Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

143results about How to "Improve purging effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

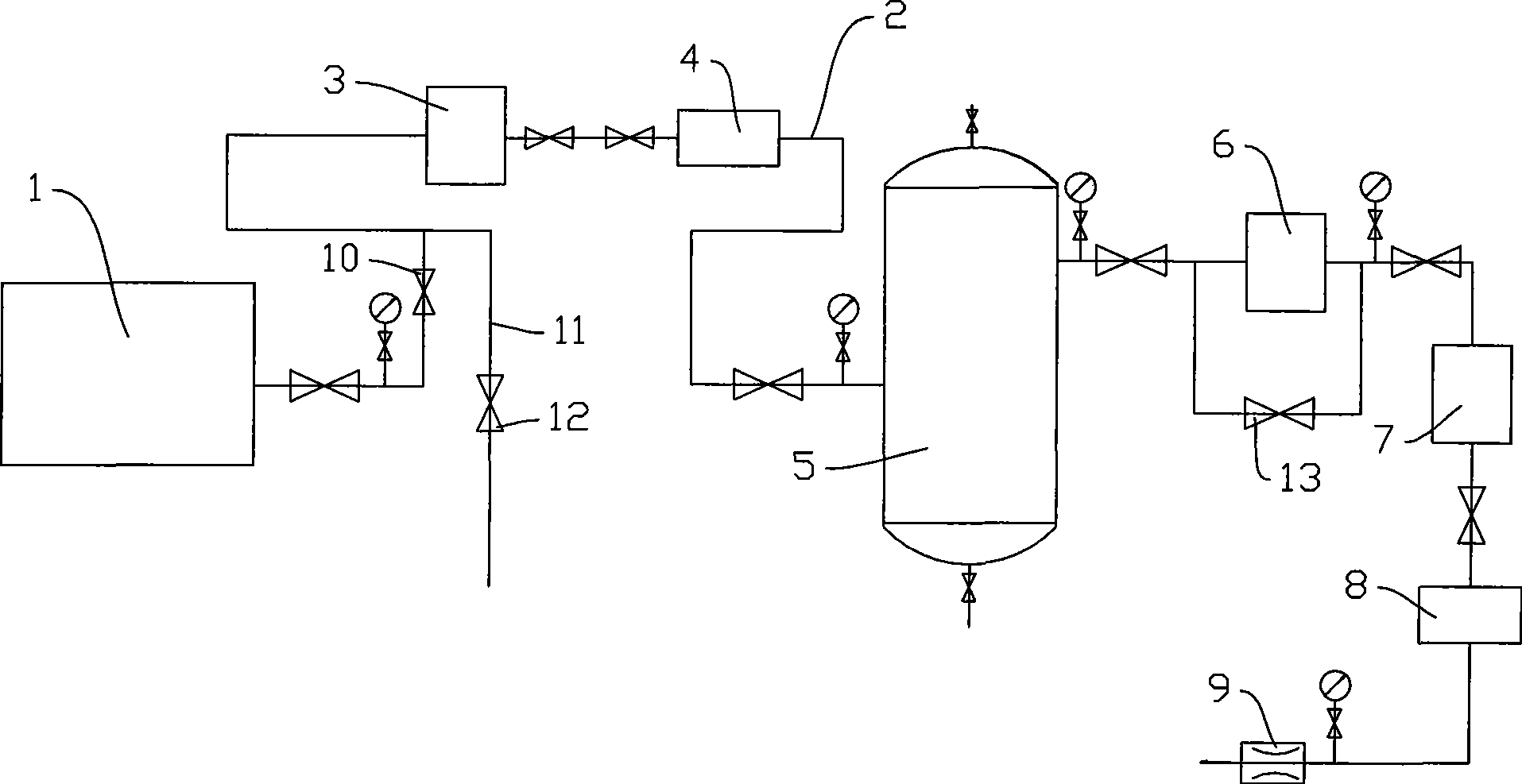

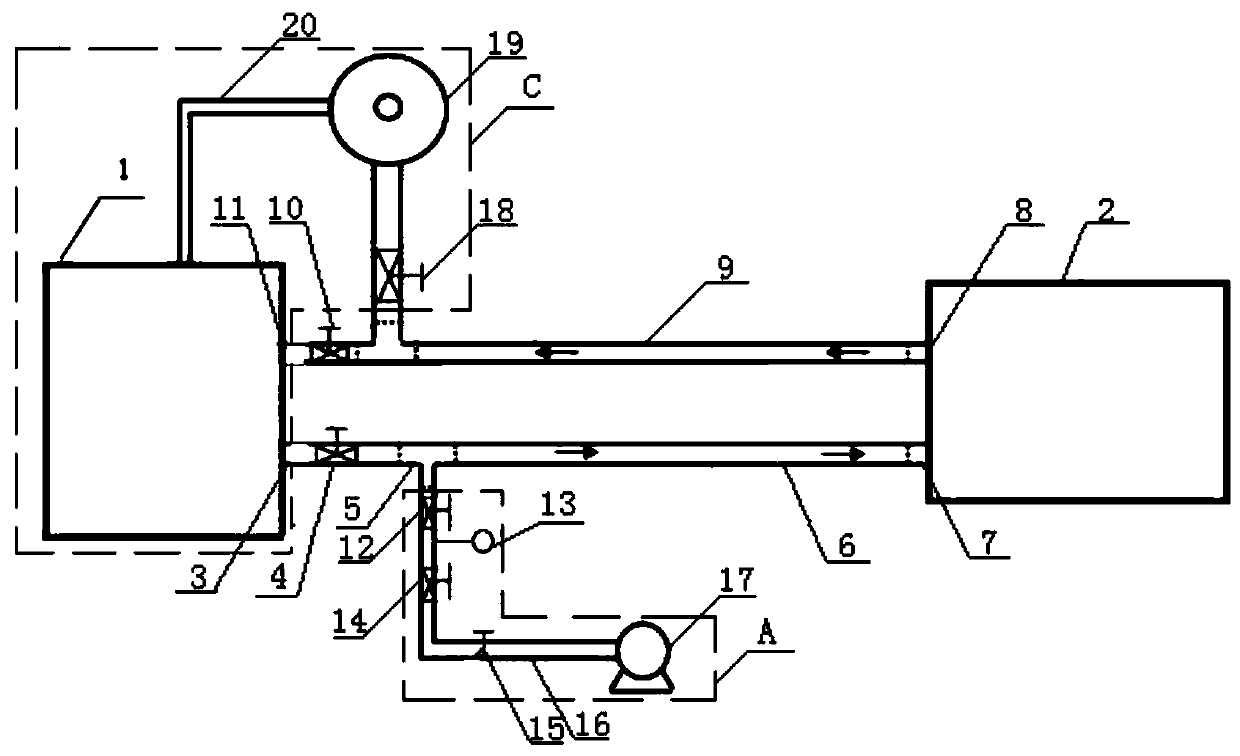

Nitrogen purging device of hydraulic line and method for cleaning hydraulic line

InactiveCN101480653AReduce adhesionEasy to useHollow article cleaningProcess engineeringNitrogen source

The invention provides a device and a method for cleaning hydraulic pipelines, in particular to a nitrogen purging device (cleaning device) for hydraulic pipelines, which has good cleaning effect, high efficiency and not pollution. The nitrogen purging device for hydraulic pipelines adopts the structure that a gas drier used for the drying treatment of nitrogen, a gas filter used for the filtering treatment of nitrogen and a flow control valve used for regulating the output flow of nitrogen are connected in series on an output pipeline which is connected with a nitrogen source. In addition, the cleaning method for hydraulic pipelines adopts nitrogen after being dried and filtered to purge the hydraulic pipelines.

Owner:CHINA 19TH METALLURGICAL CORP

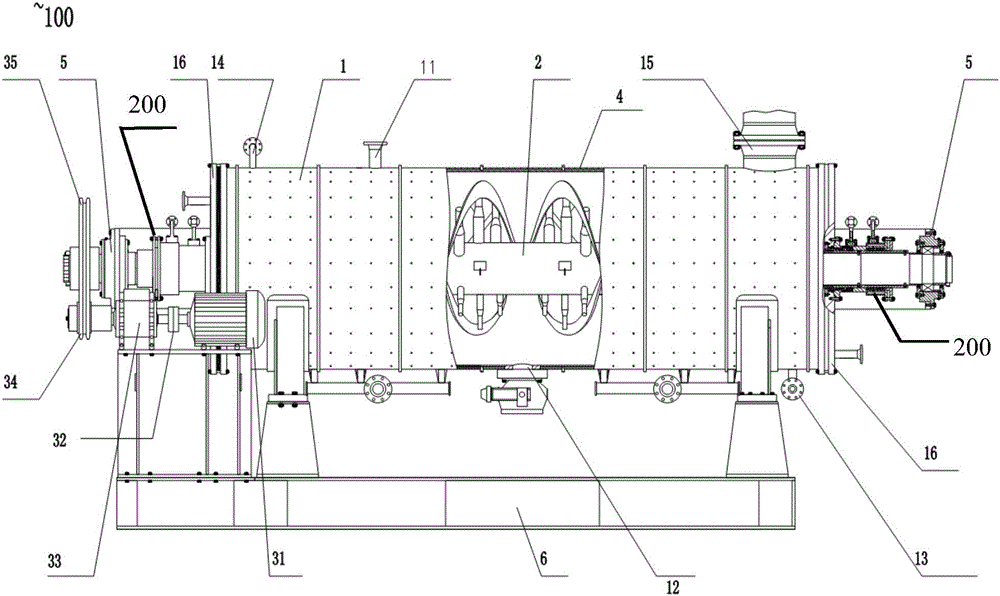

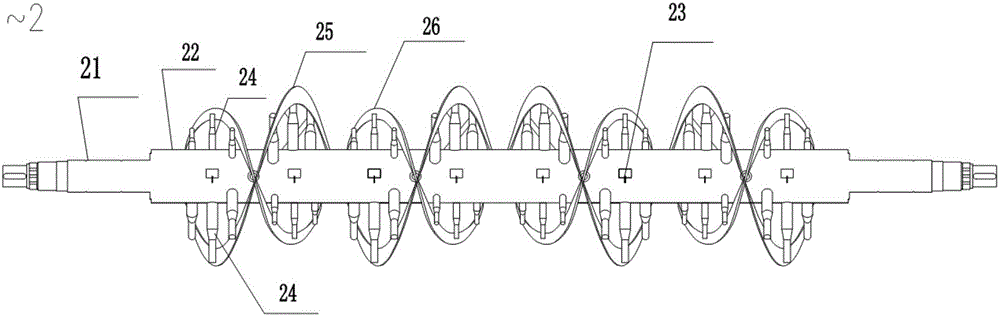

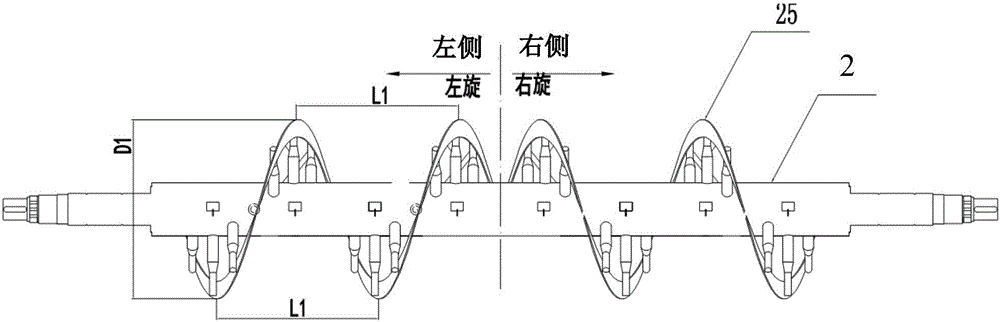

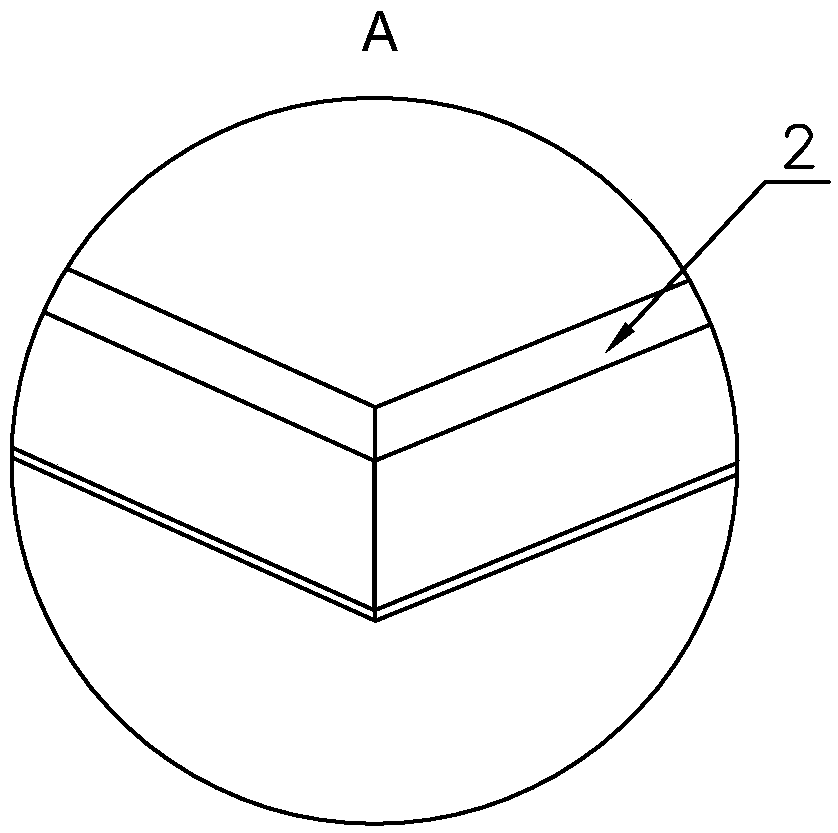

Drying stirrer and treatment system and method for silicon tetrachloride slag slurry in cold hydrogenation technology

InactiveCN106288705ANot easy to stick to the wallNot easy to agglomerateDrying gas arrangementsDrying solid materialsSlagEngineering

The invention provides a drying stirrer for silicon tetrachloride slag slurry in a cold hydrogenation technology. The drying stirrer comprises a shell, a stirring shaft and a transmission device. A drying cavity is defined by the shell. The shell is provided with a feeding port and a discharging port. The stirring shaft is horizontally arranged in the drying cavity and comprises a shaft head and a hollow shaft tube, wherein the shaft head and the hollow shaft tube are welded together. The hollow shaft tube is provided with stirring blades. A first helical band and a second helical band are fixed to the hollow shaft tube through supporting rods and are wound around the periphery of the hollow shaft tube. The respective spiral directions, on the left side and the right side of the hollow shaft tube, of the first helical band and the second helical band are opposite, and the spiral directions of the first helical band and the second helical band are opposite. Under rotation of the stirring shaft, the first helical band enables the slurry to move from the two sides to the middle, and the second helical band enables the slurry to move from the middle to the two sides. The drying stirrer enables the slurry to flow circularly, and the slurry is stirred more evenly. The invention further provides a treatment system and method for the silicon tetrachloride slag slurry.

