Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

357results about How to "Improve the quality of workmanship" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

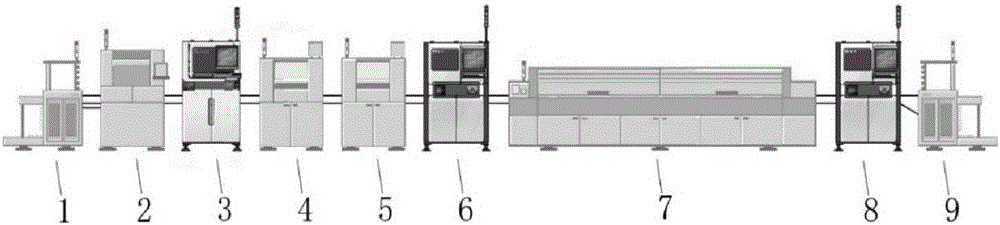

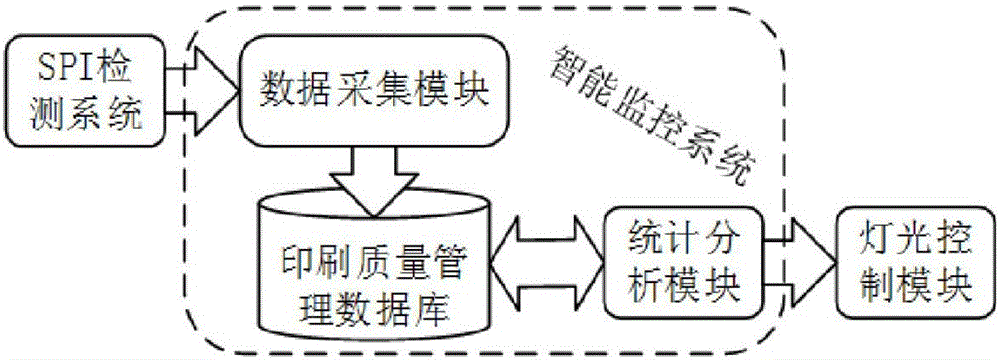

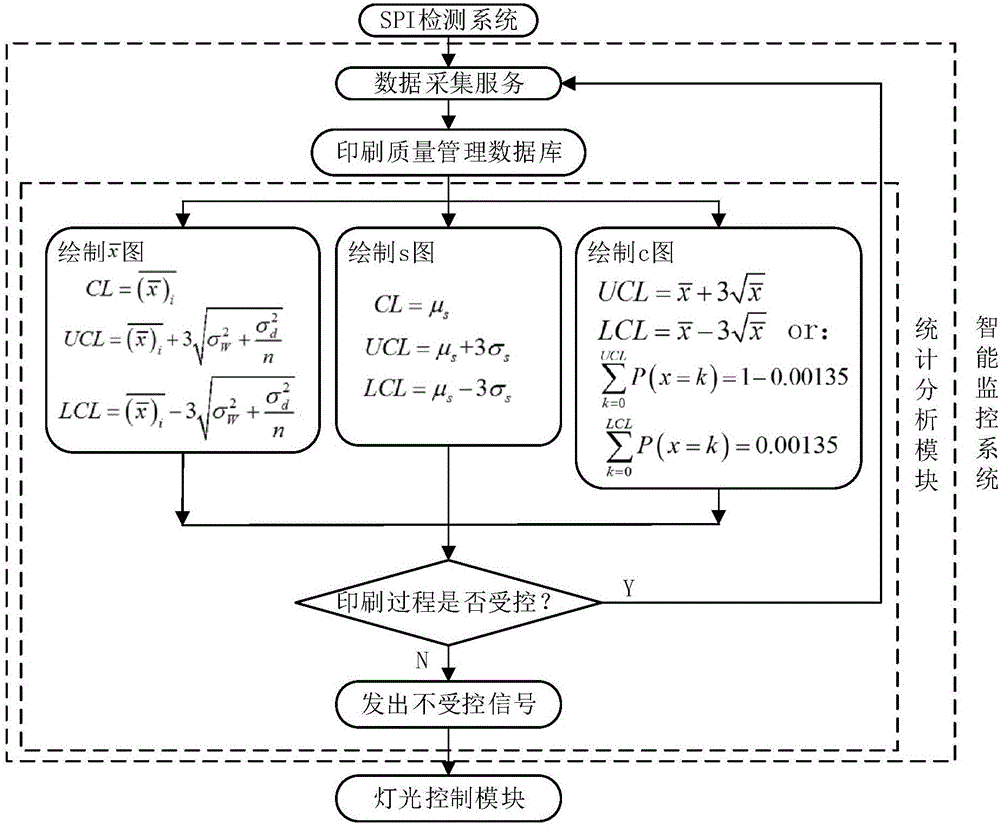

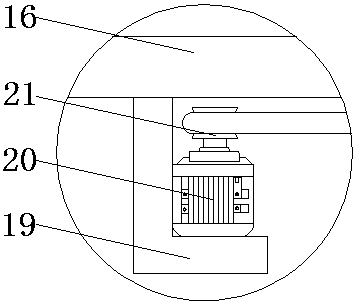

Intelligent monitoring system for quality of PCB solder paste printing process and method

InactiveCN106079892AReduce printing defectsSolve runnabilityTotal factory controlPrinting press partsIntelligent lightingData acquisition

The invention provides an intelligent monitoring system for the quality of a PCB solder paste printing process and a method. The system comprises a data acquisition module, a printing quality management database, a statistical analysis module and a light control module, wherein the data acquisition module is used for performing real-time acquisition of various parameter data of PCB printing solder paste, which is detected by an SPI detection system; the statistical analysis module is used for acquiring and analyzing the data acquired by the data acquisition module, judging whether the quality of the solder paste printing process is controlled or not according to an analysis result, and sending a signal representing that the quality of the printing process is out of control to the light control module when the quality of the solder paste printing process is out of control or tends to be out of control; and the light control module can control different warning lights to give a warning of specific out-of-control conditions. Through the system and the method, the defect that the quality of a printing process cannot be monitored in the prior art is overcome, the printing process can be monitored, and a warning can be given in time when that the printing process is out of control is found so as to reduce defects in solder paste printing.

Owner:CHONGQING UNIV

Test method of residual stress of silicon single crystal piece

ActiveCN102435361AEasy to pressImprove the quality of workmanshipForce measurementSingle crystalStrain gauge

The invention discloses a test method of residual stress of a silicon single crystal piece. Main test steps comprise preparing a three-dimensional strain rosette, a strain gauge, a detected silicon single crystal piece and the like, pasting the three-dimensional strain rosette, testing an initial value of each resistor of the three-dimensional strain rosette and recording the value, cutting a silicon chip to release a stress, testing each data of the three-dimensional strain rosette again and recording the data, processing the data, and analyzing and discussing a result. According to the invention, the three-dimensional strain rosette is taken as a strain sensor, a cutting method is employed to release a residual stress of the silicon chip, through employing an YE2539 high speed static strain indicator to measure reverse direction strain of the strain rosette tightly pasted on the silicon chip, size and direction of a residual stress of each point on the silicon chip can be calculated, and a unique test operation process of the silicon chip is formed. Test precision is high, speed is fast, and cost is low. A test result analysis shows that: total residual stress of a monocrystalline silicon piece is small, a residual stress at a circumference edge is large relative to an internal measuring point, a maximum residual stress of an unprocessed monocrystalline silicon piece is large relative to a processed monocrystalline silicon piece.

Owner:扬州晶新微电子有限公司

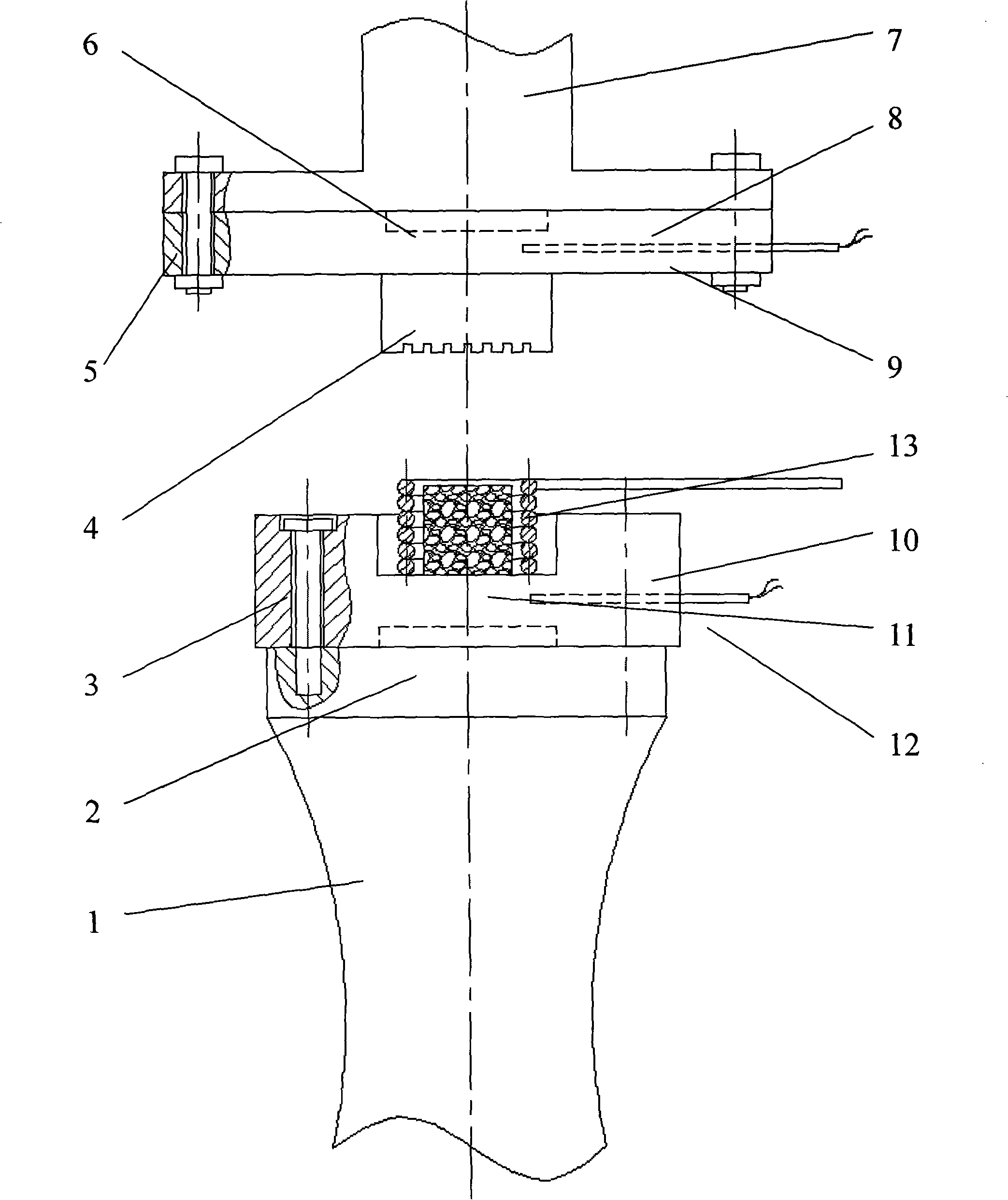

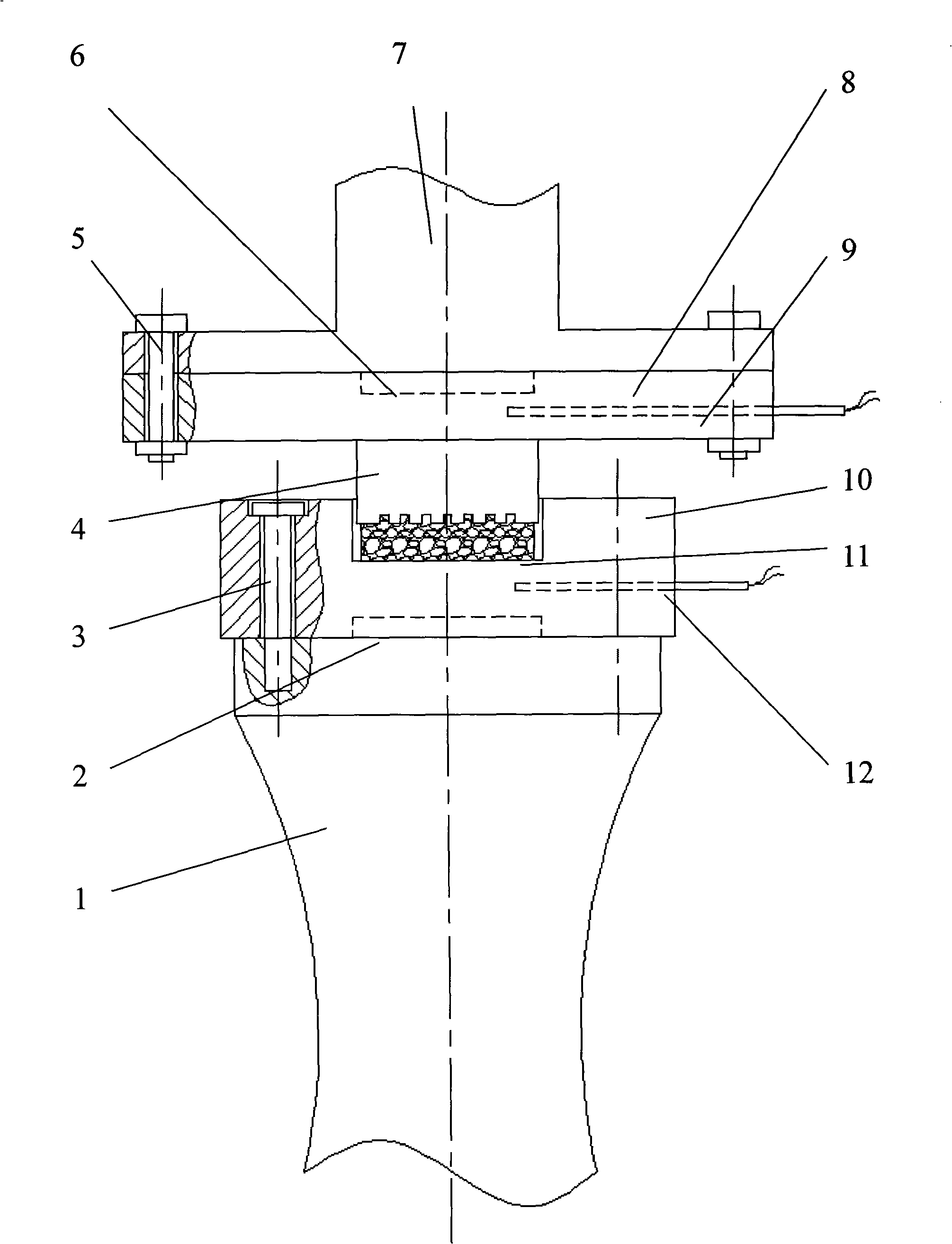

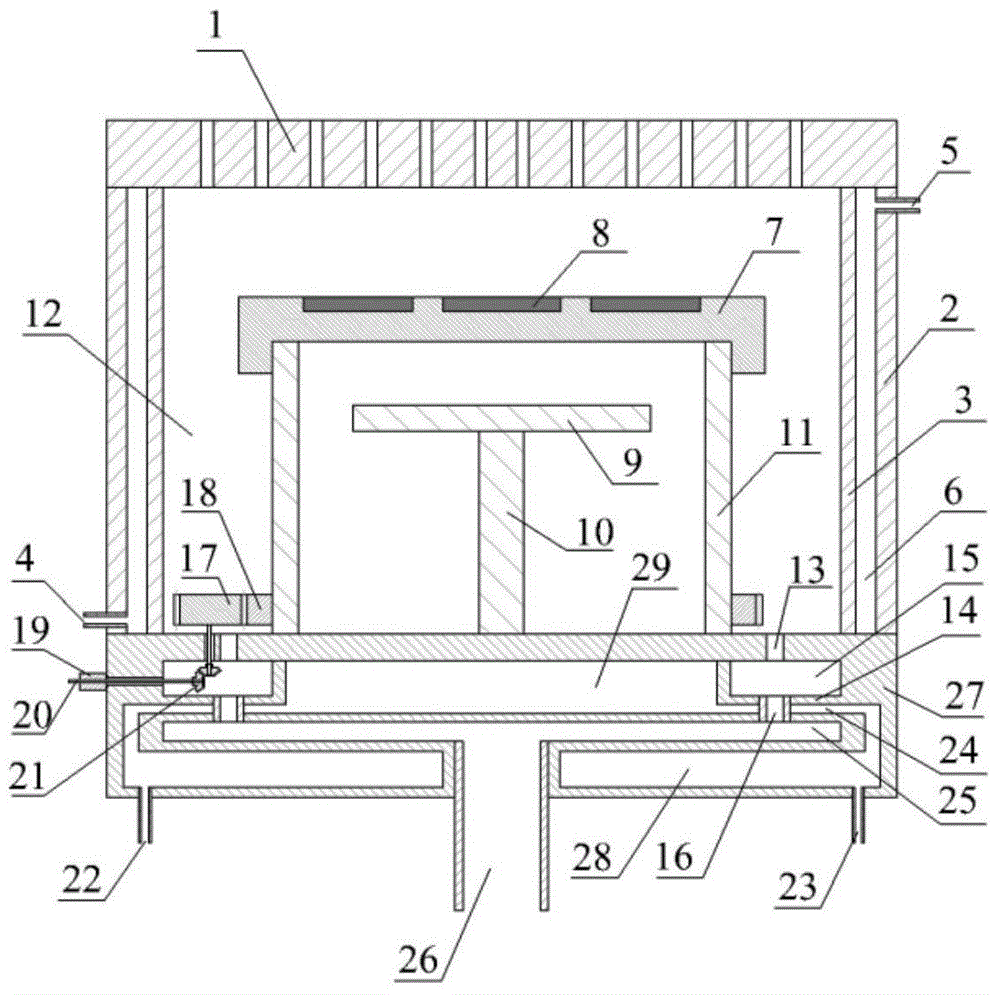

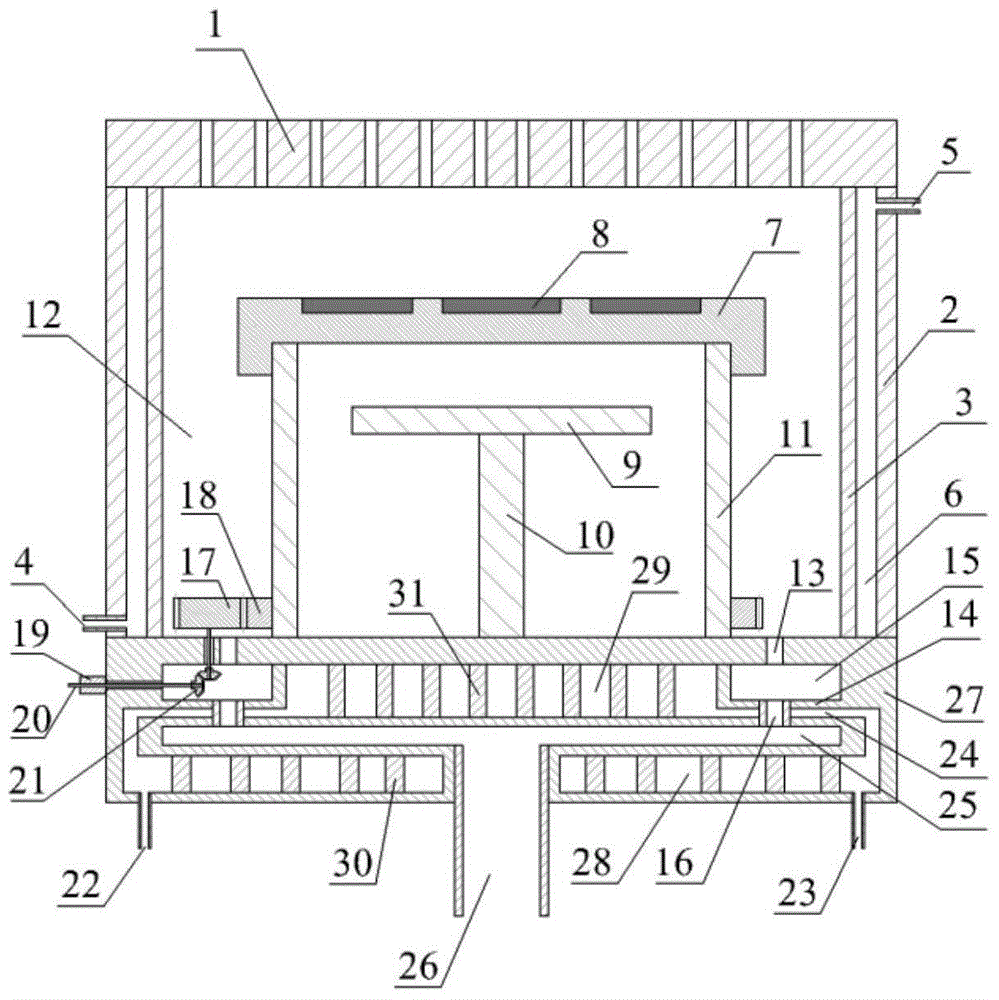

Method for device for forming metal micro-thixotropy in semi-solid state assistant by supersonic vibration

InactiveCN101406925AGood formabilityReduce processing timeMetal-working apparatusElectricityPunching

The invention discloses a method for the micro-thixotropy and molding of semisolid metal through the assistance of supersonic vibration. The lower end of a lower mould is provided with an electric heater of the lower mould; the lower mould is connected with a supersonic amplitude transformer; the lower mould is provided with a thermocouple of the lower mould; the upper end of a punching head is connected with an upper mould; the upper end of the upper mould is provided with an electric heater of the upper mould; the upper mould is connected with a pressure lever; and the upper mould is provided with a thermocouple of the upper mould. A semisolid metal blank material is remelted and heated to a solid-liquid coexisting region and is subjected to pressure machining; at the same time, supersonic vibration is applied to reduce friction and micro-molding resistance between the semisolid metal blank material and a micro-mould, strengthen the fluidity of the semi-solid metal material, improve the filling performance of the semisolid metal material in the micro-mould, and achieve good micro-molding effect. The method promotes the micro-thixotropy and molding of the semisolid metal, improves the efficiency of micro-molding, reduces equipment cost, avoids the disadvantages of hole contraction and the like in micro-machining process and improves the effects of micro-thixotropy and molding of the semisolid metal.

Owner:ZHEJIANG UNIV

Large-scale industrialized technology for beer yeast extract

ActiveCN101536772AImprove qualityIncrease production costFungiFood processingYeast ProteinsResource saving

The invention discloses new large-scale industrialized technology for producing novel yeast extract series products 3,000 t / a by using beer yeast slurry as an initial raw material, and belongs to the technical field of preparing series biological products from yeast. The production steps comprise preliminary treatment, debitterizing process, controllable hydrolysis process, separation and refining, condensation or spray drying. The technology is characterized in that the waste beer yeast with low cost is used as the raw material, the technology combining a physical wall-breaking method, an automatic dissolution method and an enzymolysis method is provided, the hydrolysis ratio of beer yeast protein reaches 55 percent, and the total yield reaches 60 percent. The invention also discloses a biochemical controllable debitterizing process, which solves the technical bottlenecking problems of more impurities, heavy bitter taste and low yield of the yeast slurry raw material. Three series and more than 20 yeast extract series products are successfully obtained. The comprehensive utilization rate of the yeast slurry is over 90 percent; and the technology is typical environment-friendly, clean and resource-saving technology and has remarkable economic and social benefits.

