Gas sampling and detecting device

A detection device and gas sampling technology, applied in the direction of measuring devices, sampling devices, instruments, etc., can solve problems such as dust blockage, atmospheric environment interference, etc., achieve the effects of reducing pollution and blockage, increasing purging equipment, and optimizing dust removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

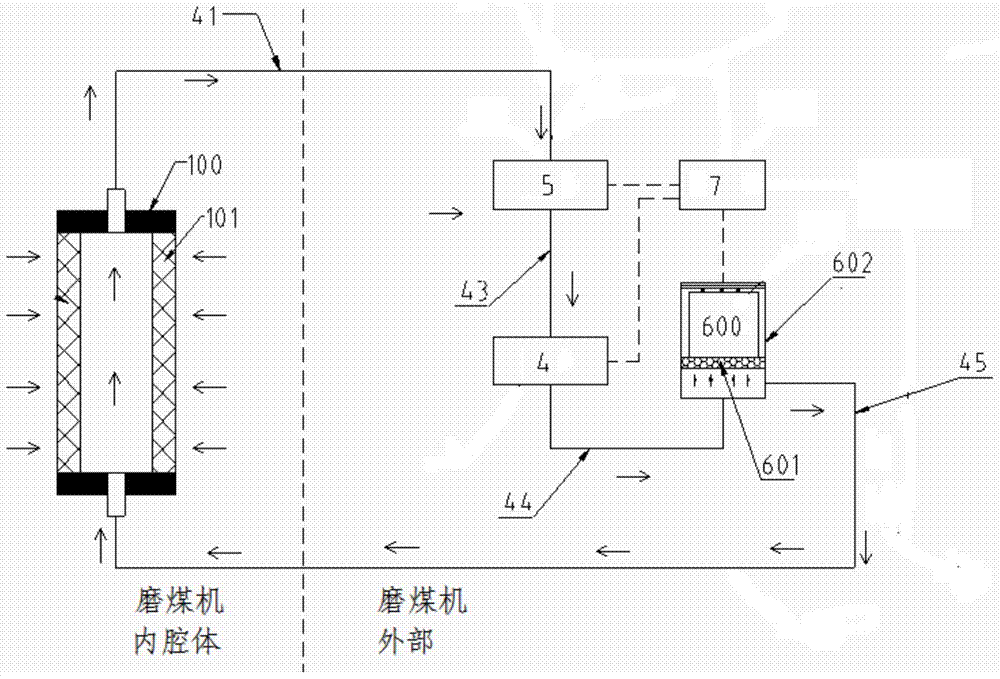

[0032] Such as figure 1 The gas sampling and detection device shown is used for carbon monoxide sampling of coal mills. It includes a closed circulation air path, in which a collecting and filtering device 100 and a sampling main body are arranged in series. The collecting and filtering device 100 has an internal cavity communicated with the closed circulation air path, and a filter channel 101 for communicating the internal cavity with the external dust environment. The sampling main part includes an air pump 4 and a gas detection device for driving the gas flow in the closed loop air circuit.

[0033] The filter channel 101 is a filter arranged around the inner cavity of the collection filter device 100 , and the main purpose of the present invention is to reduce the pollution and blockage of the filter by dust.

[0034] The air pump 4 adopts a vacuum air pump, such as an explosion-proof vacuum air pump.

[0035] The collection and filtration device 100 is installed on th...

Embodiment 2

[0044]Although the solution in Example 1 fundamentally reduces the clogging of the filter by coal dust, when it is placed in a coal dust environment for a long time, coal dust is still easy to adhere to the filter.