Owner:江西赛维LDK光伏硅科技有限公司

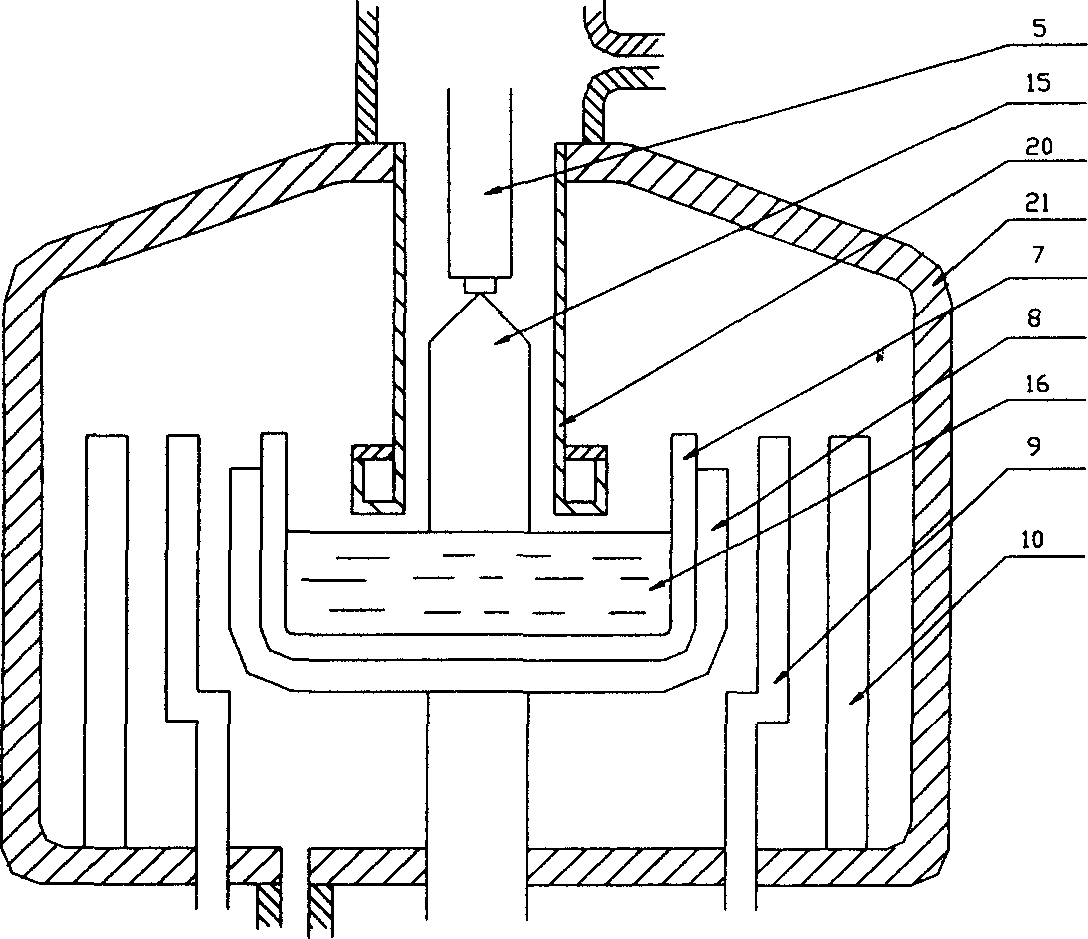

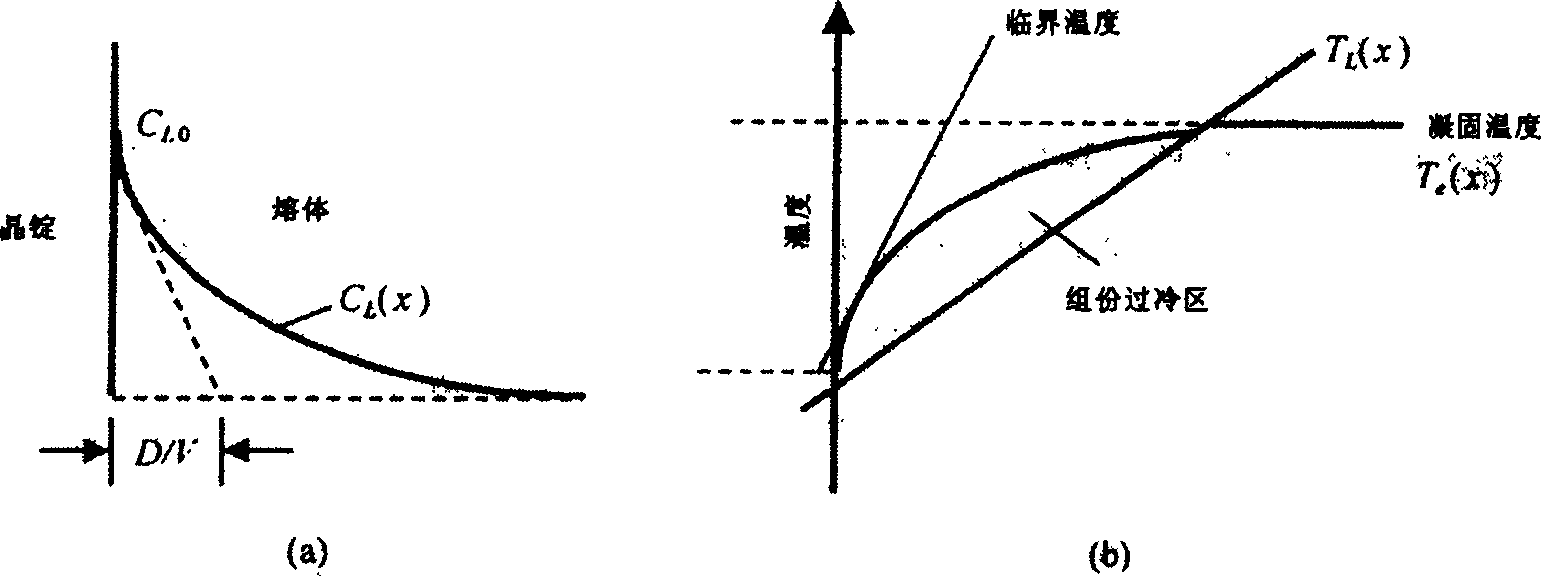

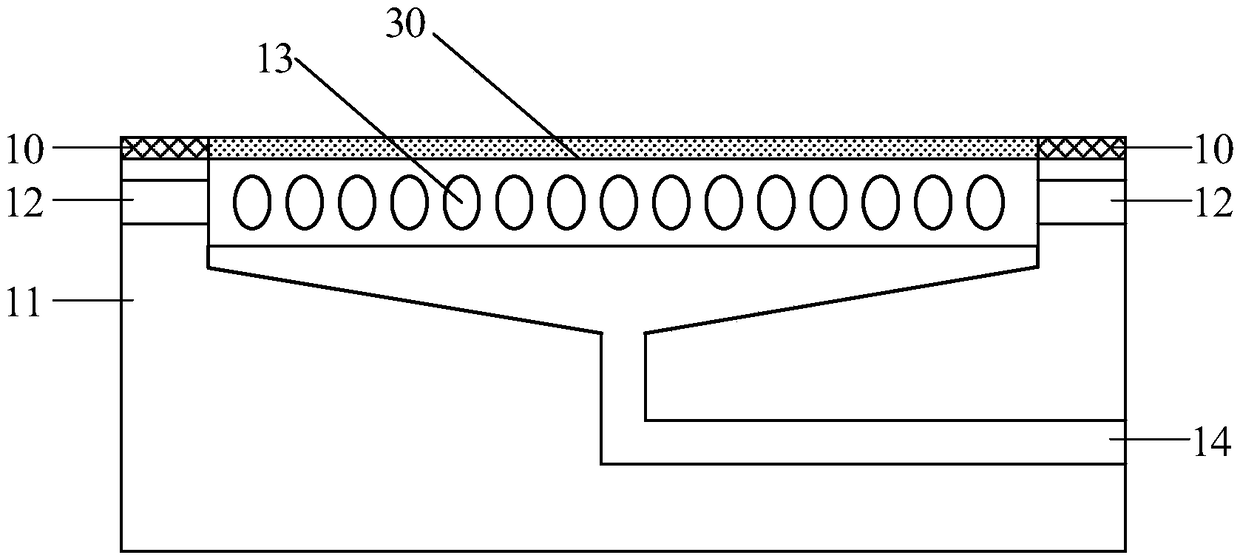

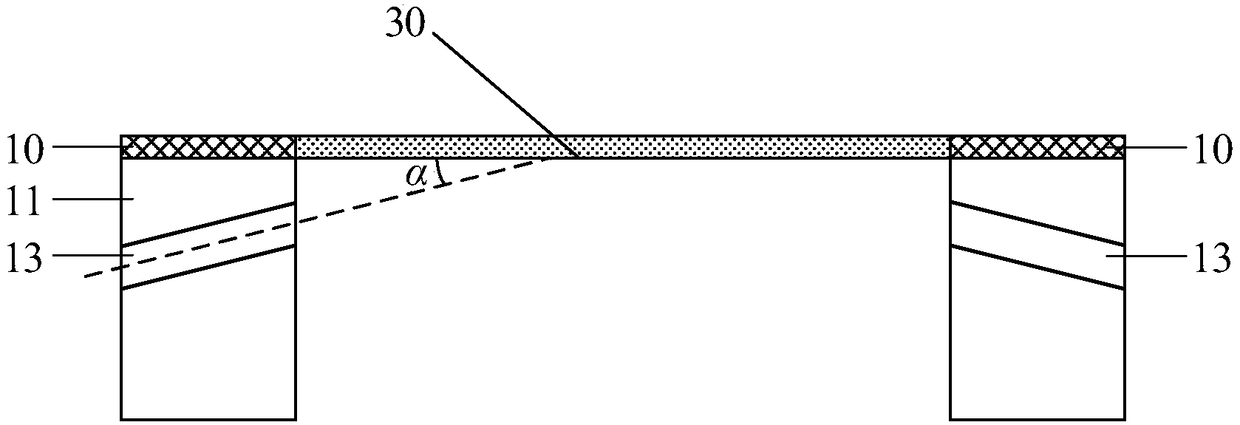

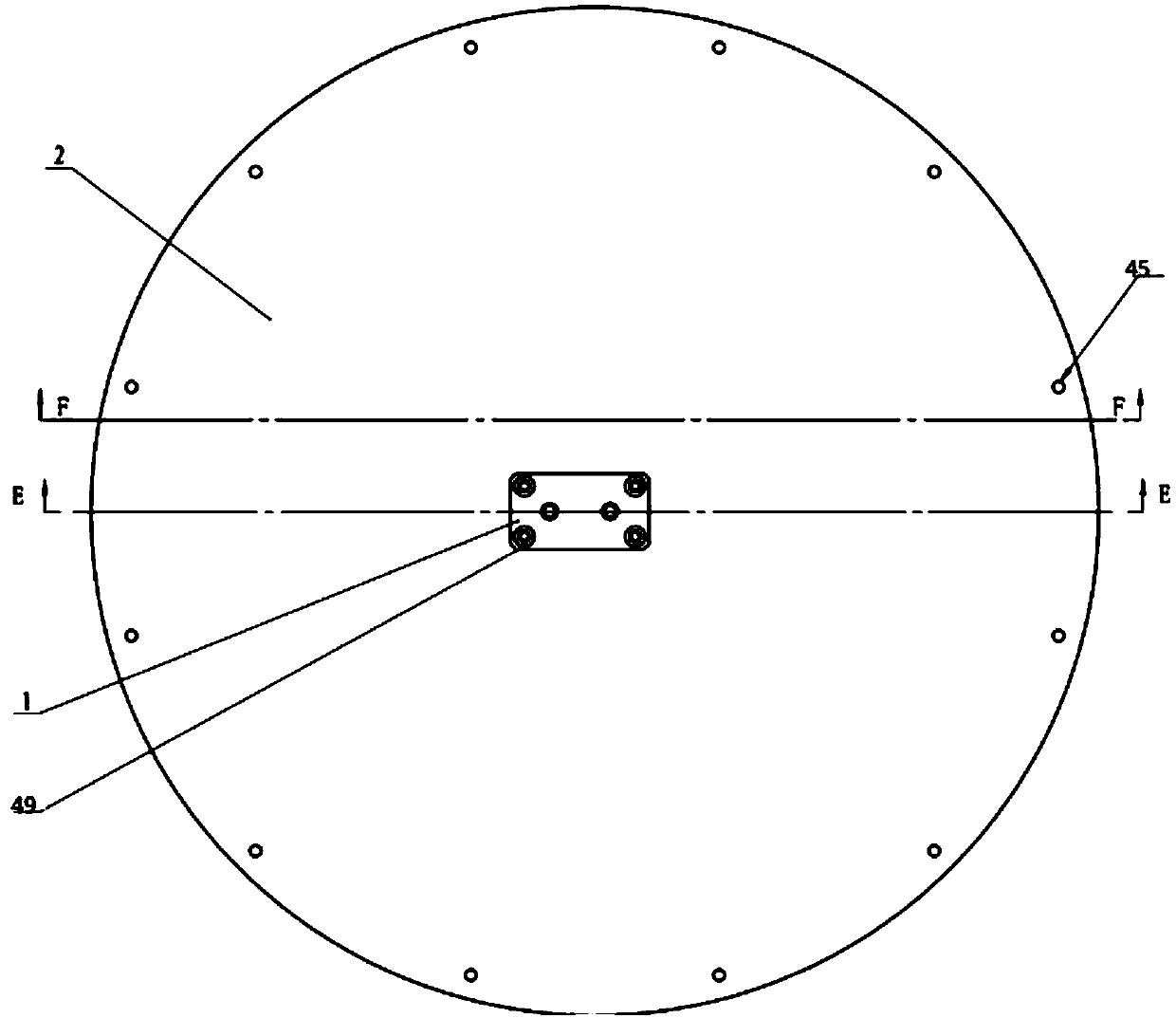

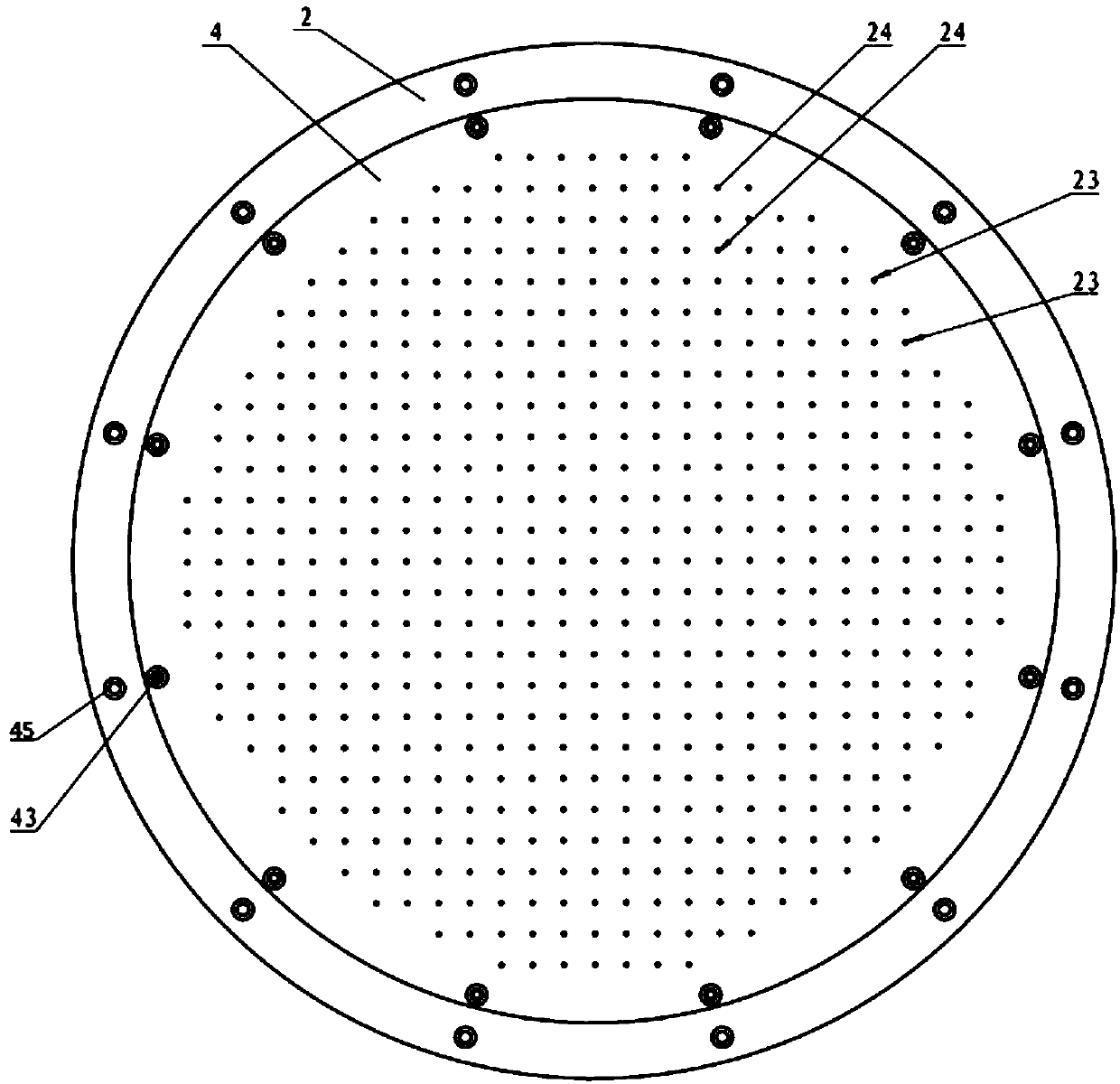

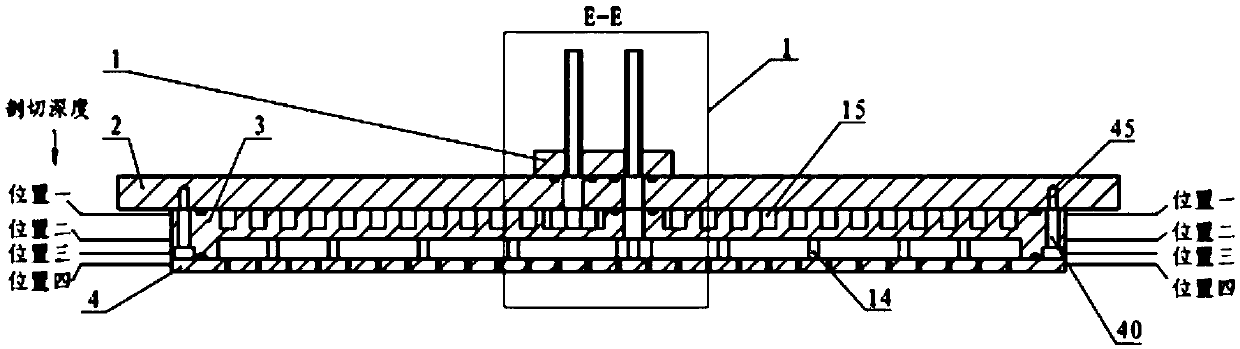

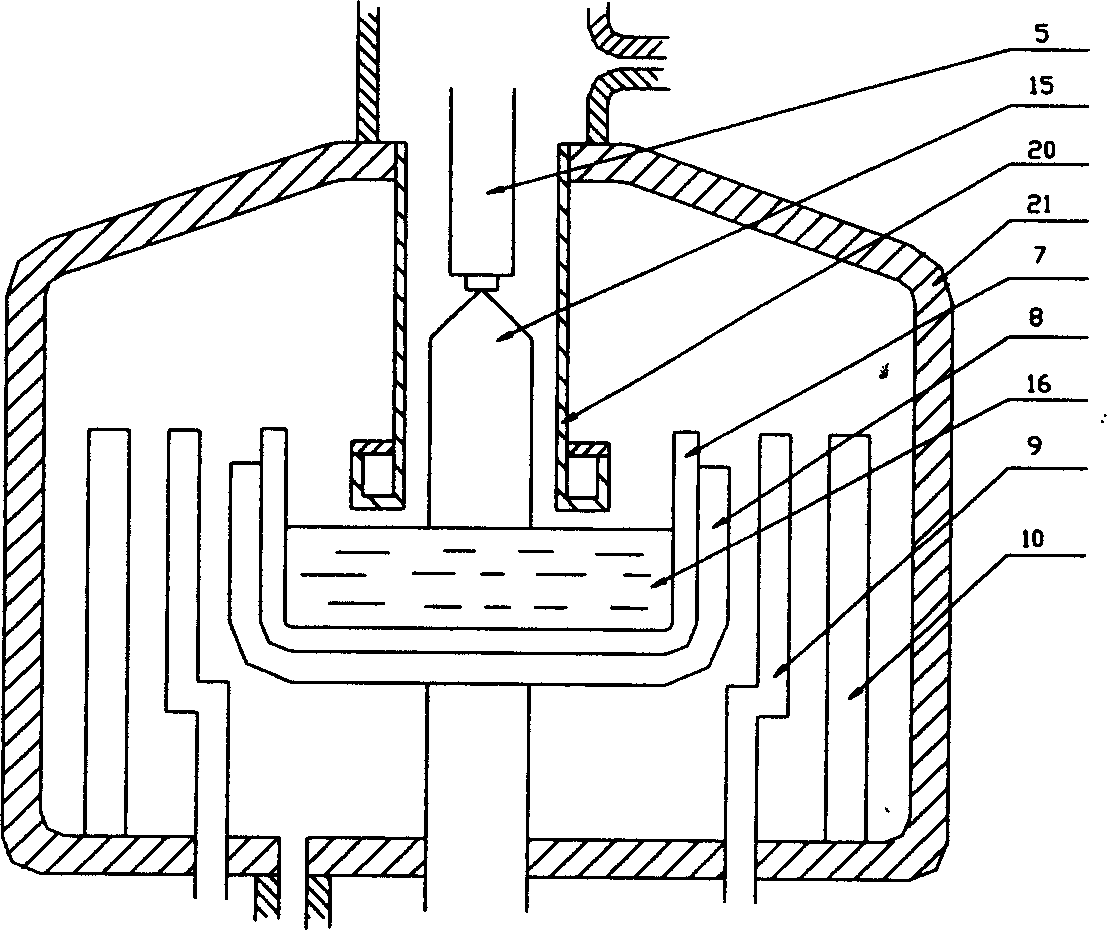

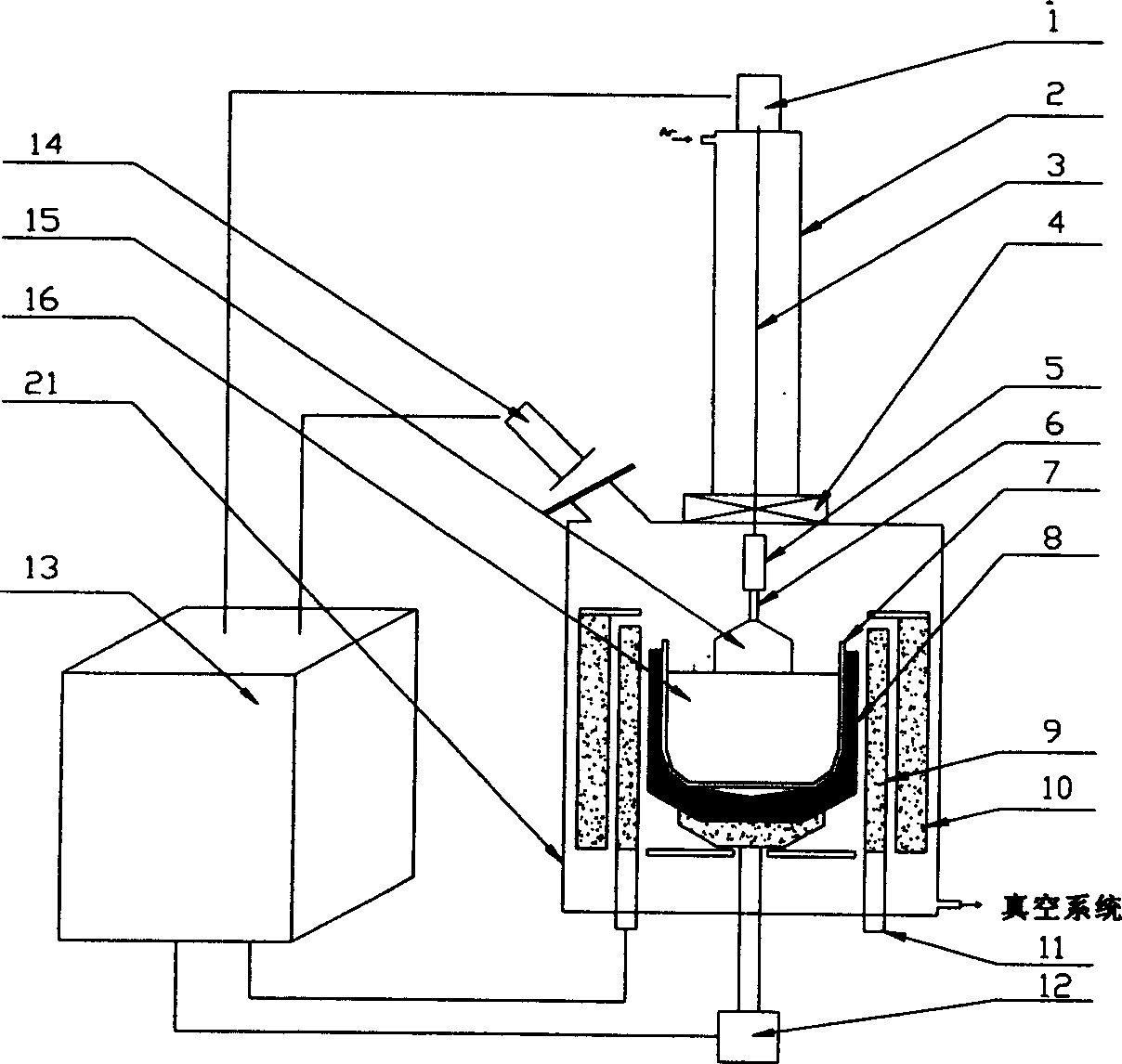

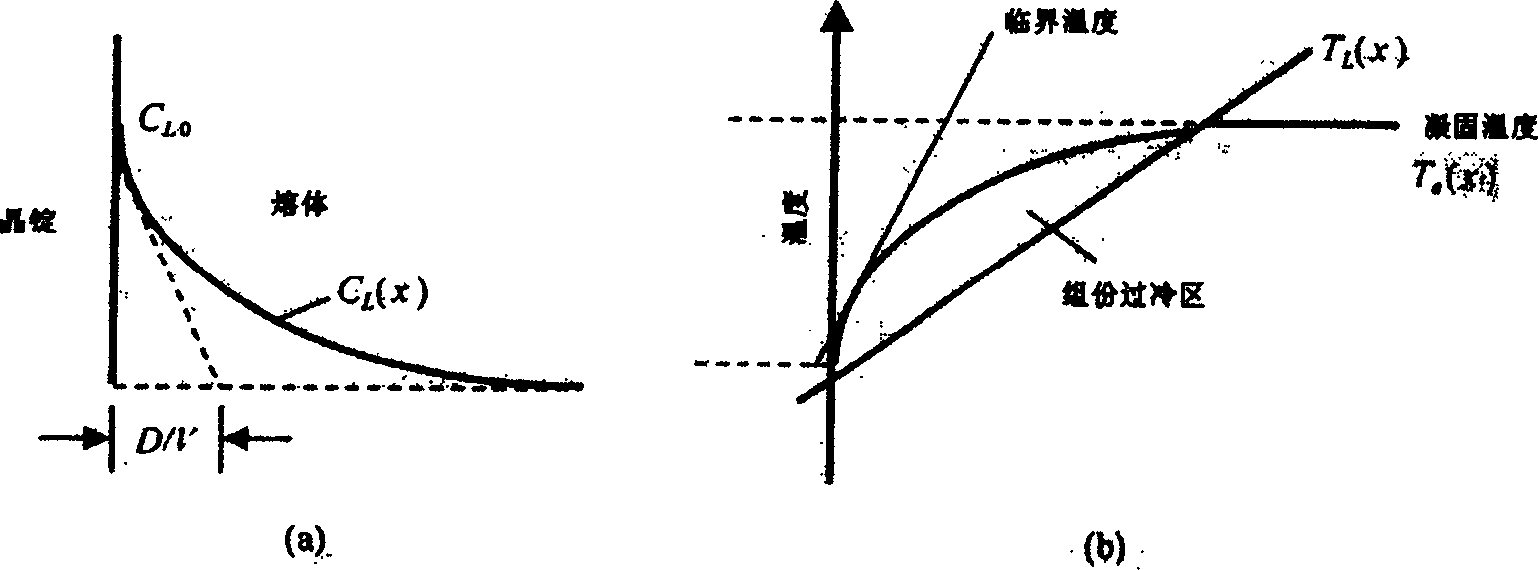

Upper thermal field used for six inch and eight inch adulterated phosphorus vertical pulling silicon mono crystal manufacture

ActiveCN1556257AImprove purging effectEffective blow offPolycrystalline material growthBy pulling from meltElectrical resistance and conductanceEngineering

A top heat field for preparing 6-inch and 8-inch heavyly doped monosilicon by straight pulling up is composed of an insulating cover consisting of the upper and lower hollow trancated cones, and an upper cover plate fixed to the top of said insulating cover and put on a supporting pipe. It can enhance the scavenge action of the airflow on the surface of molten body for removing the fine particles from the surface.

Owner:金瑞泓科技(衢州)有限公司

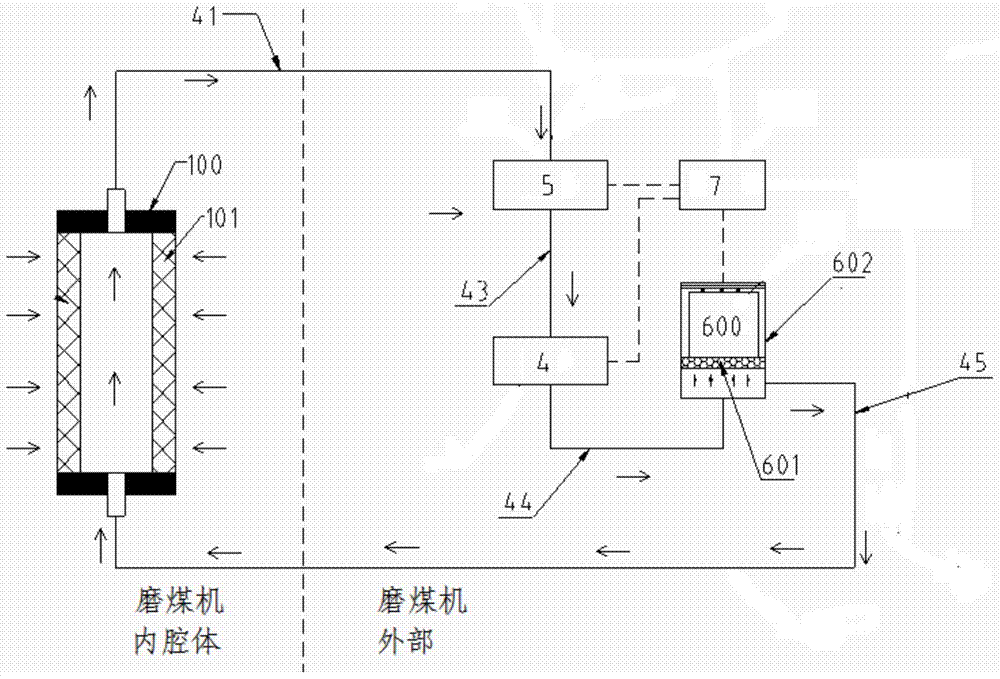

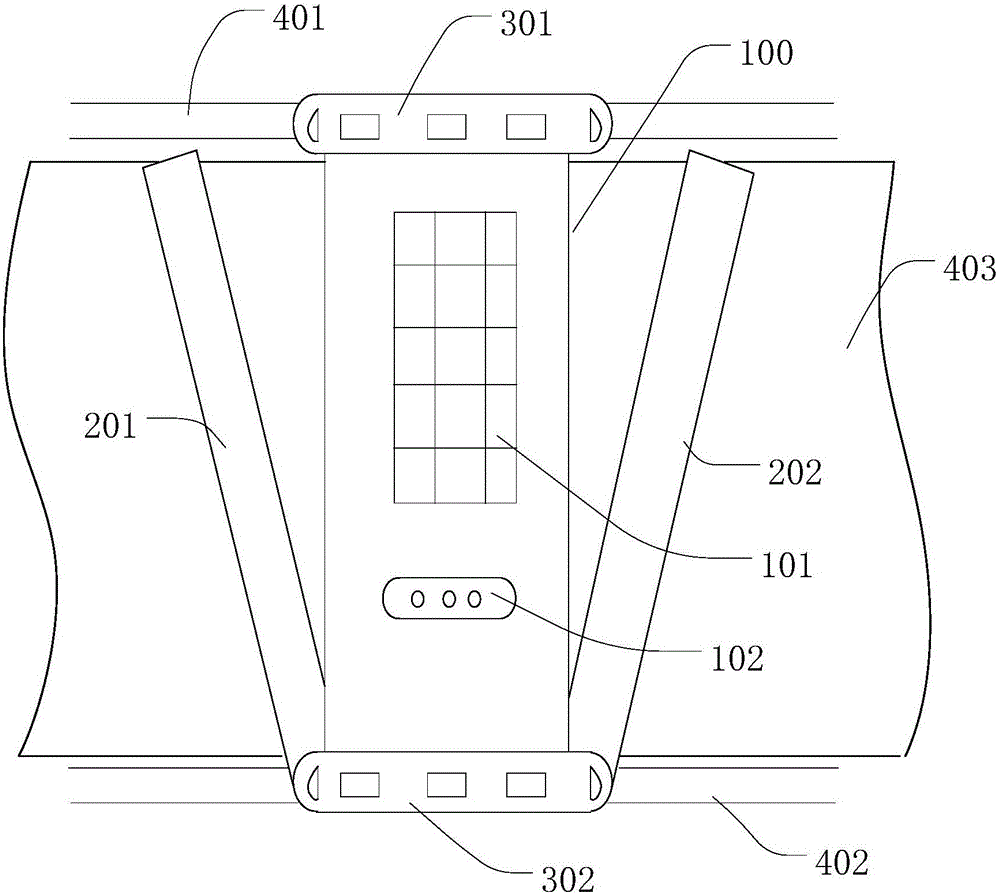

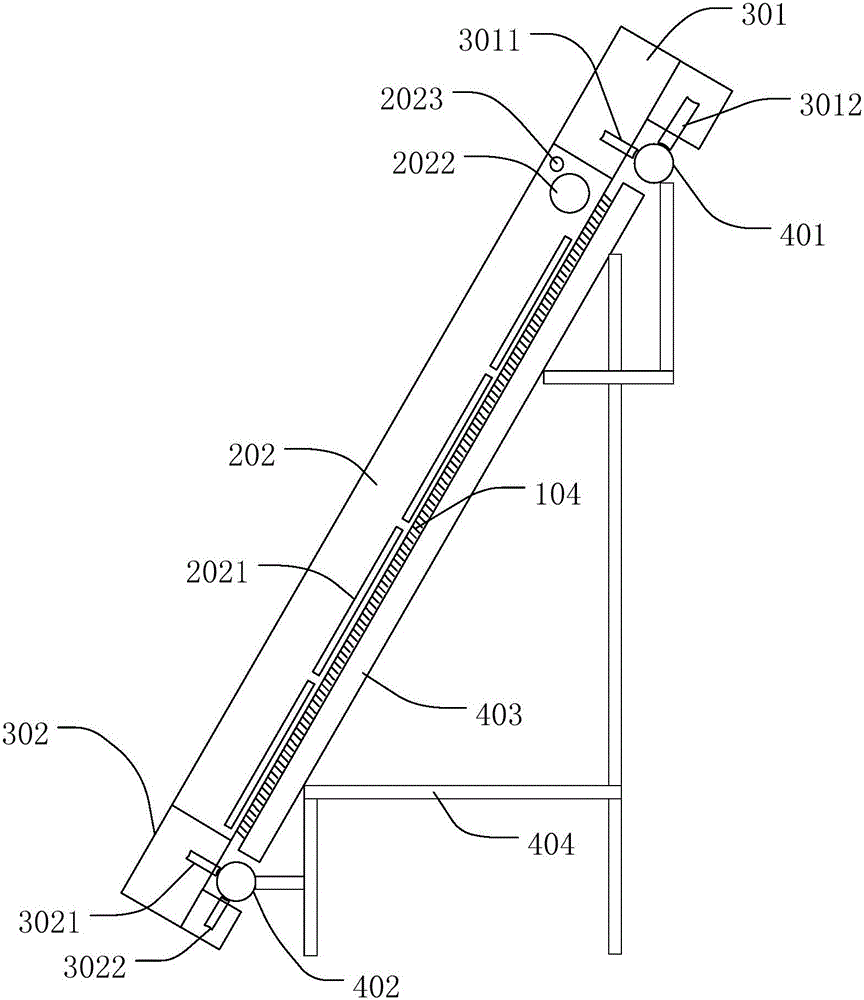

Gas sampling and detecting device

The invention relates to a gas sampling and detecting device. The gas sampling and detecting device comprises a closed circulation gas circuit, wherein a collecting and filtering device (100) and a sampling main body are connected in series in the closed circulation gas circuit; the collecting and filtering device (100) is provided with an inner cavity and a filtering channel, the inner cavity is communicated with the closed circulation gas circuit, and the filtering channel (101) is used for communicating the inner cavity with the outside dust environment; and the sampling main body comprises a gas pump and a gas detecting device, and the gas pump is used for driving gas in the closed circulation gas circuit to flow. According to the closed-circuit self-circulation gas sampling principle, the sampled gas is made to circulate in a relatively closed environment, and the gas in the dust environment is not pumped directly by the gas pump, thus the filter pollution and blockage caused by dust can be reduced fundamentally. More importantly, the closed gas circuit can not be disturbed by the outside environment, and a filtering device for filtering the disturbance of the outside environment does not need to be arranged additionally.