Owner:SHANDONG BIO SUNKEEN

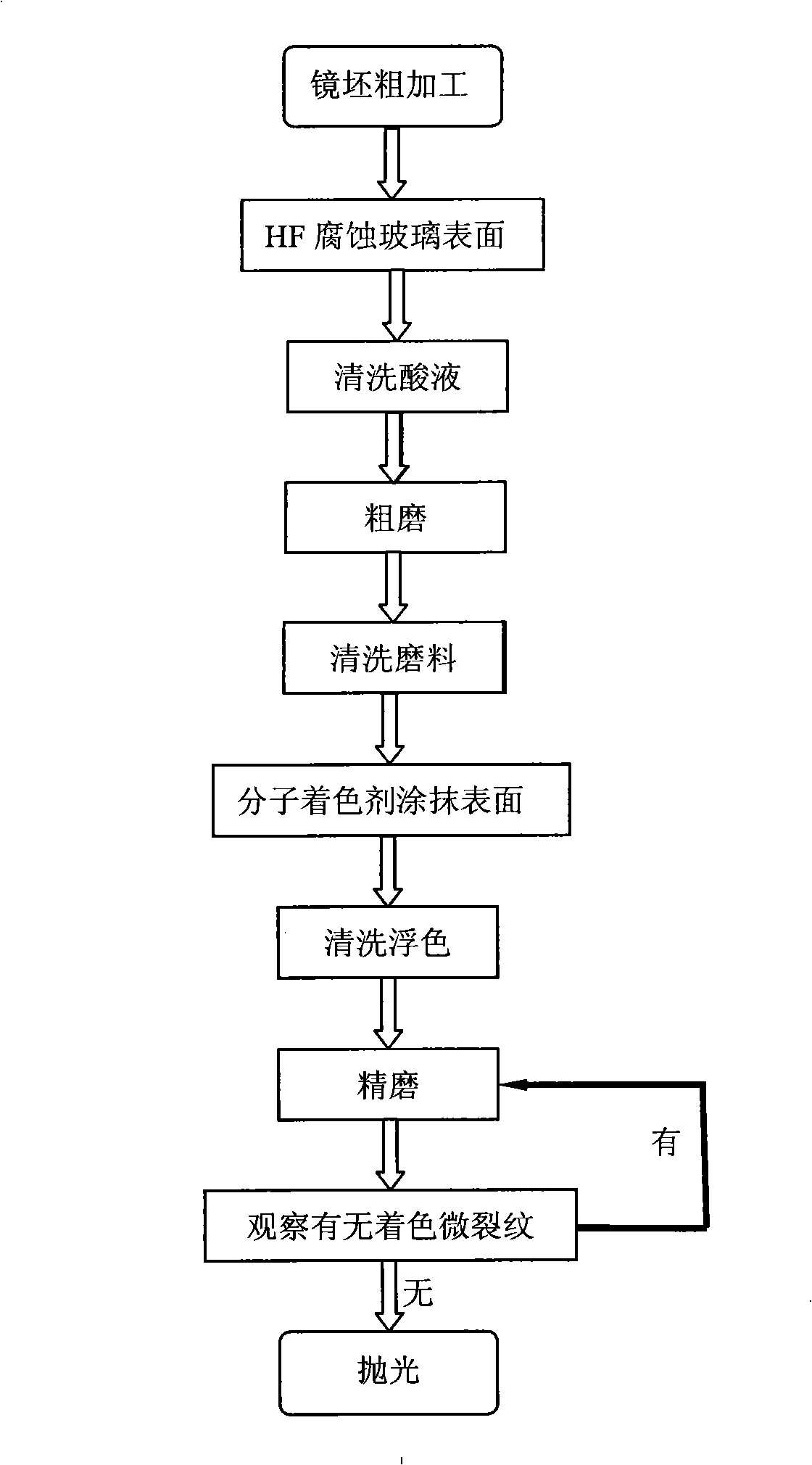

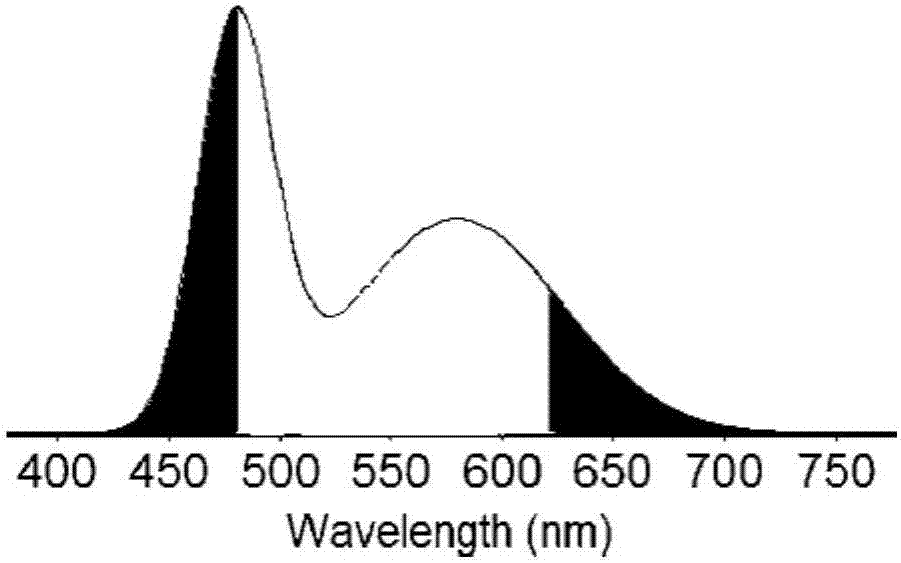

Method for glass micro-crack detection by molecule stainer

InactiveCN101403707AImprove surface chemistryImprove mechanical propertiesOptically investigating flaws/contaminationCrazingProcess quality

The invention provides a method used for detecting microcracks of glass by a molecule colorant, belonging to a real-time detection method in the technical field of optical cold working; the method comprises the steps as follows: after chunk glass is roughly machined, the chunk glass is arranged statically for several tens of hours so as to release the stress; subsequently, the surface of the chunk glass is corroded by acid, coated by the molecule colorant and arranged statically for several minutes; the colorant molecules infiltrate the interior of the microcrack passage till the bottom end by the compatibility of the glass on the aqueous solution and the scattering nature of the colorant; and the floating color on the surface of the chunk glass is washed away by water and the shape and depth of the microcrack can be clearly displayed, thus providing reliable basis for removing the microcrack. The method has the active effects that HF corrosion is used for reinforcing the chemical and mechanic performance of the glass surface, natural high-strength characteristic of the glass is partly recovered, the limits of microcrack theory detection method are overcome, the process flow is simplified, the processing time is saved, the processing cost is reduced, and the working efficiency and process quality are improved.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

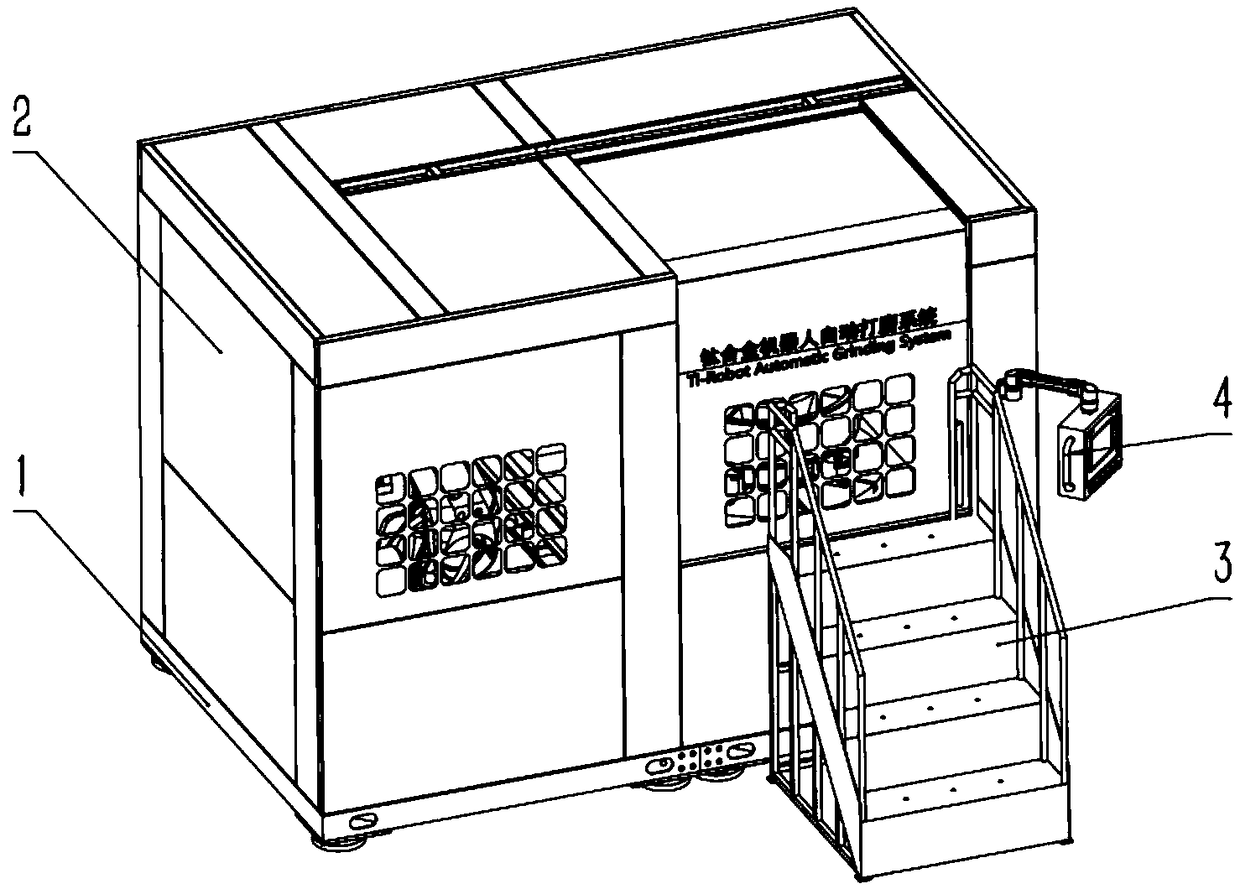

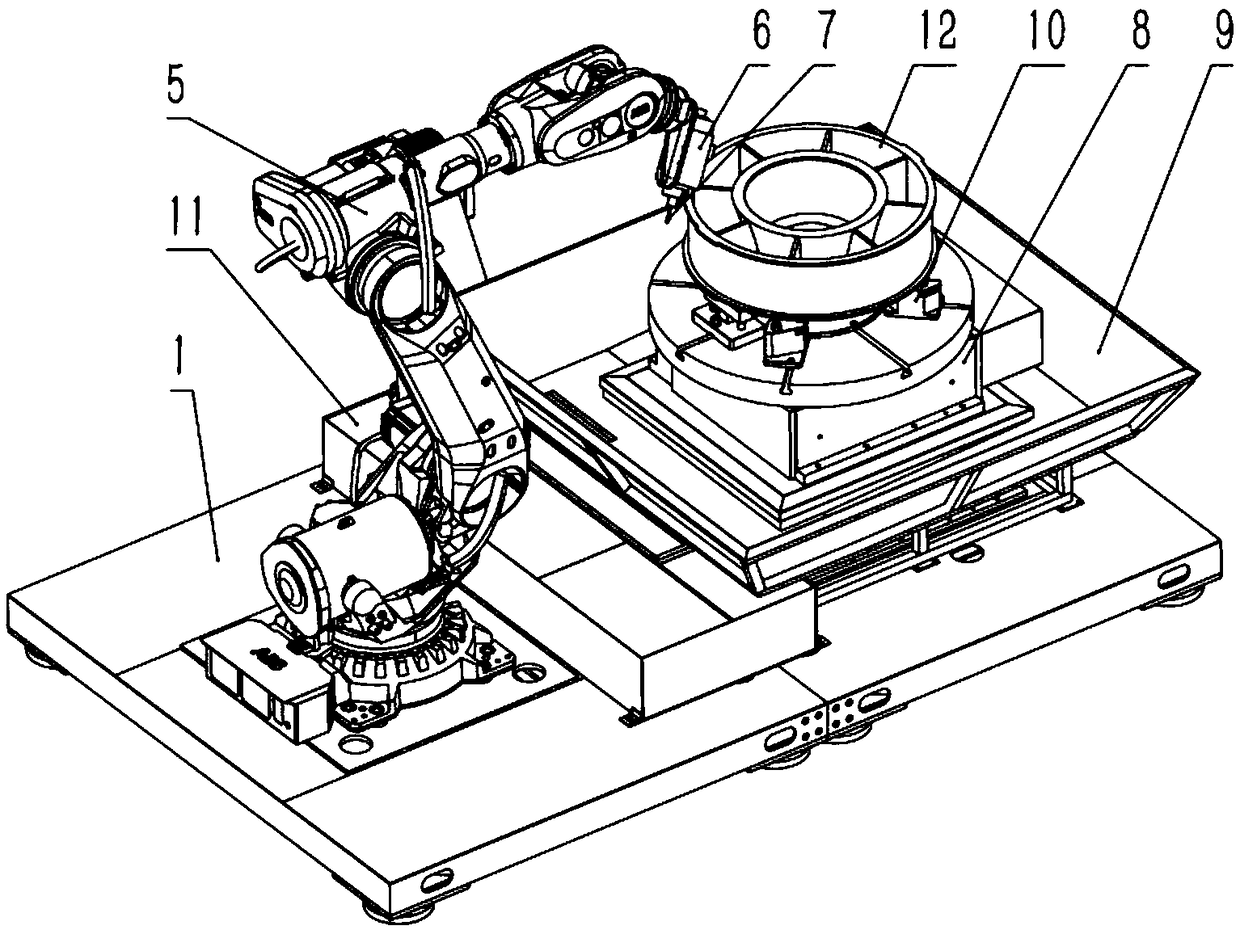

Automatic grinding and polishing process for titanium alloy annular casting

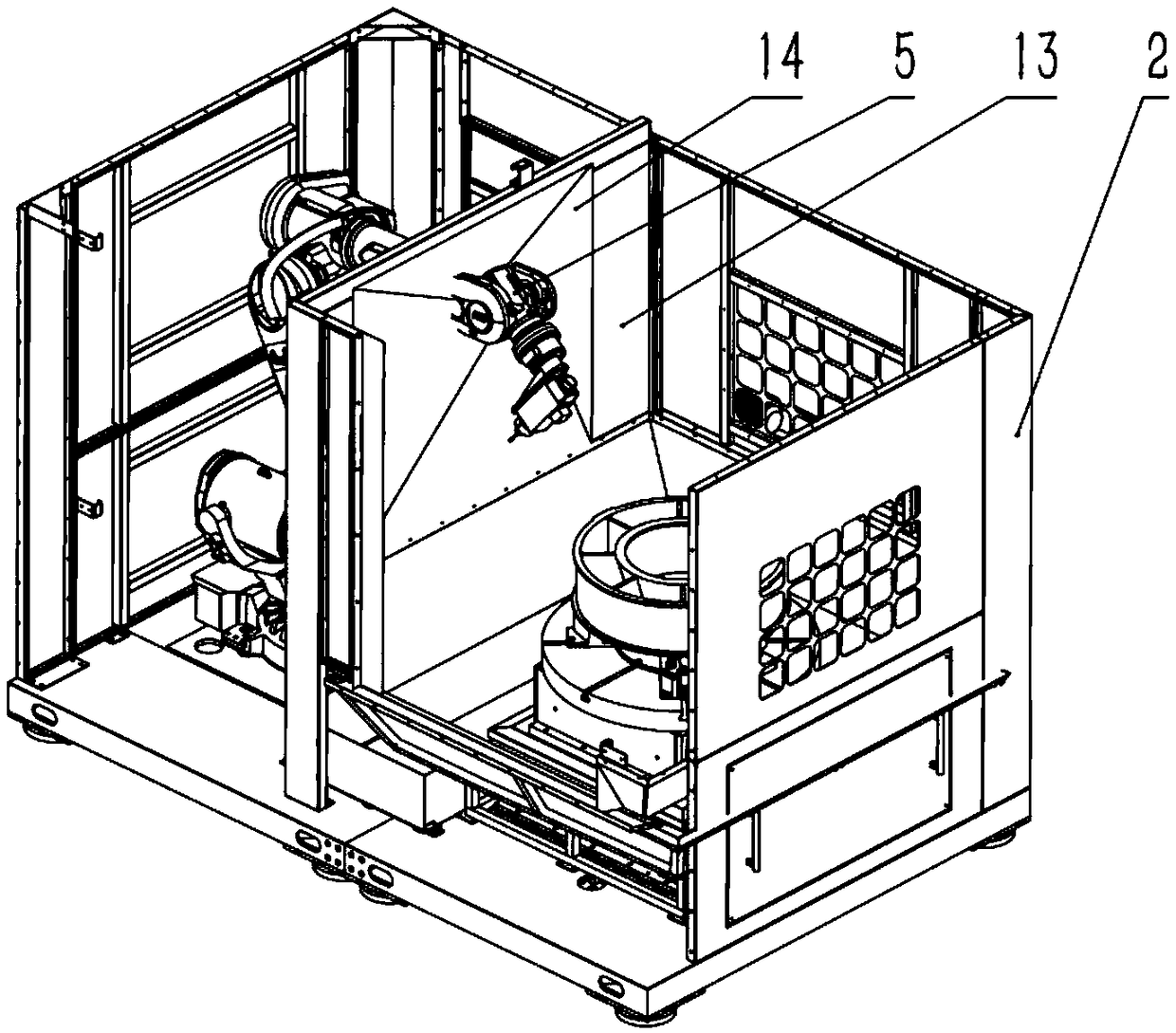

ActiveCN109365793ARealize automatic grinding and polishing operationsExtend your lifeFiling/rasping devicesManipulatorTitanium alloyMachining

The invention provides an automatic grinding and polishing process for a titanium alloy annular casting. An automatic grinding and polishing system for the titanium alloy annular casting mainly comprises a base, an outer cover, an industrial robot, an electric main shaft, a rotating workbench, a positioning clamp, a water tank, a cooling chip removal machine, a PLC and a display screen. The titanium alloy annular casting is positioned and clamped on the surface of the rotating workbench through the clamp; the robot clamps the electric main shaft to move according to a certain trajectory so that the grinding and polishing work of the titanium alloy annular casting is realized, moreover, multiple kinds of sensors are adopted for cooperation to adjust a machining path so as to adapt to the complicated contour and shape difference of a part, therefore, the automatic grinding and polishing system for the titanium alloy annular casting has a wide application prospect in titanium alloy annular casting machining, the production efficiency can be improved, and considerable benefits can be brought to enterprises.

