Explosion-enlarging stake construction process

A construction technique and explosive expansion technology, which is applied in sheet pile walls, foundation structure engineering, construction, etc., can solve the problems affecting the stability of the soil around the blasting piles, failing to meet the design requirements, and affecting the bearing capacity of pile foundations, etc. Achieve good soil compaction effect, improve process quality and bearing capacity, and improve bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

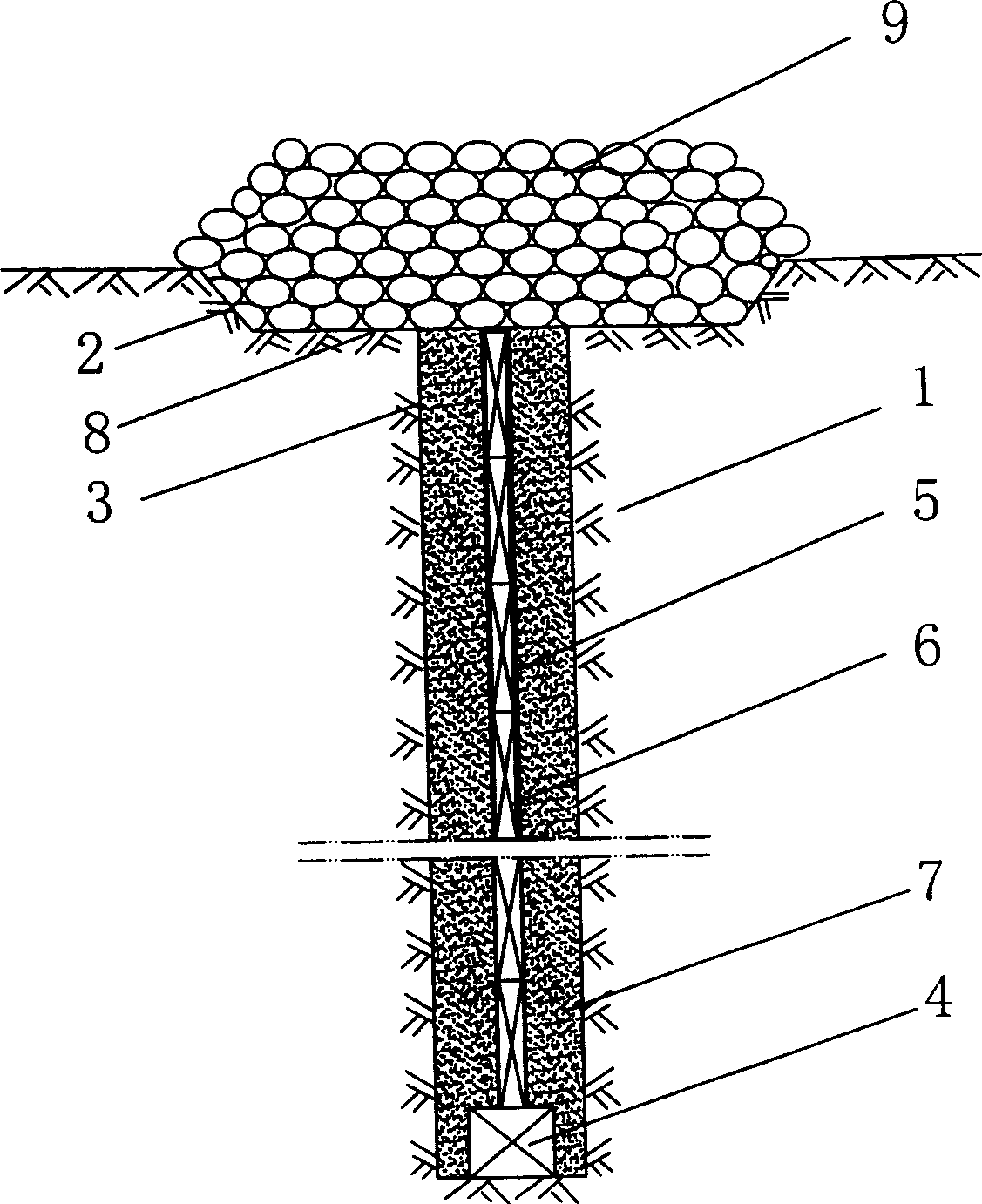

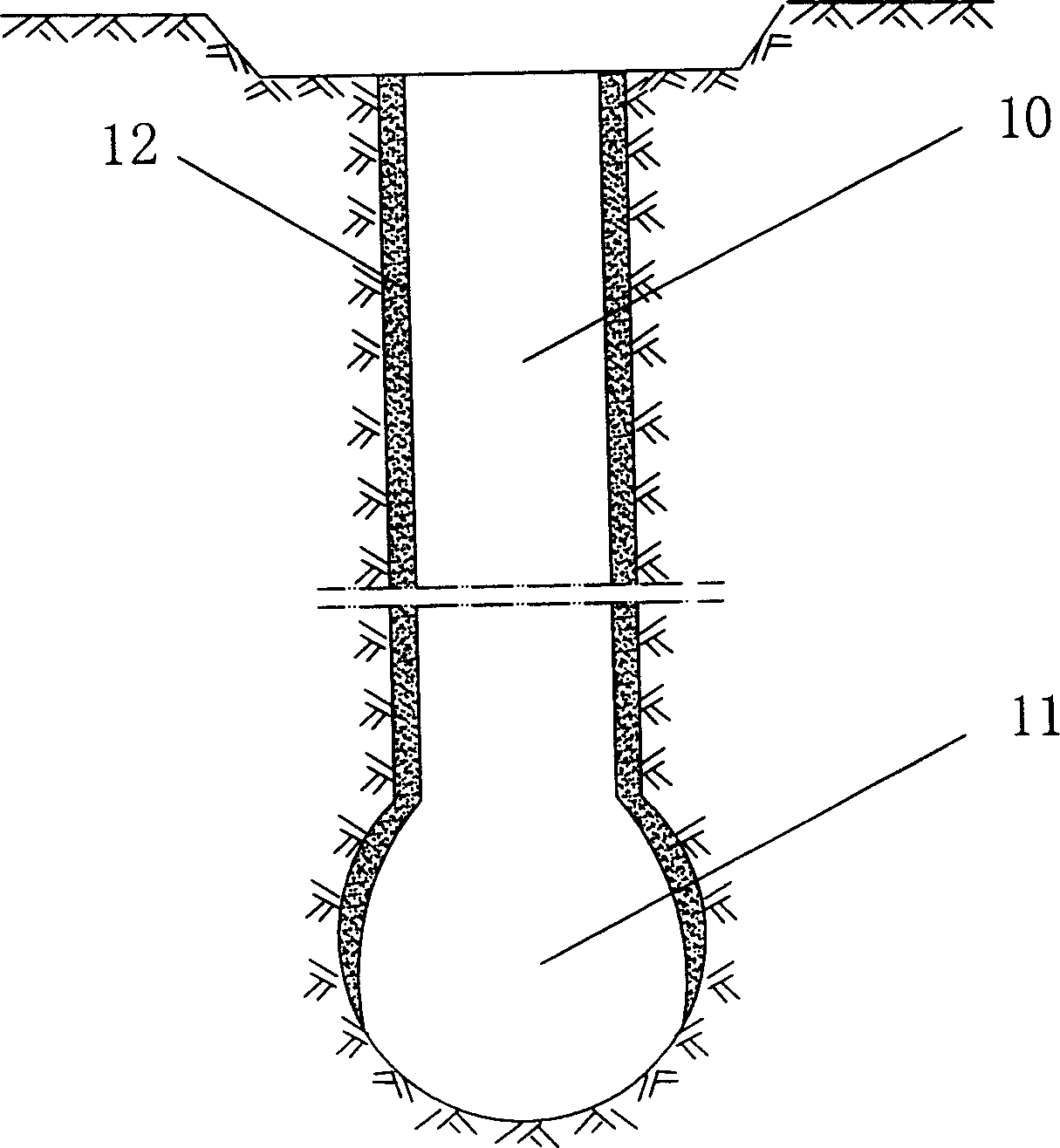

[0009] The invention relates to a construction technique of blasting expanding piles. The blasting parameters are set according to the actual situation on site, and the required aperture, hole depth, charge diameter, charge amount, concrete consumption and detonation time are determined. In order to avoid the formation of blasting funnels near the pile mouth during blast expansion, a trumpet-shaped wellhead 2 is dug out in the soil layer 1 at the pile mouth before blast expansion. A blast hole 3 with a diameter of 100 mm to 300 mm is drilled at the center of the wellhead 2, and the set concentrated charge 4 is placed at the bottom of the blast hole. Then the thin-walled plastic tube 5 with an inner diameter of 25mm to 40mm is positioned at the center of the blasthole 3, and then the strip-shaped charge pack 6 with a diameter of 25mm to 38mm is packed into t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com