Owner:GL TECH CO LTD

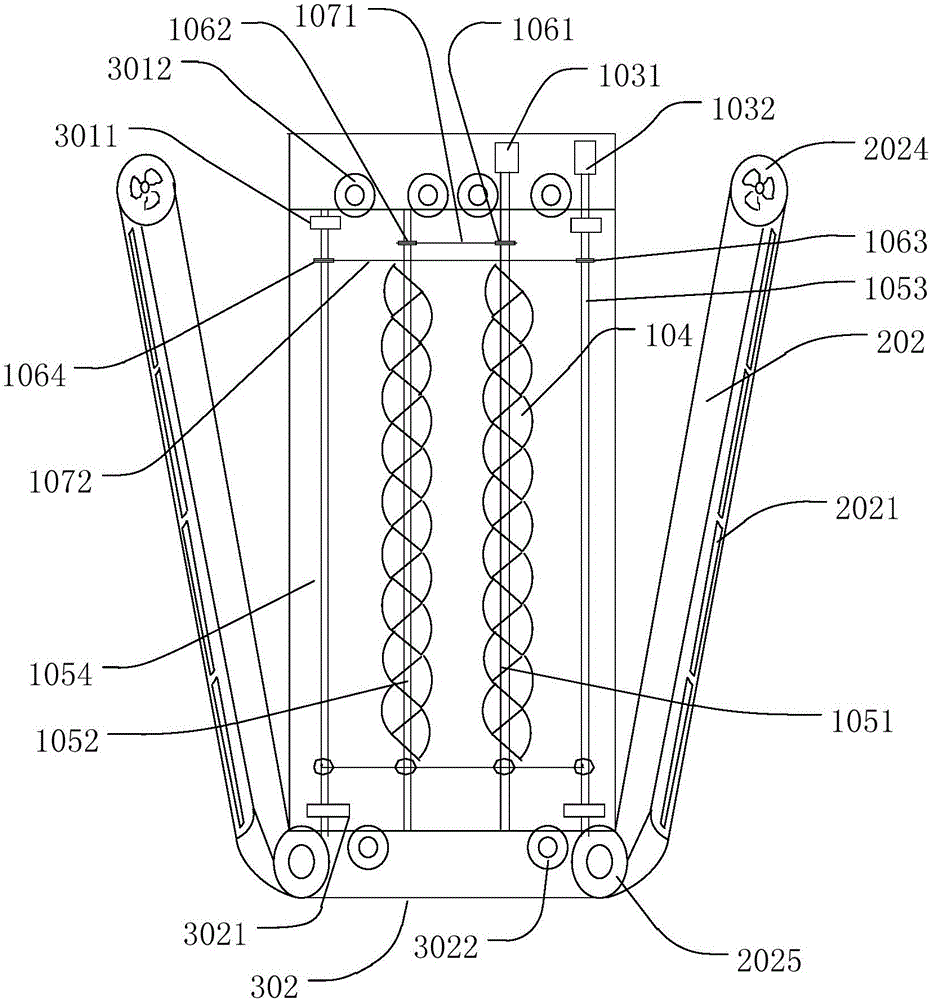

Photovoltaic intelligent dust and snow removing robot

ActiveCN105773572AImprove purging effectClean up thoroughlyProgramme-controlled manipulatorPhotovoltaicsReciprocating motionElectrical and Electronics engineering

The invention relates to the technical field of photovoltaic panel cleaning maintenance, in particular to a photovoltaic intelligent dust and snow removing robot. The photovoltaic intelligent dust and snow removing robot comprises a machine body, opening and closing purging devices and walking devices, wherein the two opening and closing purging devices are respectively arranged on the two sides of the machine body; the lower ends of the opening and closing purging devices are rotatably connected with the machine body, so that the opening and closing purging devices can rotate around the rotatable connection parts with the machine body; at least one air outlet is formed in the outer side walls of the opening and closing purging devices; fans are arranged inside the opening and closing purging devices; the walking devices are arranged at the upper and lower ends of the machine body, so that the machine body can perform reciprocating motion along a preset track; fur brushes are arranged on the back side of the machine body; and a solar photovoltaic panel is arranged on the front side of the machine body. According to the photovoltaic intelligent dust and snow removing robot, the openable and closable purging devices are adopted, and during the operation process, the opening and closing purging devices can be opened to certain angles according to the sliding direction of accumulated snow on the photovoltaic panel, so that the air blowing direction is basically downwards, the robot has a quite good purging effect on the accumulated snow difficult to remove, the removing rate reaches 99% or above, the cost is low, and the working efficiency is high.

Owner:陶永安 +1

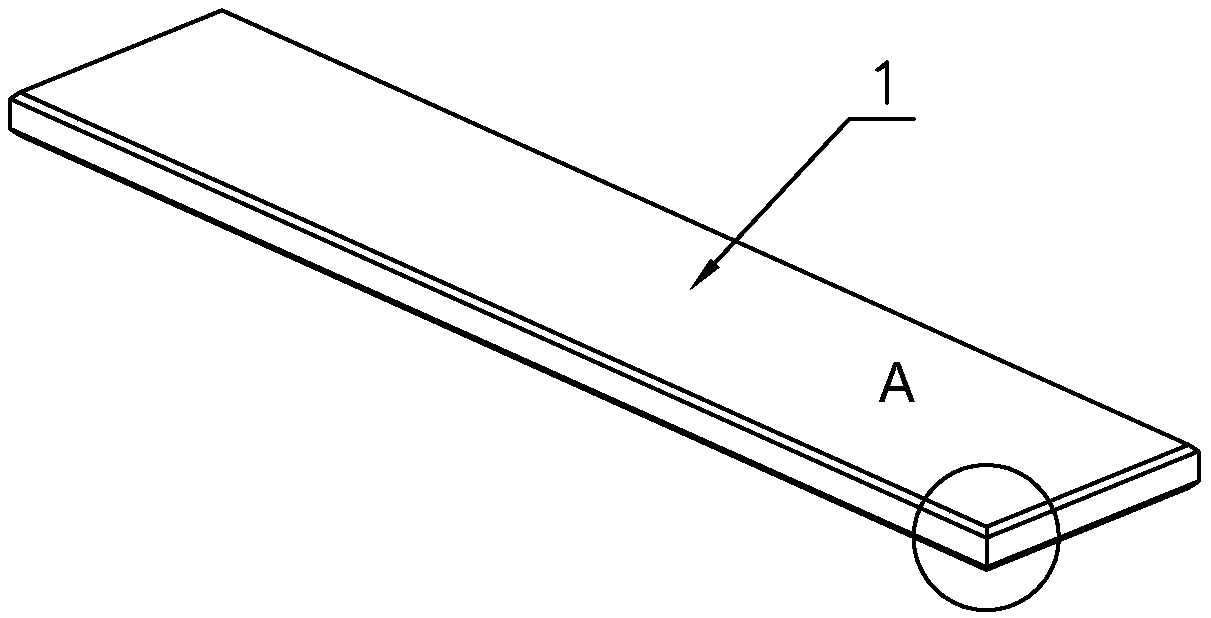

Titanium plate hot continuous rolling large-scale manufacturing method

ActiveCN109317518AReduce drum distortionGuaranteed temperatureCleaning using toolsWork heating devicesMetallurgyIngot

The invention discloses a titanium plate hot continuous rolling large-scale manufacturing method. The titanium plate hot continuous rolling large-scale manufacturing method comprises the following steps of: step (1) heating; (2) carrying out rough rolling; step (3) carrying out finish rolling; step (4) crimping; step (5) welding; and step (6) pickling and annealing. According to the titanium platehot continuous rolling large-scale manufacturing method, the temperature required for rolling a titanium plate is ensured by arranging a heat preservation cover on a conveying roller; before an titanium ingot is heated, the edge of the titanium ingot is chamfered, and the chamfering reduces the drum type deformation of the edge of the titanium plate and ensures the shape of a plate formed by rolling the titanium plate.