Owner:WUHAN UNIV OF TECH

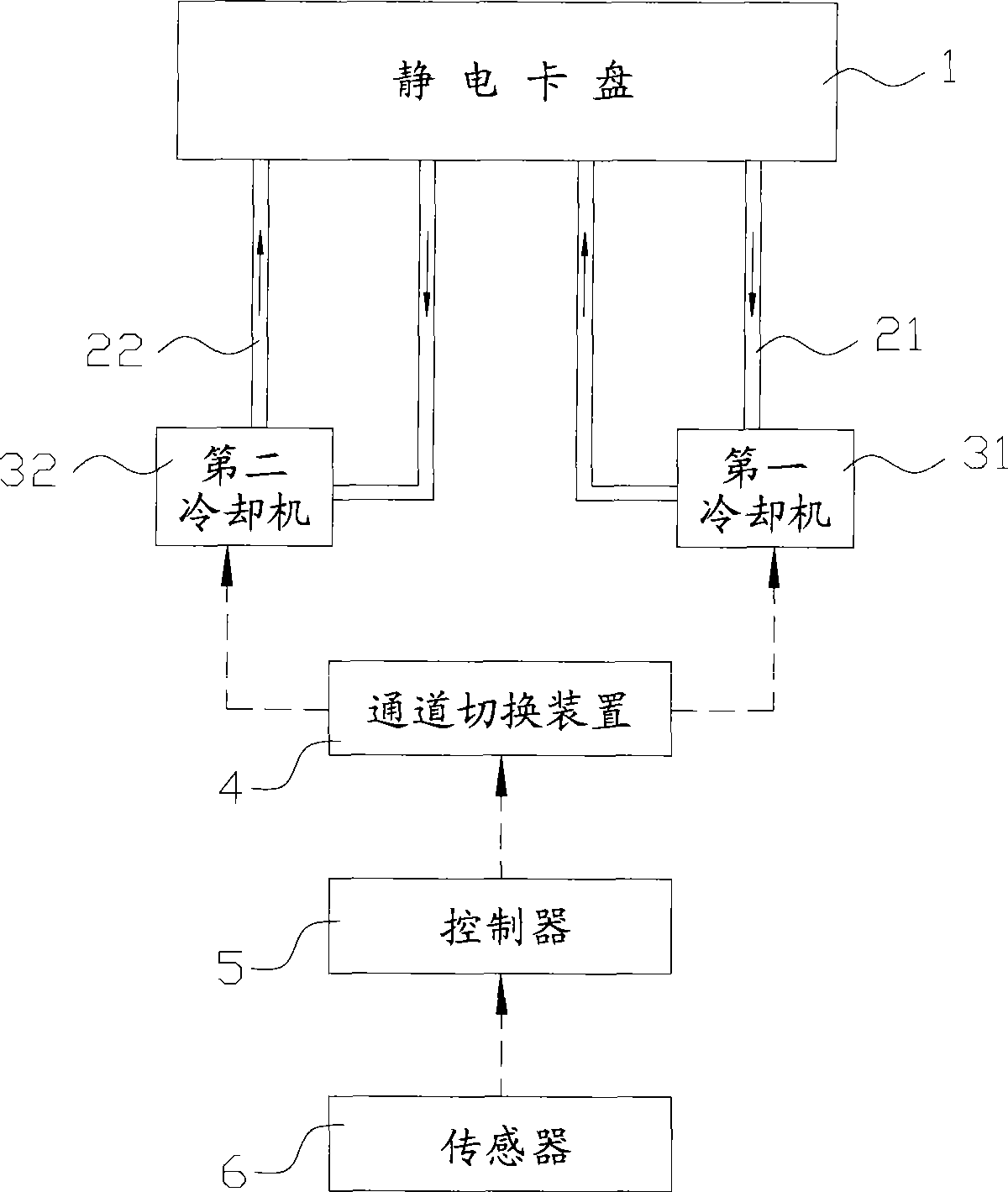

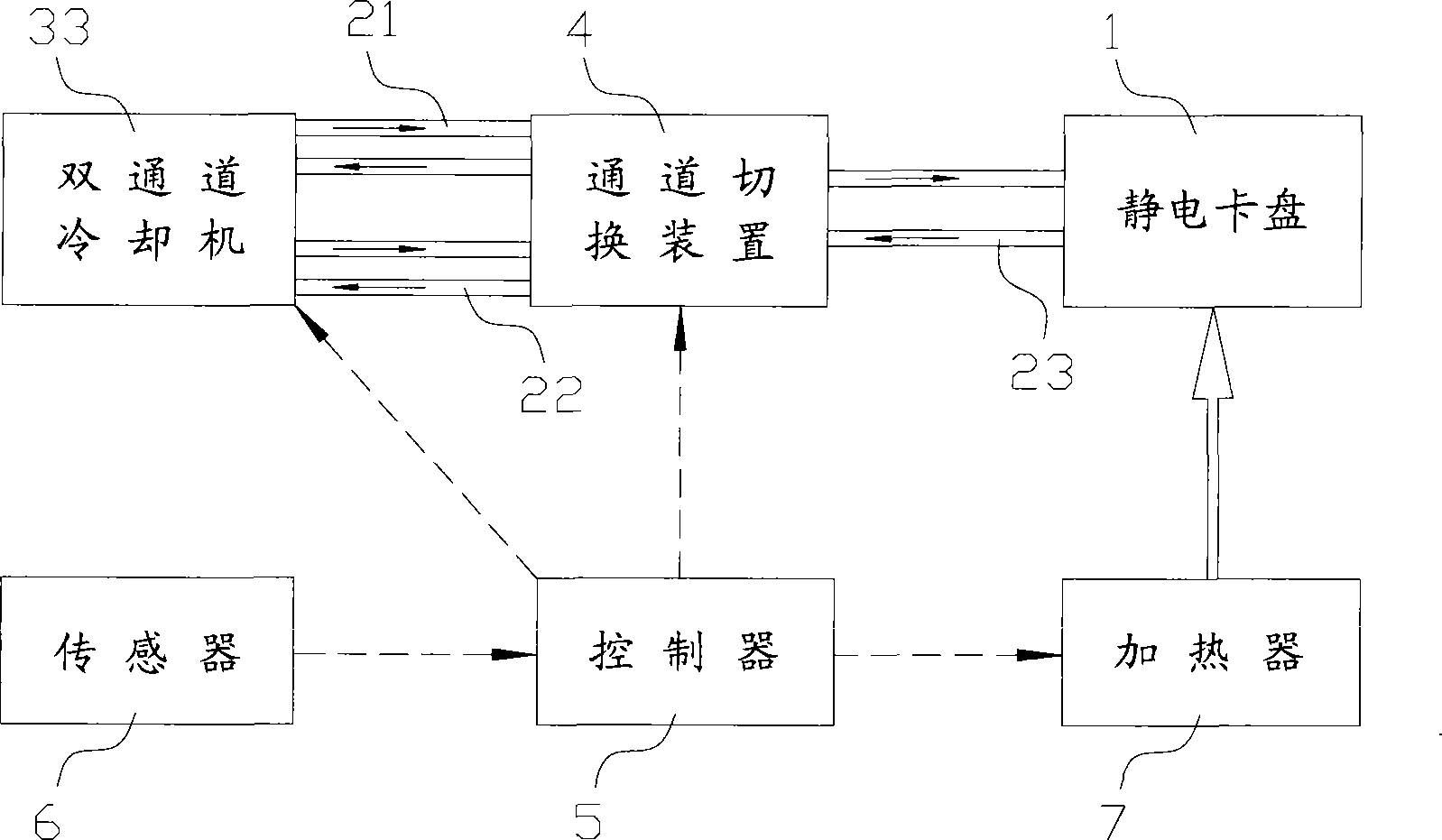

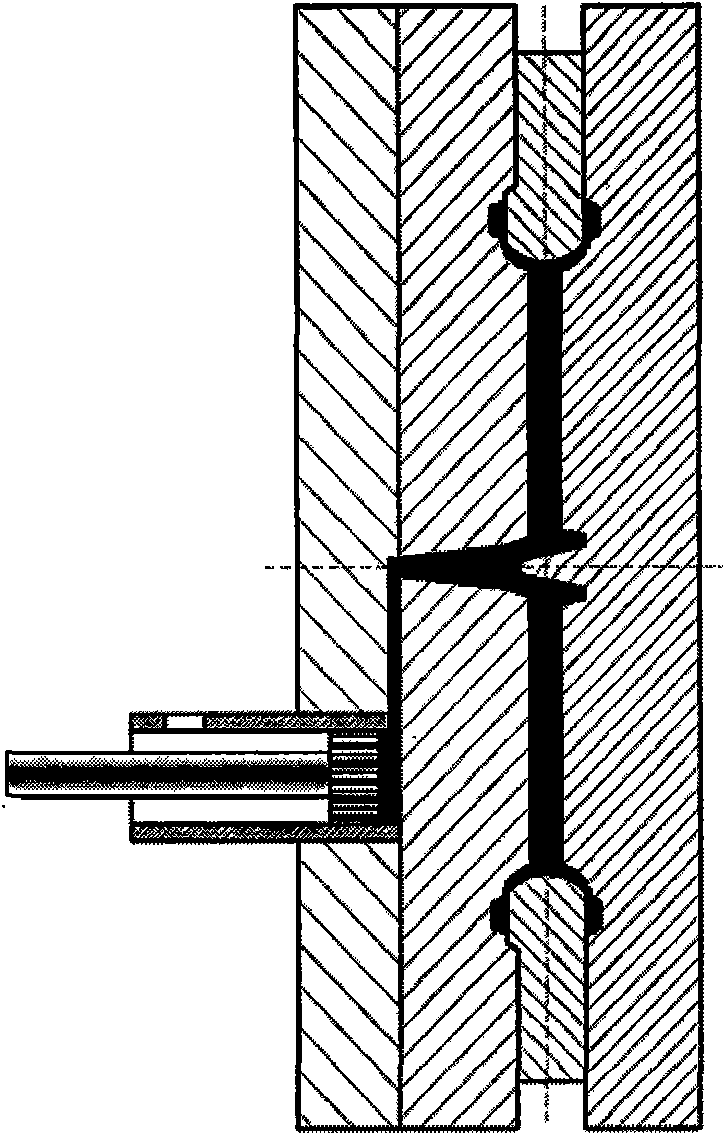

Electrostatic chuck apparatus and temperature control method thereof

ActiveCN101373731AAdjustable temperatureAchieve substantial coolingElectric discharge tubesVacuum evaporation coatingTemperature controlHeating time

The invention discloses a plasma processing device and an electrostatic chuck assembly. The electrostatic chuck assembly comprises a first cooling passage and a second cooling passage which can provide cooling media to a cooling medium cavity, and a passage switching device which selects either of the first cooling passage or the second cooling passage to be communicated with the cooling medium cavity. Temperature differences exist between the cooling media in the two cooling passages. The invention further discloses a temperature control method of the electrostatic chuck assembly. Through the method, cooling media at different temperatures are provided for the cooling medium cavity in a substrate of the electrostatic chuck assembly through at least two cooling passages; when temperature rise is needed, the cooling medium at the higher temperature is imported to the cooling medium cavity; and when temperature reduction is needed, the cooling medium at the lower temperature is importedin the cooling medium cavity. When the temperature is increased, the electrostatic chuck assembly can obtain higher basic temperature, thereby being conducive to reducing the power of a heater and saving heating time. When the temperature is reduced and the temperature reduction gradient is increased, the electrostatic chuck assembly can be greatly cooled in a short time.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

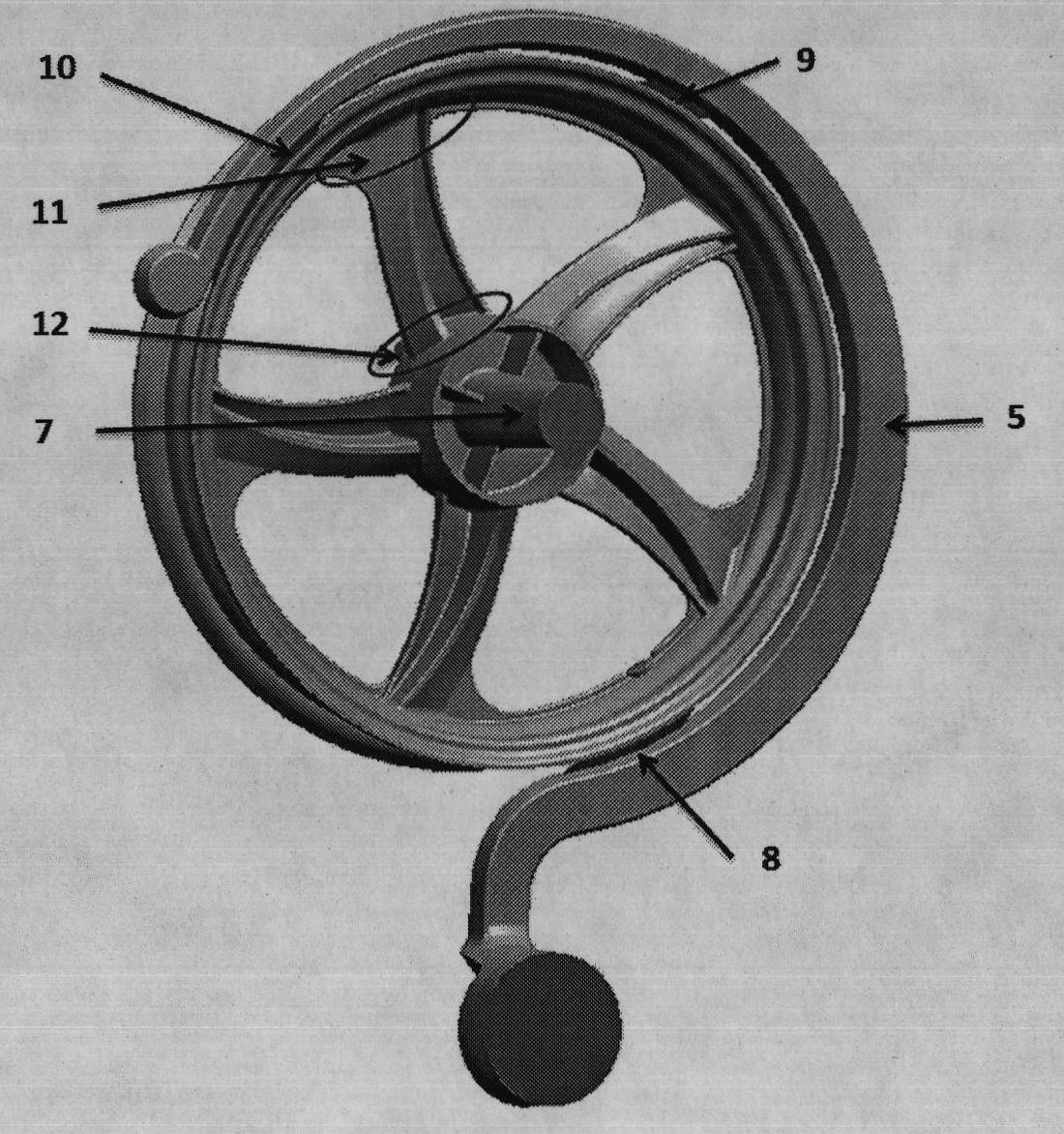

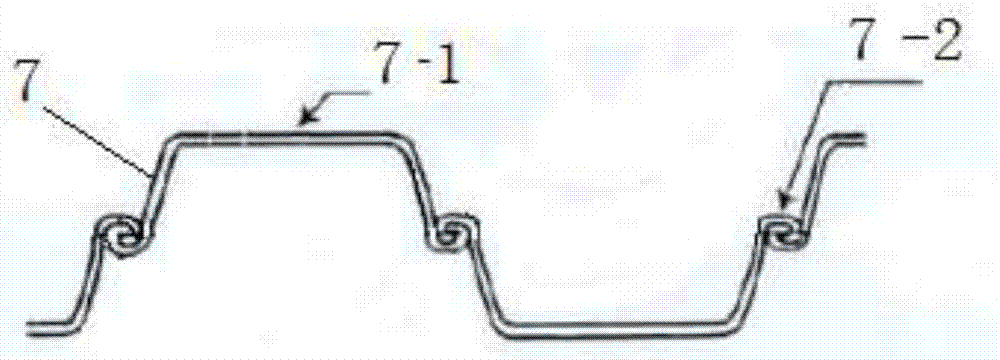

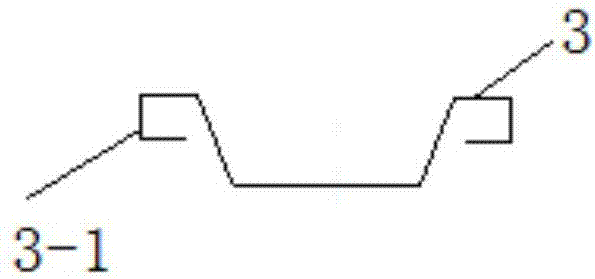

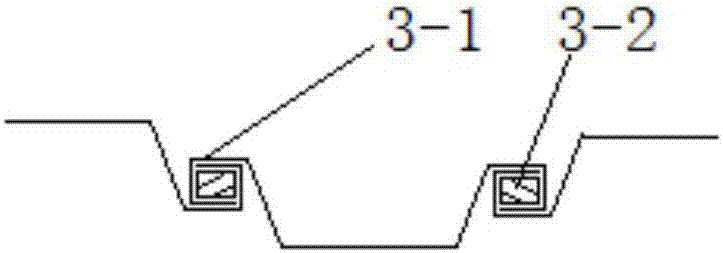

Vacuum high-pressure casting method

The invention relates to a vacuum high-pressure casting process method for a wheel disc casting. The method comprises the following steps of: after melt casting is finished, sequentially and centripetally filling a model from a wheel flange to a wheel center through a broken ring-shaped runner and a tangential ingate with the assistance of vacuum; and after model filling is finished, jointly pressurizing by a pressure head and a pressure filling head which is positioned on an epitaxial slag ladle of the wheel center and maintaining the pressure till a casting is fully solidified to obtain a high-quality wheel disc casting which has the advantages of high-quality wheel flange model filling and no solidification contraction and blowhole defect on a wheel flange hot spot and a wheel center hot spot.

Owner:重庆硕龙科技有限公司

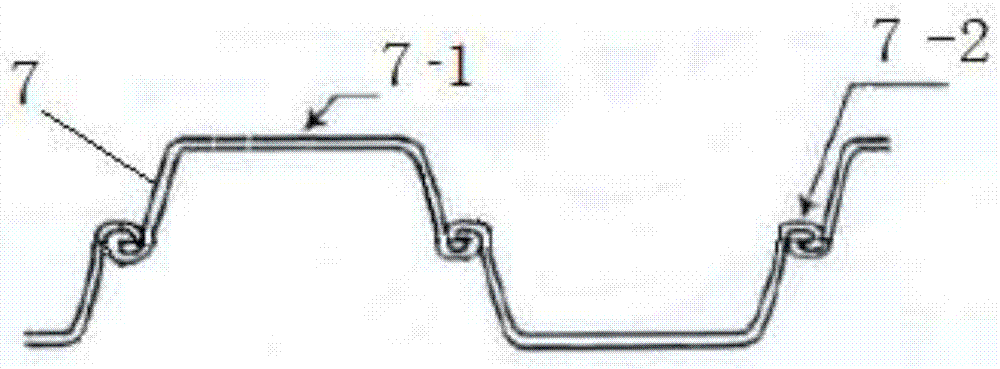

Enclosure for continuous wall foundation pit formed by steel cylinders or steel plate piles adopting seal grooves and occlusion structures and construction method of enclosure

PendingCN107268636AImprove mechanical propertiesGuarantee smooth implementationExcavationsBulkheads/pilesStructural engineeringPipe

The invention relates to an enclosure for a continuous wall foundation pit formed by steel cylinders or steel plate piles adopting seal grooves and occlusion structures. The steel cylinders or steel plate piles adopting the seal grooves are connected to form the continuous pile wall so as to form the foundation pit enclosure, according to the steel cylinders or steel plate piles with the seal grooves, at least one seal groove is formed at the connecting positions of steel plates or piles of steel cylinder piles, the cross section of each groove is in a convex arc shape, a concave shape or a polygon shape, a matched pipe is inlaid in each groove, the steel plates or steel cylinder piles and the pipes in the grooves are jointly and independently tampered into the stratum, pipe cavities in the grooves are left or waterproof sealing materials are injected into the pipe cavities to serve as sealing layers at the connecting positions of the steel plates or the piles of the steel cylinder piles; the cross section of the connecting positions of the steel plates or the piles of the steel cylinder piles is in a hook shape or concave-convex matched or third filling block filling connecting shape; and one or more sealing grooves are formed in the pile connecting positions.

Owner:JIANGSU GREEN RIVER ENVIRONMENTAL TECH CO LTD

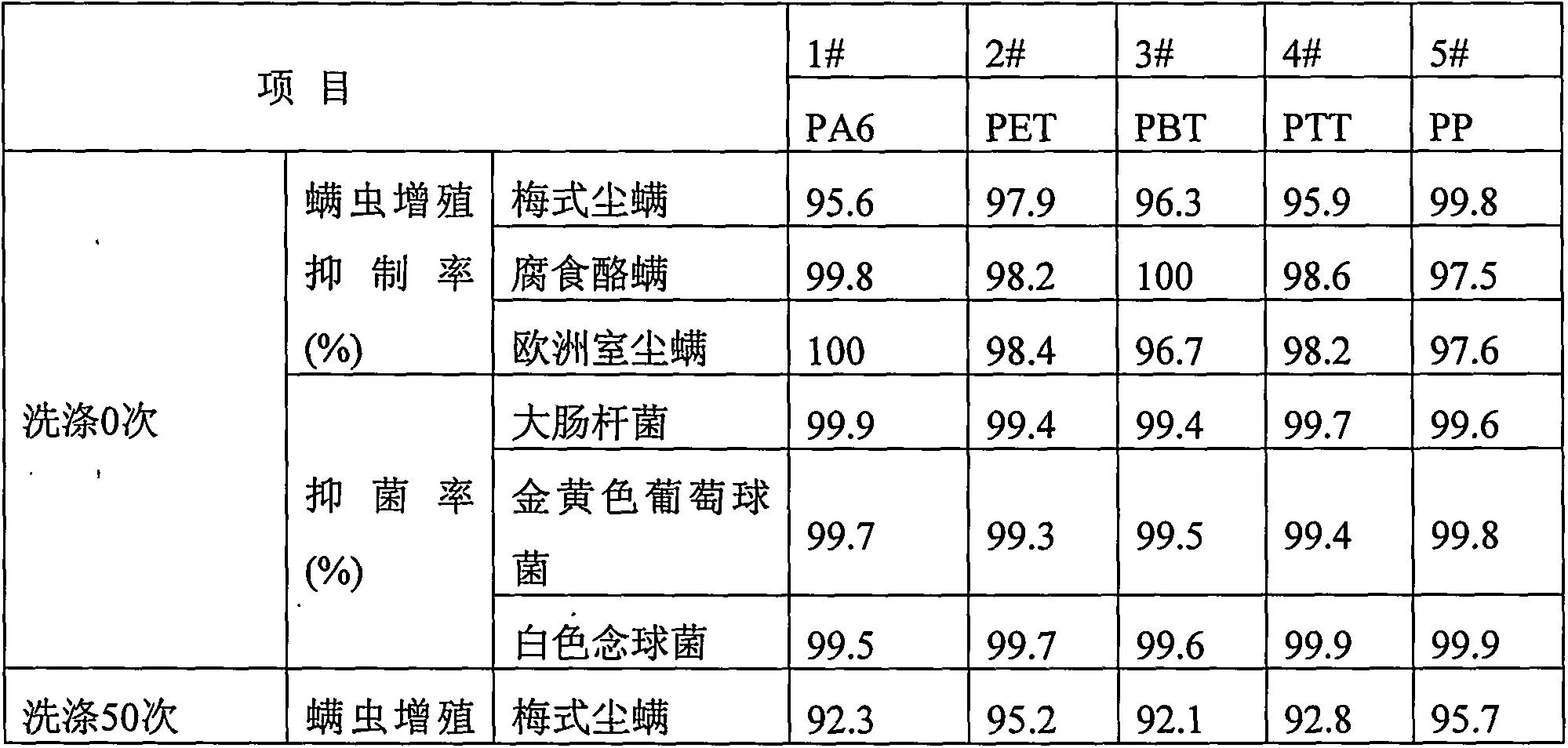

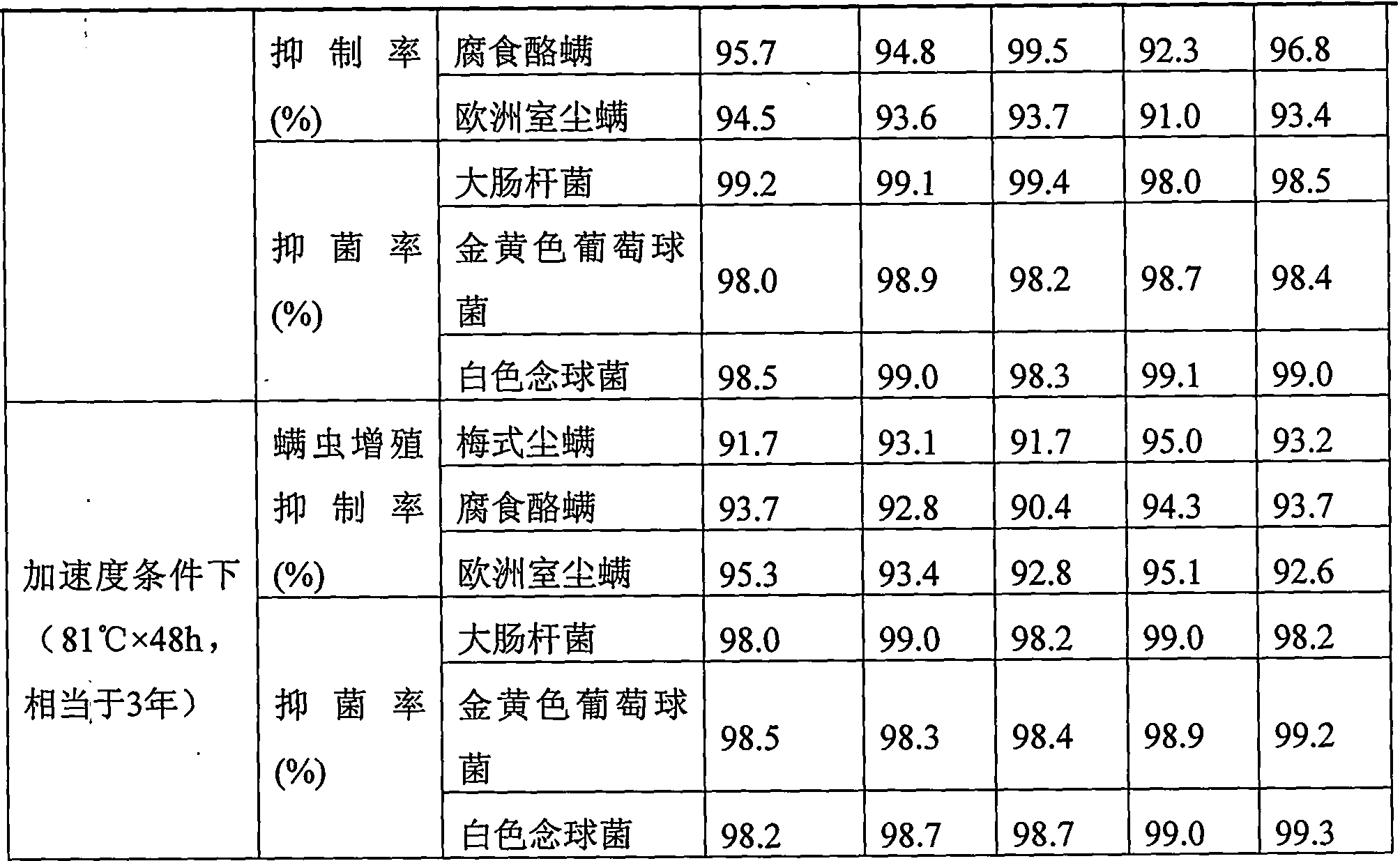

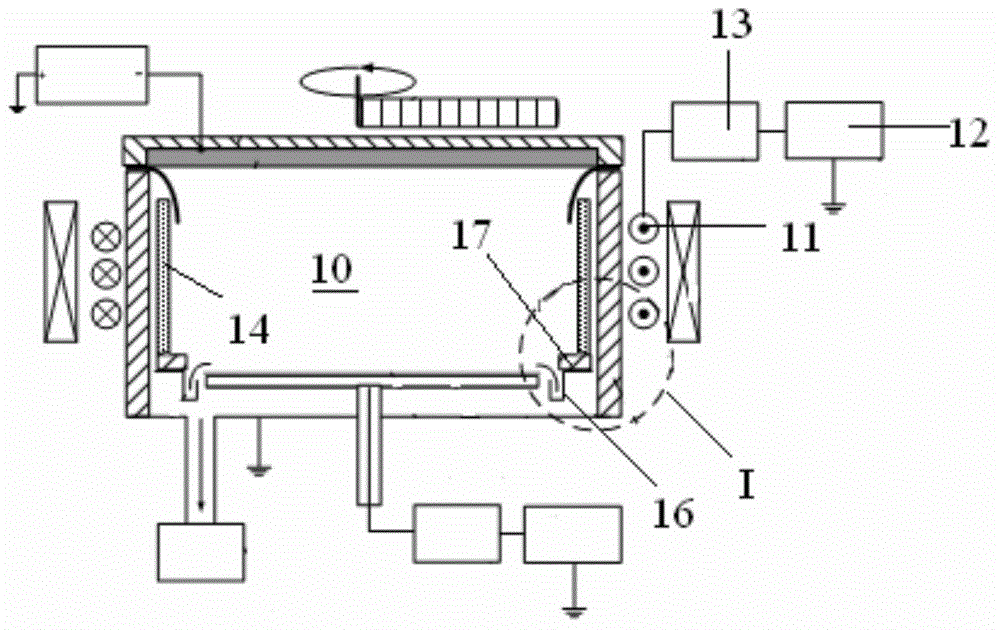

Anti-mite antibacterial thermoplastic polymer melt spun fiber and preparation method thereof

ActiveCN103882543AImprove durabilityAllergy freeSpinning head liquid feederArtificial filament heat treatmentHigh concentrationPolymer science

The invention relates to a thermoplastic polymer melt spun fiber with anti-mite and antibacterial functions and a preparation method thereof. The preparation method comprises the following steps: preparing a silver-loaded soda borosilicate ceramic powder which serves as an anti-mite and antibacterial component through a sol-gel method, performing surface modification on superfine ceramic powder through a coupling agent, granulating to prepare a high-concentration anti-mite and antibacterial master batch which takes a thermoplastic polymer as a matrix in a double-screw extruder, and finally, blending the anti-mite and antibacterial master batch with the thermoplastic polymer according to a certain ratio, and performing melt spinning to obtain the anti-mite and antibacterial fiber. The anti-mite and antibacterial fiber prepared by the method has obvious effects, is high in durability, high in washing resistance and high in safety.

