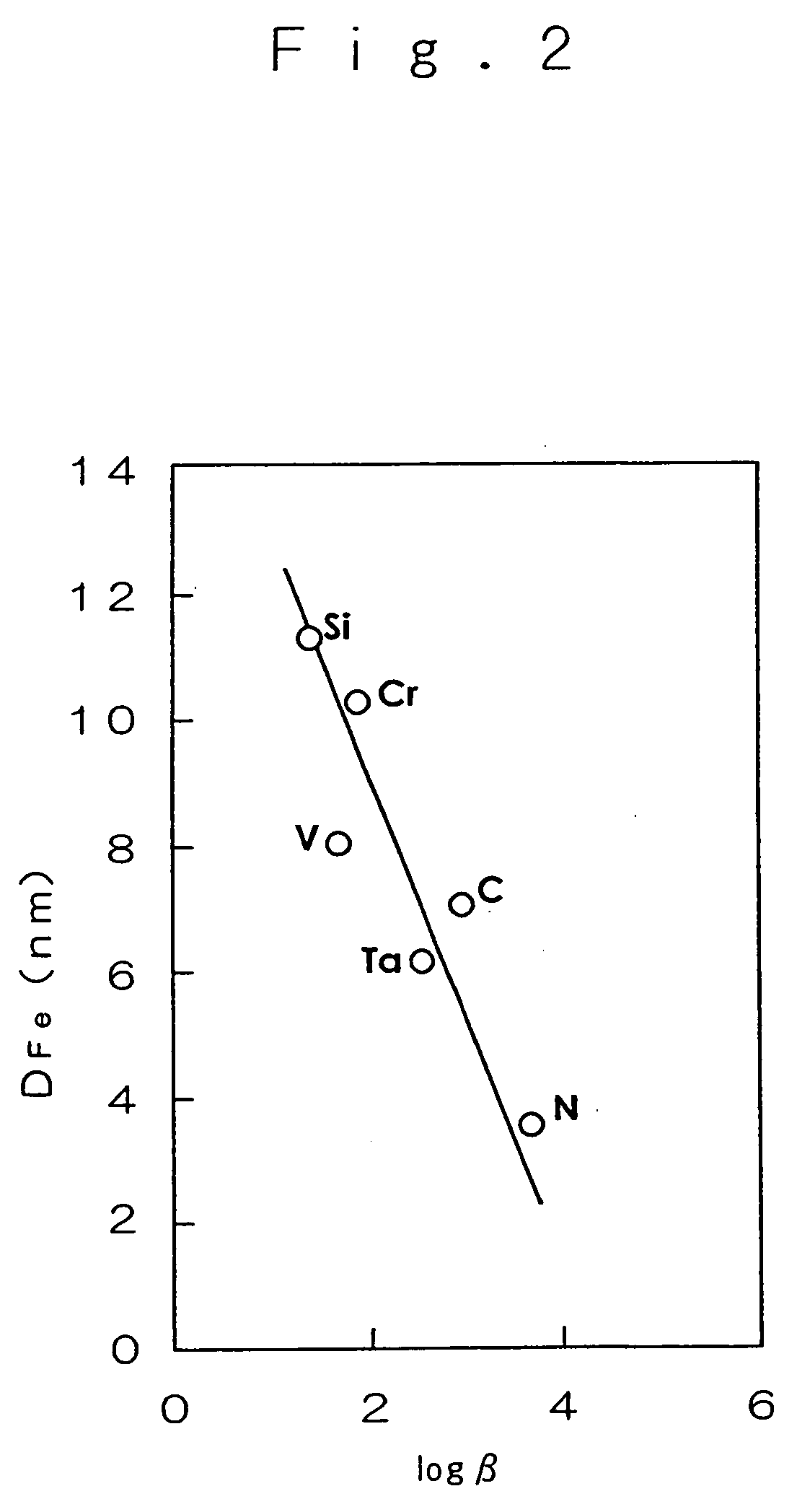

[0070]FIG. 1 is illustrative of changes in the mean crystal grain diameter of each mechanically alloyed element, that is, iron, cobalt and nickel when a 50-hour mechanical alloying (MA) was applied to an elementary powder mixture having an M85A15 (at %) (M is iron, cobalt or nickel), which comprised powders of the elements iron, cobalt and nickel with the addition thereto of 15 at % of carbon (C), niobium (Nb), tantalum (Ta), titanium (Ti) and so on as other elements (A).

[0071] In FIG. 1, DFe, DCo and DNi are the mean crystal grain diameter (nm) of the mechanically alloyed iron, cobalt, and nickel, respectively. From FIG. 1, it has been found that the reduction of crystal grain diameters of each of the elements iron, cobalt and nickel can be more effectively promoted by mechanical alloying with the addition thereto of carbon, niobium, tantalum, titanium and so on, all the three elements being refined down to grain diameters of a few nano-orders.

[0072] It has also been found that t...

example 2

[0079]FIG. 4 is illustrative in graph of the relationships between the mean crystal grain diameter D (nm) of an Fe64-yCr18Ni8TaYN10 (at %) where y=0 to 15, obtained by a 100-hour MA treatment of a powder mixture of elements iron, nickel and tantalum with the addition thereto of iron nitride, and the amount of tantalum added y (at %).

[0080] From FIG. 4, it has been found that the marked grain refinement effect of the additions elements A having the large value of the grain boundary segregation factor β in the binary Fe and A materials is similarly seen in the multicomponent materials based on component Fe as well.

example 3

[0081] A powder sample of Fe99.8C0.2 (% by mass) was obtained by the mechanical alloying (MA) of a powder mixture of elements iron and carbon for 200 hours. Then, the sample was vacuum charged in a stainless steel tube (sheath). Consolidation (i.e., sintering) of the vacuum charged powder sample was performed by sheath rolling (SR) at a temperature of 900° C., obtaining an SR formed product (bulk material) as shown in Table 1.

TABLE 1Mean crystal grain diameter D, Vickers hardness Hv and thevalue of oxygen upon analysis of Fe99.8C0.2 (% by mass) bulkmaterial obtained by 900° C.-sheath rolling (SR) of powdermaterial mechanically alloyed from a power mixture ofelements iron and carbonSampleD (nm)HvOxygen % by massSR formed material*239800.485

The value of D was calculated from Scherrer's equation, and * indicates that the material thickness was about 1.4 mm.

[0082] From Example 3 and Table 1, it has been found that according to the invention, the Vickers hardness Hv of the formed mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com