Owner:山东盛阳金属科技股份有限公司

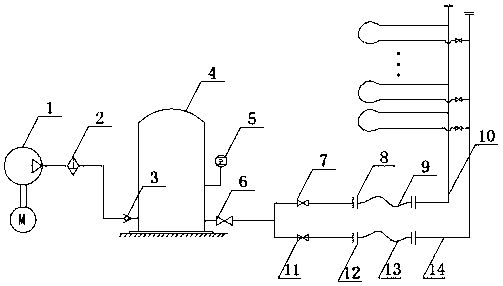

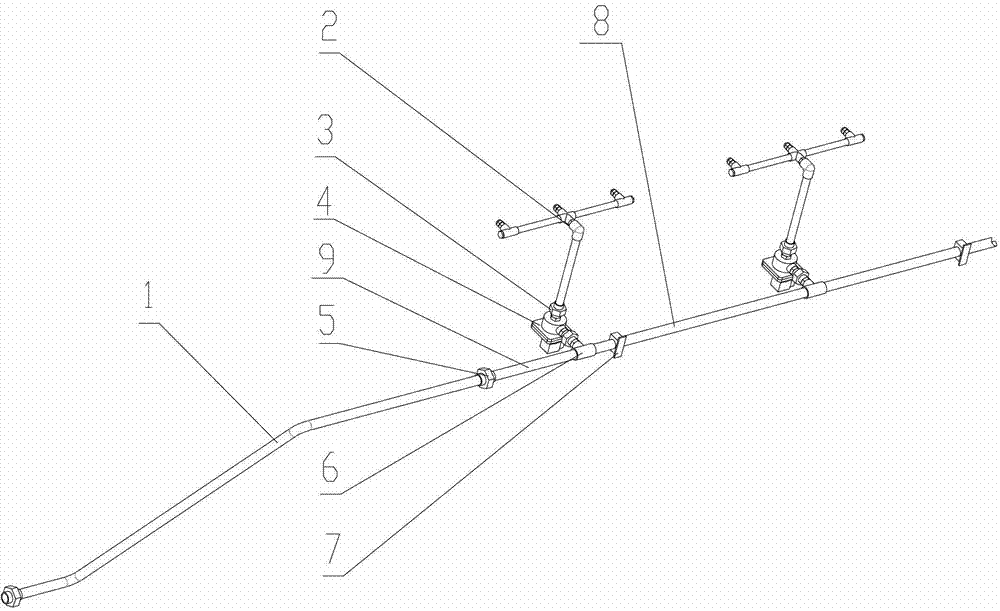

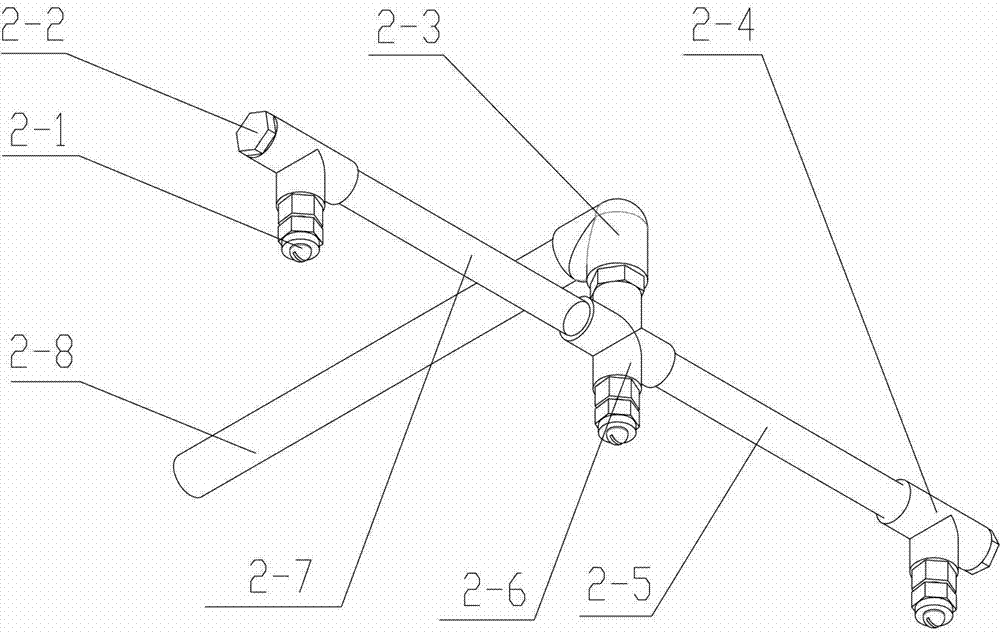

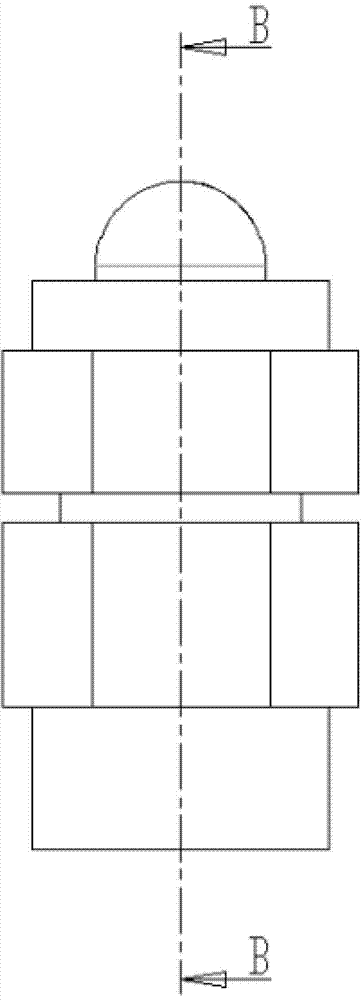

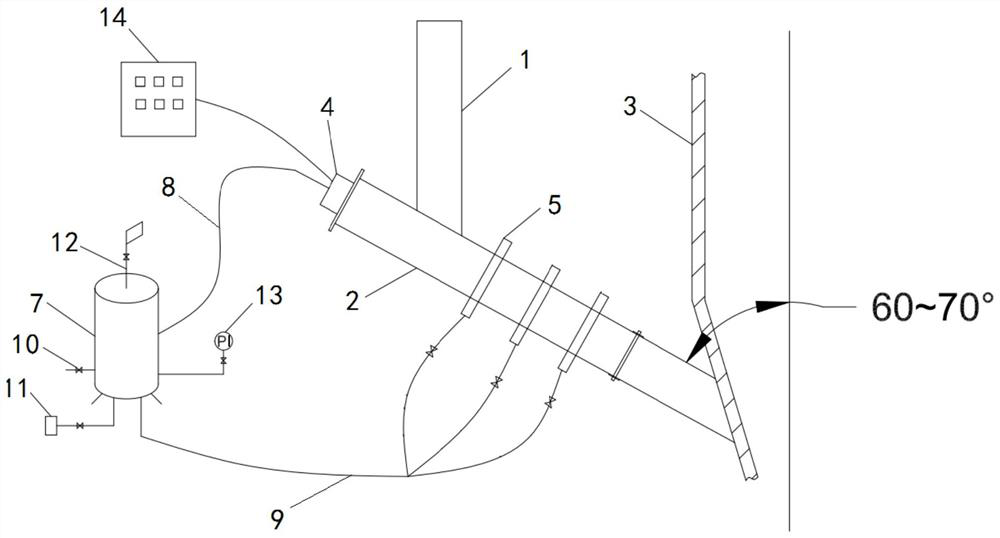

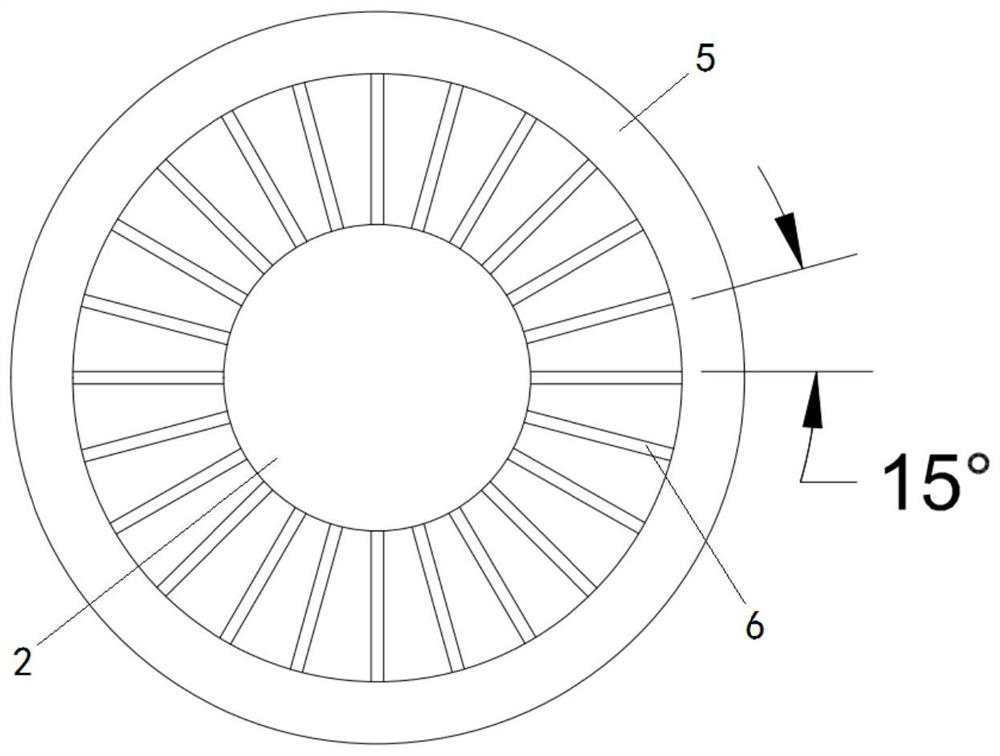

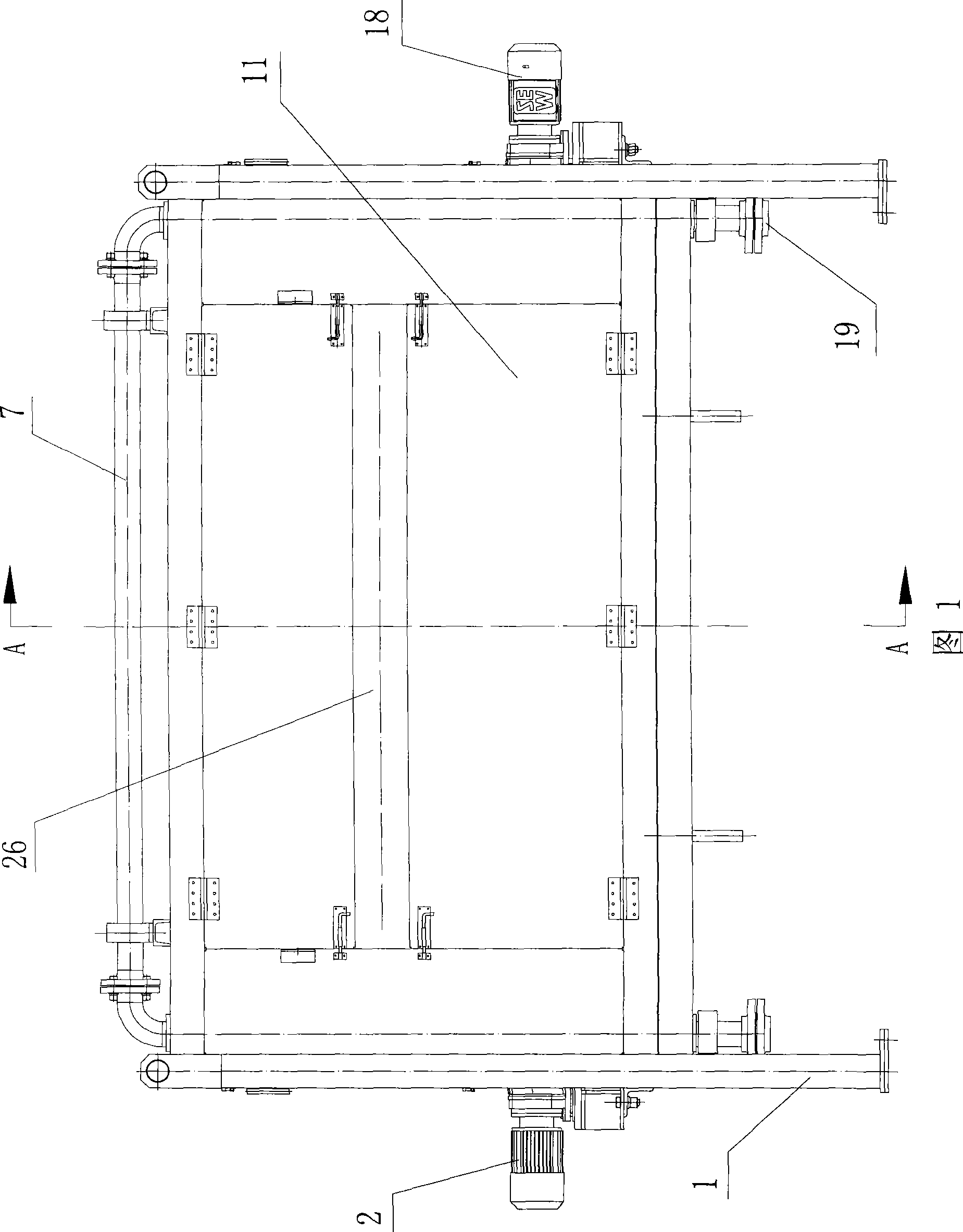

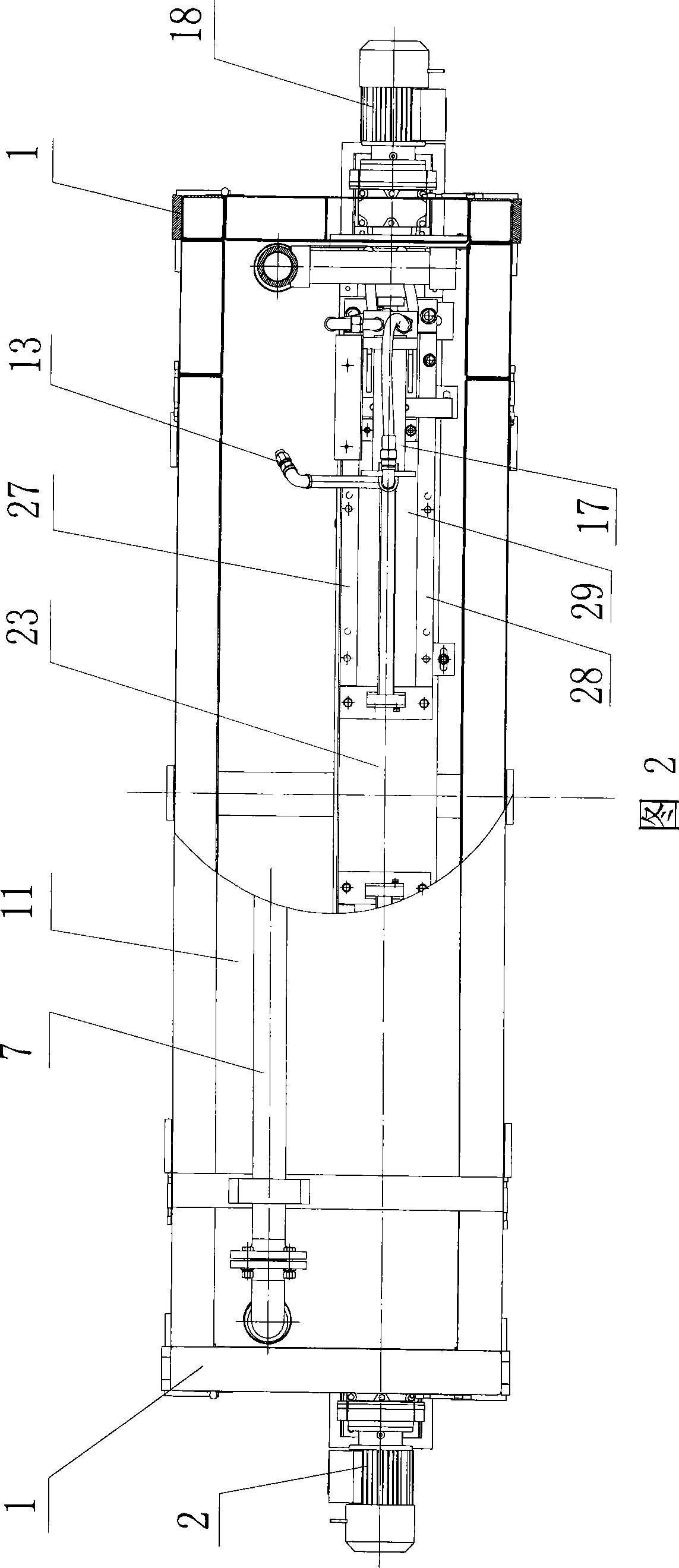

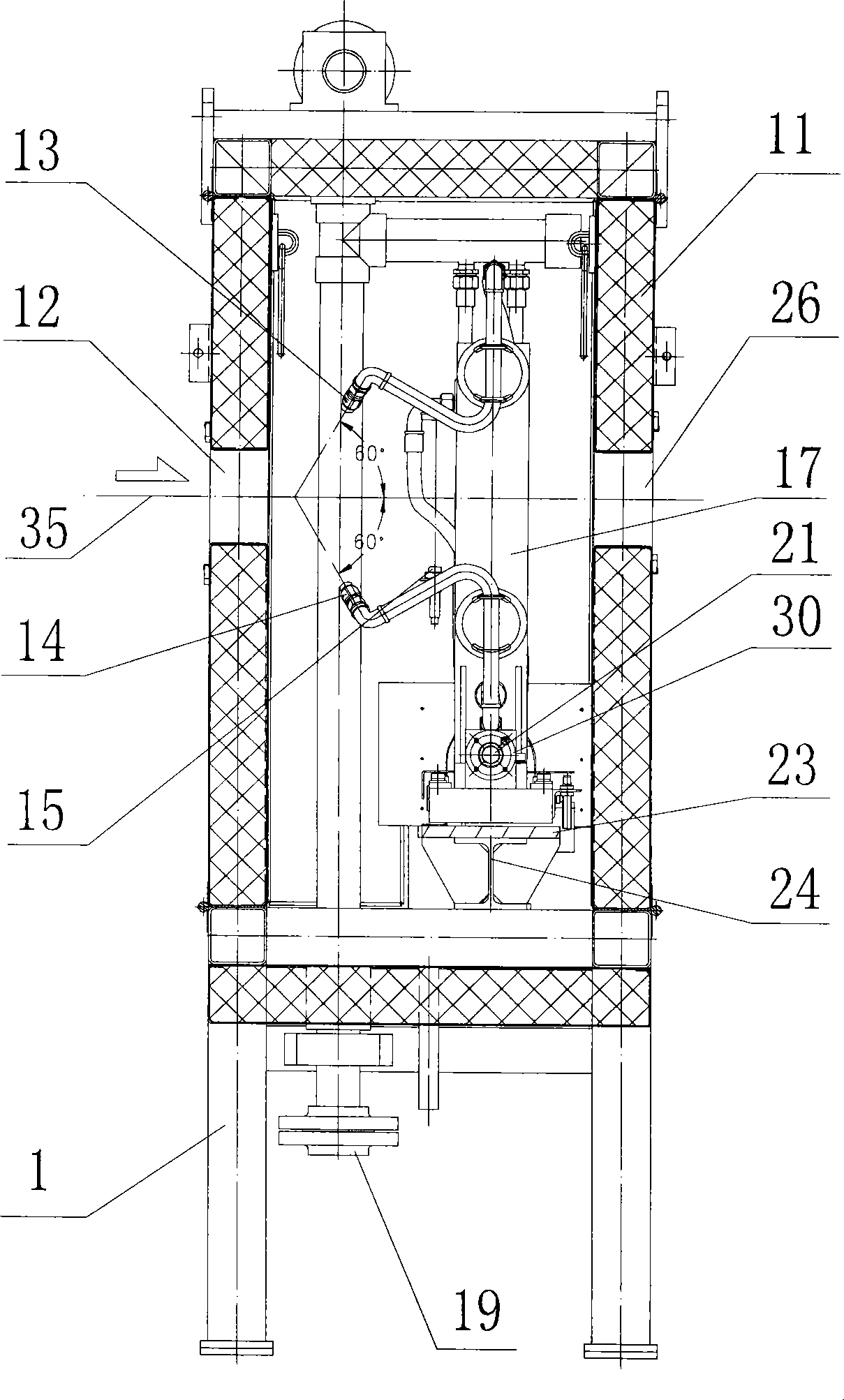

A bidirectional pulse purge precleaning system of a hydraulic pipeline system

ActiveCN108655119AReduce purge dead spaceGood purging effectHollow article cleaningProcess engineeringHigh pressure

The invention relates to a hydraulic pipeline system and especially relates to a purge precleaning system of the hydraulic pipeline system. The bidirectional pulse purge precleaning system of the hydraulic pipeline system includes a gas storage tank with a pressure gauge; an air compressor is connected with the gas storage tank through a non-return valve; a pair of switch valves are connected in parallel in the outlet of the gas storage tank, and gas pipe interfaces are arranged in the outlets of the switch valves; the pipeline system includes a main pipeline P pipe and a main pipeline T pipe,gas pipe interfaces are arranged in the inlets of the main pipeline P pipe and the main pipeline T pipe, and the gas pipe interfaces are connected with the corresponding gas pipe interfaces in the outlets of the switch valves through temporary pipelines. The air compressor is used for inflating the gas storage tank to high pressure, and forward and reverse purge is realized by utilizing the connection and disconnection of the temporary connecting pipes. The precleaning with high efficiency and quality of the hydraulic pipelines is realized, and the flushing efficiency and quality of the subsequent oil flushing are improved.

Owner:CHINA MCC20 GRP CORP

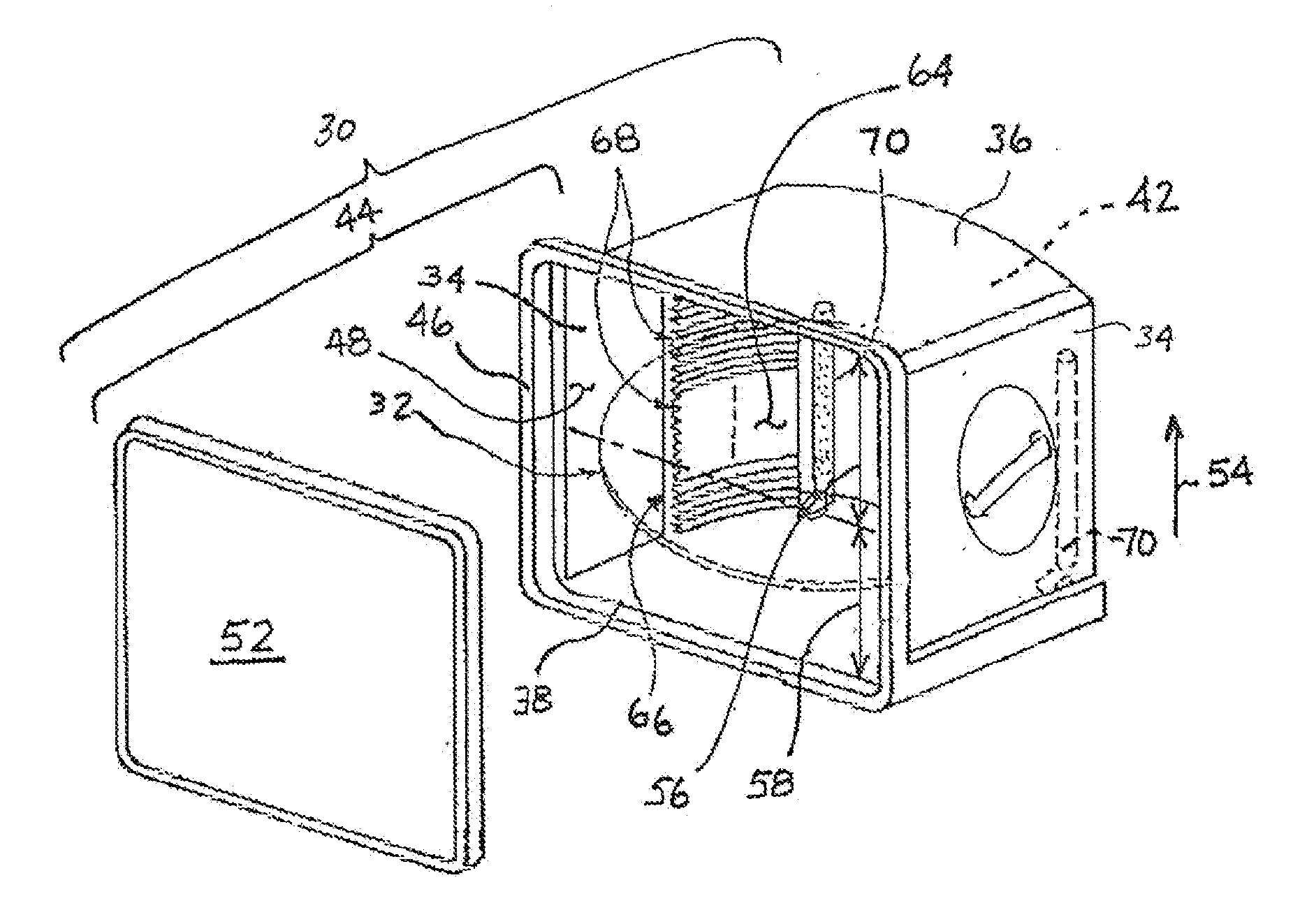

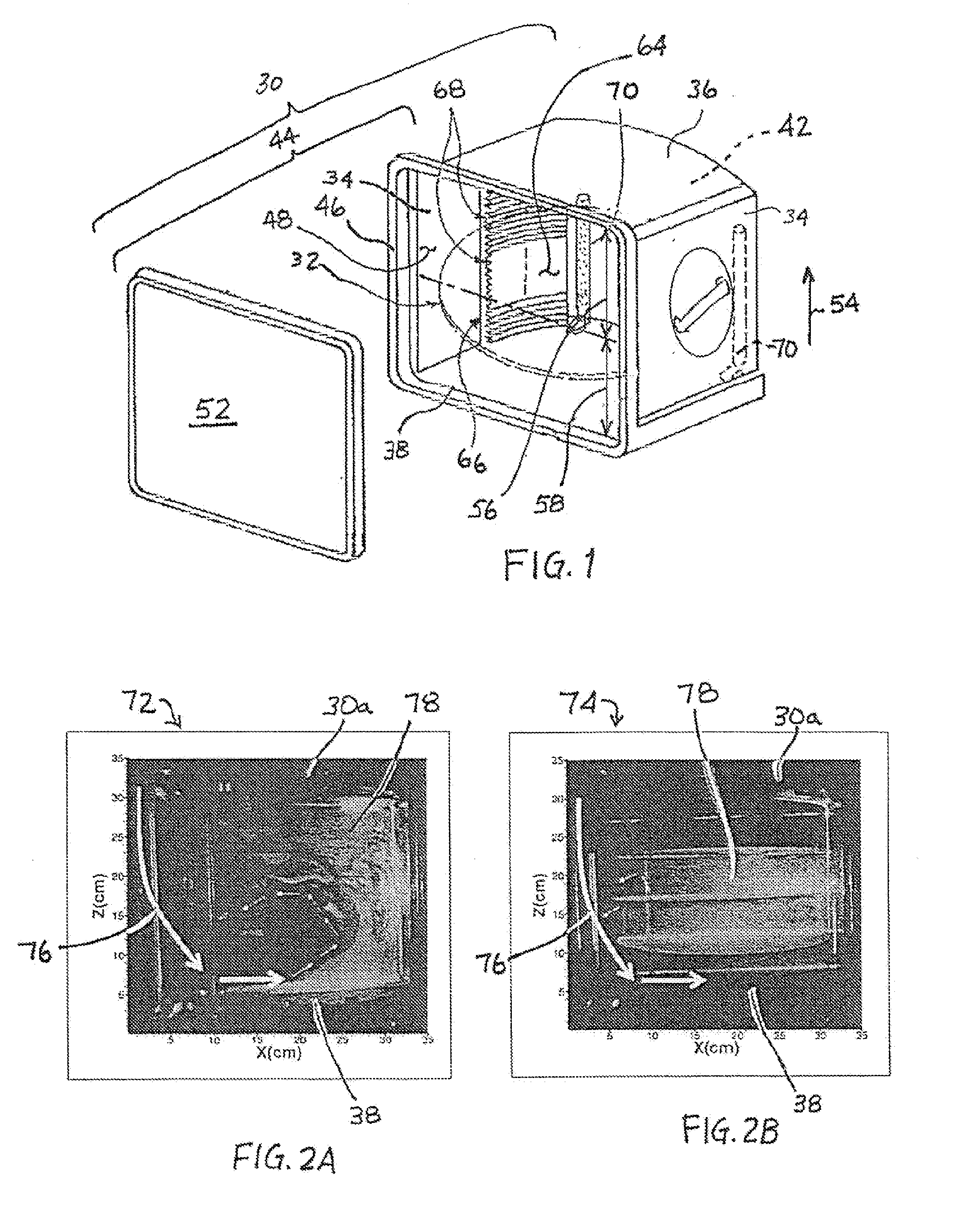

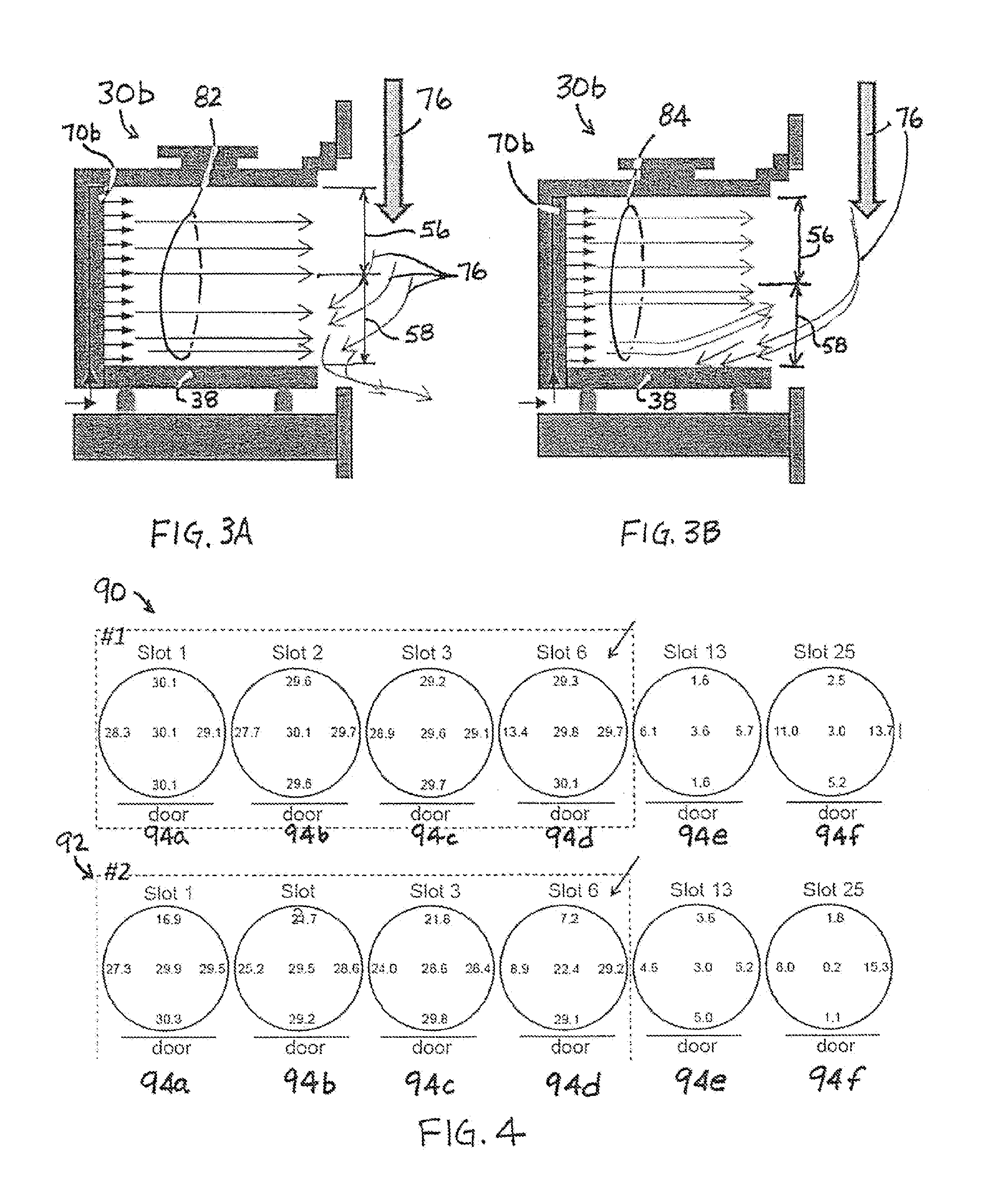

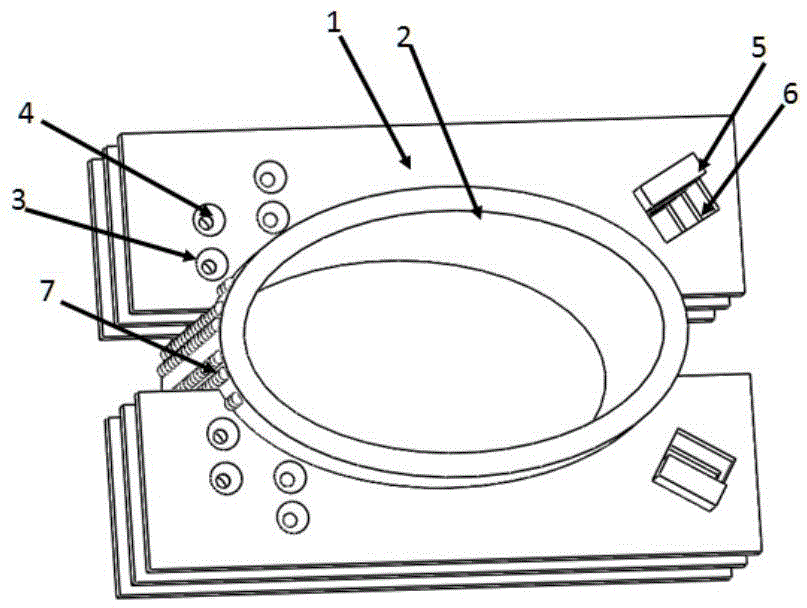

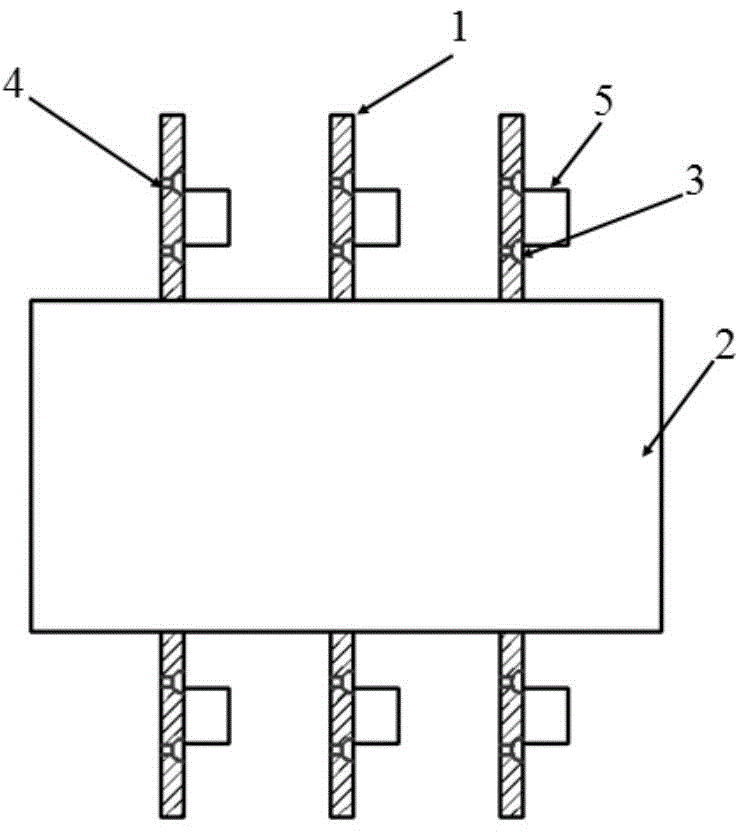

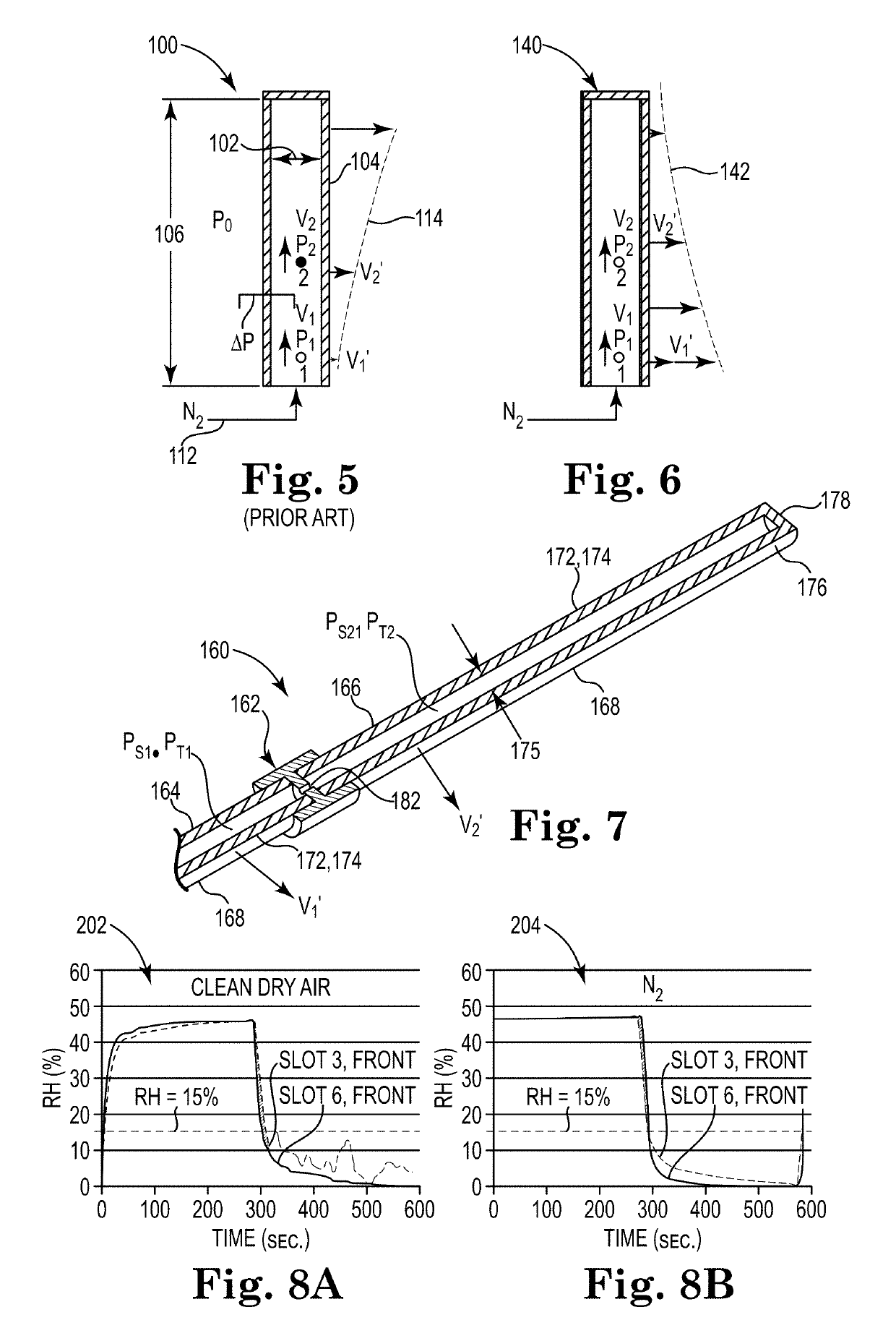

Towers for substrate carriers

ActiveUS20160276190A1Enhanced purge performanceImprove purging effectSemiconductor/solid-state device manufacturingPorous mediumEngineering

A diffuser tower assembly having a diffuser with a flared end and a fitting with an offset portion and nipple sized for the flared end. The assembly may be configured for providing low coverage purging. Diffuser tower assemblies may be in the form of a kit for retrofitting existing front opening wafer containers. The inlet fitting may include structure that enhances purge characteristics near the base of the porous media diffuser for enhanced sweeping of the floor of the substrate container. Embodiments of the disclosure generate an uneven flow distribution that provides a non-uniform flow distribution at the opening. In an embodiment, where the opening is in a substantially vertical orientation, the non-uniform flow distribution is tailored to deliver a greater flow rate to the bottom half of the opening than to the top of the opening.