Owner:上海市合成纤维研究所有限公司

Reaction chamber and semiconductor processing equipment

ActiveCN105097401AReduce thicknessIncrease inner diameterElectric discharge tubesVacuum evaporation coatingEngineeringMetal particle

A reaction chamber and semi-conductor processing device, comprising a Faraday shielding ring (21) made of nonconductive magnetic material and an insulating ring (22) made of insulating material; the Faraday shield ring (21) is provided with a slot thereon passing through the ring surface thereof in an axial direction; both the Faraday shielding ring (21) and the insulating ring (22) are disposed in the reaction chamber surrounding the inner peripheral wall of the reaction chamber; the Faraday shielding ring (21) is stacked on the insulating ring (22) in a vertical direction; a shielding ring (211) is disposed surrounding the inner peripheral wall of the insulating ring (22), the shielding ring (211) is connected to an area on the lower surface of the Faraday shielding ring (21) adjacent to the center of the reaction chamber; and the shielding ring (211) is made of the nonconductive magnetic material, and is provided with the slot thereon passing through the ring surface thereof in the axial direction. The reaction chamber and the semi-conductor processing device avoid or reduce the risk of sparking, reduce pollution of the reaction chamber caused by the flaking off of metal particles, and increase the inner diameter and available space of the reaction chamber.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

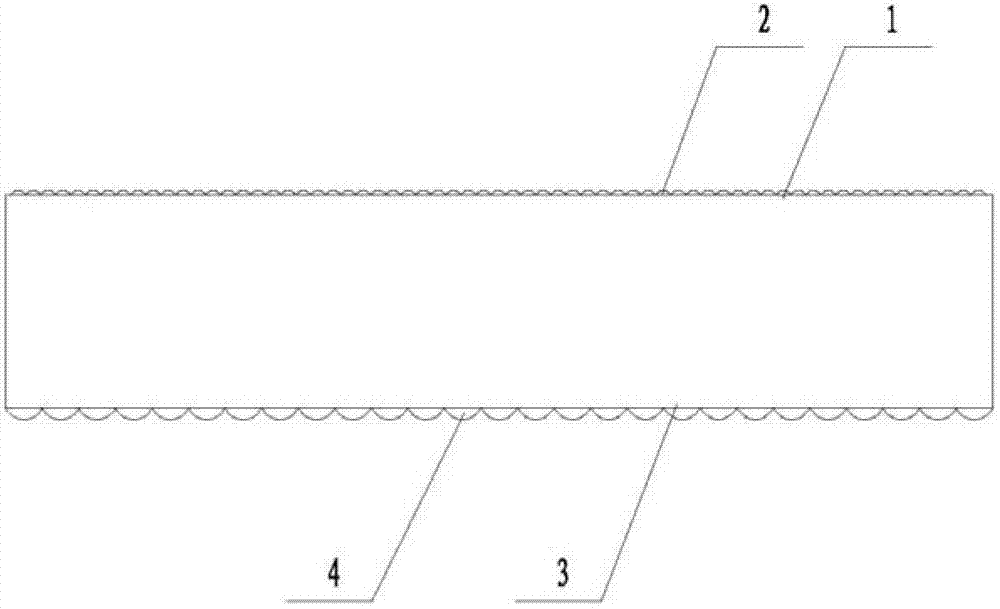

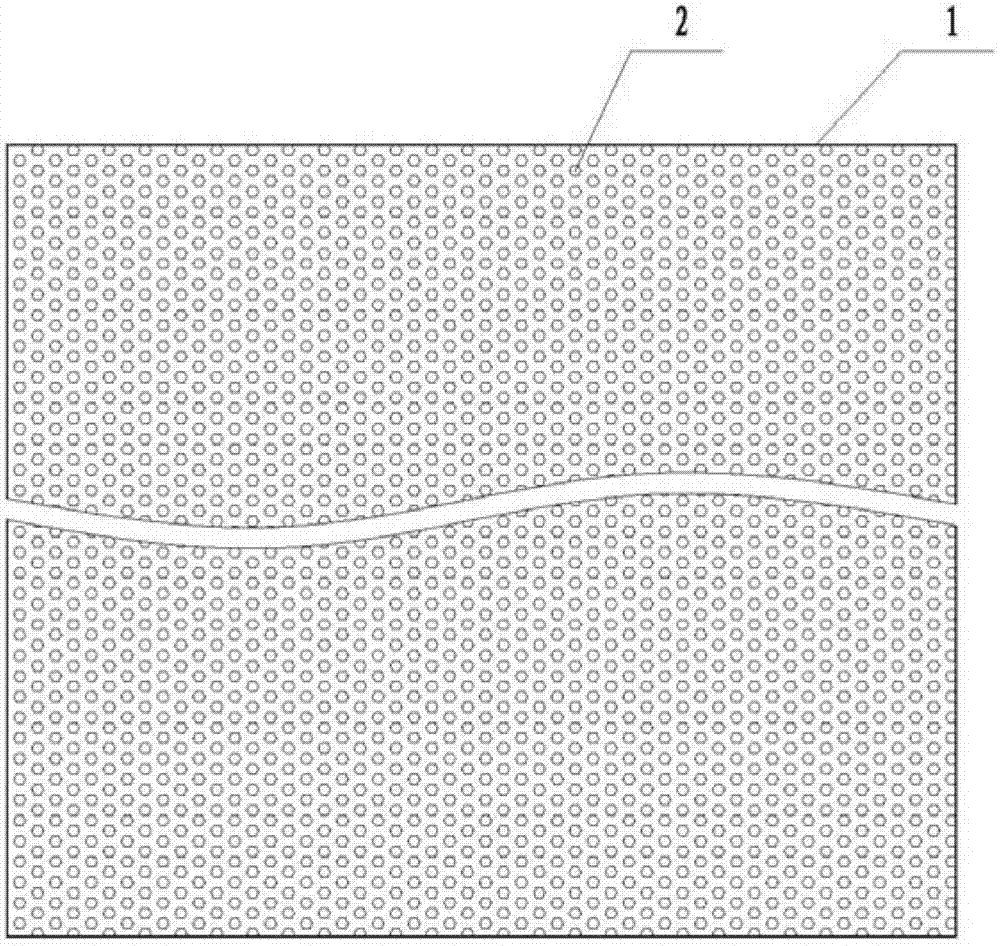

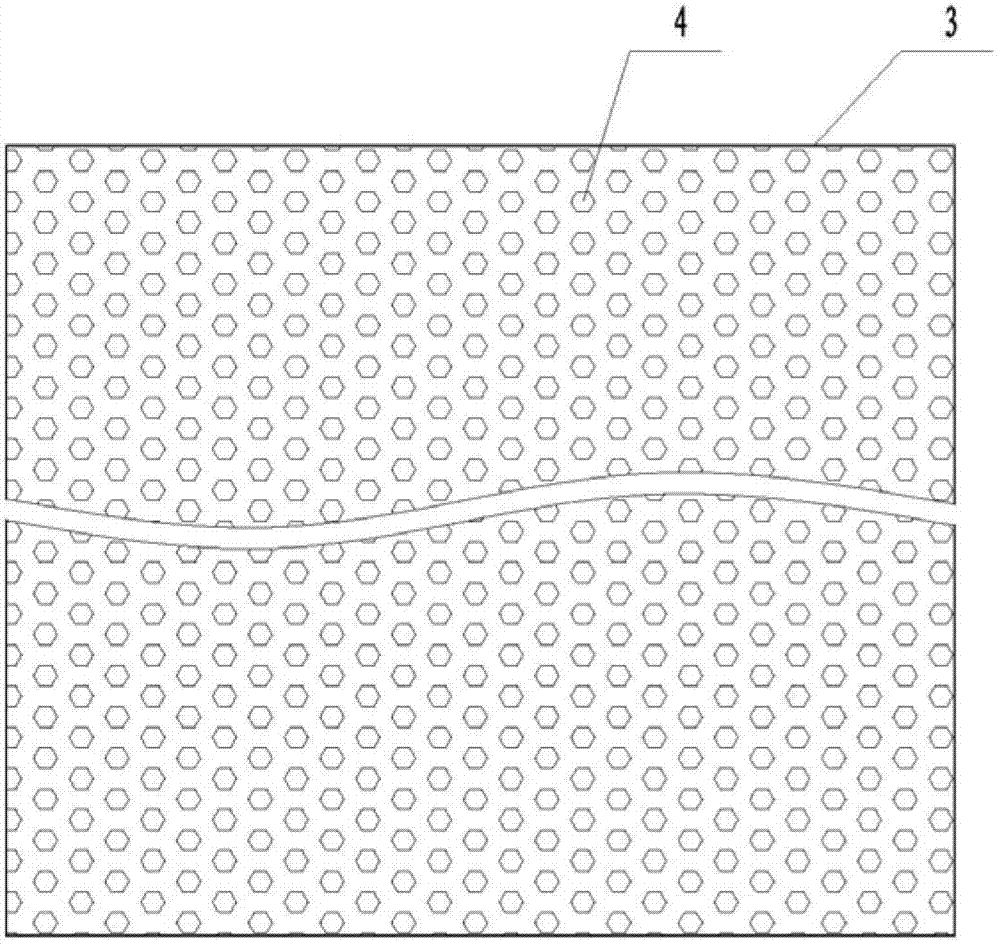

Light guide plate and manufacturing method of light guide plate as well as backlight module and display device

InactiveCN102928911AIncrease display brightnessImprove product qualityPolishing machinesPoint-like light sourceLight guideDisplay device

The invention relates to the technical field of display and particularly relates to a light guide plate capable of utilizing a micro-penetration surface to collect light and a manufacturing method of the light guide plate as well as a backlight module and a display device. An emergent surface of the light guide plate is the micro-penetration surface; the micro-penetration surface comprises a plurality of micro-penetration points and the micro-penetration points are provided with convex surfaces; and the bottom surface of the light guide plate is a net surface and the net surface comprises a plurality of net points and the net points are provided with convex surfaces. The manufacturing method of the light guide plate comprises the steps of: presetting a micro-penetration point distribution pattern by a precision engraving machine; putting a micro-penetration surface die core base plate into a precision engraving machine; engraving the micro-penetration surface die core base plate into a micro-penetration face die core according to the micro-penetration point distribution pattern; assembling the micro-penetration surface die core and a light guide plate die core into a light guide plate die; and injecting and molding into the light guide plate by the light guide plate die. A micro-penetration surface design is adopted and directions of all scattering lights in the light guide plate can be adjusted by using the micro-penetration surface to collect the scattering lights; and the development brightness and the influence definition of a liquid crystal liquid screen are improved and the product quality is improved.

Owner:BOE TECH GRP CO LTD +1

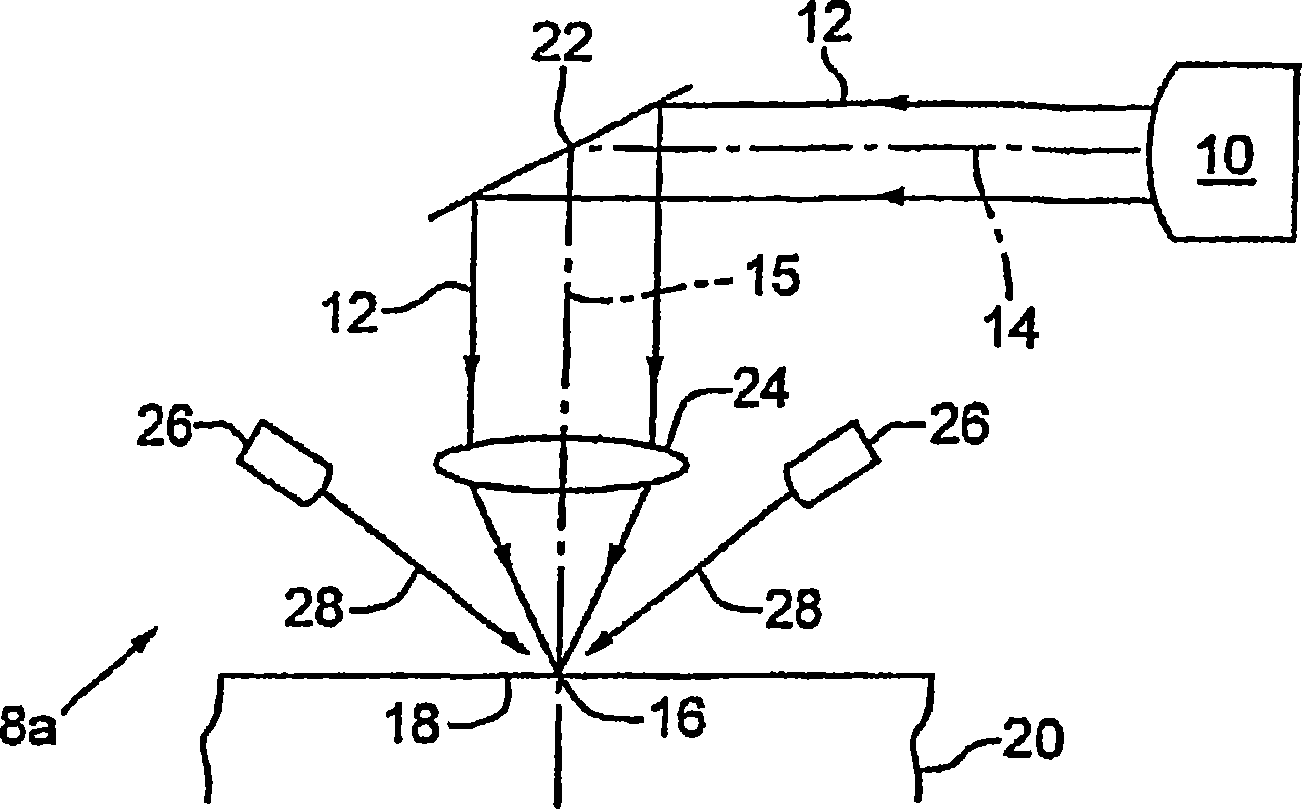

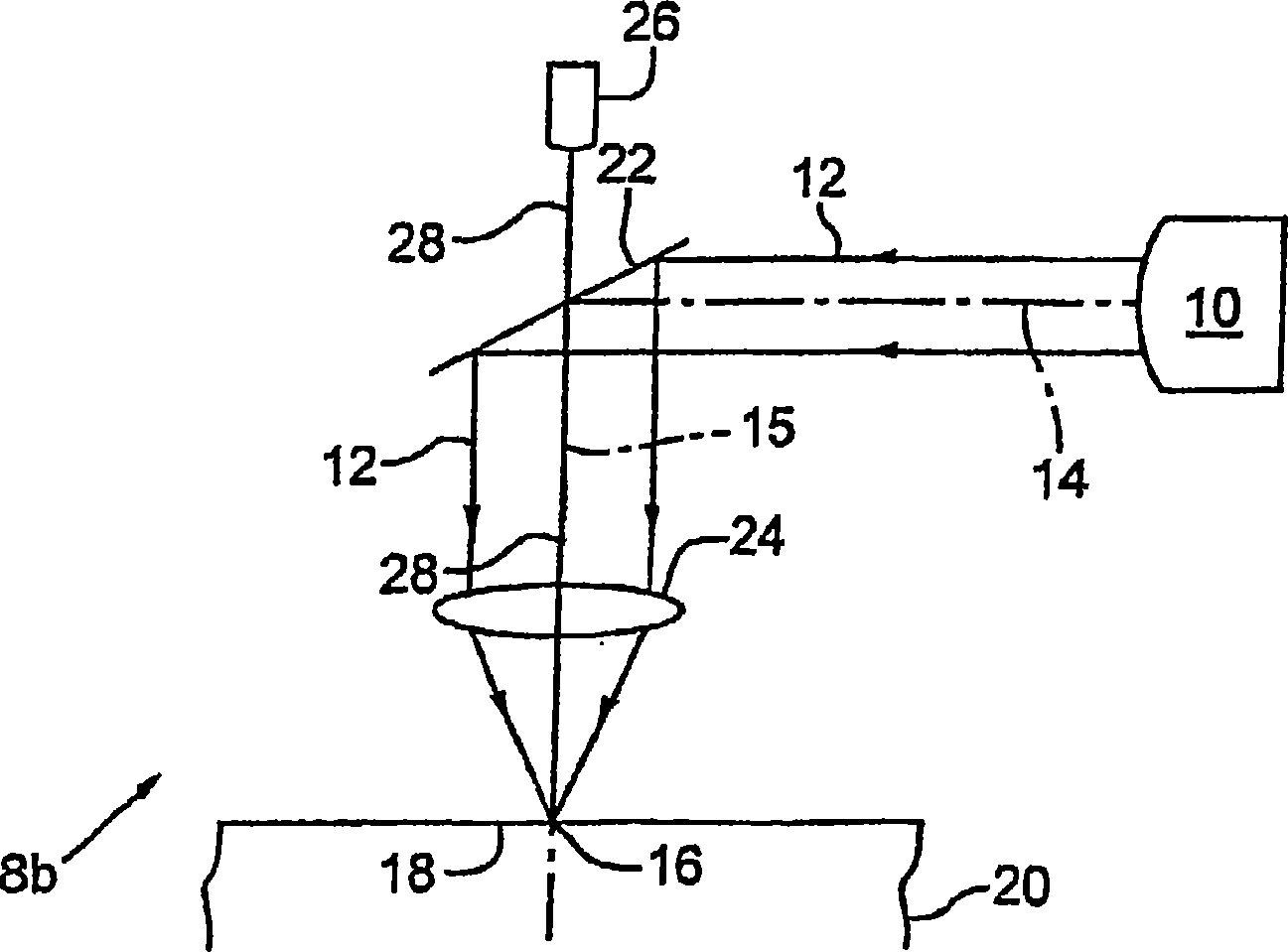

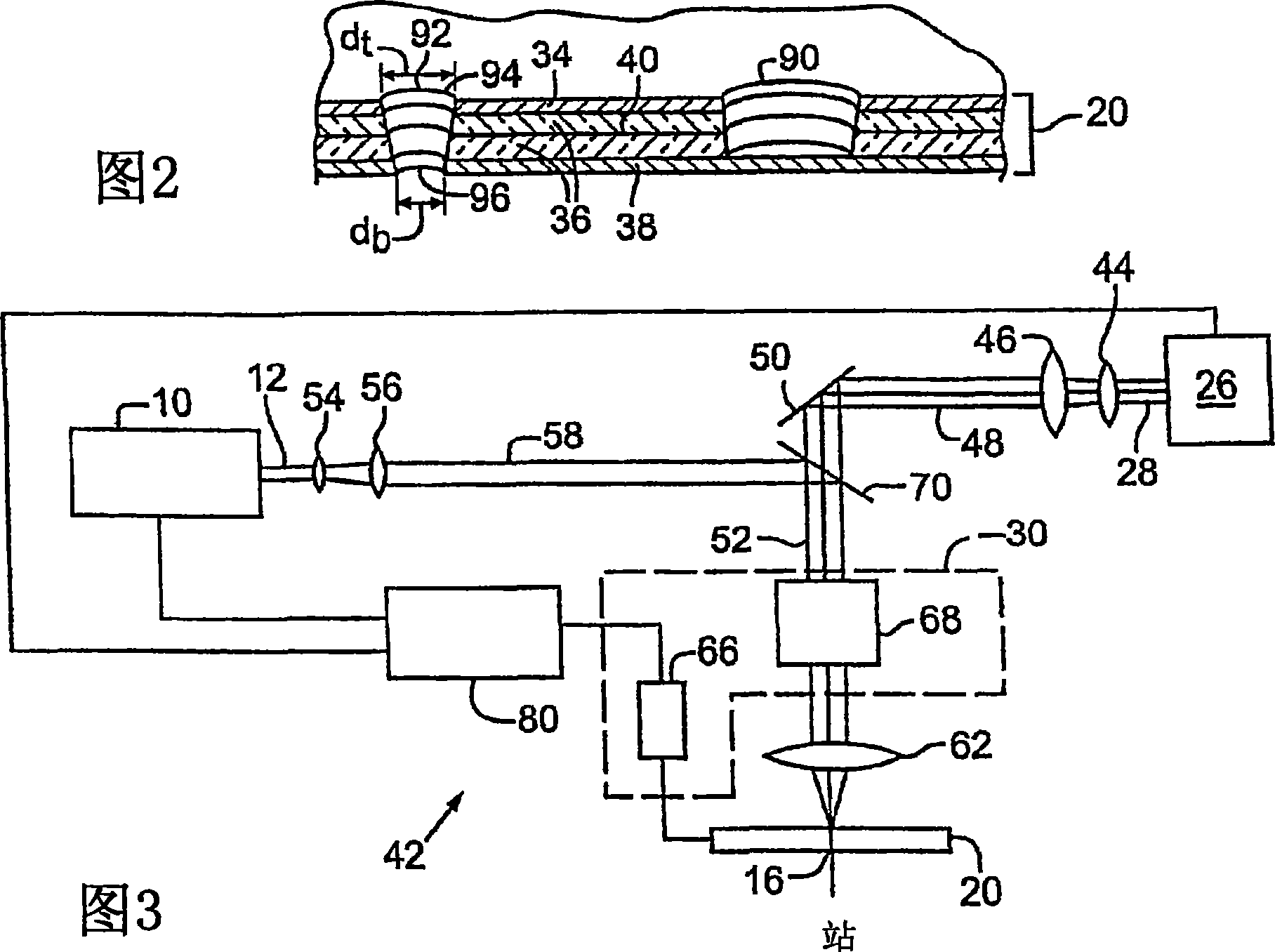

Laser processing of a locally heated target material

InactiveCN1882408AIncrease production speedImprove removal rateLaser beam welding apparatusLaser processingMaterial removal

A method and laser system effect rapid removal of material from a workpiece (20) by applying heating energy in the form of a light beam (28) to a target location (16) on the workpiece to elevate its temperature while maintaining its dimensional stability. When the target portion of the workpiece is heated, a laser beam (12) is directed for incidence on the heated target location. The laser beam preferably has a processing laser output that is appropriate to effect removal of the target material from the workpiece. The combined incidence of the processing laser output and the heating energy on the target location enables the processing laser output to remove a portion of the target material at a material removal rate that is higher than the material removal rate achievable when the target material is not heated.

Owner:ELECTRO SCI IND INC

Steel cylinder pile or steel sheet pile with sealing grooves and occlusion structures and steel structure continuous wall

PendingCN107217676AEnsure construction safetyEnsure safetyProtective foundationExcavationsSteel tubeEngineering

The invention discloses a steel cylinder pile or steel sheet pile with sealing grooves and occlusion structures. The steel cylinder pile or steel sheet pile is provided with the waterproof sealing grooves; at least one groove used for sealing is formed in the connecting positions of steel sheet piles or steel cylinder piles; the cross section of each groove is convex-arc-shaped, concave or polygonal; pipes with the same sectional area are inlaid in the grooves; the steel sheet piles or the steel cylinder piles and the pipes inside the grooves are rammed into a stratum together or separately; and after the steel pipes are pulled out, waterproof sealing materials are reserved in or injected into cavities inside the grooves so as to form waterproof sealing layers at the connecting positions of the steel sheet piles or the steel cylinder piles. The steel cylinder pile or steel sheet pile has the advantages that in the application of a steel structure continuous wall, a foundation and a foundation pit, particularly, the sealing structural steel cylinder pile is a rectangular steel cylinder pile, and rectangular steel cylinders are tightly arranged.