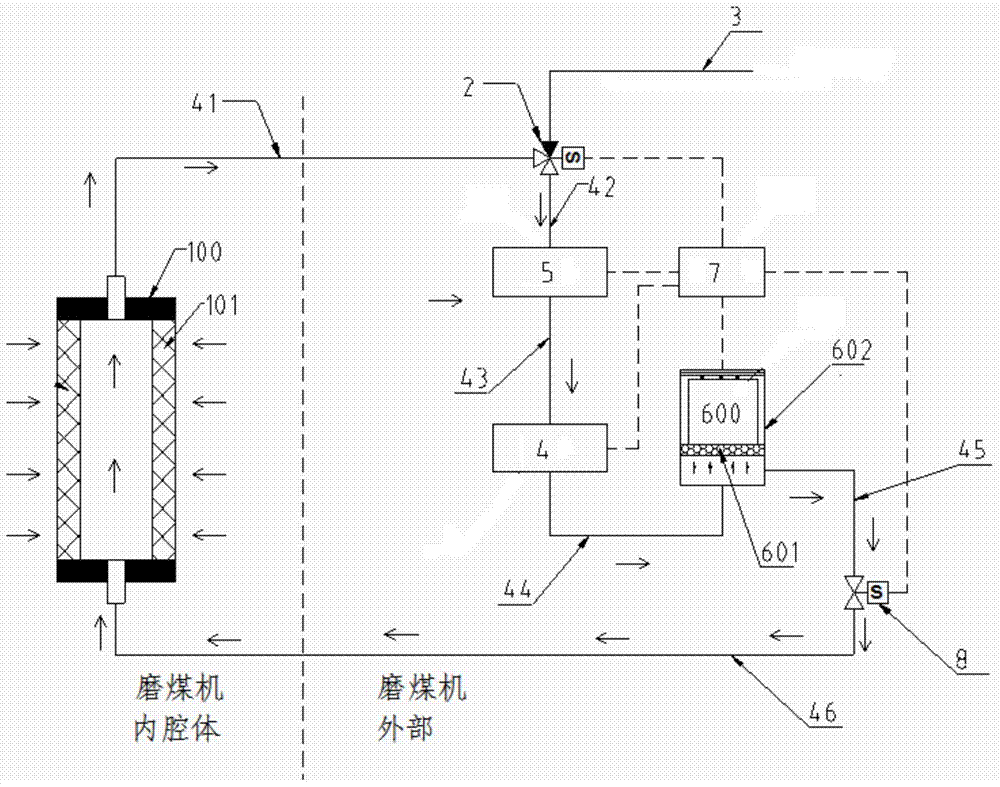

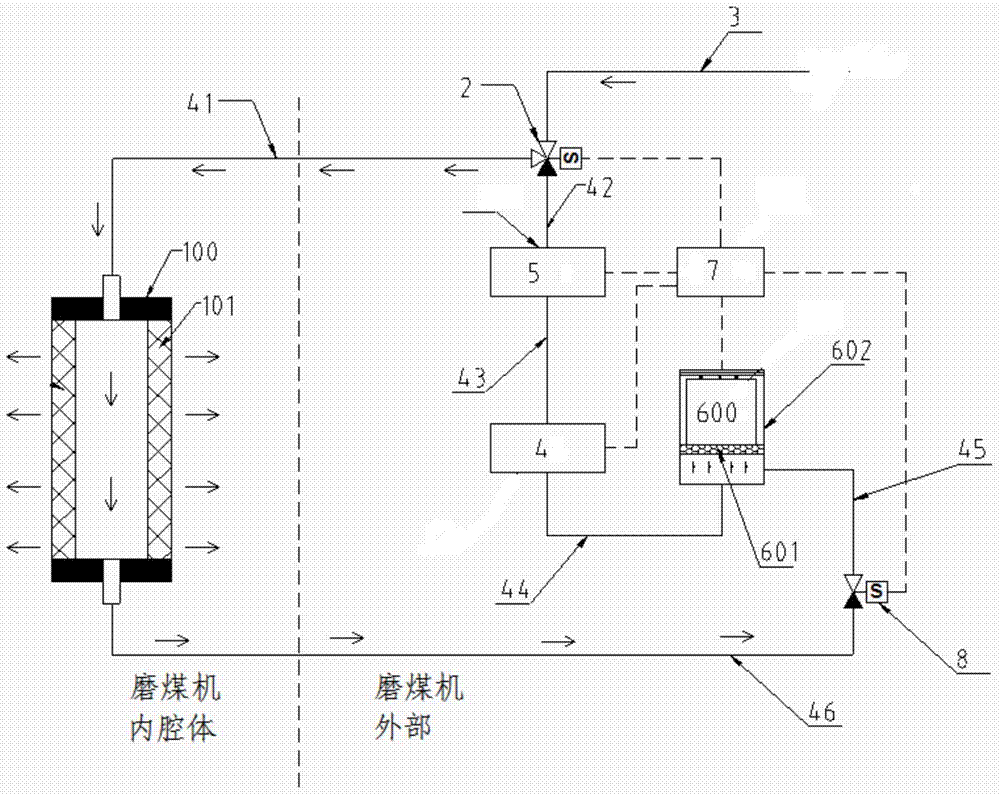

[0045] Such as figure 2 , image 3 It is an embodiment to increase the purging function to remove the attached coal dust by purging. In this way, the closed loop gas path has two working states, one is the sampling detection state, and the other is the purging state.

[0046] The system is implemented as follows:

[0047] A purge control valve 2 and a blocking valve 8 are set in the closed cycle gas circuit. The purge control valve is a three-way valve, the three-way valve has first, second and third gas ports, the first gas port is the purge gas inlet, connected to the compressed air 3; The air passage section 41 communicates with the internal cavity of the collection and filtration device 100 , and the third air port communicates with the sampling main body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com