Owner:ENTEGRIS INC

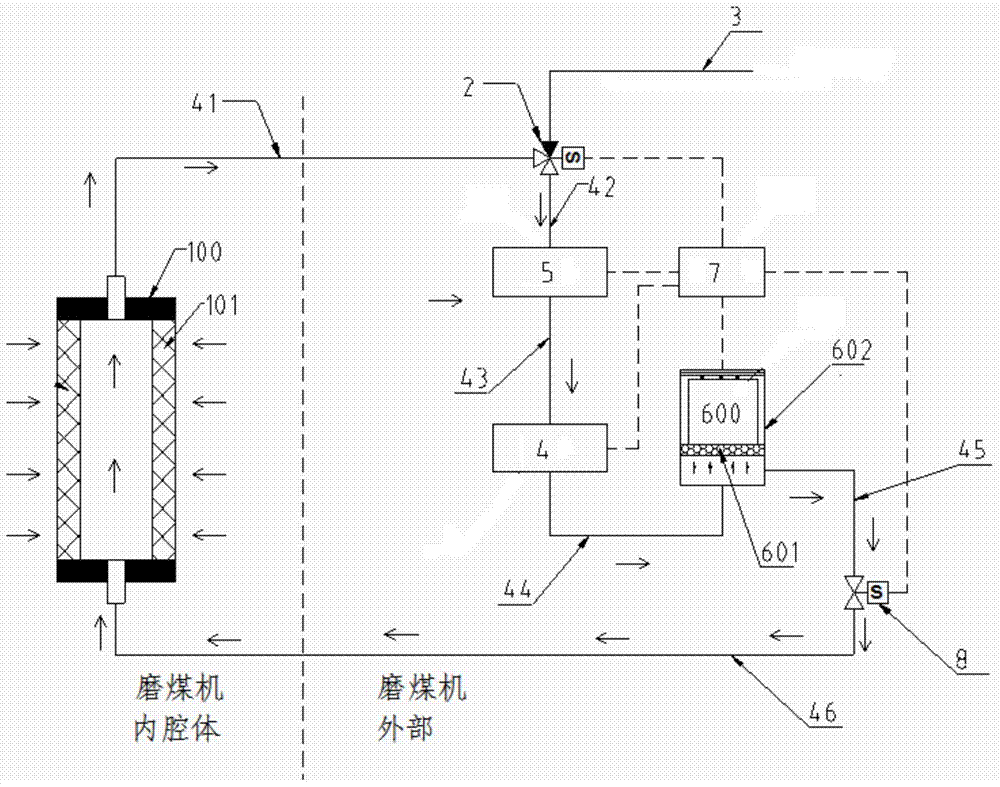

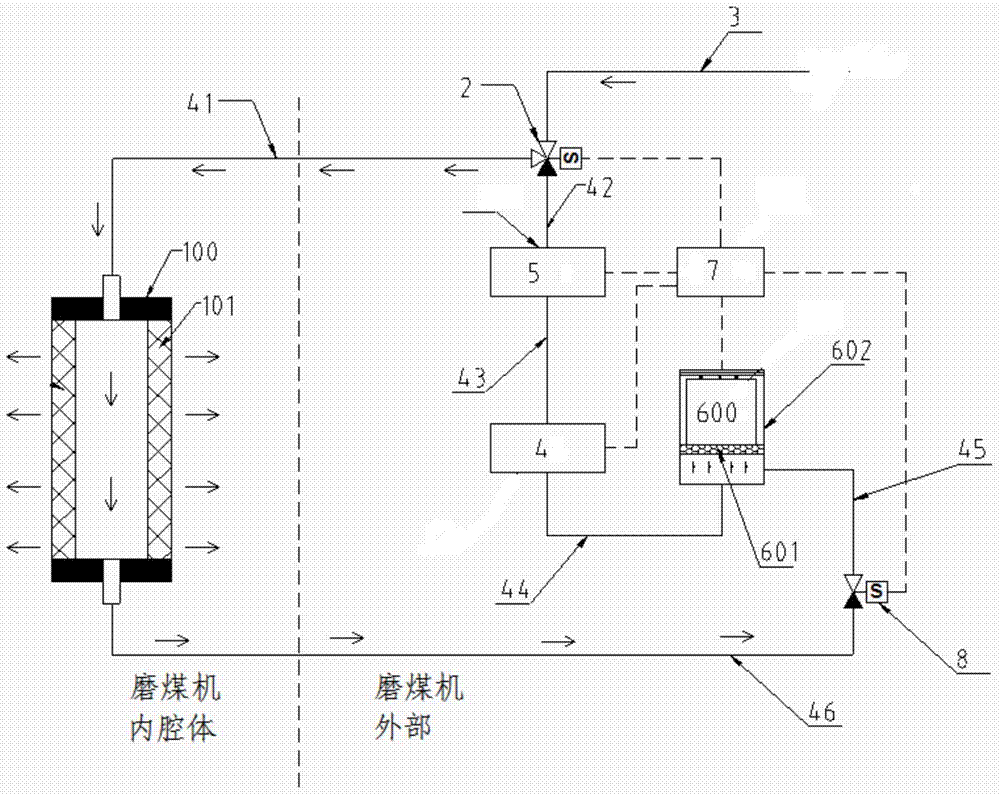

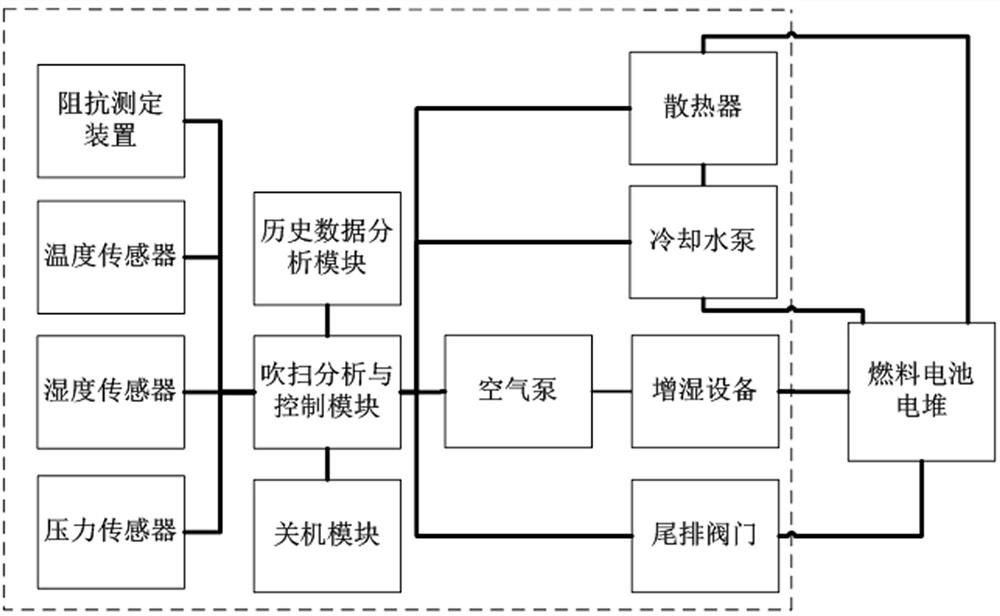

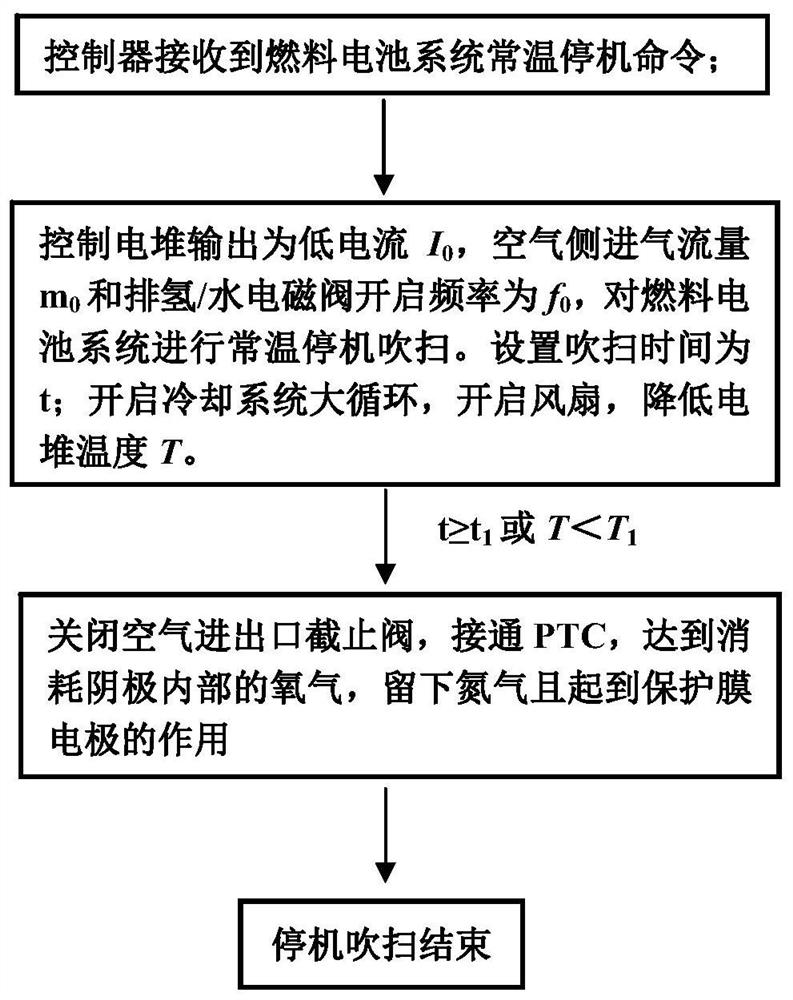

Shutdown purging method and device for fuel cell stack

The invention provides a shutdown purging method of a vehicle-mounted fuel cell, belongs to the technical field of shutdown purging of fuel cell stacks, and solves the problem that modal water in a proton exchange membrane cannot be effectively eliminated in the prior art. The method comprises the steps of acquiring an impedance range when the water content of the fuel cell is lower than a preset value at different environment temperatures; after a whole vehicle shutdown instruction sent by a user is received, monitoring the environment temperature at the current moment, and recognizing the impedance range when the water content, which corresponds to the environment temperature, of the fuel cell is lower than a preset value; performing first purging on the fuel cell stack, monitoring the real-time high-frequency impedance of the stack in the purging process, stopping purging until the real-time high-frequency impedance falls into the recognized impedance range, and obtaining the first purging time; and after the purging is stopped for a preset time, monitoring the environment temperature again, continuously performing purging on the fuel cell stack until the last purging time reaches a specified threshold value, stopping the whole vehicle, and shutting down the fuel cell stack.

Owner:BEIJING SINOHYTEC

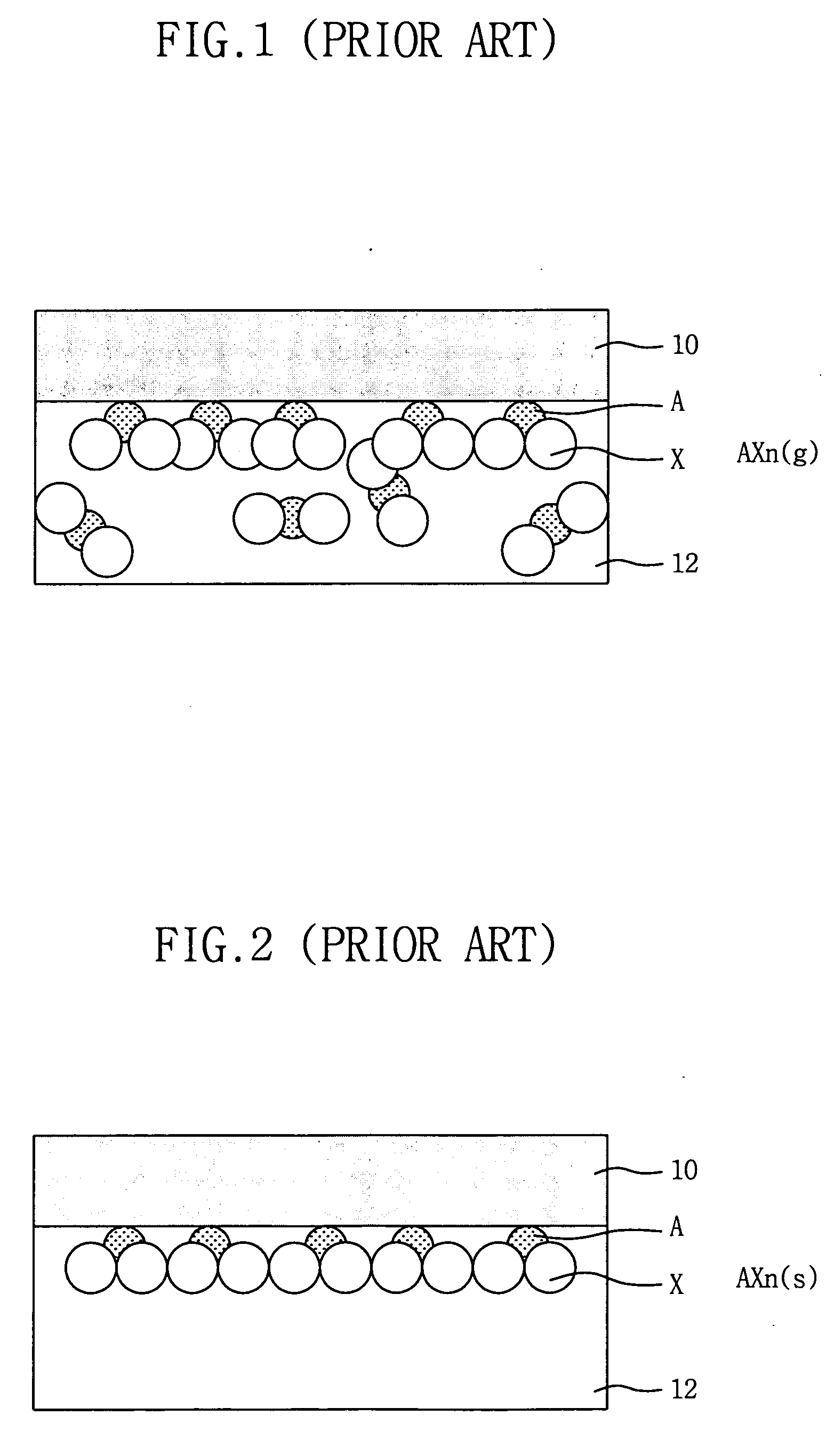

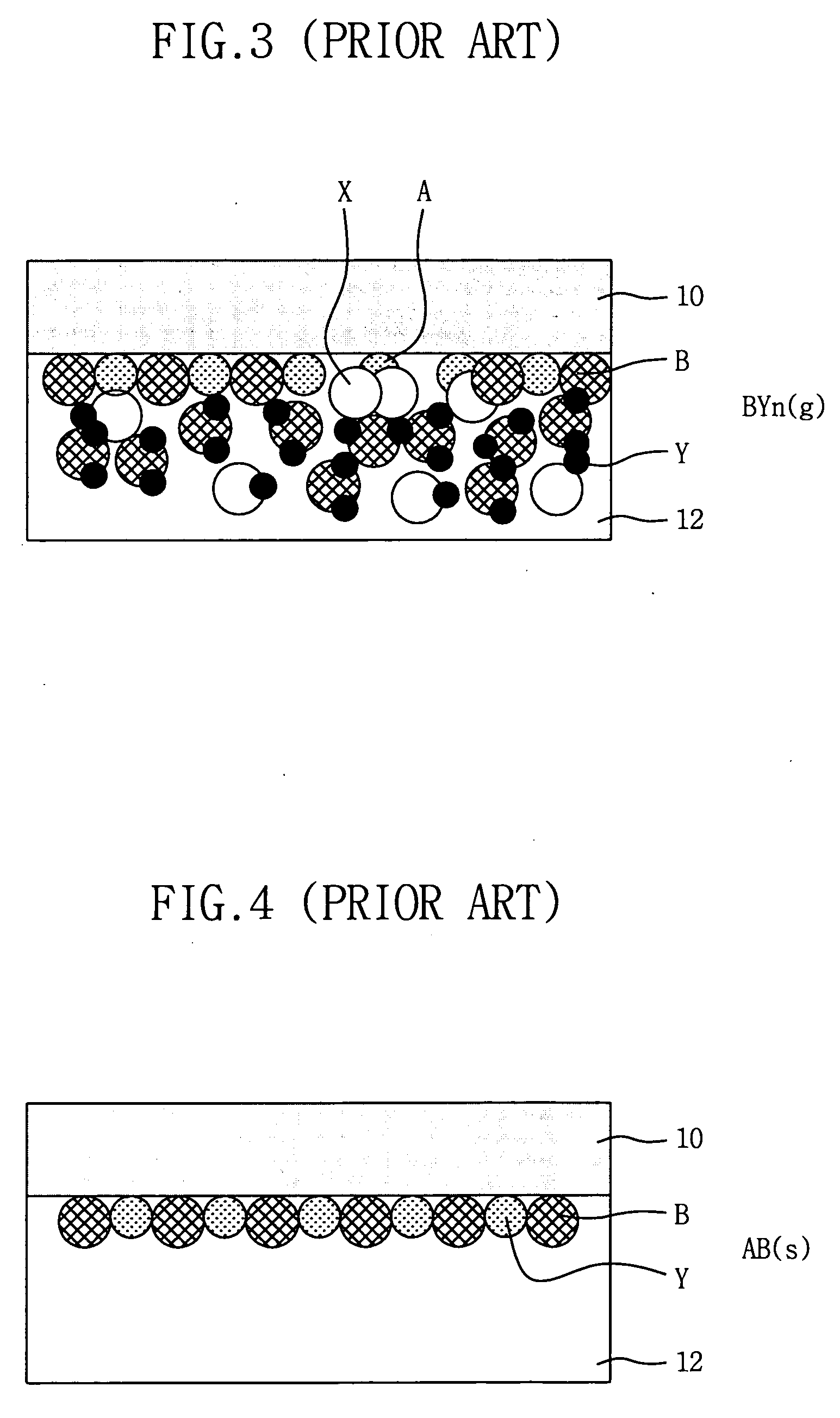

Realization method for film preparation by applying atomic layer deposition technology

ActiveCN105506581AImprove purging effectImprove the quality of workmanshipChemical vapor deposition coatingProcess qualityEngineering

The invention discloses a realization method for film preparation by applying an atomic layer deposition technology. A different ALD technological mode of a vacuumizing mode or a variable flow mode is used for changing an intake quantity of sweeping gas in a reaction cavity to form disturbance of an airflow field in the cavity, so that the sweeping effect on a surplus reaction source and a reaction byproduct can be effectively improved, the process time of film growth period is shortened, the productivity is improved, the parasitic CVD reaction can be reduced on the basis, the ALD process quality is improved, and the film uniformity is improved.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

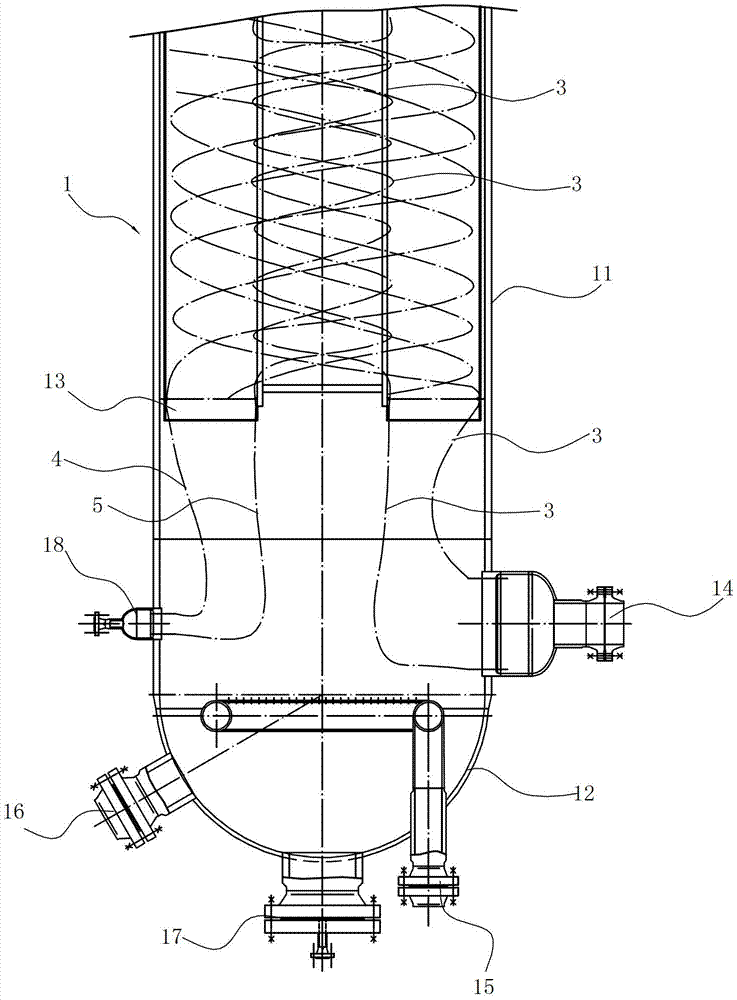

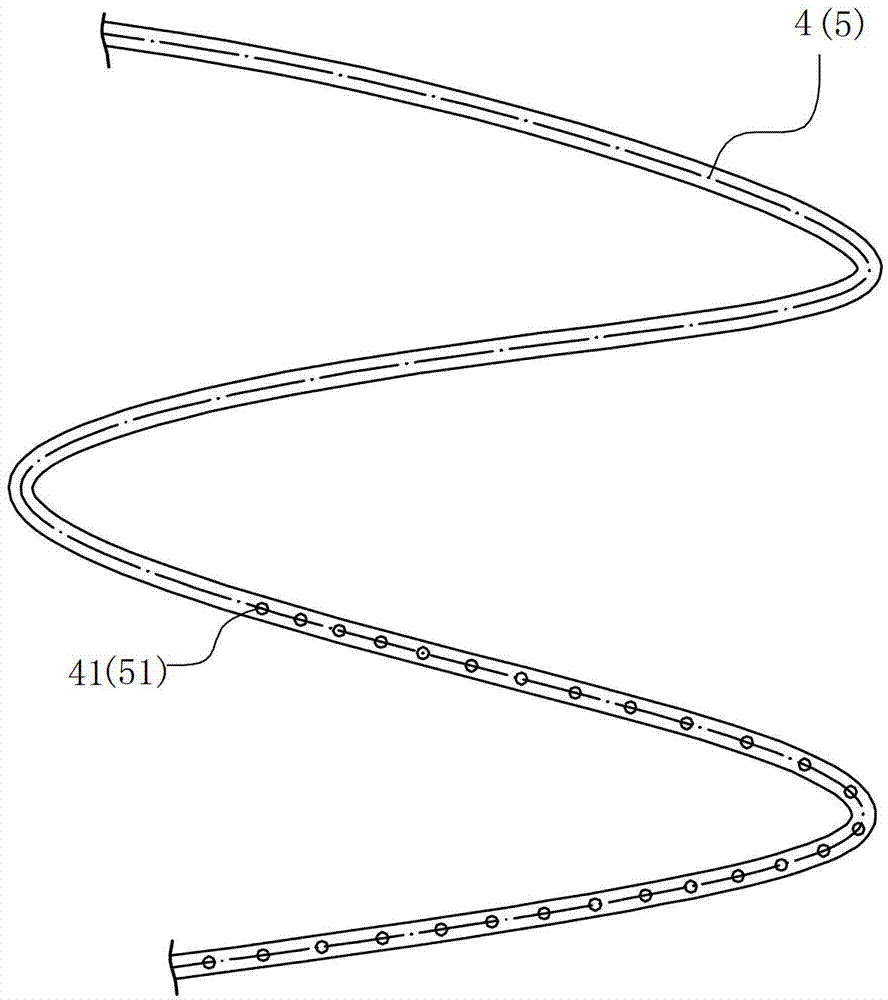

Heat exchanger structure

InactiveCN102927837AWell mixedAvoid depositionCorrosion preventionHeat exchanger casingsEngineeringHeat transfer efficiency

Owner:ZHENHAI PETROCHEM JIANAN ENG

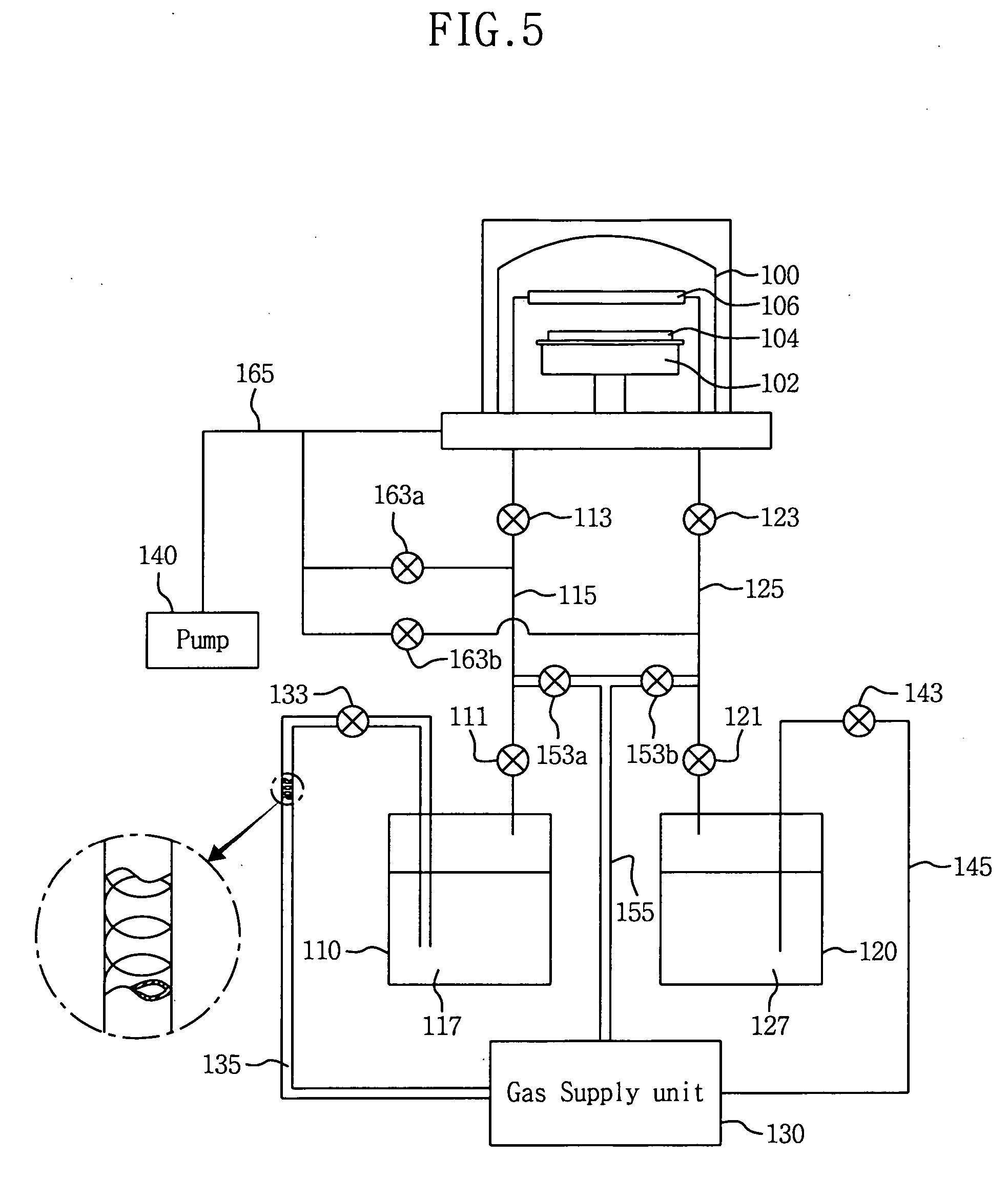

Methods and apparatus for forming thin films for semiconductor devices

ActiveUS20050158977A1Improve purging effectIncrease supplySemiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineeringSemiconductor

Methods and apparatus are provided for forming thin films for semiconductor devices, which enable supplying and removing reactants containing constituent elements of a thin film to be formed, by preheating and supplying a process gas and a purging gas at a predetermined temperature in forming the thin film on a substrate. For example, a method for forming a thin film includes supplying a first reactant to a chamber to chemically adsorb the first reactant onto a substrate, the first reactant being bubbled by a first gas that is preheated, purging the chamber to remove residues on the substrate having the first reactant chemically adsorbed, and forming the thin film by a means of chemical displacement by supplying a second reactant to the chamber to chemically adsorb the second reactant onto the substrate.

