Reduction gear for SCARA industrial robot

A technology of industrial robots and deceleration devices, applied in transmission devices, manipulators, manufacturing tools, etc., can solve the problems of low movement speed, low precision, high noise and heat generation of robots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The purpose of the present invention is to provide a kind of deceleration device for SCARA industrial robot, mainly aimed at four-axis SCARA industrial robot, solves in the prior art:

[0015] 1. The J4 joint depends on the harmonic reducer, which leads to the high cost of the SCARA robot;

[0016] 2. Due to the heavy mass of the J4 joint harmonic reducer and the placement at the farthest end of the arm span, there is a technical defect in the partial loss of the performance of the J1, J2 axis motors and the reducer.

[0017] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

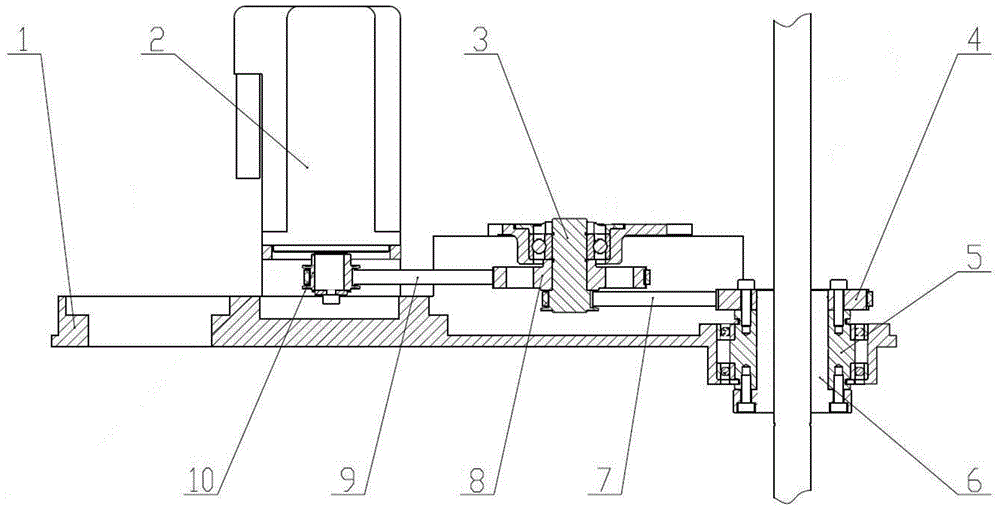

[0018] Such as figure 1 As shown, the deceleration device for the SCARA industrial robot of the present invention is arranged on the forearm 1 at the end of the robot, and includes a motor 2, a first-stage synchronous belt, a second-stage synchronous belt and a ball spline mechanism, and the motor 2 is arranged on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com