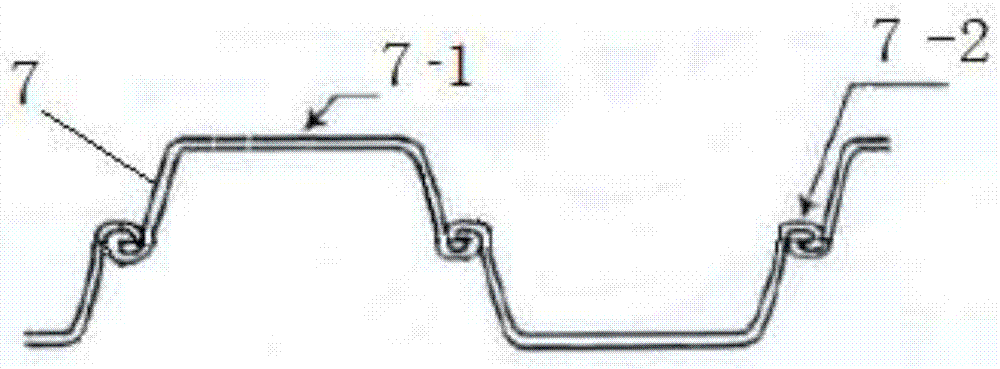

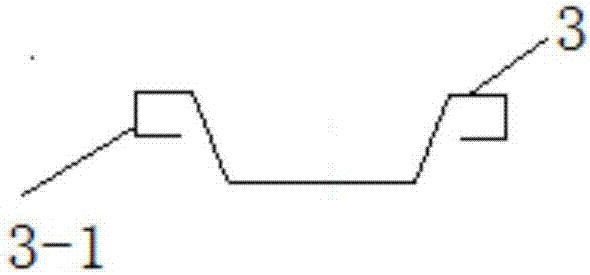

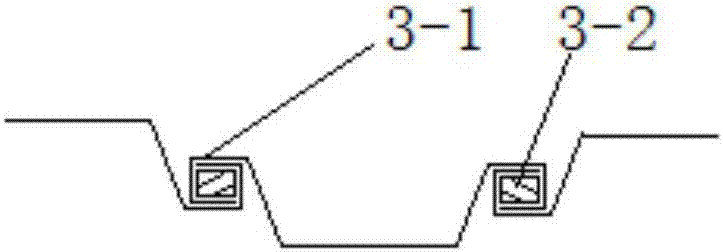

Steel cylinder pile or steel sheet pile with sealing grooves and occlusion structures and steel structure continuous wall

A technology with sealing and steel sheet piles, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve problems such as poor waterproof effect, high cost, and large engineering volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0105] Embodiment: The present invention includes a pile wall composed of sheet piles, a pile wall (closeable) composed of two or more sheet piles in application; a pile wall formed by connecting tube piles and sheet piles, two or more tube piles The pile wall composed of piles and sheet piles also includes the pile wall formed by the connection of tube piles, and the pile wall formed by two or more tube piles.

[0106] The diameter of the steel cylinder pile (including the width of the rectangular cylinder steel pile unit) in the cylinder pile is about 50cm, and the distance between the edges of adjacent steel cylinder piles is 20-30cm, which is the narrowest point of the connecting pile. . for Figure 24-27 Although the various foundation pits are the most commonly used rectangular foundation pits, the enclosure of polygonal or irregular shaped foundation pits can be formed by connecting the unit steel cylinder piles and connecting piles of the present invention.

[0107] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cross-sectional area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com