Owner:SAMSUNG ELECTRONICS CO LTD

Combined bionic anti-abrasion H-shaped fin elliptical flue gas heat exchange tube

ActiveCN103954161ALow flow resistanceAvoid the formation of large eddy turbulenceCorrosion preventionTubular elementsCHEEK DIMPLESFlue gas

The invention discloses a combined bionic anti-abrasion H-shaped fin elliptical flue gas heat exchange tube which comprises more than two rows of elliptical tubes in the flowing direction of gas and fins arranged on the two sides of the elliptical tubes, wherein a plurality of pairs of semispherical dimples are arranged on the windward sides of the fins; first through holes penetrating through the fins are formed in the bottoms of the semispherical dimples; a plurality of eddy generators are arranged on the leeward sides of the fins; a through hole adjacent to each eddy generator is formed in one side of the eddy generator. According to the flue gas heat exchange tube, the elliptical tubes are used as base tubes, the fins are arranged on the inner two sides of the elliptical tubes, the semispherical dimples and the eddy generators are arranged on the fins, and by the dimples, the flowing resistance can be effectively reduced to avoid the formation of large eddy turbulence in a flow field; in addition, by the novel combined fin structure, the comprehensive heat exchange efficiency can be effectively improved, and tail soot formation and tube abrasion can be greatly reduced.

Owner:SHANDONG XINGQIANG CHEM IND TECH RES INST CO LTD

Cleaning and sweeping device and method and mechanical arm for cleaning and sweeping wafer

InactiveCN108336002AAvoid cross contaminationAvoid process problemsSemiconductor/solid-state device manufacturingParticulatesProcess equipment

The technical scheme of the invention discloses a cleaning and sweeping device and a method and mechanical arm for cleaning and sweeping a wafer. The cleaning and sweeping device comprises sucking parts and a cleaning and sweeping mechanism; the sucking parts are used for being sucked under a grasping part of the mechanical arm; the cleaning and sweeping mechanism includes a support part, air inlets and cleaning and sweeping holes, the support part supports the sucking parts, and the cleaning and sweeping holes are communicated with the air inlets; the cleaning and sweeping holes are used forpurging the back side of an object when the grasping part of the mechanical arm grasps the object. According to the technical scheme, cleaning and sweeping can be achieved in the process of conveyingthe object, not only is excessive cleaning and sweeping time not required to be add, but also pollution particles on the back side of the object can be reduced, cross-contamination between process equipment caused by particulate matter and process defects are prevented, and therefore the production yield of the wafer is improved.

Owner:HUAIAN IMAGING DEVICE MFGR CORP

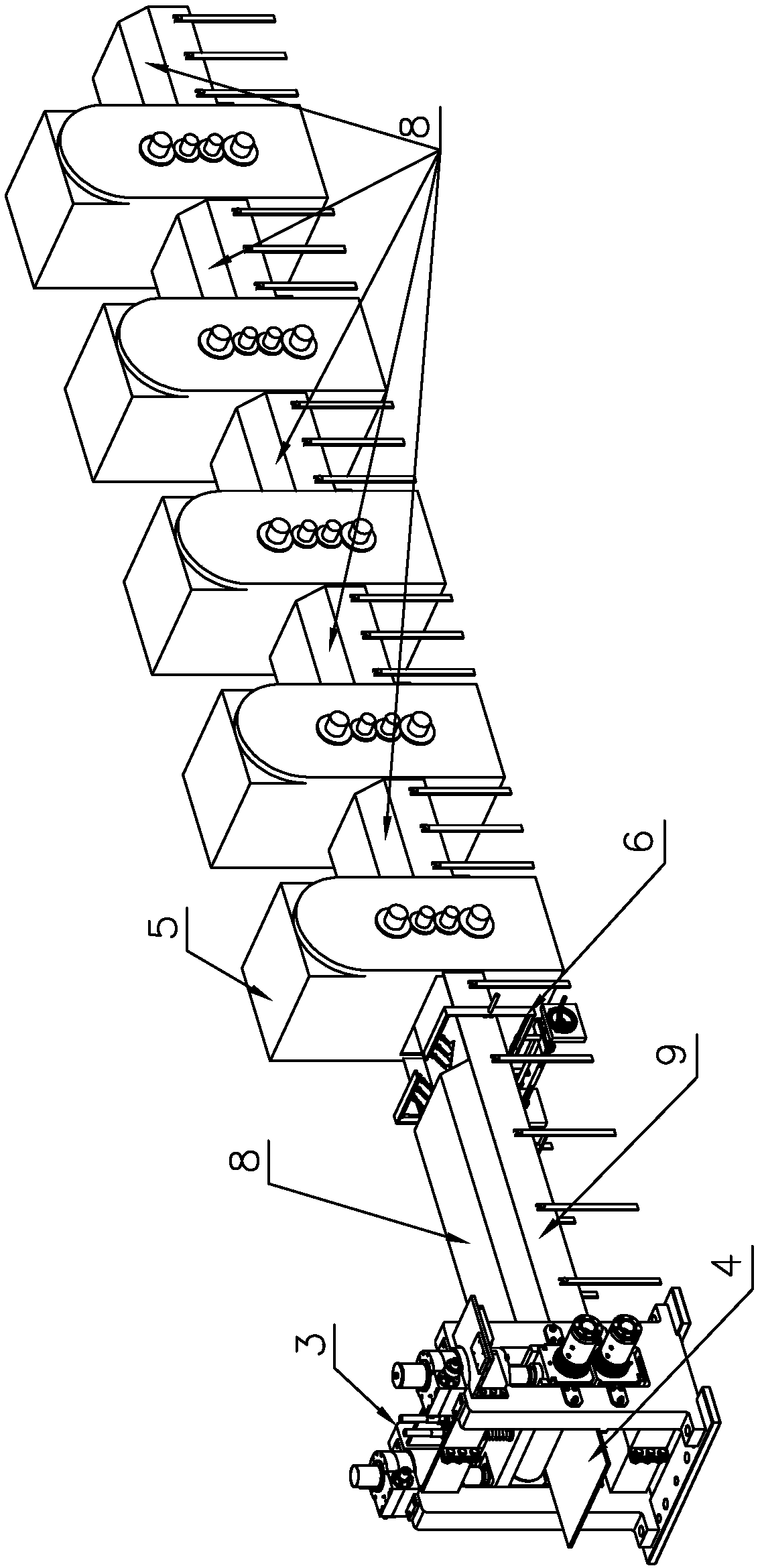

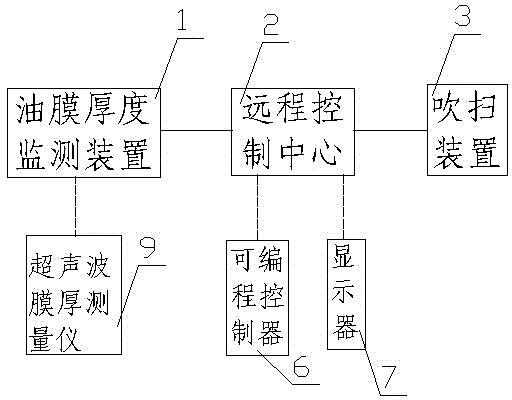

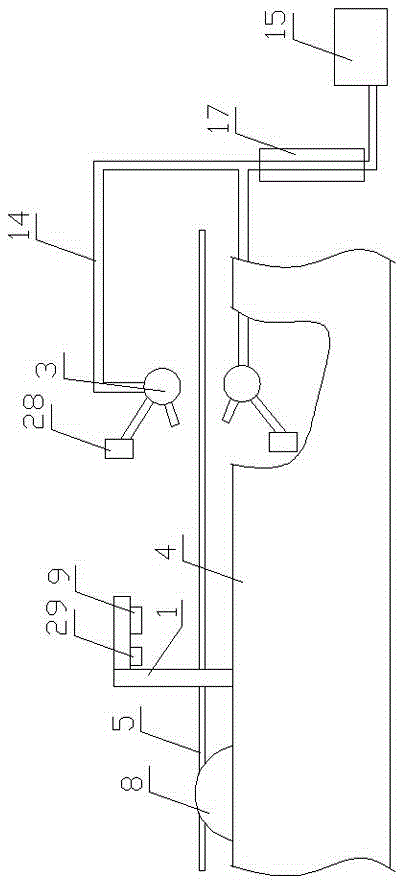

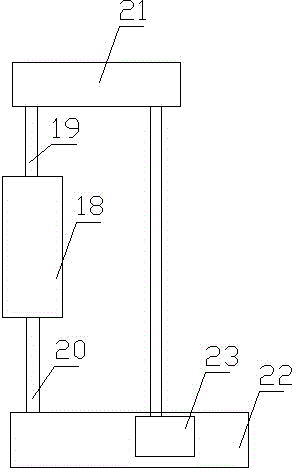

Automatic purging system and method for aluminum strip mill

ActiveCN104826881APurge evenly and thoroughlyTemperature controlWork treatment devicesMetal rolling arrangementsRemote controlEngineering

The invention discloses an automatic purging system for an aluminum strip mill. The automatic purging system comprises an oil film thickness monitoring device, a remote control center, the mill and a purging device. The oil film thickness monitoring device, the remote control center and the purging device are sequentially connected. The oil film thickness monitoring device and the purging device are arranged on the mill. The mill comprises a mill body and an aluminum strip on the mill body. The automatic purging system can purge redundant oil in the cold rolling process of the aluminum strip and achieves remote control over the purging intensity through oil film thickness monitoring which is performed in advance. The invention further discloses an operation method of the automatic purging system for the aluminum strip mill, temperature monitoring for the aluminum strip and thickness monitoring for the redundant oil are achieved, the temperature of purging gas is controlled during heating, and therefore the redundant oil can be better blown off. The purging device can blow evenly within a large range, so the oil on the aluminum strip can be purged more evenly and thoroughly, and the purging effect is better.

Owner:南阳晟发新材料有限公司

Gas homogenizing device and semiconductor processing equipment

ActiveCN111101117AInput uniformConvey evenlyChemical vapor deposition coatingThermodynamicsProcess engineering

The invention discloses a gas homogenizing device and semiconductor processing equipment. The device comprises a gas inlet piece, a flow homogenizing piece and an exhaust piece, wherein at least two gas inlet channels are formed in the gas inlet piece; at least one first distribution part and a plurality of first flow homogenizing parts are arranged on a first surface of the flow homogenizing piece, and the first distribution part is in communication with the corresponding gas inlet channel and the corresponding first flow homogenizing parts; at least one second distribution part and a plurality of second flow homogenizing parts are arranged on a second surface of the flow homogenizing piece, and the second distribution part is in communication with the corresponding gas inlet channel andthe corresponding second flow homogenizing parts; and the exhaust piece is provided with a plurality of first exhaust parts and a plurality of second exhaust parts, wherein the first exhaust parts arein communication with the corresponding first flow homogenizing parts and a process chamber, and the second exhaust parts are in communication with the corresponding second flow homogenizing parts and the process chamber. The effect that at least two process gases are independent from each other and are uniformly conveyed and distributed to the process chamber can be achieved.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

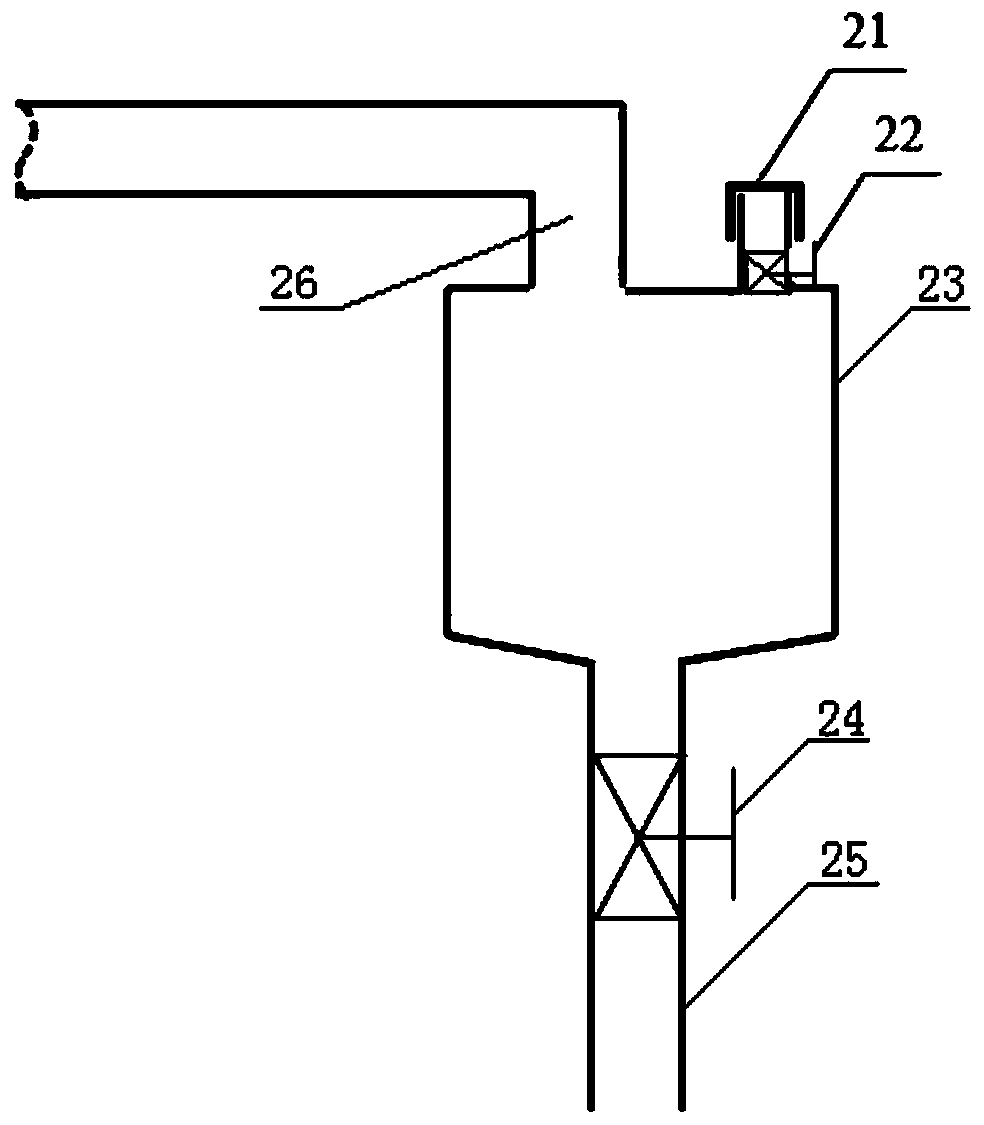

Anti-clogging device for drum screen

InactiveCN102921631AImprove purging effectImprove blowing efficiencySievingScreeningEngineeringElectromagnetic valve

The invention relates to an anti-clogging device for a drum screen, comprising a main pipe, a jet device, a movable joint, a pulse electromagnetic valve, a main pipe movable joint, a variable-diameter three-way connector and a pipe clamp, wherein one end of the main pipe is connected with a gas source, and the other end of the main pipe is connected with a first branch pipe through the main pipe movable joint; the first branch pipe is connected with a branch pipe through the variable-diameter three-way connector; and the pipe clamp is arranged on the branch pipe, and the variable-diameter three-way connector is connected with the jet device through the moveable joint; and a nozzle is arranged on the jet device. The anti-clogging device blows an object through the action of gas flow, and the blowing area can cover the effective area of all the sieve plates, and therefore better blowing effect is formed; air produces intermittent blowing through the throttling action of the electromagnetic valve, and the blowing efficiency is improved; the anti-clogging device is simple in structure, low in manufacture cost and energy-saving, and is conveniently mounted and used; and the labor intensity of workers is reduced, the pollution is reduced, and the industrial popularization and application are convenient.

Owner:天津百利阳光环保设备有限公司

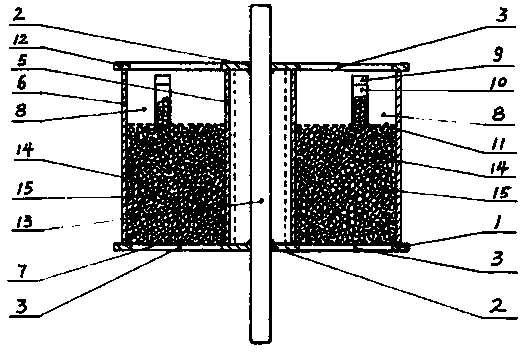

Radar antenna cooling anti-adhesion device for high temperature dust measurement

InactiveCN101640311AImprove purging effectExtended maintenance timeProtective material radiating elementsRadiating element housingsRadarNitrogen gas

The invention relates to a radar antenna cooling anti-adhesion device for high temperature dust measurement, belonging to the field of high temperature radar survey. The device is characterized by comprising an adjustable radar heat insulation sleeve (1), a gas induct hole (2), a flange piece (3), an antenna inner cover (4) and an antenna outer cover (5); the processing length of the radar heat insulation sleeve can be adjusted, and the upper part of the radar heat insulation sleeve is provided with a cooled sink which has the functions of radar heat insulation and heat dissipation; the gas induct hole is externally connected with nitrogen pressure gas, and the pressure of the gas is 0.9-1.1kg higher than that near an antenna; the antenna inner cover takes on a horn shape, the outer coveris fixed on the inner cover and screwed down by screw thread or compressed by the flange piece, the antenna outer cover is parallel to the axis of the antenna by axial cylinder, and the inner cover istaken as an echo reflecting surface of a bellmouth of a radar. The radar antenna cooling anti-adhesion device has the advantages of good sweeping effect, long maintenance free time and the like, canbe used for the places needed to be swept and cooled, and is widely applied to the fields such as metallurgy, petrochemical engineering, etc.