Owner:JIANGSU GREEN RIVER ENVIRONMENTAL TECH CO LTD

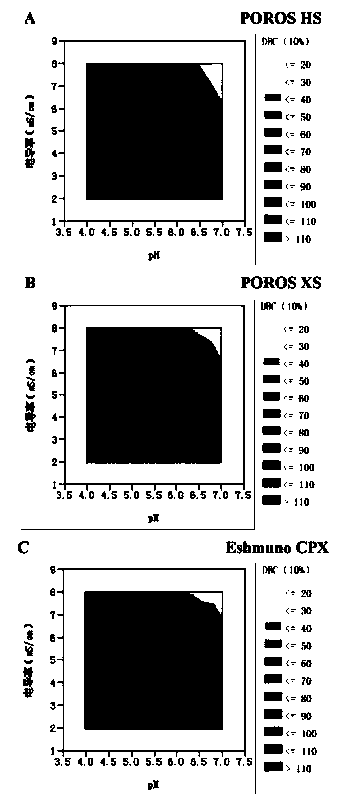

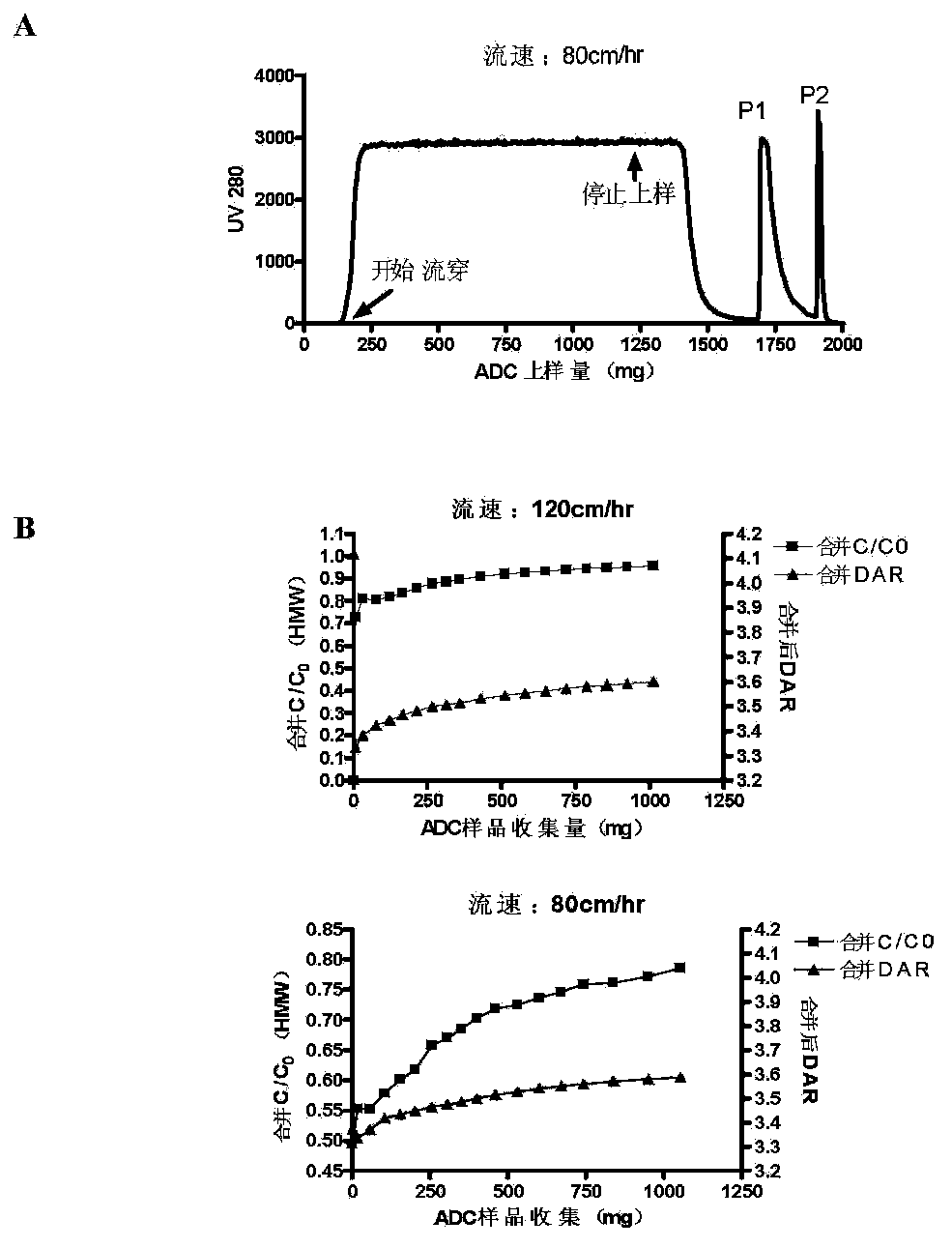

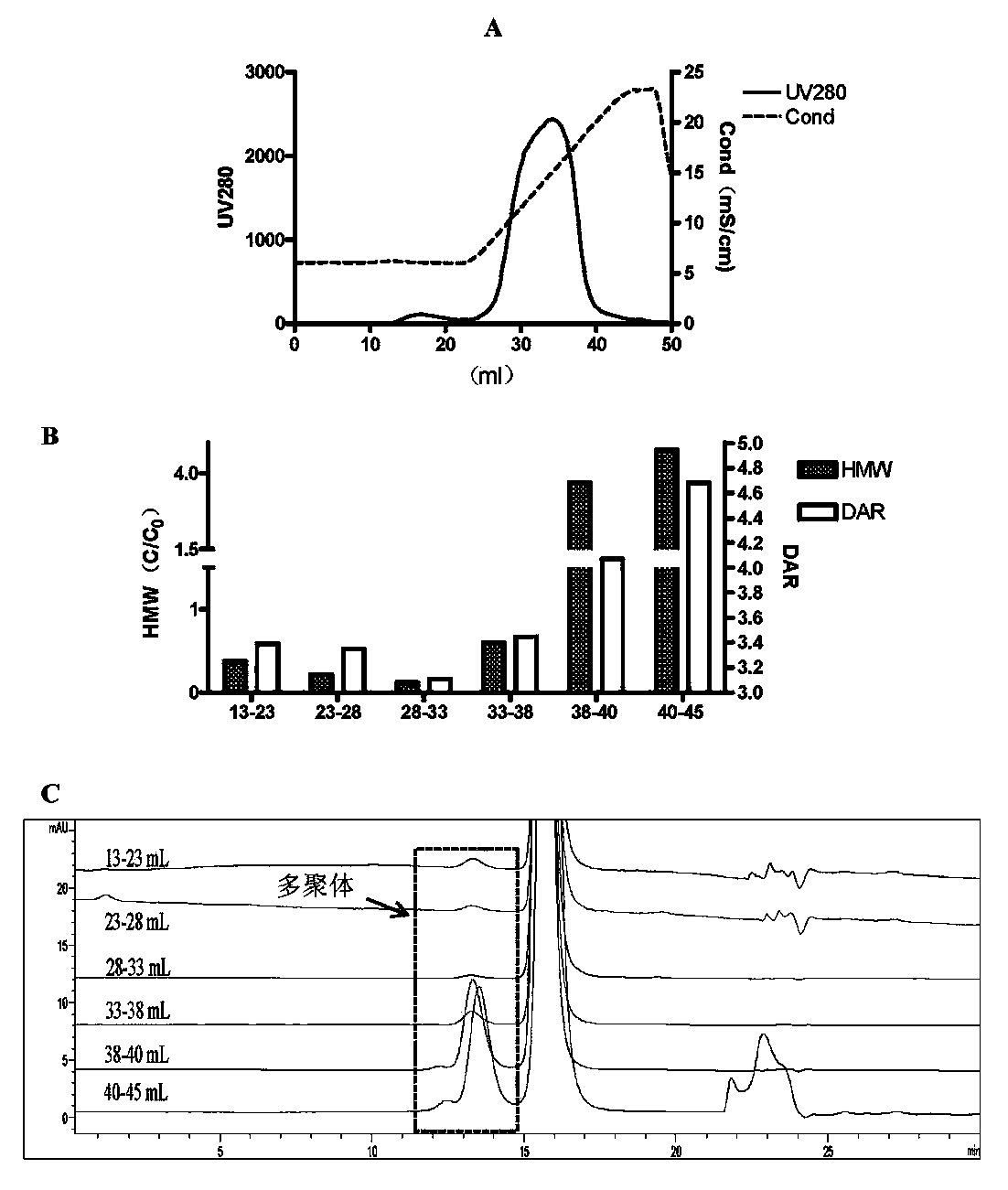

ADC (antibody-drug conjugate) cation exchange chromatographic purification method

ActiveCN104208719AExpand the scope of applicationSimple and efficient operationCation exchanger materialsOrganic anion exchangersAntiendomysial antibodiesCationic exchange

The invention provides an ADC cation exchange chromatographic purification method. The ADC cation exchange chromatographic purification method can be used for performing purification in a combined elution mode or an overload mode, control the DAR (drug antibody ratio) of ADC drugs within a target technology range and meanwhile achieve the effects of eliminating polymers. The ADC cation exchange chromatographic purification method is a novel ADC preparation and purification technique, reduces the production cost and risk, meanwhile, achieves control to the mole DAR of micromolecules / antibodies and polymers of the ADC drugs, is beneficial to development of ADC production processes with higher controllability, lower cost and lower risks, obtains products with higher quality and guarantees medication safety and therapeutic effects.

Owner:BEIJING MABWORKS BIOTECH +1

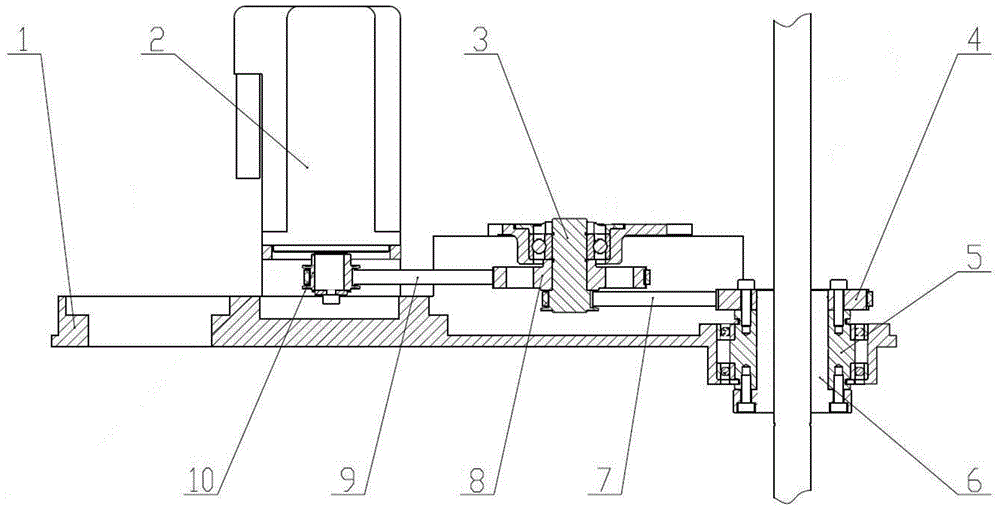

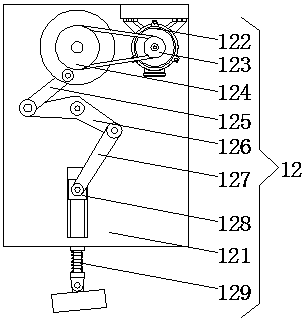

Reduction gear for SCARA industrial robot

InactiveCN105041993AShorten the production cycleCenter of gravity offset distance reducedProgramme-controlled manipulatorGearingOffset distanceSCARA

Provided is a reduction gear for an SCARA industrial robot. A motor is arranged on a forearm, the tail end of the forearm is connected with a ball spline mechanism through a bearing, and the motor outputs torque and rotating speed to a ball spline through a first level synchronous belt and a second level synchronous belt. According to the reduction gear for the SCARA industrial robot, an alternative solution of a harmonic drive is provided, a reducing mechanism with compound transmission through the second level synchronous belt is adopted, the barycener offset distance of the SCARA robot is reduced, and the improvement of the acceleration performance of the whole machine is facilitated; meanwhile, the reduction gear for the SCARA industrial robot has the advantages of being long in service face, high in precision, high in speed, stable in transmission, high in space utilization, low in heat productivity, low in noise and the like, the use performance is improved, and the cost of the whole machine is reduced.

Owner:NANJING ESTUN ROBOTICS CO LTD

Method of raising binding force of chemical coating on the surface of NdFeB permanent magnet

ActiveCN1847451AEvenly degreasingGood degreasing effectLiquid/solution decomposition chemical coatingUltrasonic assistedCavitation

The present invention provides method of raising binding force of chemical coating on the surface of NdFeB permanent magnet. The NdFeB permanent magnet is pre-coated in alkaline plating solution under ultrasonic action, and by means of the activation, cavitation and stirring of ultrasonic wave, one homogeneous and compact initial deposited layer is formed on the surface of the magnet, so as to raise the binding force of chemical nickel-base coating on the surface of the magnet obviously and reduce pores in the coating. The present invention also provides the technological process including deoiling and pickling to activate before plating, the ultrasonic pre-plating and the conventional chemical plating. The formed coating has high corrosion resistance, raised binding to the substrate and perfect protection on the NdFeB permanent magnet.

Owner:ZHEJIANG UNIV

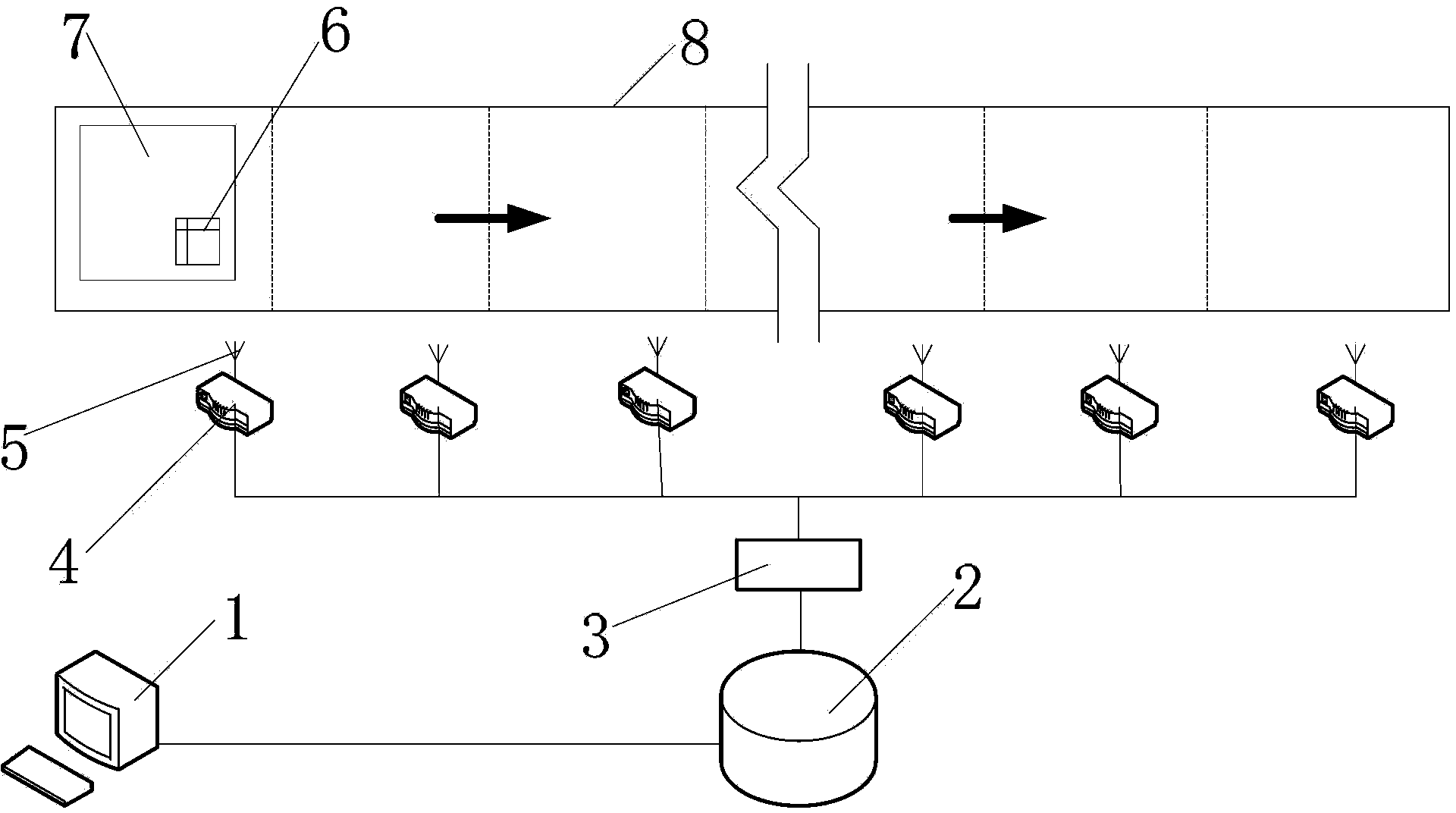

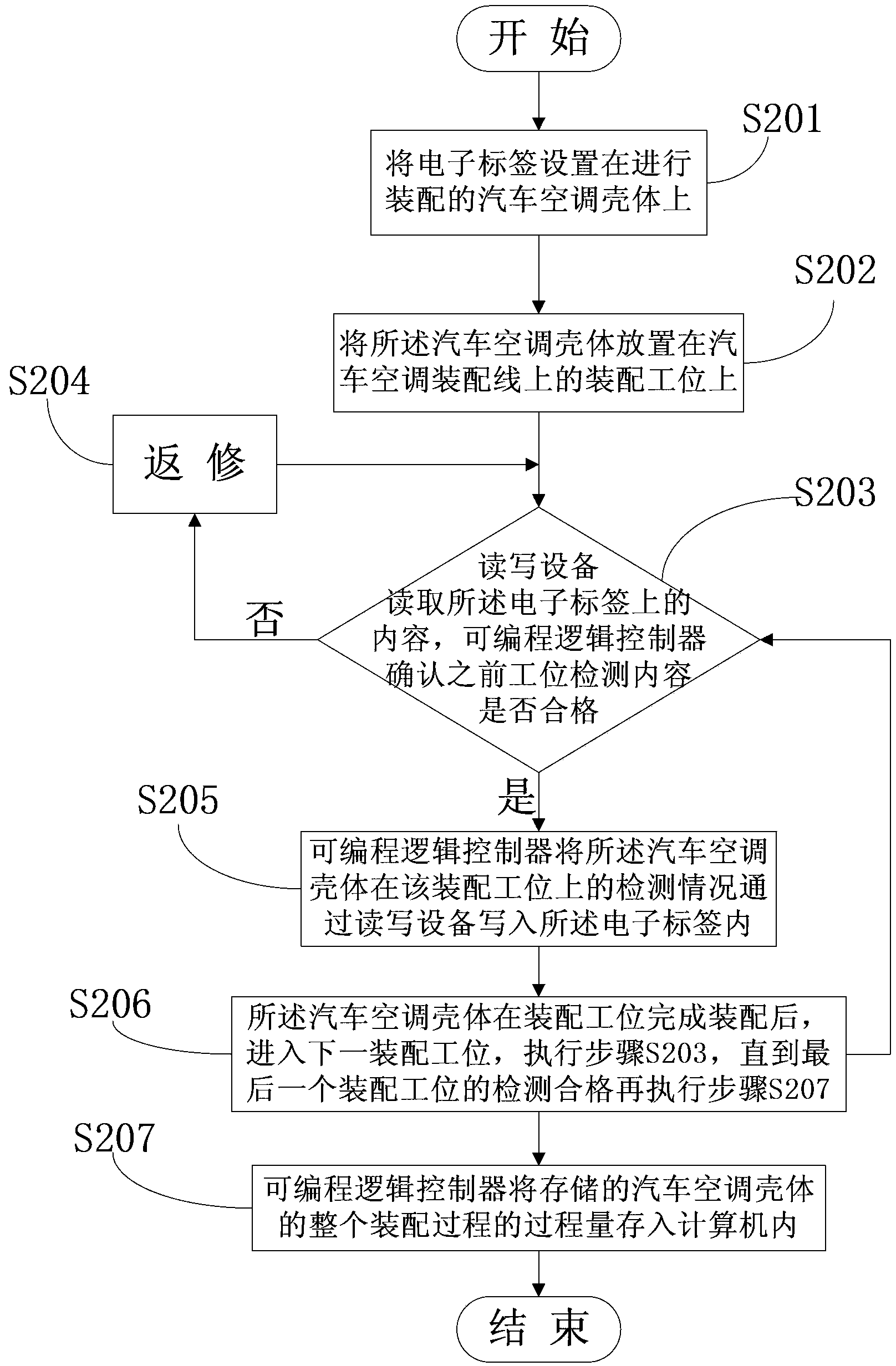

Data acquisition system and method for automobile air conditioner assembly line

InactiveCN103914715AOvercoming disadvantagesConvenient statisticsCo-operative working arrangementsProgrammable logic controllerAutomobile air conditioning

The invention discloses a data acquisition system for an automobile air conditioner assembly line. The data acquisition system comprises a computer, electronic tags, read-write devices and a programmable logic controller. The electronic tags are arranged on assembled automobile air conditioner shells. The multiple read-write devices are arranged on all stations on the automobile air conditioner assembly line respectively, and are respectively provided with an antenna which is used for transmitting radio frequency signals to the corresponding electronic tag. The read-write devices are connected with the programmable logic controller through bus modules. The programmable logic controller is connected with the computer. The invention further discloses a data acquisition method for the automobile air conditioner assembly line. The data acquisition system and method are particularly suitable for the automobile air conditioner assembly line, all the process amount and detection result data generated when the automobile air conditioner shells are assembled at all the assembly stations on the automobile air conditioner assembly line can be effectively acquired and stored in time.

Owner:SHANGHAI BEHR THERMAL SYST

Realization method for film preparation by applying atomic layer deposition technology

ActiveCN105506581AImprove purging effectImprove the quality of workmanshipChemical vapor deposition coatingProcess qualityEngineering

The invention discloses a realization method for film preparation by applying an atomic layer deposition technology. A different ALD technological mode of a vacuumizing mode or a variable flow mode is used for changing an intake quantity of sweeping gas in a reaction cavity to form disturbance of an airflow field in the cavity, so that the sweeping effect on a surplus reaction source and a reaction byproduct can be effectively improved, the process time of film growth period is shortened, the productivity is improved, the parasitic CVD reaction can be reduced on the basis, the ALD process quality is improved, and the film uniformity is improved.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

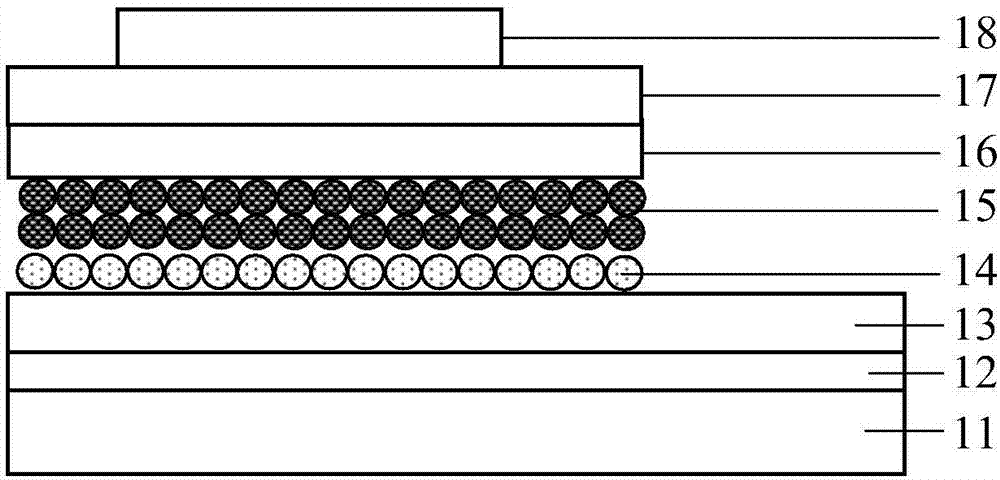

Manufacturing method of luminescent device, luminescent device, and display device

InactiveCN107394020ASpin coating evenlyImprove the quality of workmanshipStatic indicating devicesSemiconductor devicesDisplay deviceQuantum dot

The invention provides a manufacturing method of a luminescent device, a luminescent device, and a display device. The manufacturing method of the luminescent device includes a step of forming a luminescent layer on a substrate, including: depositing a plurality of different quantum dot solutions on the substrate successively to form a plurality of layers of different quantum dot films in a stacked manner, and forming a luminescent layer through by the plurality of layers of different quantum dot films together, wherein any adjacent deposited two quantum dot solutions include the first quantum dot solution and the second quantum dot solution; the first quantum dot material as the solute in the first quantum dot solution is not dissolved in the solvent of the second quantum dot solution; and the second quantum dot material as the solute in the second quantum dot solution is not dissolved in the solvent of the first quantum dot solution. The scheme of the manufacturing method of a luminescent device can continuously prepare a plurality of layers of quantum dot films with relatively higher homogeneity to enable the luminescent device of the plurality of layers of quantum dot films to give out light normally.

