Automatic grinding and polishing machine for engine crankshafts

An engine and polishing machine technology, applied in grinding/polishing equipment, surface polishing machine tools, automatic grinding control devices, etc., can solve the problem that the consistency of multiple parts is very different, limit the service life of the engine, and affect the entire engine. performance and other issues, to achieve the effect of shortening processing time, reducing force, and improving consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

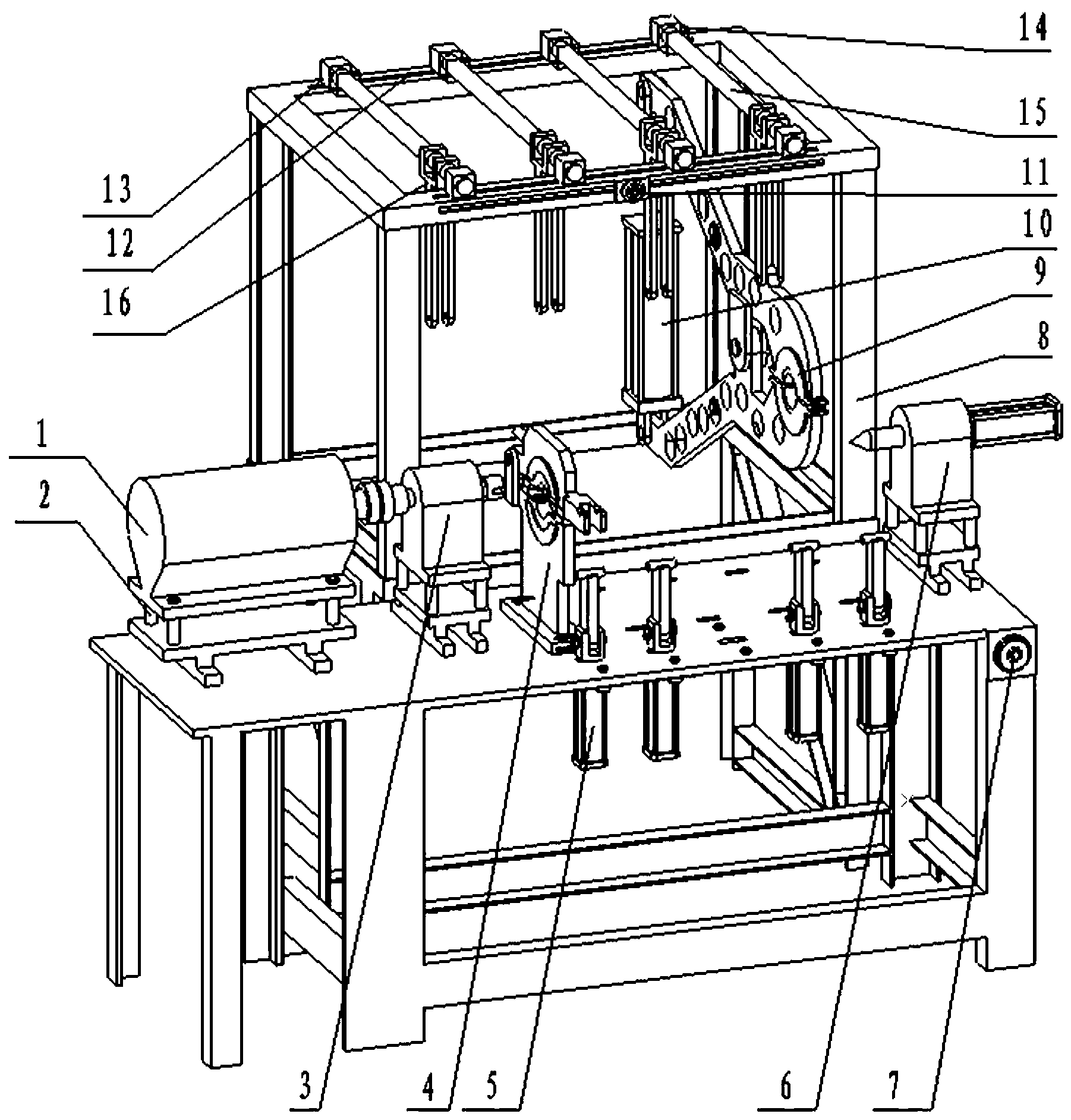