Owner:UNIV OF SCI & TECH BEIJING

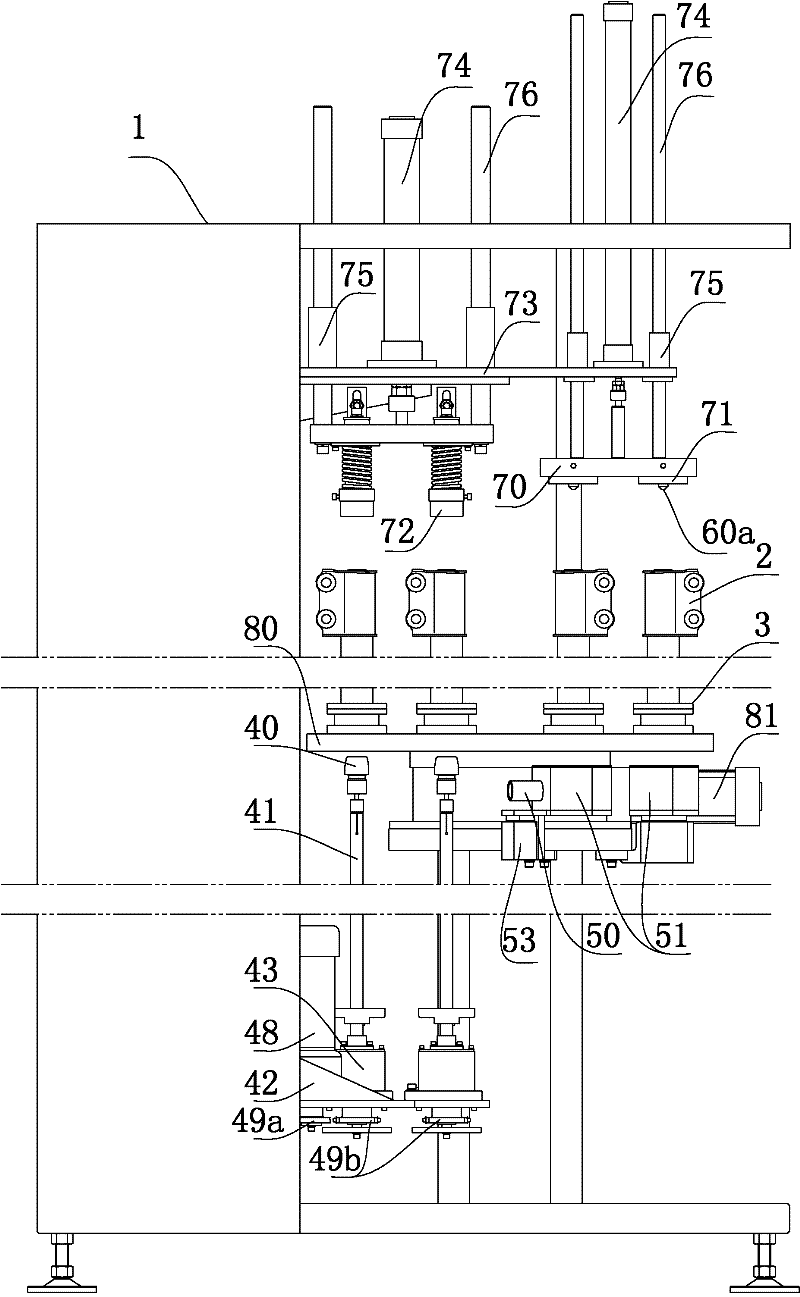

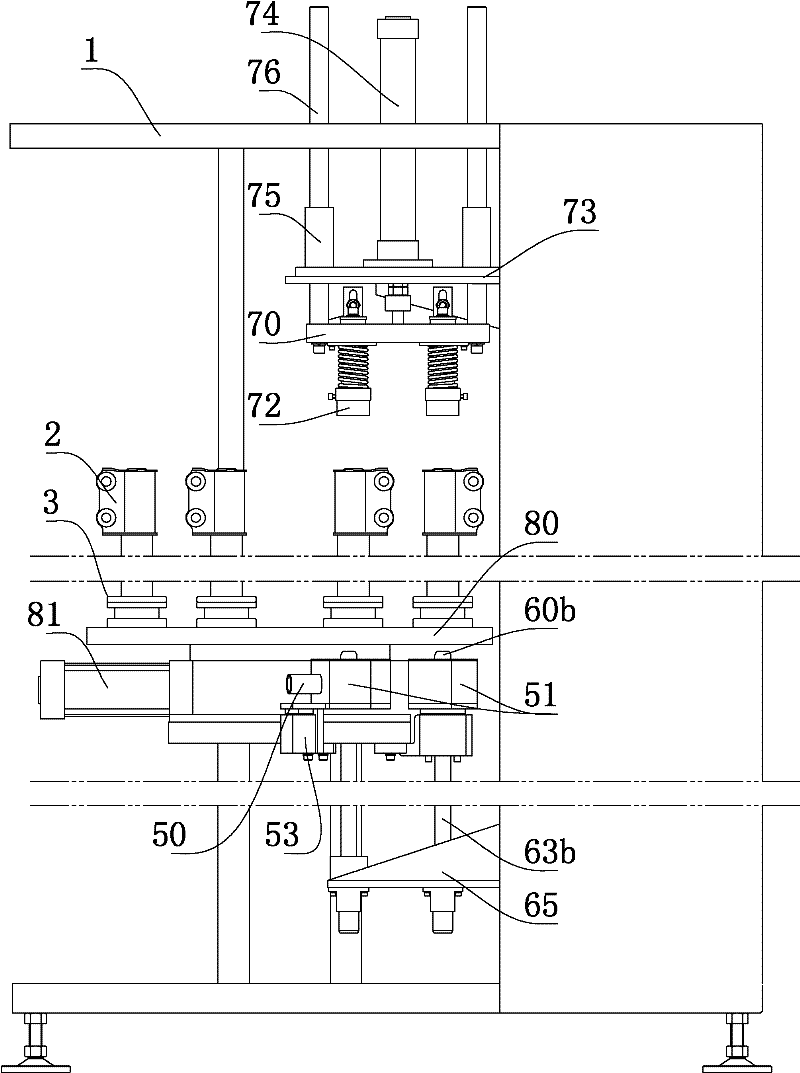

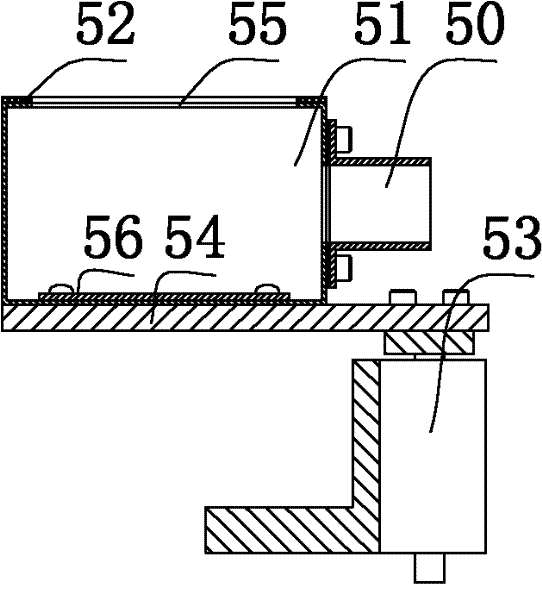

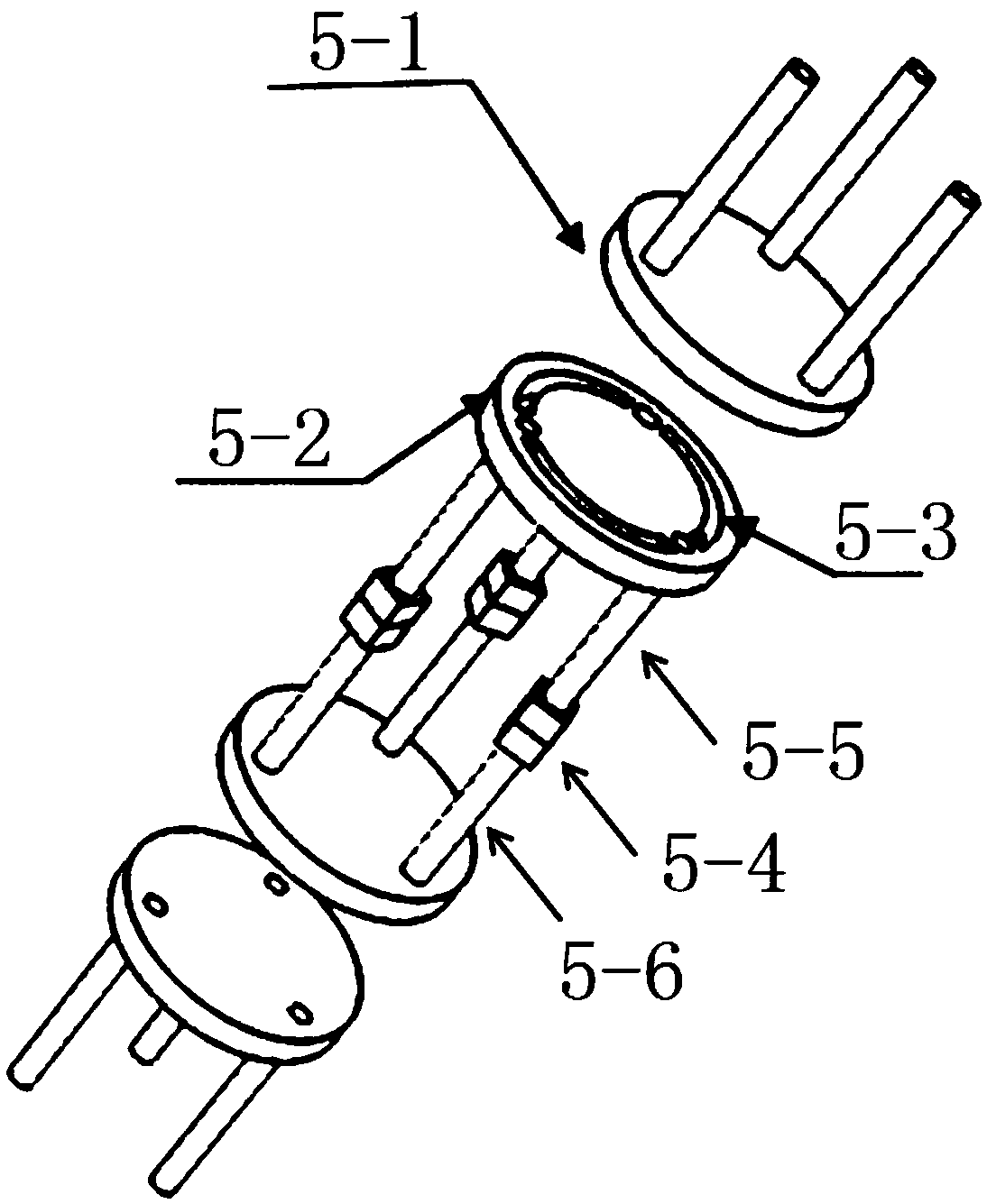

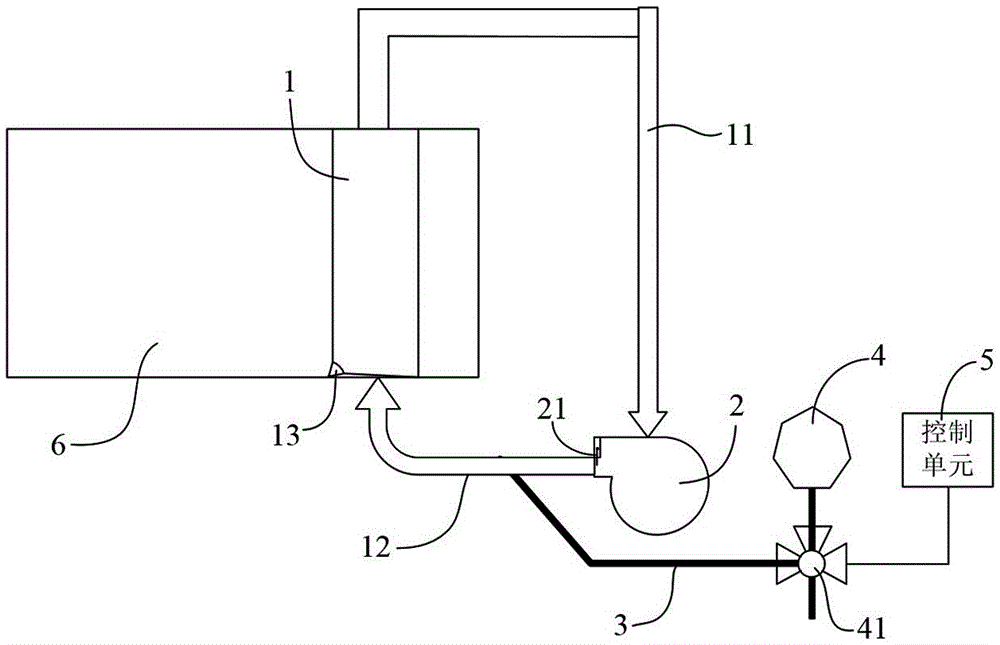

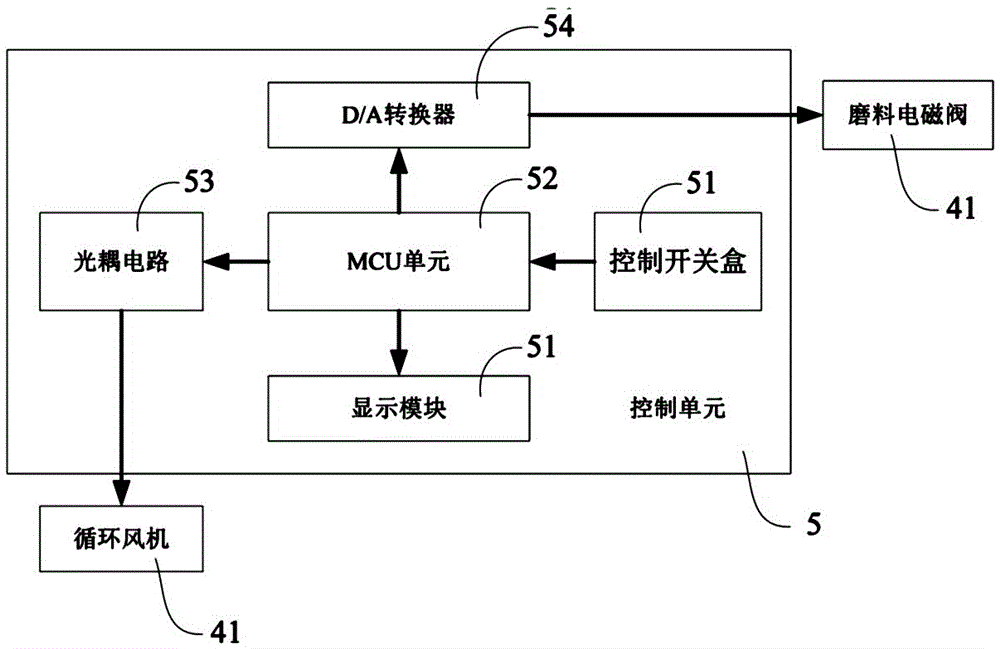

Coolant purging device and purging method for battery assembly testing

PendingCN110783648AMeet the needs of rapid dischargeAvoid harmFuel cell controlSecondary cells testingProcess engineeringCooling fluid

The invention discloses a coolant purging device for battery assembly testing. The coolant purging device comprises a battery assembly, a compressed gas control unit for purging the coolant and a liquid storage unit for recovering and circulating the coolant, wherein the battery assembly and the liquid storage unit are connected through a coolant outlet pipe and a coolant inlet pipe and the compressed gas control unit is connected with the coolant inlet pipe. The invention also discloses a coolant purging method for battery assembly testing. With application of the coolant purging device and purging method for battery assembly testing, the gas purging function can be realized, the purging efficiency is high and the purging effect is better.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

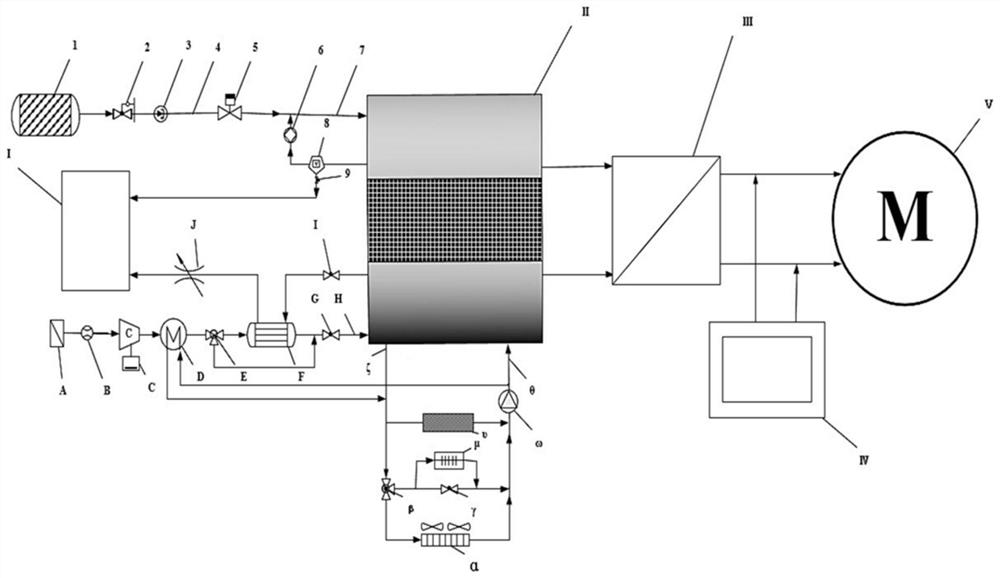

Fuel cell system and shutdown purging method thereof

ActiveCN113629277AExtend your lifeReduce layout complexityFuel cell heat exchangeWater management in fuel cellsConvertersTemperature control

The invention relates to a fuel cell system and a shutdown purging method thereof. The system comprises a galvanic pile, an air supply subsystem connected with a cathode of the galvanic pile, a hydrogen supply subsystem connected with an anode of the galvanic pile, a cooling circulation subsystem connected with the galvanic pile, a hydrogen / air mixing box respectively connected with the air supply subsystem and the hydrogen supply subsystem and a controller used for controlling the subsystems. The output end of the galvanic pile is connected with the driving motor by being connected with the DC / DC converter, and after the controller receives a shutdown command, in the fuel cell system shutdown process, the controller controls the temperature of the galvanic pile according to the cooling circulation subsystem and controls the actuator to correspondingly purge the interior of the galvanic pile. The method has the advantages of improving the cold start capability of the fuel cell galvanic pile at low temperature, effectively prolonging the service life of the fuel cell galvanic pile and the like.

Owner:TONGJI UNIV

Cleaning method and special cleaner for liquid storage cylinder of hydraulic shock absorber

InactiveCN102161046AImprove cleanlinessImprove purging effectHollow article cleaningReciprocating motionEngineering

The invention relates to the field of manufacturing of liquid storage cylinders of hydraulic shock absorbers and provides a cleaning method for a liquid storage cylinder of a hydraulic shock absorber. The method comprises the following steps of: dryly brushing the inner cavity of the liquid storage cylinder through relative axial movement and relative rotation of a brush and the liquid storage cylinder; and then aerating the inner cavity to blow the inner cavity and exhausting the inner cavity to suck dust in the inner cavity while the inner cavity of the liquid storage cylinder is sealed. A special cleaner is provided with a dust brushing position, a dust sucking position, a compressed air source, a filter-containing compressed air pipeline, a negative pressure dust sucking device and a negative pressure pipeline, wherein a brush head of the dust brushing position and the liquid storage cylinder do relative axial movement along the axial direction of a brush rod through the driving of a reciprocating mechanism and do relative rotation along the axial direction of the brush rod through the driving of a rotation driving mechanism; and in the dust sucking position, a sealing structure seals the inner cavity of the liquid storage cylinder to form a sealed dust sucking cavity, and the cavity wall of the whole dust sucking cavity is blown and the dust in the dust sucking cavity is sucked through a dust sucking structure and a blowing structure. The cleaning effect is good; clean water, a detergent and drying are not required; the method is environment-friendly, and is low in consumption and low in cost; and no liquid is left. Therefore, the method is suitable for cleaning the liquid storage cylinder before the liquid storage cylinder is assembled.

Owner:CHENGDU NINGJIANG SHOWA AUTOMOBILE PARTS

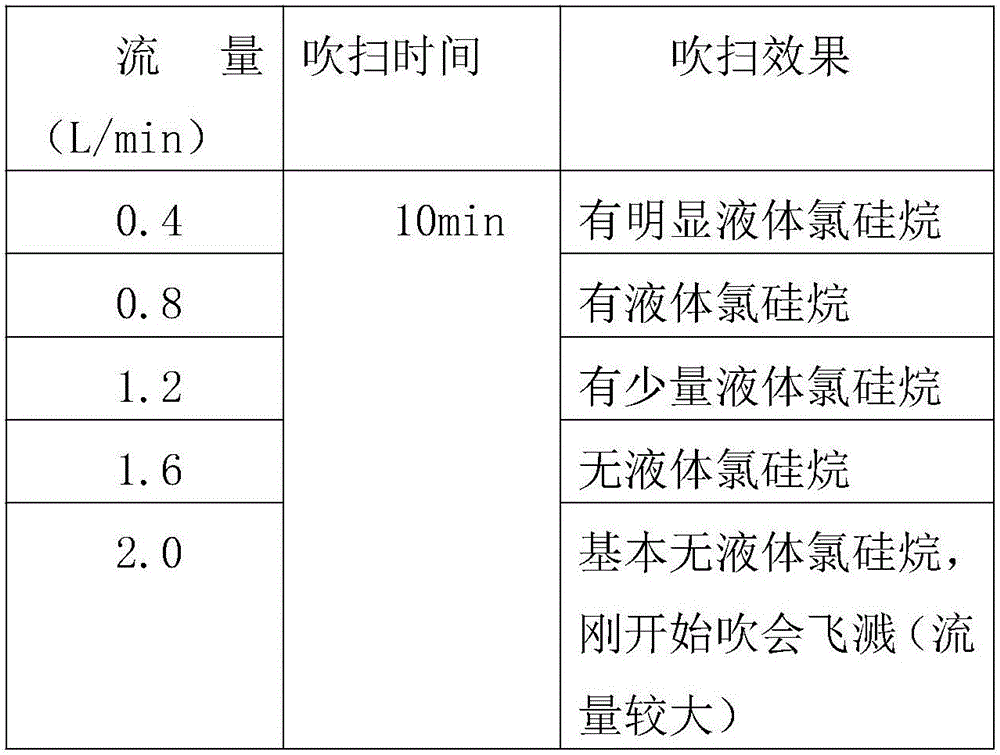

Method for detecting solid content of slurry

InactiveCN106370553ANot easy to polluteNot easy to corrodeWeighing by removing componentNitrogenHydrogenation process

The invention discloses a method for detecting the solid content of slurry so as to overcome the defects in the prior art. The method comprises the following steps: a, performing centrifugal treatment on a stirred chlorosilane slurry sample by a centrifugal machine; b, purging the residual volatile chlorosilane liquid by introducing nitrogen; and c, weighing the weight of the residual solid to obtain the solid content of the slurry. According to the method for detecting the solid content of the chlorosilane slurry in a cold hydrogenation process provided by the invention, the chlorosilane slurry and the chlorosilane liquid are separated by the centrifugal machine and then are treated, so the detection time is greatly shortened. The detection method is simple and convenient to operate, clean, safe and insusceptible to environmental pollution; furthermore, a polytetrafluoroethylene centrifugal test tube is insusceptible to corrosion, and cleaning and maintenance of appliances, such as the centrifugal test tube and the like, are facilitated after detection is finished.

Owner:ASIA SILICON QINGHAI

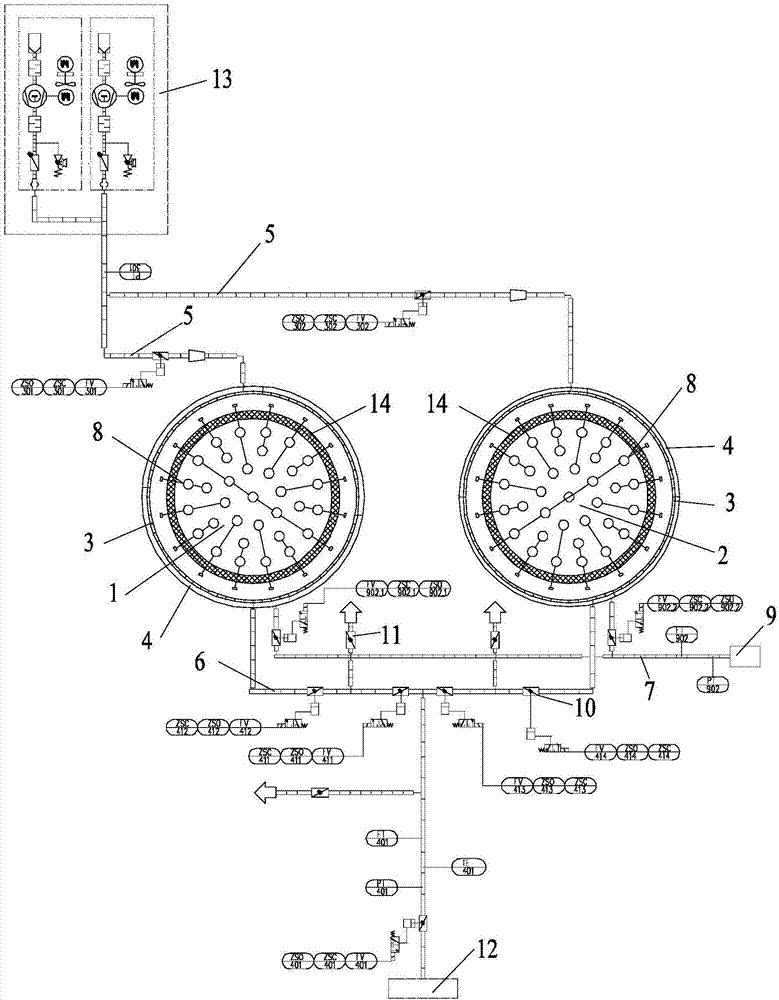

Gas guide system for gas-burning double-hearth lime kiln

The invention discloses a gas guide system for a gas-burning double-hearth lime kiln. The gas guide system comprises a first kiln hearth and a second kiln hearth, wherein first ring pipes are respectively arranged on the outer walls of the hearth bodies of the first kiln hearth and the second kiln hearth; a gas pipeline, a cooling air duct and a nitrogen pipeline are connected to the first ring pipes; a plurality of spray gun hoses are connected onto the first ring pipes; a plurality of spay guns corresponding to the spray gun hoses are connected onto inner walls of the heart bodies of the first kiln hearth and the second kiln hearth; the spray guns are communicated with the spray gun hoses; a gas pressuring machine is connected onto the gas pipeline; check valves are connected onto the gas pipeline and the cooling air duct; a protective cover is connected onto the spray guns; and the spray guns are positioned inside the protective cover. The gas guide system disclosed by the invention is simple in structure, and the using cost and maintenance cost of the hearths are saved. Meanwhile, the usage amount of purge gas is saved, the purging effect is excellent, process concatenation is simple, the concatenation points of the process are greatly reduced, the process is conveniently controlled, and the production efficiency is improved.

Owner:SHANGHAI BAOYE CONSTR INDAL FURNACE ENG TECH

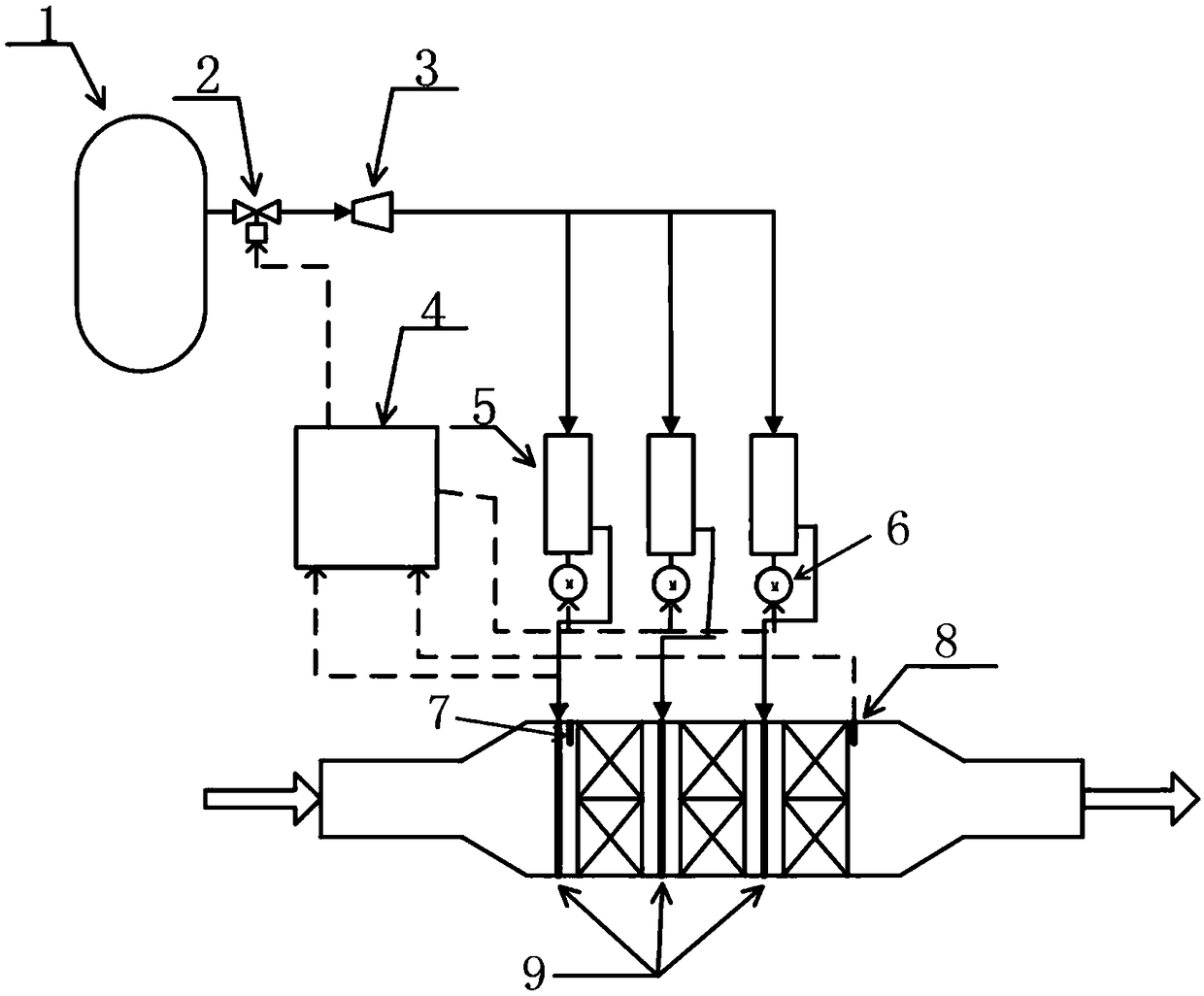

Soot blowing system and method for SCR (Selective Catalytic Reduction) reactor

The invention provides a soot blowing system for an SCR (Selective Catalytic Reduction) reactor and a soot blowing method implemented by the system, and belongs to the technical field of marine dieselengine tail gas posttreatment. The soot blowing system in the invention takes compressed air as purging gas, and comprises an air bottle, a decompression module, a control module, a rotary pressure pulse converter, a rotary power device and a soot blowing pipeline. When the flue gas pressure at the inlet / outlet of the SCR reactor exceeds a set value, a controller of the soot blowing system automatically starts deposited soot blowing, the compressed air in the air bottle is conveyed to the top of the rotary pressure pulse converter through a pressure reducer, and the rotary pressure pulse converter can rotate to drive the soot blowing pipeline to produce purging gas of different pressures over time in order to form strong turbulent disturbance on the surface of a catalyst, thereby improving the purging effect. The soot blowing pipeline is reasonably arranged, and can effectively avoid secondary soot accumulation. At the same time, a soot blowing hole is located in the soot blowing pipeline, and has a simple structure, thereby facilitating later maintenance.