Owner:BOE TECH GRP CO LTD

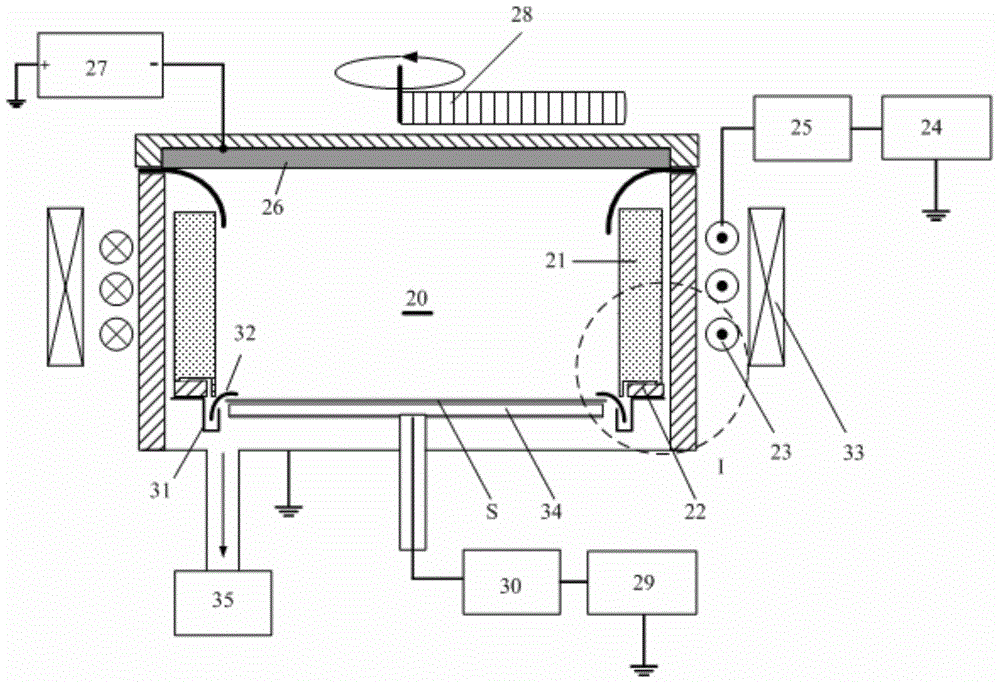

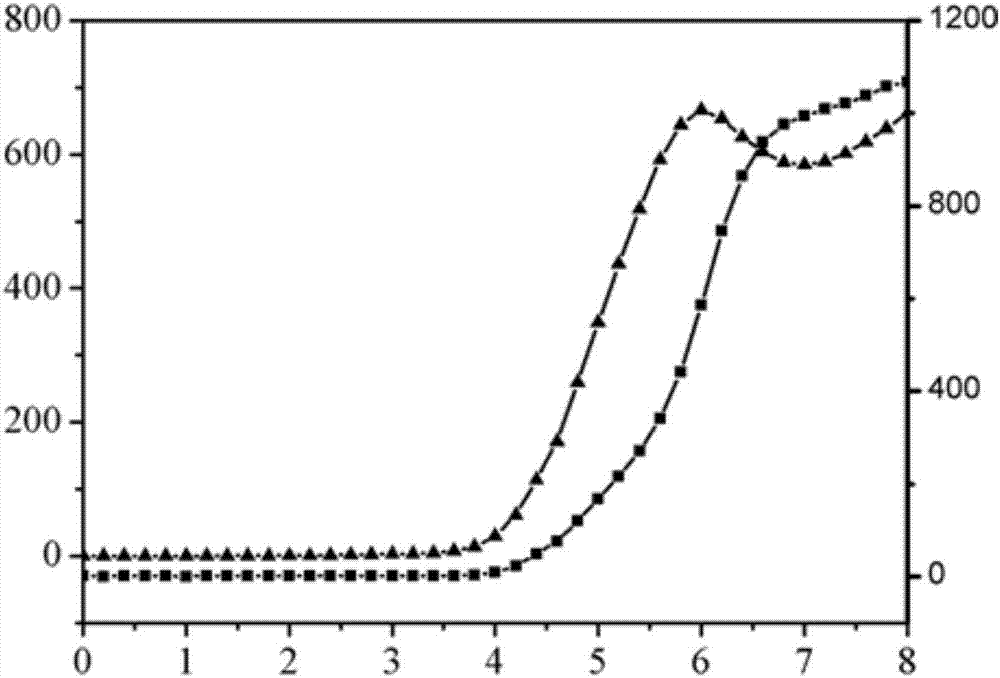

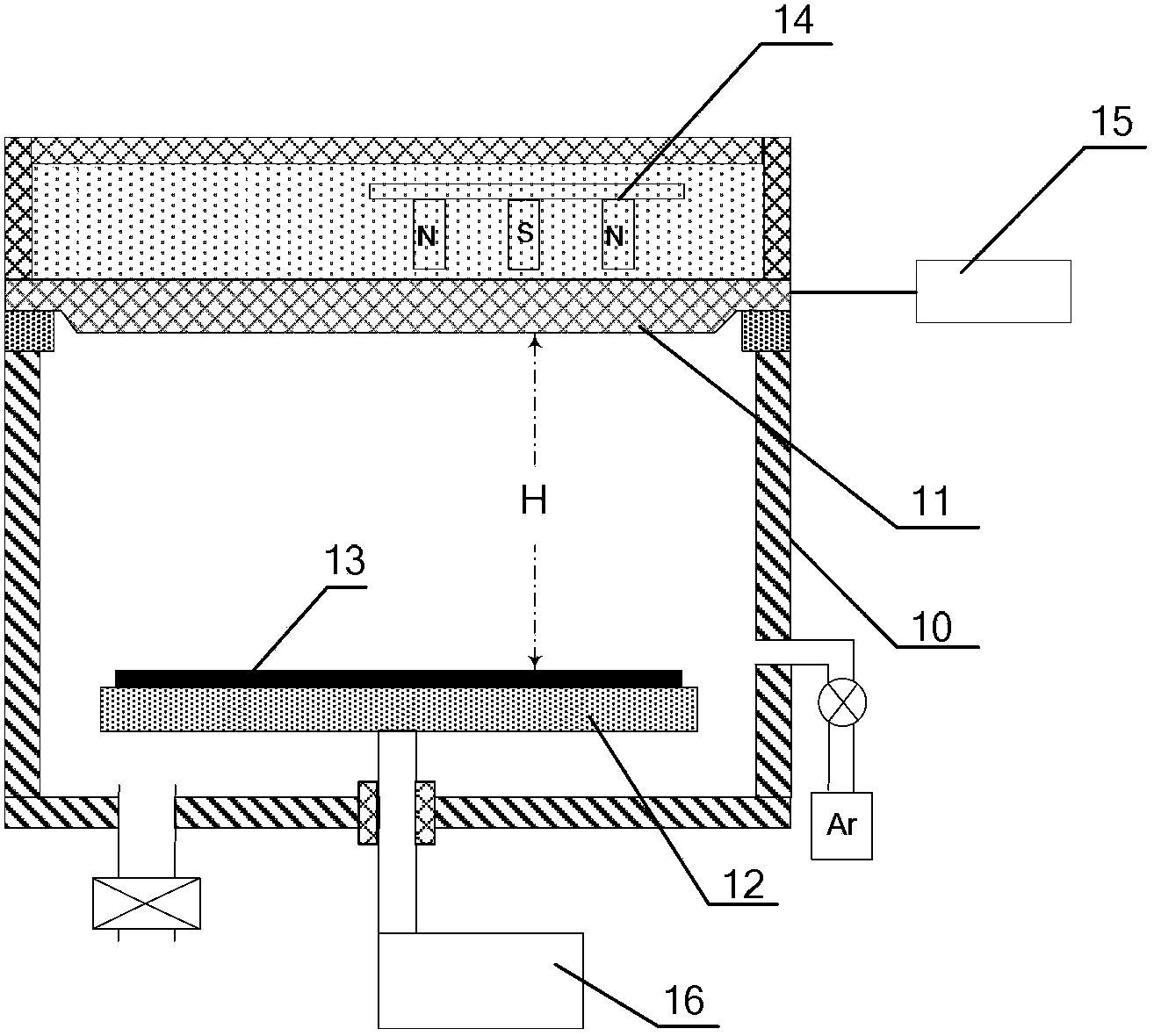

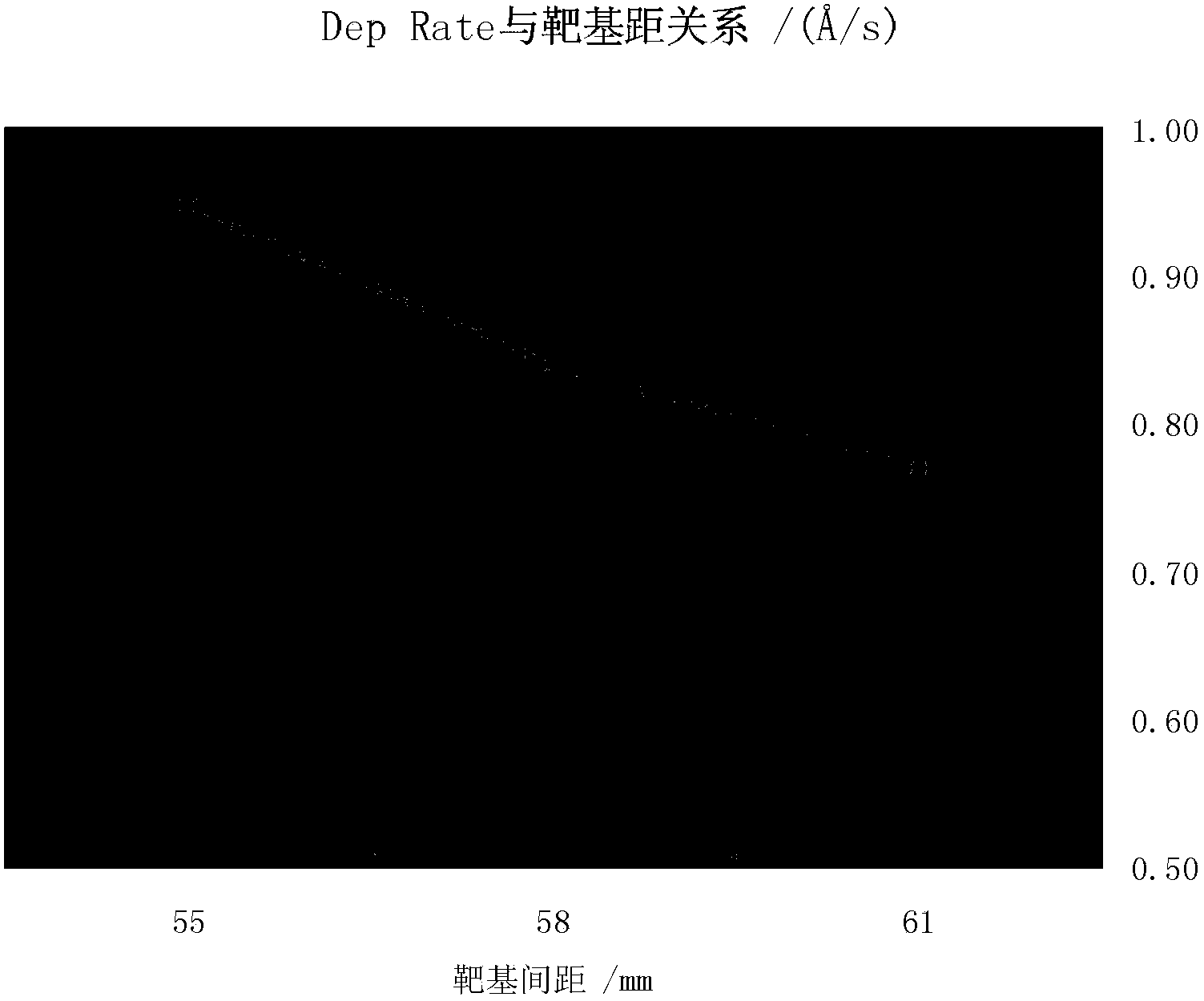

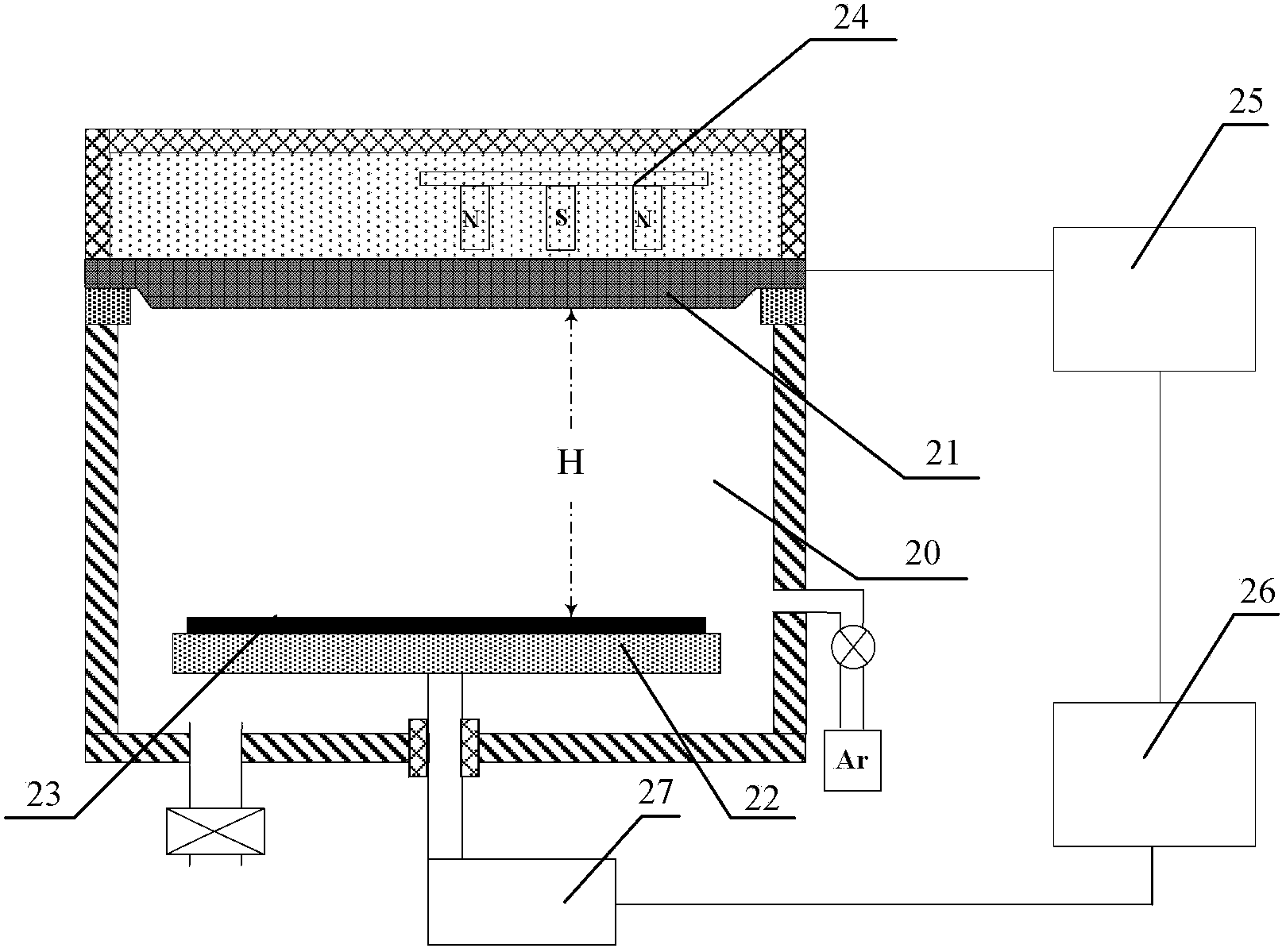

Magnetron sputtering device and magnetron sputtering method

ActiveCN104112640AImprove film uniformity and deposition rateImprove the quality of workmanshipElectric discharge tubesVacuum evaporation coatingElectricityEngineering

The present invention provides a magnetron sputtering device and a magnetron sputtering method. The magnetron sputtering device comprises a reaction chamber, a sputtering power supply and a driving source, a target is arranged at the top of the reaction chamber, and the sputtering power supply is electrically connected with the target, and is used to output a sputtering power to the target during the magnetron sputtering process. A pedestal is arranged in the reaction chamber, is located below the target, and is used to bear a processed workpiece. The driving source is used to drive the pedestal to rise or drop. Moreover, the magnetron sputtering device also comprises a control unit used for controlling the driving source to drive the pedestal to rise during the magnetron sputtering process, so that the spacing between the target and the pedestal is always kept at a predetermined value and does not change. The magnetron sputtering device provided by the present invention uses the control unit to control the driving source to drive the pedestal to rise during the magnetron sputtering process, so that the spacing between the target and the pedestal is always kept at the predetermined value, does not change, and is always kept at an optimal value, and accordingly, the thin film uniformity and deposition rate can be improved.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