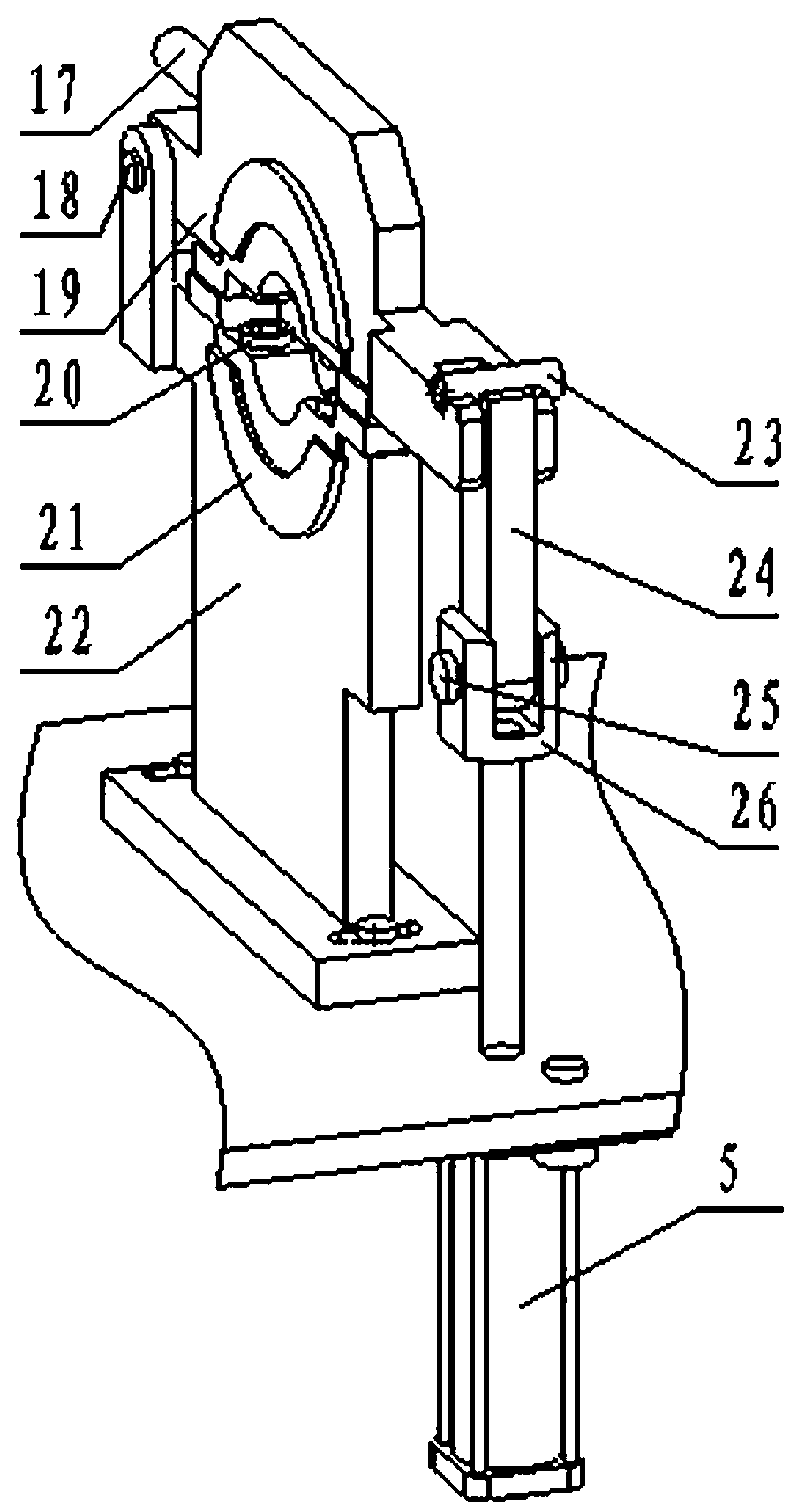

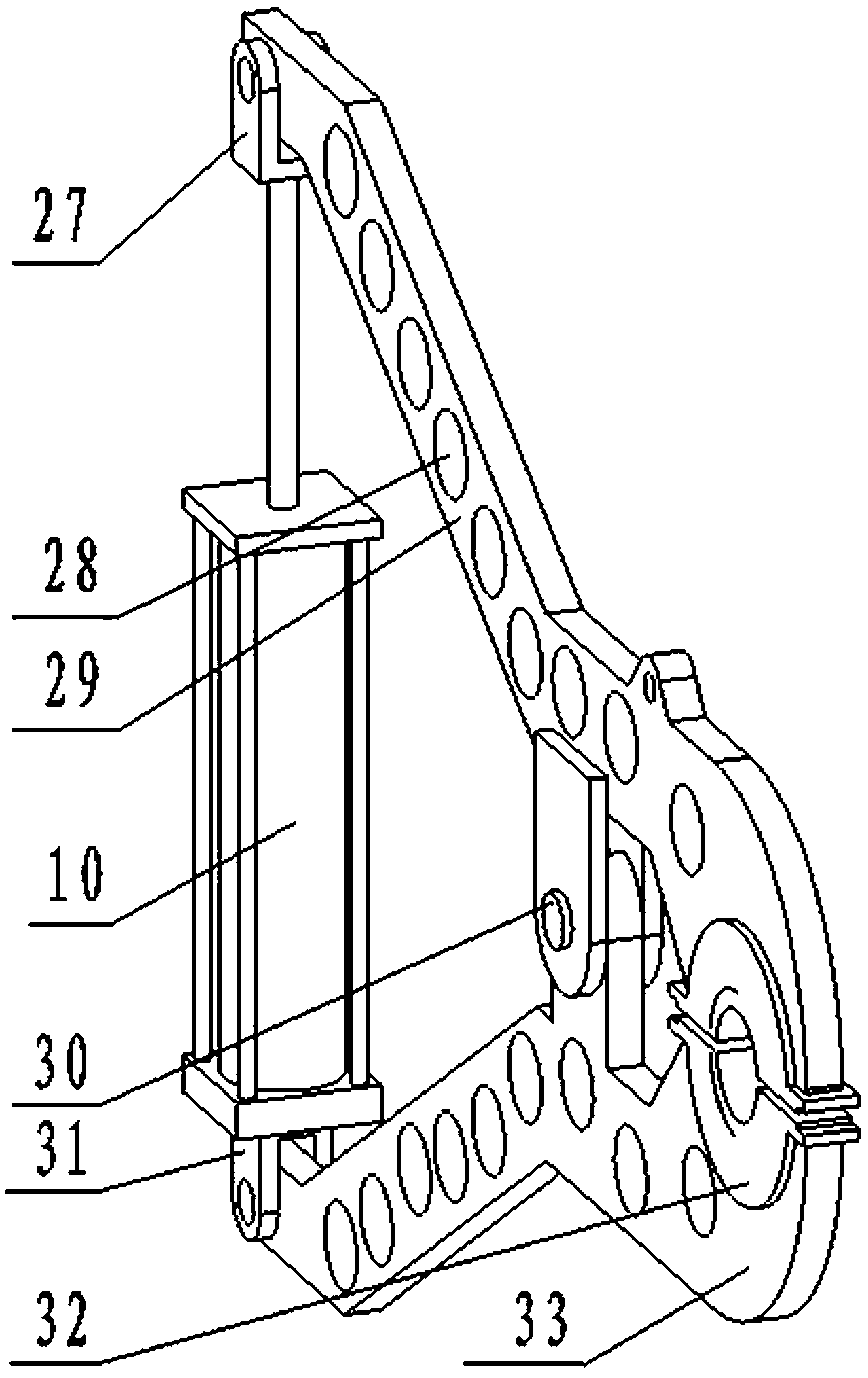

[0025] An engine crankshaft automatic grinding and polishing machine, such as figure 1 Shown, comprise front body 2 and rear body 8. The left end of the front body 2 is equipped with a motor 1 and a transmission adjustment device 3 in sequence, the output shaft of the motor 1 is connected with the transmission adjustment device 3, the right end of the front body 2 is equipped with a tail positioning device 6, and the transmission adjustment device 3 and the tail positioning device The crankshaft spindle polishing device 4 and the first cylinder 5 are installed between the 6, the first cylinder 5 is arranged on the crankshaft spindle polishing device 4, the crankshaft spindle clamping controller 7 is installed on the front body 2, and the crankshaft spindle clamping controller 7 Connect with the first cylinder 5. The rear body 8 is provided with a crankshaft connecting rod polishing device 9 and a crankshaft connecting rod clamping controller 11, the crankshaft connecting rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com