Owner:HARBIN ENG UNIV

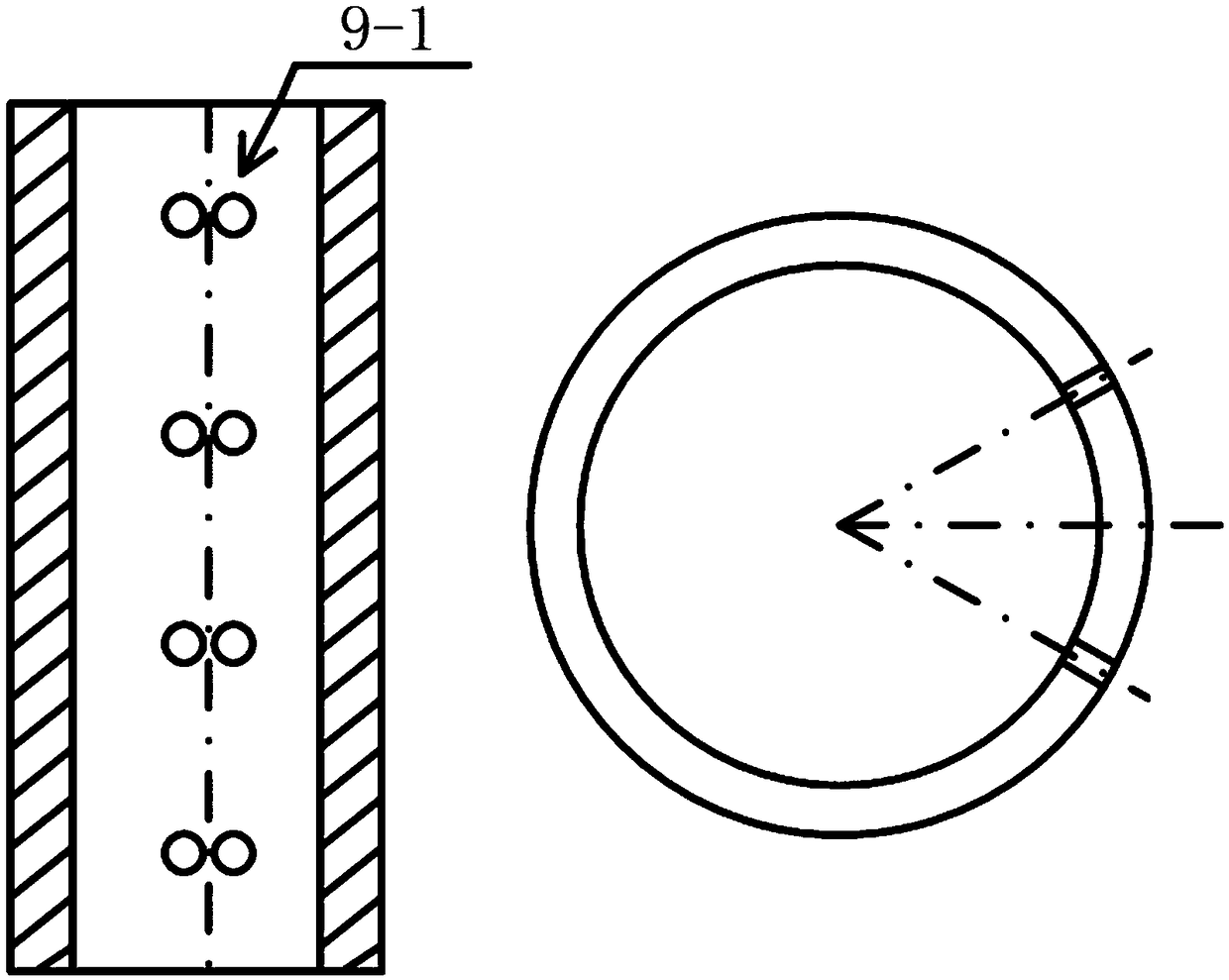

Circulating air type ash blocking preventing device and rotary air preheater

InactiveCN106546124AReduce fouling and cloggingAvoid harmCombustion processIndirect carbon-dioxide mitigationAir preheaterSolenoid valve

The invention discloses a circulating air type ash blocking preventing device and a rotary air preheater. The circulating air type ash blocking preventing device comprises a circulating air bin, a circulating draught fan, a conveying pipe, a grinding bin and a control unit, wherein the upper end of the circulating air bin is a hot end, and the lower end of the circulating air bin is a cold end; an upper air channel is connected to the outside of the hot end of the circulating air bin, and a lower air channel which is connected with an air outlet of the circulating draught fan is connected to the outside of the cold end of the circulating air bin; the upper air channel is connected with an air inlet of the circulating draught fan; the conveying pipe communicates with the lower air channel; a grinding solenoid valve which is mounted on the conveying pipe is arranged at a discharging port of the grinding bin; a control end of the grinding solenoid valve is connected with a control unit. The rotary air preheater is provided with the abovementioned circulating air type ash blocking preventing device. The circulating air type ash blocking preventing device influences the smoke exhausting temperature a little, and does not influence the primary air, the secondary air and the smoke; the grinding sweeping mode shows good effect on sweeping an intermediate temperature area of a heat storing plate; the damage of NH4HSO can be effectively solved, and the quantity of air leaking in smoke as well as the air leakage rate can be reduced.

Owner:STATE GRID CORP OF CHINA +2

Circulating fluidized bed boiler coal drop pipe anti-blocking system

ActiveCN112728530AAvoid easy cloggingSolve the blockageFluidized bed combustionApparatus for fluidised bed combustionFluidized bedEngineering

The invention discloses a circulating fluidized bed boiler coal drop pipe anti-blocking system which comprises a vertically-arranged first coal drop pipe and an obliquely-arranged second coal drop pipe, the upper end of the first coal drop pipe is used for being connected with an outlet of a coal feeder, and the lower end of the first coal drop pipe communicates with the side wall of the second coal drop pipe. One end of the second coal drop pipe is installed on a furnace wall, an air cannon is installed at the other end of the second coal drop pipe, the second coal drop pipe is sleeved with a plurality of annular gas spray pipes, and each annular gas spray pipe communicates with the second coal drop pipe through a plurality of nozzles. The air cannon and each annular gas spray pipe are connected with a gas source. According to the circulating fluidized bed boiler coal drop pipe anti-blocking system, raw coal is not easy to dry and bond at the furnace inlet, so that the raw coal smoothly enters the hearth, and the problem of blockage of the coal dropping pipe is effectively solved.

Owner:XI AN JIAOTONG UNIV

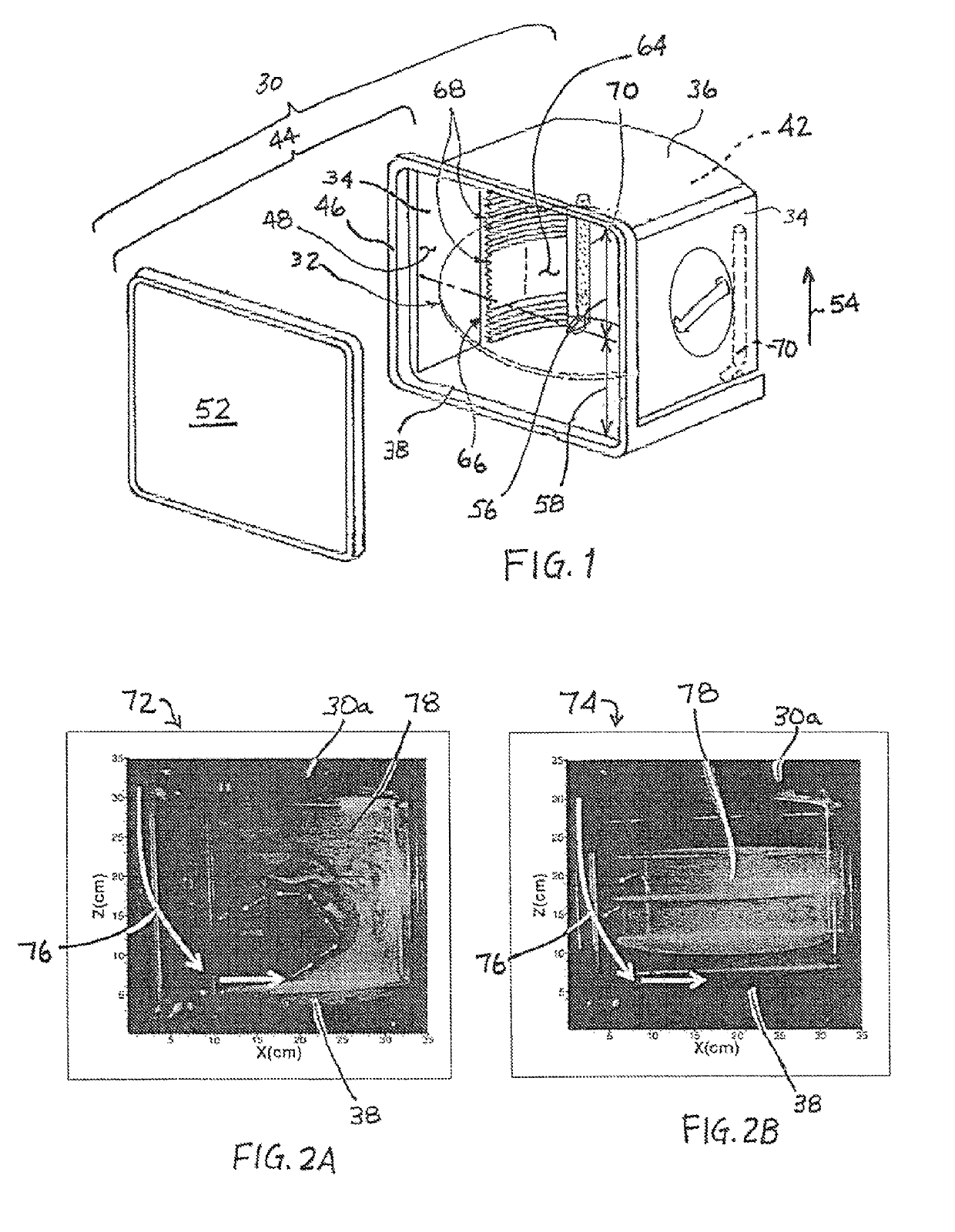

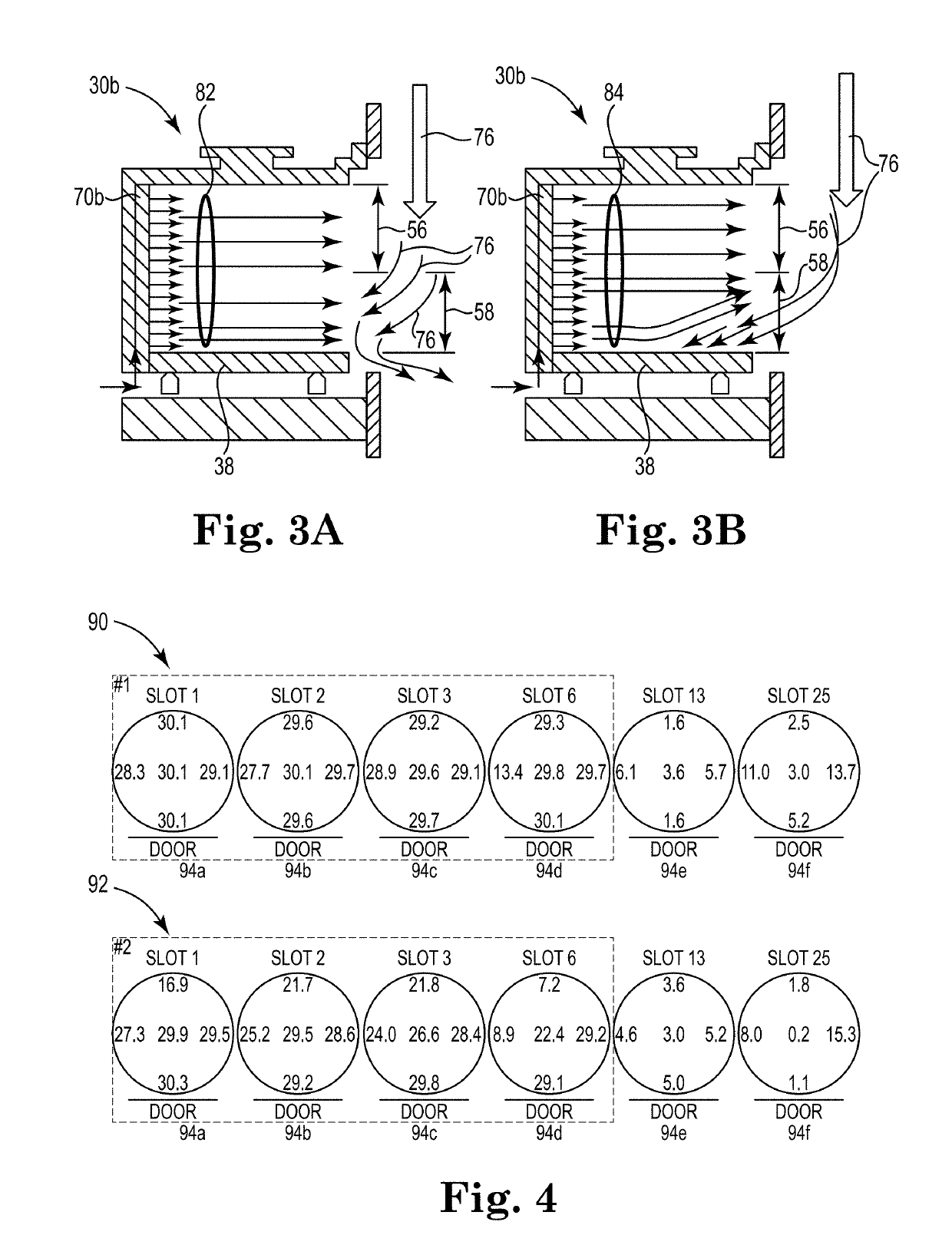

Towers for substrate carriers

ActiveUS10347517B2Improve purging effectEfficient removalSemiconductor/solid-state device manufacturingPorous mediumEngineering

A diffuser tower assembly having a diffuser with a flared end and a fitting with an offset portion and nipple sized for the flared end. The assembly may be configured for providing low coverage purging. Diffuser tower assemblies may be in the form of a kit for retrofitting existing front opening wafer containers. The inlet fitting may include structure that enhances purge characteristics near the base of the porous media diffuser for enhanced sweeping of the floor of the substrate container. Embodiments of the disclosure generate an uneven flow distribution that provides a non-uniform flow distribution at the opening. In an embodiment, where the opening is in a substantially vertical orientation, the non-uniform flow distribution is tailored to deliver a greater flow rate to the bottom half of the opening than to the top of the opening.

Owner:ENTEGRIS INC

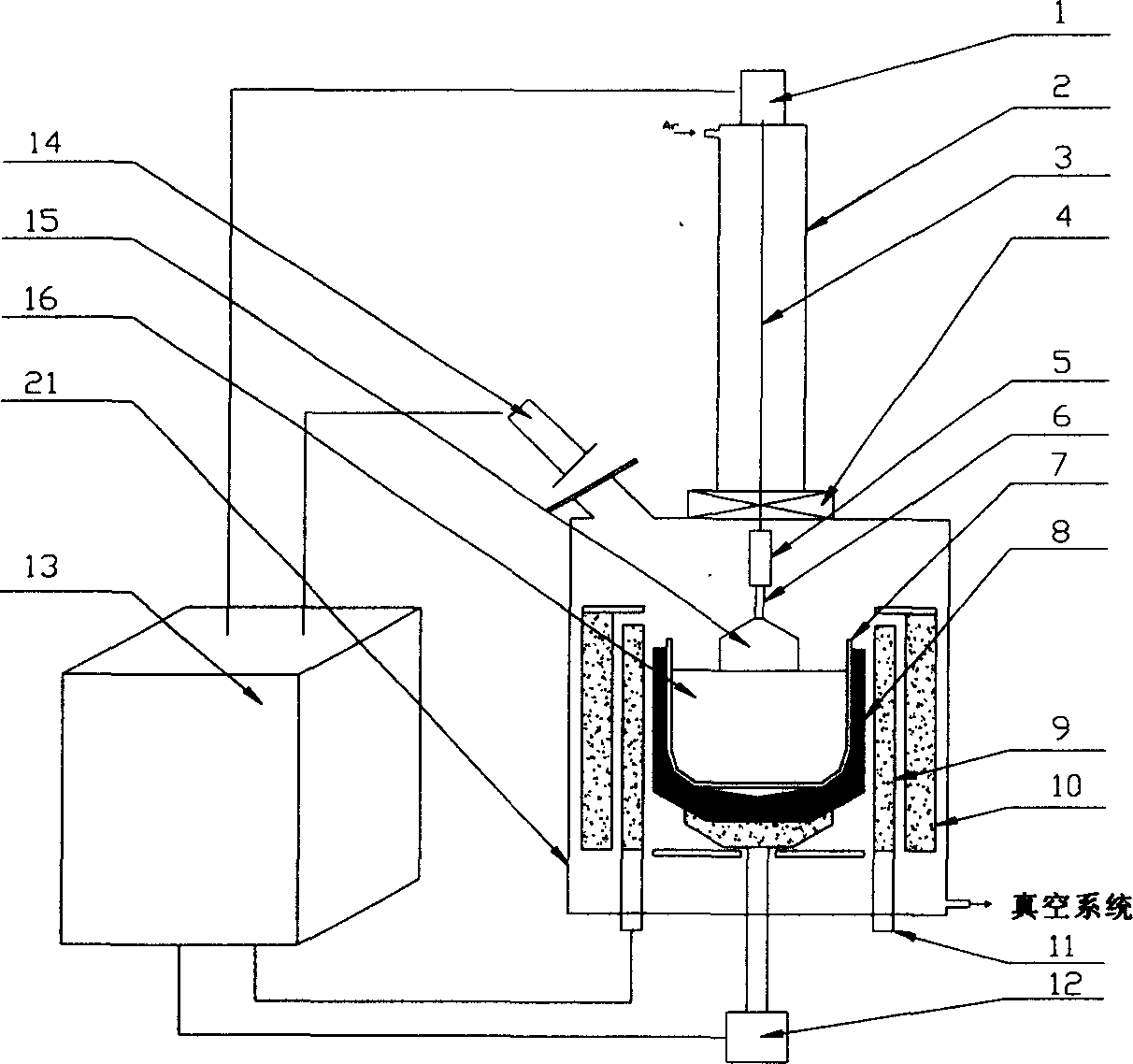

Upper thermal field used for eight inch adulterated arsenic vertical gulling monocrystal manufacture

ActiveCN1556256AImprove purging effectImprove cooling effectPolycrystalline material growthBy pulling from meltSingle crystalEngineering

A top heat field used for preparing 8-inch heavyly doped monosilicon by straight pulling up is composed of a hollow conic insulating cover, internal air guiding barrel in said insulating cover, upper cover plate connected to top of said insulating cover. It can enhance the scavenge action of the airflow on the surface of molten body for removing the fine particles from the surface.

Owner:金瑞泓科技(衢州)有限公司

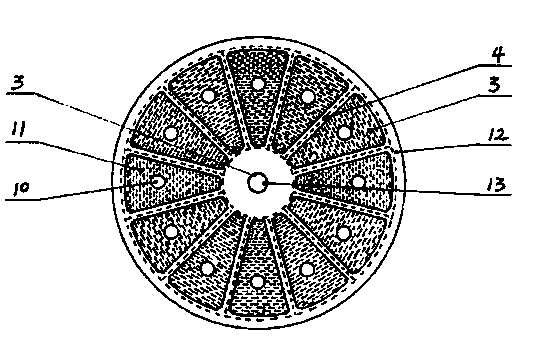

Rotary wheel of rotary wheel type dehumidifier

ActiveCN103638777AImprove integrityGood rotation tightnessDispersed particle separationAgricultural engineeringMaterial Separation

The invention discloses a rotary wheel of a rotary wheel type dehumidifier. The rotary wheel comprises a circular lower supporting plate, wherein the circular lower supporting plate is provided with radial spaced battens and a central hole; fan-shaped vent holes are uniformly formed in the circular lower supporting plate; a positioning sleeve and a peripheral cylinder with the same height are arranged at the positions, close to the inner and outer sides of each fan-shaped vent hole; a material supporting mesh plate is arranged on the upper surface of each fan-shaped vent hole; a material separation plate is arranged on each spaced batten; the bottom edge and two side edges of each material separation plate are connected with the corresponding positioning sleeve and the corresponding peripheral cylinder, and the height of each material separation plate is the same as the heights of the corresponding positioning sleeve and the corresponding peripheral cylinder; a material covering mesh plate is arranged at an appropriate position above each material supporting mesh plate and is connected with each positioning sleeve, the corresponding peripheral cylinder and the adjacent material separation plate; a charging pipe with a pipe cover is arranged in the middle of each material covering mesh plate; the height of each charging pipe is slightly smaller than that of the corresponding material separation plate; an upper cover plate is arranged above a related part and is connected with the related part; the upper cover plate and the circular lower supporting plate are of the same shape and the same structure and are opposite to each other; a main shaft penetrates through central holes of the circular lower supporting plate and the upper cover plate and is connected with the central holes; a loading cavity is filled with spherical dehumidifying agent particles through the charging pipes.

Owner:太仓市洁益环卫设备有限公司

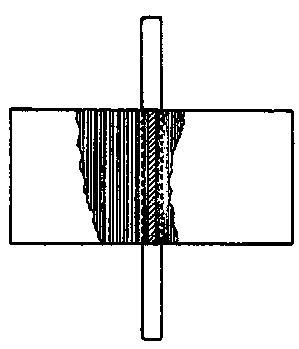

Device for sweeping continuous slab band edge part

InactiveCN101433900AAccurate purge positionIncrease profitDrying solid materials without heatCleaning using gasesEnergy consumptionNon-ferrous metal

The invention belongs to the field of cleaning and drying of a steel continuous slab band or a non-ferrous metal continuous slab band, and in particular relates to an edge sweeping device for a continuous slab band. The edge sweeping device for the continuous slab band comprises a machine body, a compressed air main pipe, an upper left nozzle, a lower left nozzle, an upper right nozzle and a lower right nozzle, wherein the inside of the machine body is provided with a sweeping cavity; the rear lateral face of the machine body is provided with a slab band inlet, and the front lateral face of the machine body is provided with a slab band outlet; the slab band inlet and the slab band outlet are communicated with the sweeping cavity respectively; the upper left nozzle and the lower left nozzle are positioned on the inner left part of the sweeping cavity of the machine body respectively; and the upper right nozzle and the lower right nozzle are positioned on the inner right part of the sweeping cavity of the machine body respectively. The edge sweeping device for the continuous slab band is characterized in that the upper left nozzle and the lower left nozzle are fixed on a left width adjusting device respectively, and the upper right nozzle and the lower right nozzle are fixed on a right width adjusting device respectively. The edge sweeping device for the continuous slab band has the advantages of accurate sweeping position, high utilization rate of compressed air, low energy consumption, good sweeping effect, and no need of manual operation when the width of the produced slab band is changed.

Owner:WISDRI ENG & RES INC LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com