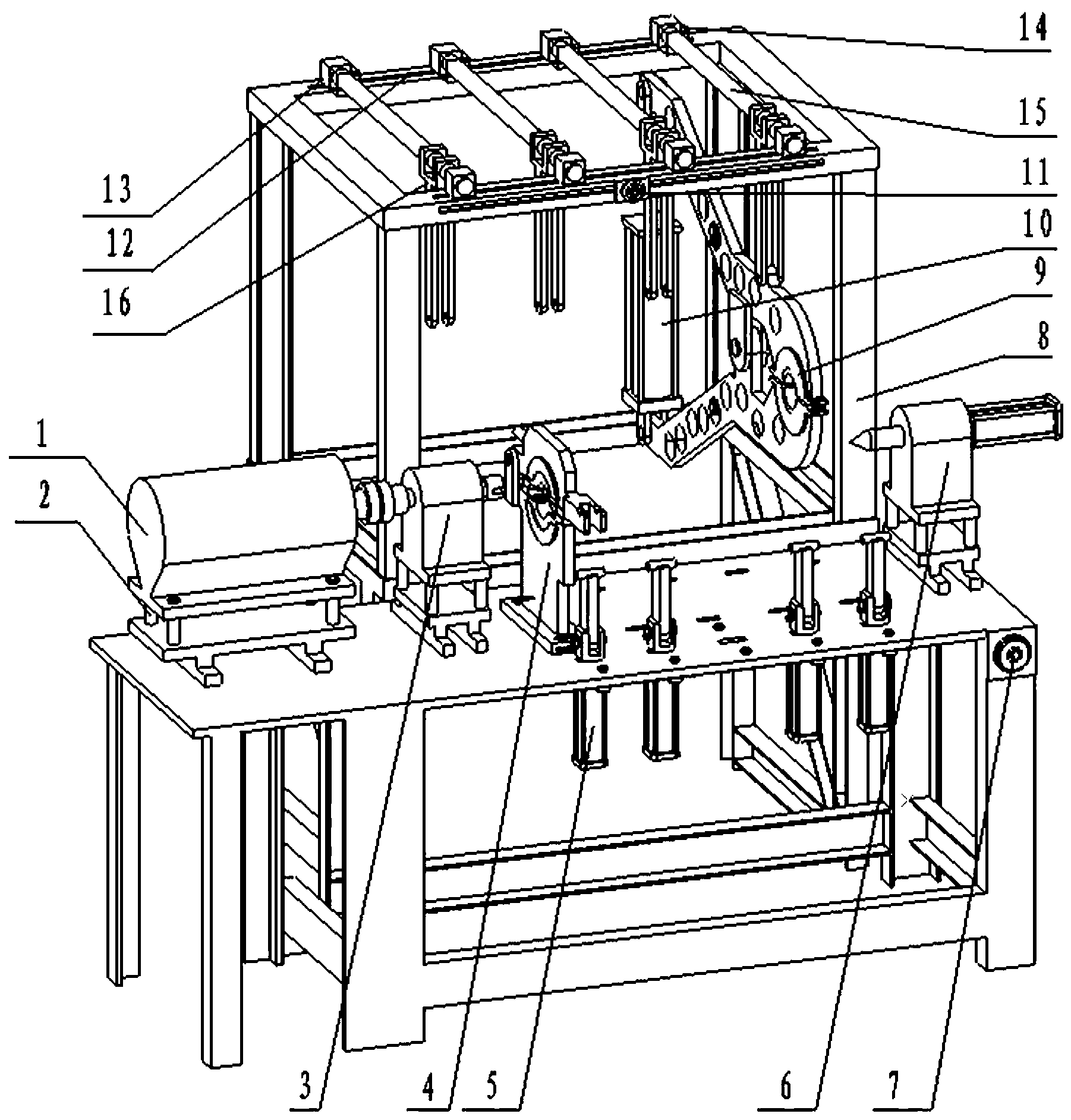

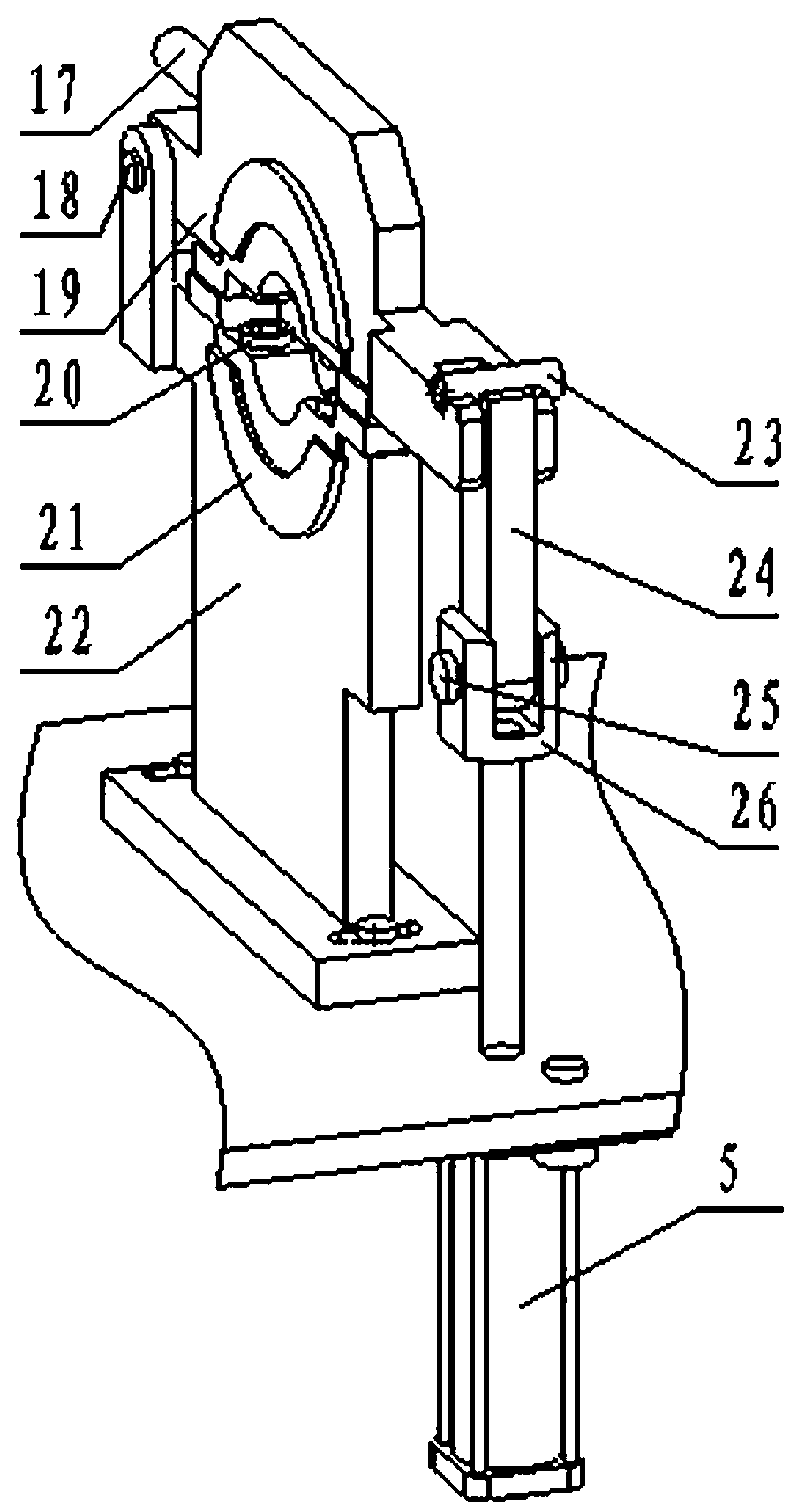

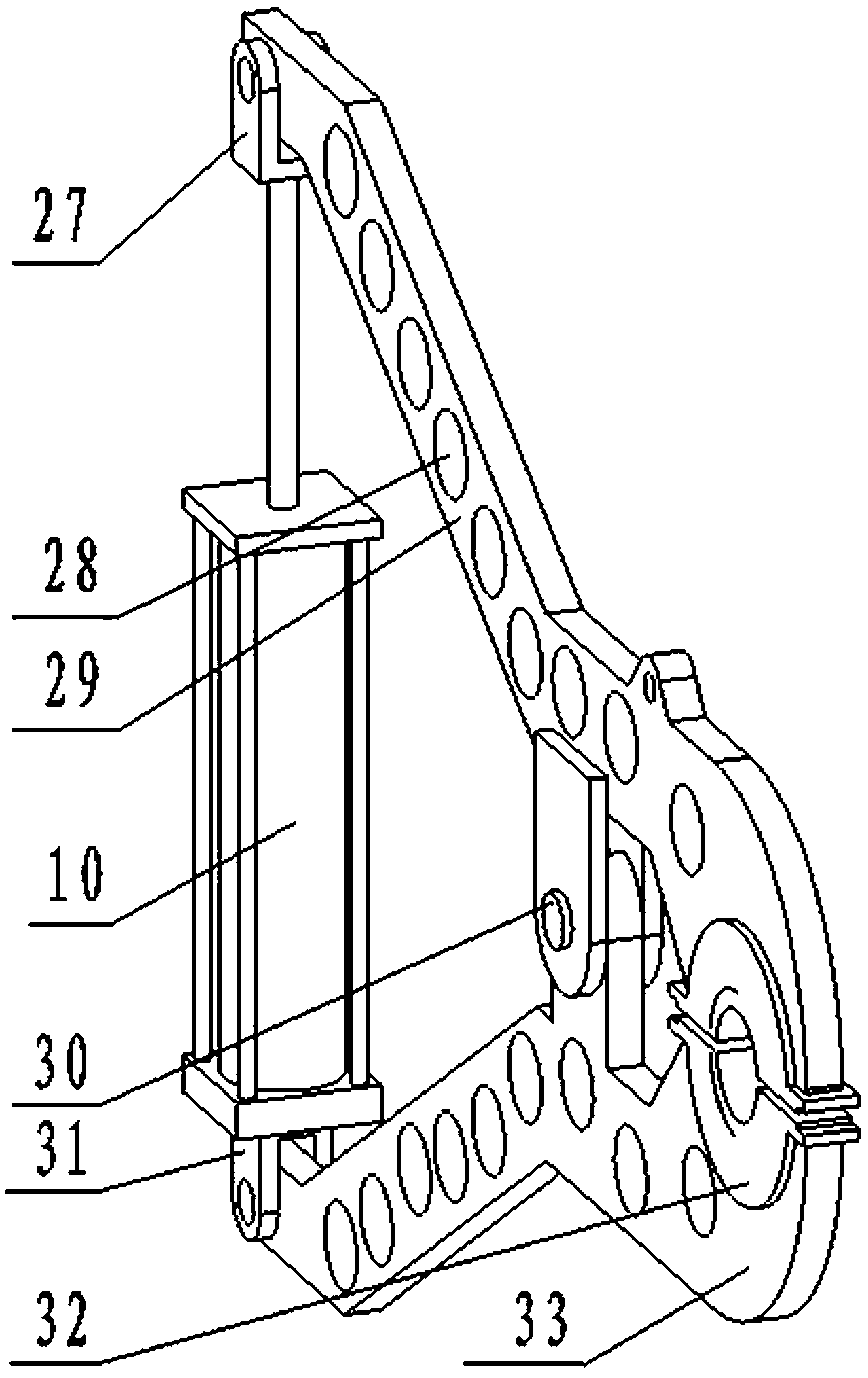

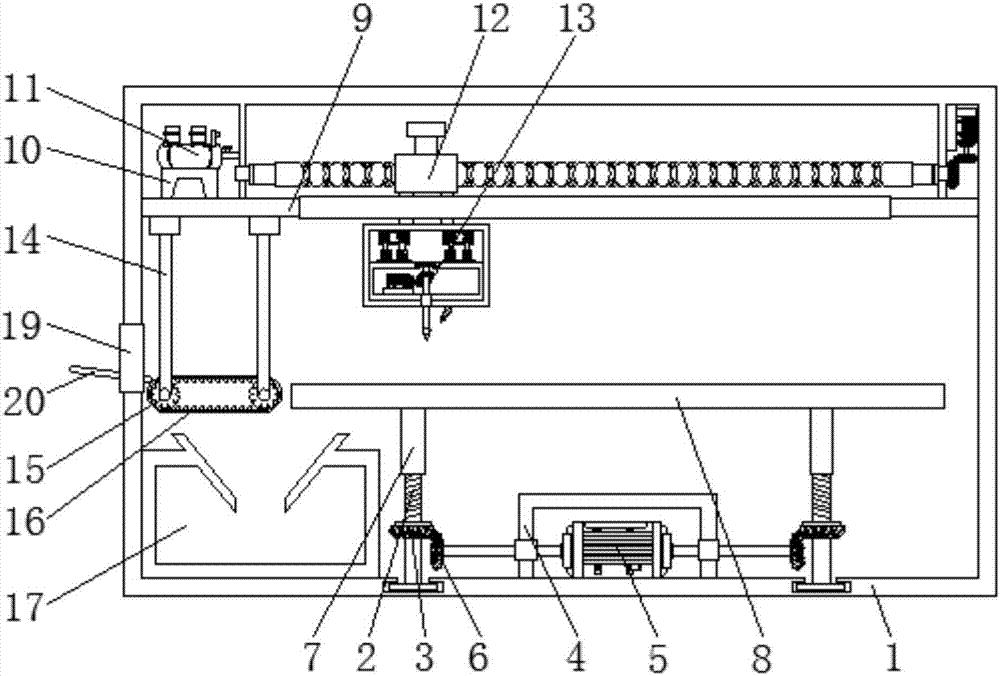

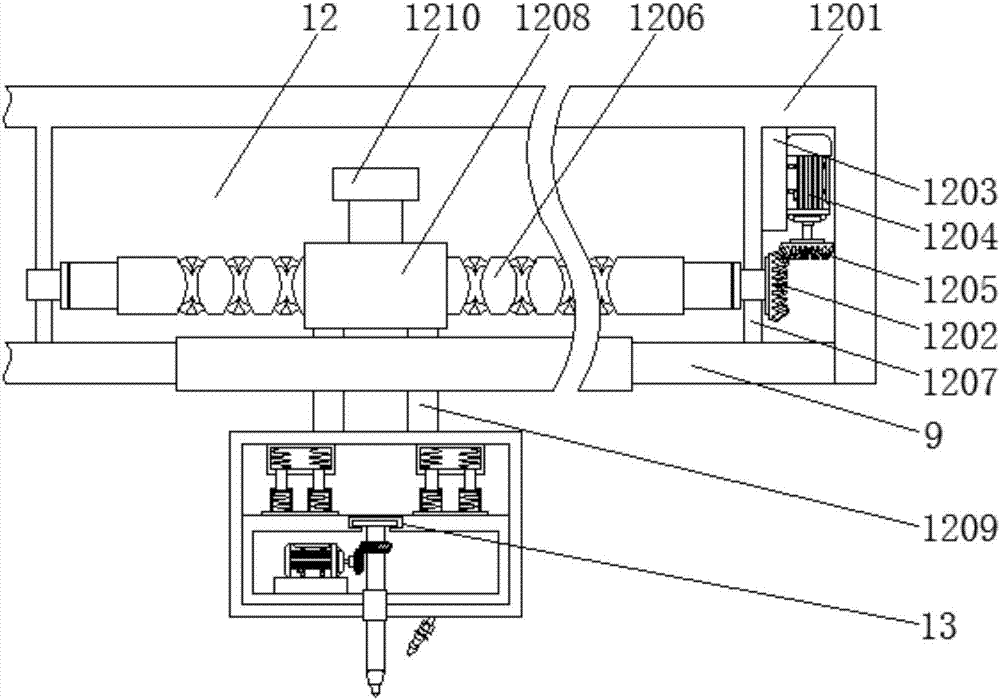

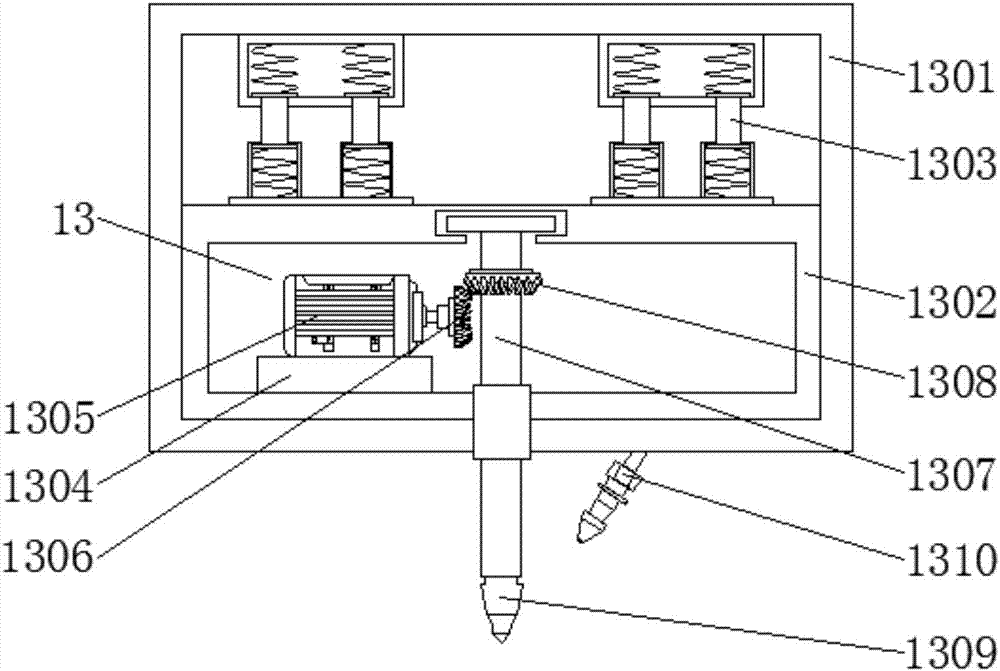

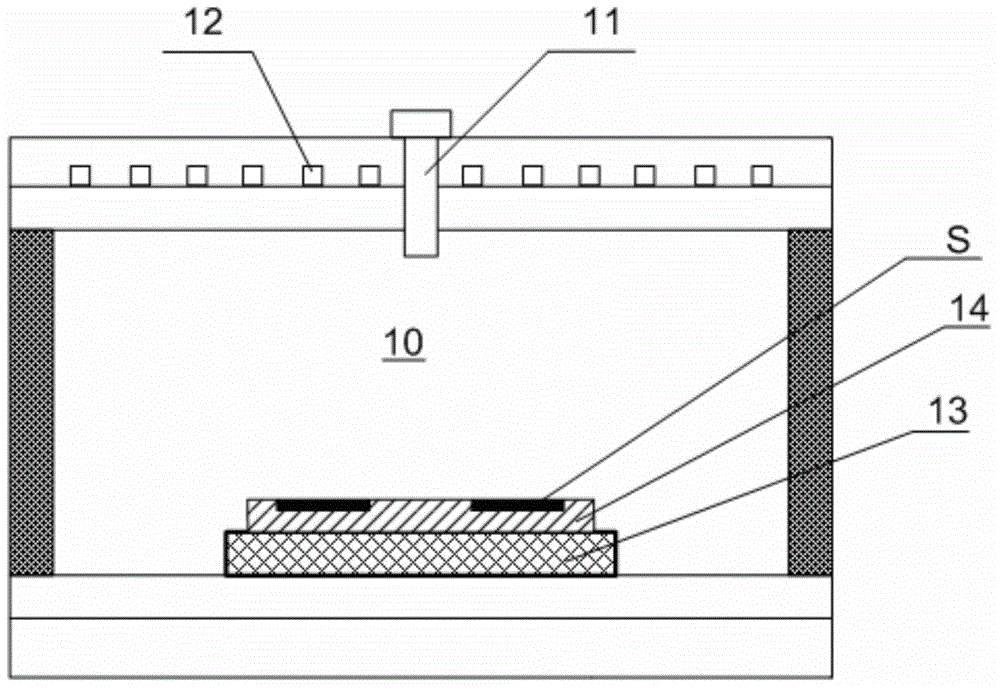

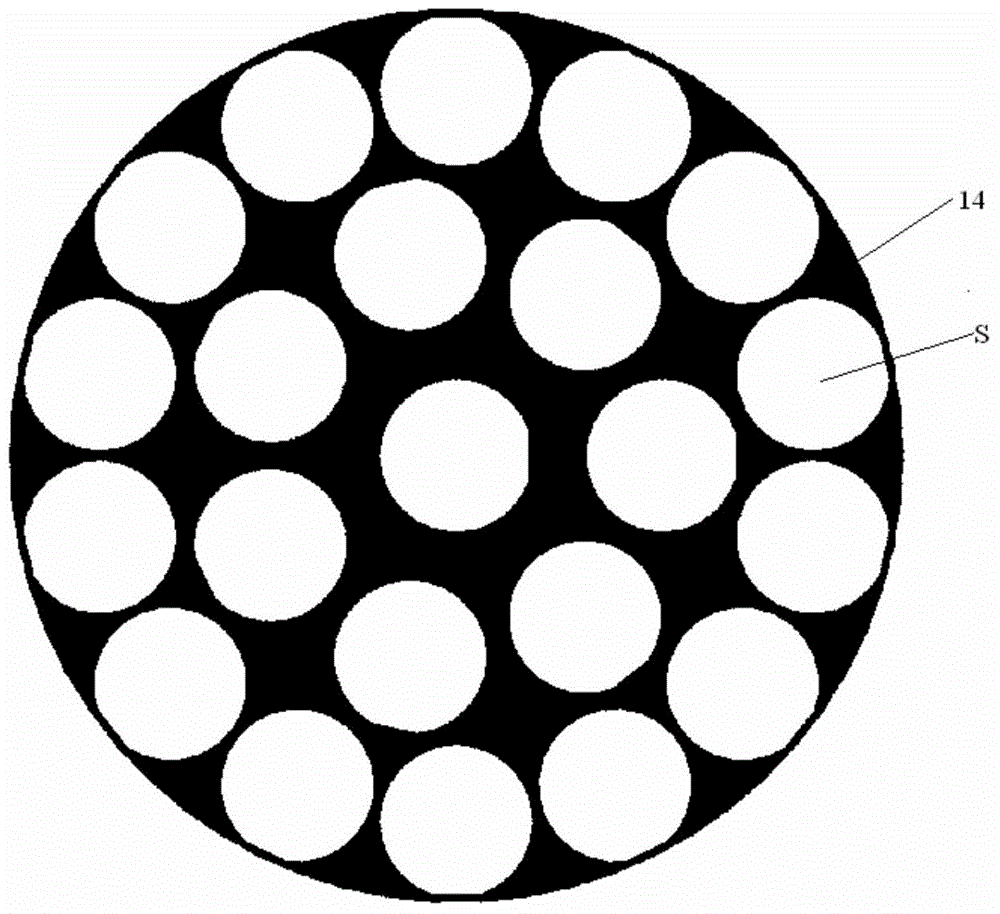

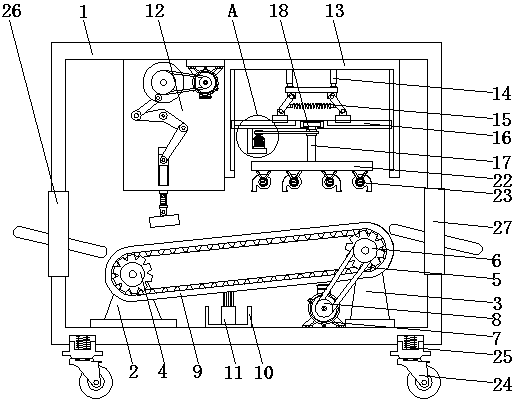

Automatic grinding and polishing machine for engine crankshafts

ActiveCN103317400AEfficient combinationReduce labor intensityPolishing machinesRevolution surface grinding machinesEngineeringMechanical engineering

The invention relates to an automatic grinding and polishing machine for engine crankshafts. The automatic grinding and polishing machine comprises a front body and a rear body. A motor and a transmission adjusting device are sequentially disposed at the left end of the front body. An output shaft of the motor is connected with the transmission adjusting device. A tail positioning device is disposed at the right end of the front body. A crankshaft spindle polishing device is disposed between the transmission adjusting device and the tail positioning device. A first air cylinder is disposed on the crankshaft spindle polishing device. A crankshaft spindle clamp controller which is connected with the first air cylinder is further disposed on the front body. A crankshaft connecting rod polishing device and a crankshaft connecting rod clamp controller which are connected are disposed on the rear body. A second air cylinder is disposed on the crankshaft connecting rod polishing device. By the automatic grinding and polishing machine which is simple to operate and high in work efficiency, crankshaft spindles and crankshaft connecting rods can be polished simultaneously, quality requirements of crankshaft polishing can be guaranteed, and consistency of the spindles and the connecting rods can be increased.

Owner:山西东鑫衡隆机械制造股份有限公司

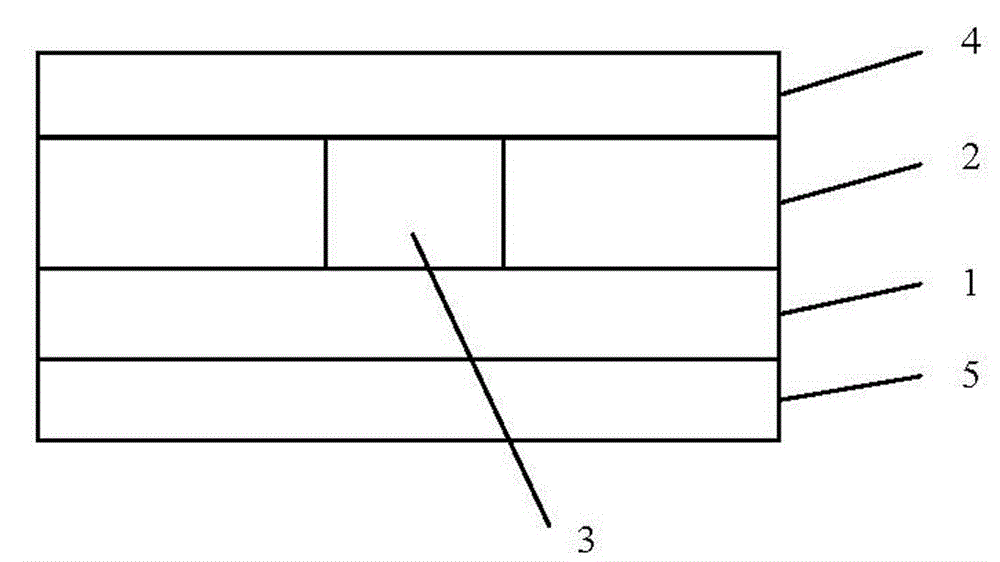

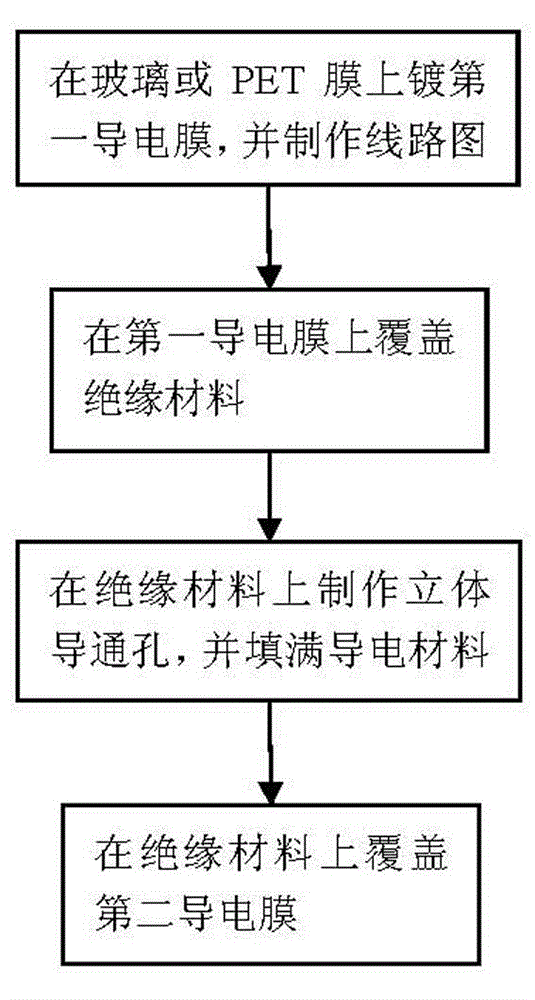

Capacitive control screen with three-dimensional via hole and manufacturing method thereof

ActiveCN103150075AIncreased sensitivityThin structureInput/output processes for data processingPolyethylene terephthalateEngineering

The invention discloses a capacitive control screen with a three-dimensional via hole and a manufacturing method thereof. The capacitive control screen comprises a first conducting film layer plated on glass or a PET (polyethylene terephthalate) film, and an insulating layer and a second conducting film layer which are sequentially arranged on the first conducting film layer, the first conducting film layer and the second conducting film layer are provided with corresponding circuits, the insulating layer is provided with a via hole, and a conducting medium used for conducting the circuits is filled in the via hole. According to the capacitive control screen disclosed by the invention, the via hole is manufactured in the insulating layer without damaging the conducting films, so that the manufacturing process of the capacitive control screen is greatly improved.

Owner:宏科有限公司

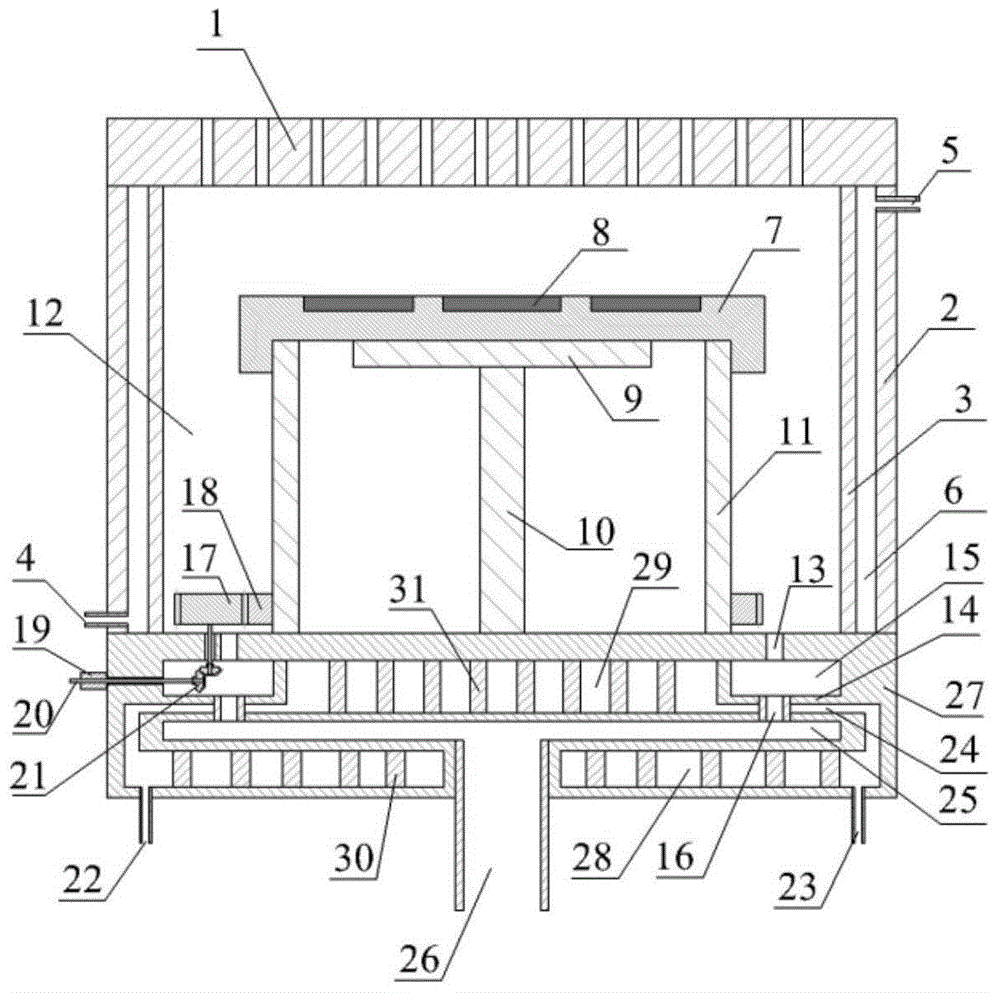

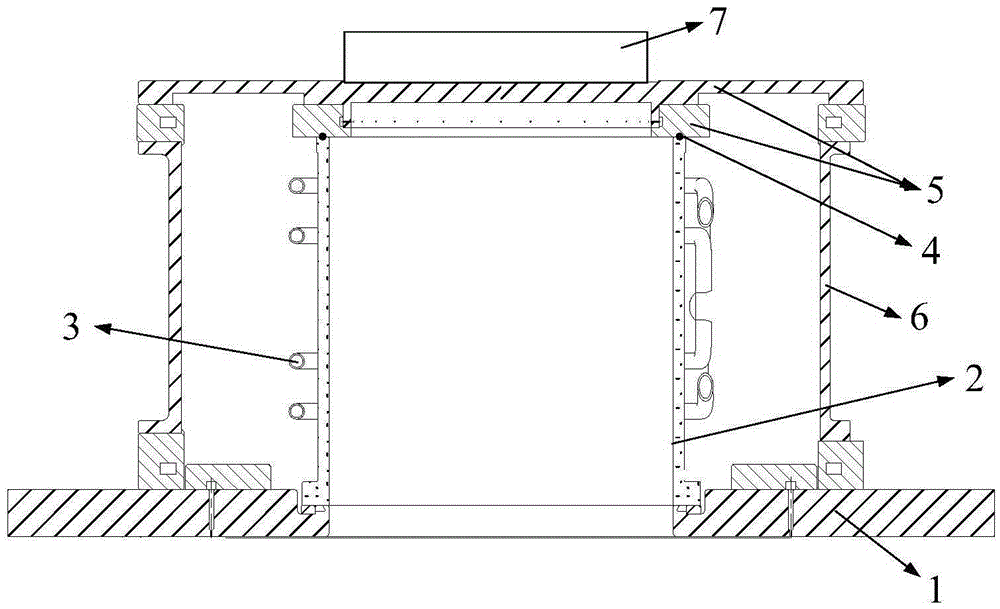

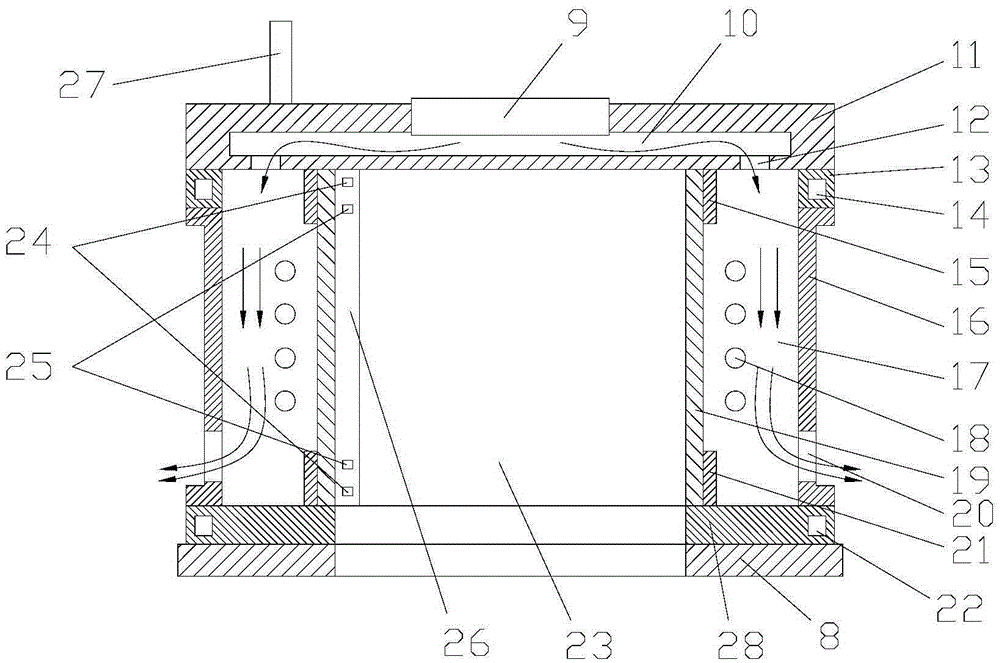

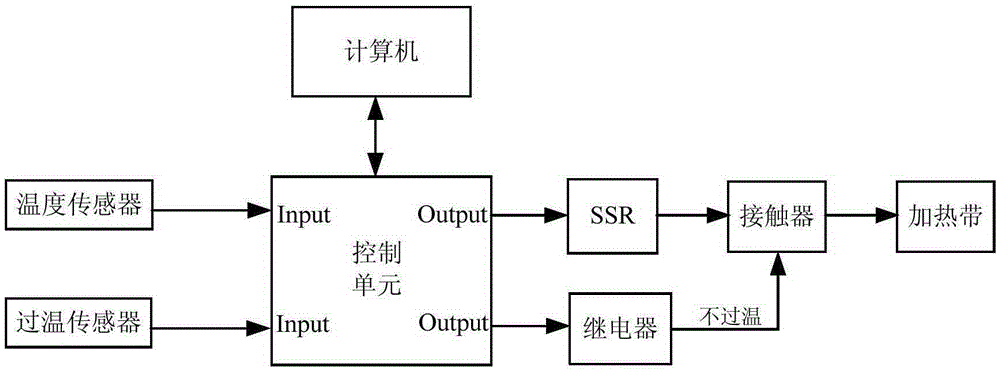

Symmetrical vapor deposition equipment reaction cavity

ActiveCN104862667AEasy to cleanReduce depositionChemical vapor deposition coatingCooling chamberProduct gas

The invention discloses a symmetrical vapor deposition equipment reaction cavity. The reaction cavity mainly comprises a gas input body, a heater, a slide carrying disc, a slide carrying disc support, a reaction cavity housing, a heater, a heater support, a reaction gas channel, a cavity pedestal and a tail gas outlet. The reaction cavity is characterized in that the tail gas outlet is arranged at the center of the cavity pedestal, a gas chamber is arranged in the middle of the cavity pedestal and a cooling chamber is arranged around the gas chamber. The tail gas outlet is arranged at the center of the cavity pedestal so that gas inlet and outlet symmetrical distribution is realized and uniformity of gas flowing distribution in the reaction cavity is guaranteed and improved. Tail gas goes through the gas chamber of the cavity pedestal and cooling surfaces of the gas chamber of the cavity pedestal cool the reaction tail gas so that the reaction tail gas is uniformly cooled, precipitates are reduced and tail gas treatment system damage caused by a high reaction tail gas temperature is avoided.

Owner:甘志银

Upper electrode component and semiconductor processing equipment

ActiveCN106711006AImprove temperature control accuracyImprove temperature uniformityElectric discharge tubesSemiconductor/solid-state device manufacturingTemperature controlHeat transfer efficiency

The invention provides an upper electrode component and semiconductor processing equipment. A medium bucket arranged on a cavity cover plate, a coil surrounding the medium bucket, a heating mechanism used for heating the medium bucket, an upper heating zone and a lower heating zone are included. The upper heating zone and the lower heating zone sleeve a top and a bottom of an outer circumferential wall of the medium bucket and are located above and below the coil respectively. By using the upper electrode component, temperature control accuracy and temperature uniformity of the medium bucket can be increased and heat transfer efficiency can also be increased so that technology quality can be improved.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

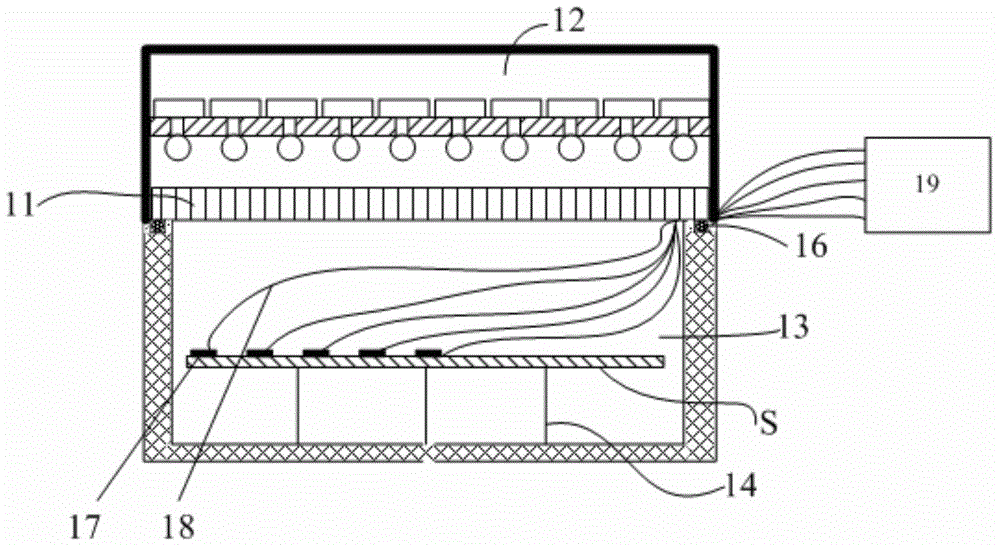

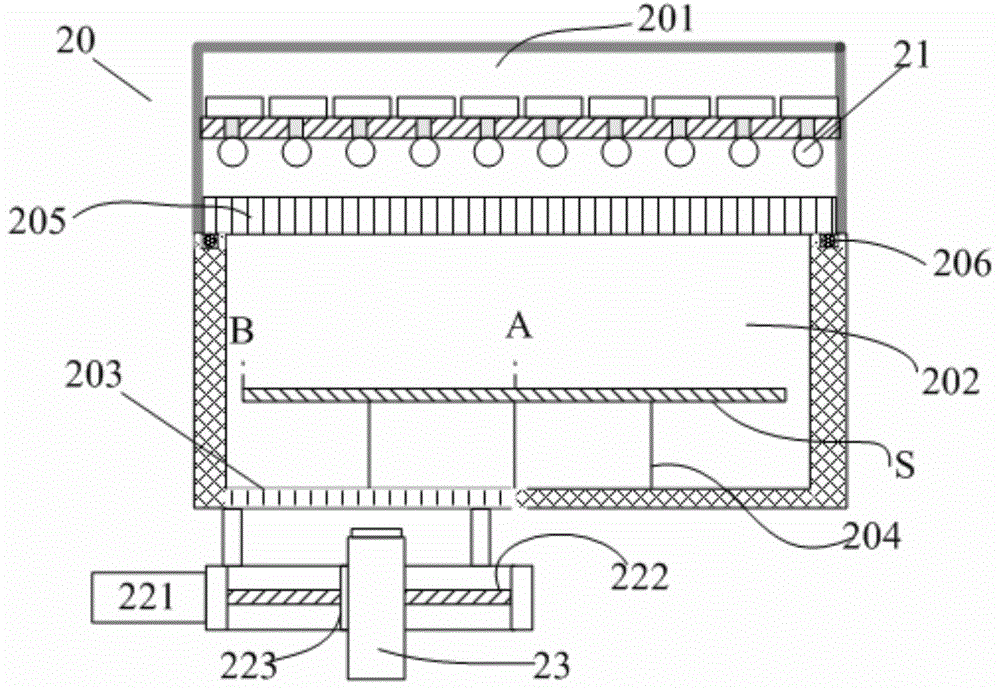

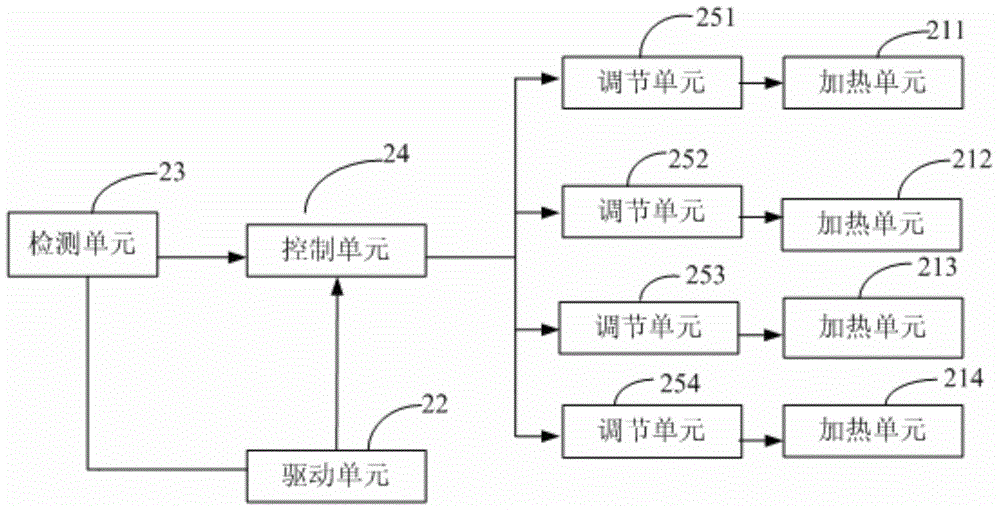

Heating chamber and semiconductor processing equipment

ActiveCN105441899AImprove accuracyImprove temperature uniformityVacuum evaporation coatingSputtering coatingEngineeringSemiconductor

The present invention relates to a heating chamber and semiconductor processing equipment, the heating chamber comprises a plurality of heating zones, heating units in one-to-one correspondence to the heating zones, a drive unit, a detection unit, a control unit and adjustment units in one-to-one correspondence to the heating units, the drive unit is used for driving the detection unit to move in a plane parallel to a wafer and transmitting a position signal of the detection unit in real time to the control unit, the detection unit is used for detecting in real time the wafer temperature in correspondence to the plurality of heating zones and transmitting the temperature to the control unit, the control unit is used for judging which one of the heating zones, the temperature transmitted by the detection unit belongs to, according to the position signal transmitted by the drive unit and judging whether a bias exists between the temperature and a preset temperature, and if the bias exists between the temperature and the preset temperature, the adjustment unit in correspondence to the heating zone, to which the temperature belongs, is adjusted so as to calibrate the output power of the corresponding heating unit. The heating chamber may improve the heating accuracy and the temperature uniformity and lowers the wafer temperature measurement difficulty.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

Metal sheet slotting machine convenient to operate

ActiveCN107538230AEasy to operateImprove practicalityLarge fixed membersMaintainance and safety accessoriesProcess qualityThin slab

The invention discloses a metal sheet slotting machine convenient to operate. The metal sheet slotting machine comprises a box body; threaded rods which are mutually symmetric are rotationally connected to the bottom of the inner wall of the box body; a first helical gear is fixedly connected to the lower part of the outer wall of each threaded rod through a flat key; a dustproof motor box is fixedly connected to the bottom of the inner wall of the box body and between the two threaded rods; a double-output motor is fixedly connected to the bottom of the inner wall of the dustproof motor box;output shafts on the two sides of the double-output motor penetrate through the two sides of the inner wall of the dustproof motor box and extend out of the dustproof motor box respectively; and a second helical gear is fixedly connected to each of the output shafts on the two sides of the double-output motor. The invention relates to the technical field of metal processing mechanical equipment. The metal sheet slotting machine convenient to operate solves the problems of complex structure, tedious operation and limited use conditions of the existing metal sheet slotting machine, reaches the purpose of more stable slotting, improves the working efficiency and the process quality and ensures cleanness of processing environment while the practicability of the machine is improved.

Owner:邯郸兴力铝模板科技有限公司

Plasma processing apparatus

ActiveCN105448774AImprove sheet-to-sheet uniformityImprove uniformityElectric discharge tubesSemiconductor/solid-state device manufacturingSingle processDrive shaft

The invention provides a plasma processing apparatus comprising a reaction chamber, a drive device and a rotating shaft. A carrying device and a tray are disposed in the reaction chamber. The tray is used for carrying a plurality of substrates. The carrying device is used for carrying the tray. An adsorbing electrode is disposed in the carrying device, and is connected electrically with a power supply so that the tray and the carrying device can be fixed by way of electrostatic adsorption. The rotating shaft is disposed corresponding to the center region of the tray. One end of the rotating shaft is connected fixedly with the carrying device, and the other end of the rotating shaft is connected with a drive shaft of the drive device. The drive shaft of the drive device is used for driving the rotating shaft to rotate horizontally around the center axis of the rotating shaft, so as to drive the carrying device and the tray to rotate horizontally around the center axis of the tray. The plasma processing apparatus can improve the uniformity among the plurality of substrates in the same circle, thereby improving the uniformity of the plurality of substrates in a single process.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

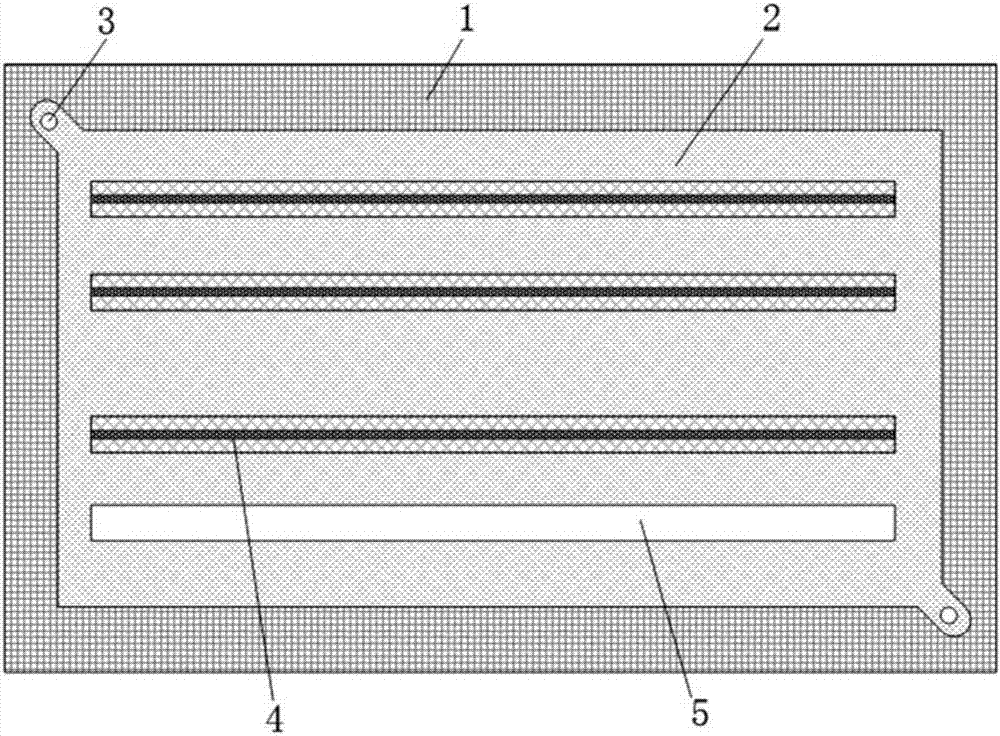

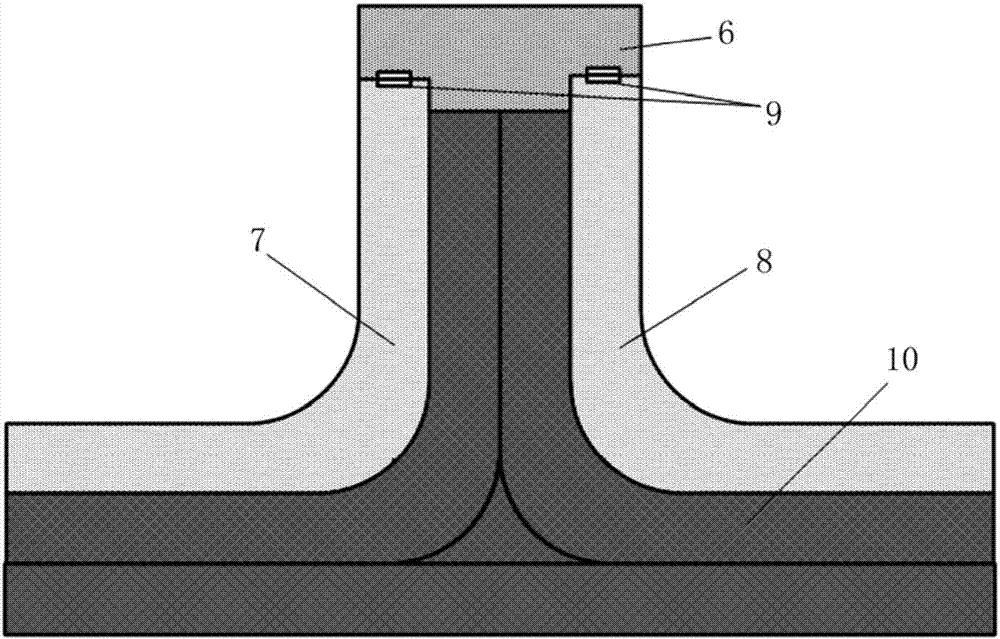

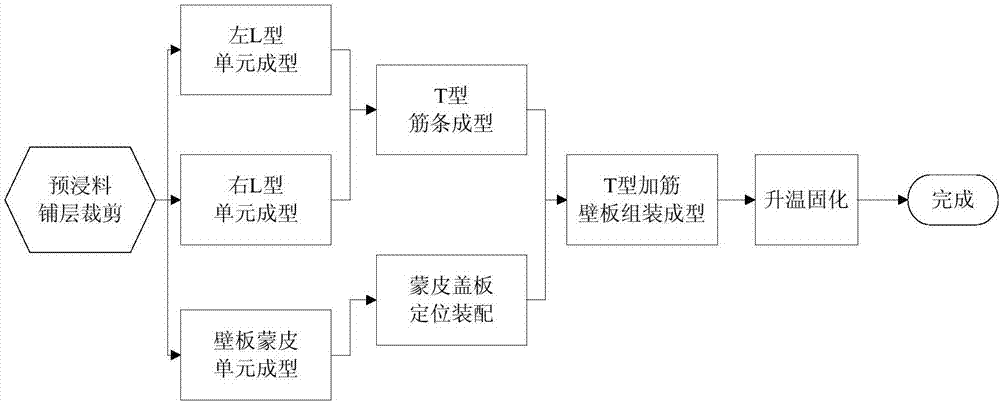

Composite material T-shaped stiffened wall plate forming tool and forming method

PendingCN106891548AImprove rigidityHigh strengthDomestic articlesWeight reductionUltimate tensile strengthWall plate

The invention mainly belongs to the field of T-shaped stiffened wall plate forming and particularly relates to a composite material T-shaped stiffened wall plate forming tool and forming method. The forming tool comprises a skin forming slab, a skin forming cover plate, positioning pins and T-shaped rib forming units for making a T-shaped rib be laid, attached and formed; the skin forming cover plate is provided with a rib positioning slot for performing accurate positioning on the T-shaped rib forming units; and the skin forming cover plate and the T-shaped rib forming units are installed above the skin forming slab through the positioning pins after being assembled. By means of the composite material T-shaped stiffened wall plate forming tool and forming method, composite material T-shaped stiffened wall plate co-curing overall forming can be completed, rigidity and strength of an overall large wall plate structure are improved, and the overall process quality of the structure is improved more effectively; and meanwhile, the process preparation cycle is shortened, and the cost is reduced.

Owner:BEIJING AERONAUTIC SCI & TECH RES INST OF COMAC +1

Full-automatic printing ink plate printing and drying device

InactiveCN109968807AReduce wearEasy and safe to movePrinting press partsMechanical equipmentPrinting ink

The invention discloses a full-automatic printing ink plate printing and drying device. The device comprises a box body, a first fixing table and a second fixing table are fixedly connected to the twosides of the bottom of the inner wall of the box body respectively, the top of the first fixing table and the top of the second fixing table are rotationally connected with a first straight gear anda second straight gear respectively, a first belt wheel is fixedly connected to the front part of the second straight gear, and a first motor is fixedly connected to the bottom of the inner wall of the box body and on the left side of the second fixing table. The invention relates to the technical field of automatic mechanical equipment. The full-automatic printing ink plate printing and drying device solves the problems that an existing equipment plate printing process is complex and cannot realize stable printing, the position deviation is easy to occur, the equipment is relatively large inabrasion and ink plate printing can not be carried out on a large scale; and the purposes of carrying out ink plate printing on the parts and buffering and protecting the parts are achieved, damage caused by too large stress on the equipment is avoided, the parts with different thicknesses can be printed, the practicability of the equipment is effectively improved, and the equipment is convenientto maintain.

Owner:宋晓莉

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com