Circulating air type ash blocking preventing device and rotary air preheater

A circulating air and circulating fan technology, applied in the direction of cleaning heat transfer devices, non-rotating equipment cleaning, lighting and heating equipment, etc., can solve the problem of reduced heat exchange area of air preheater, pressure fluctuation of boiler furnace, air preheater Serious air leakage and other problems, to achieve the effect of reducing the degree of dust accumulation and clogging, the same cleaning effect, and good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

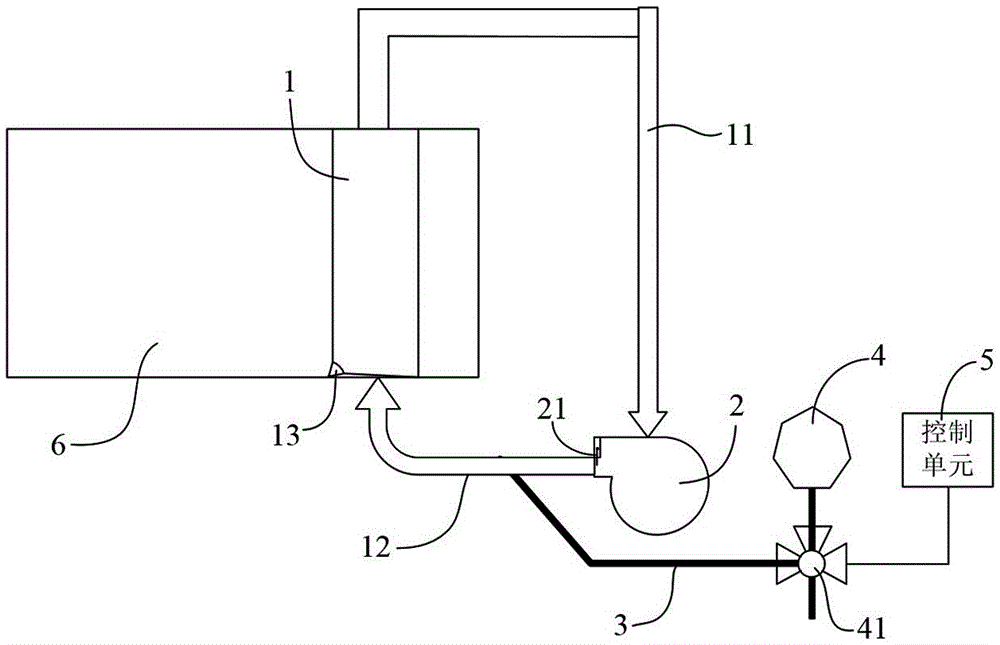

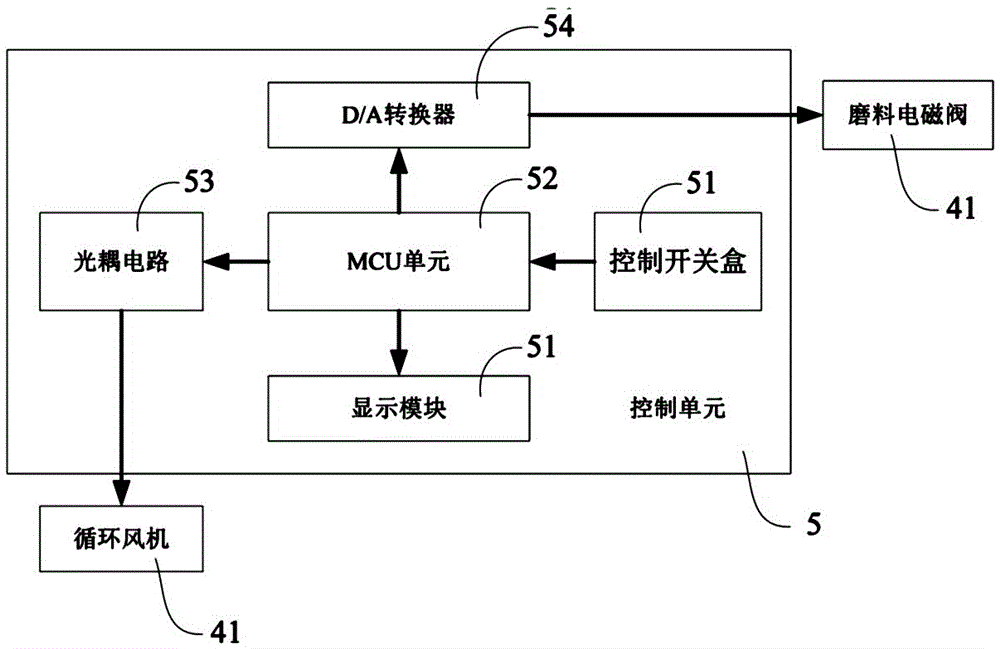

[0031] Such as figure 1As shown, the circulating air anti-clogging device of the present embodiment includes a circulating air bin 1, a circulating fan 2, a feeding pipe 3, an abrasive bin 4 and a control unit 5, and the upper end of the circulating air bin 1 is a hot end, and the lower end is a cold end. The hot end of the circulating air chamber 1 is externally connected with an upper air channel 11, and the cold end is externally connected with a lower air channel 12. The lower air channel 12 is connected to the air outlet of the circulating fan 2, the upper air channel 11 is connected to the air inlet of the circulating fan 2, and the feeding pipe 3 is connected to the lower air channel. The channel 12 is connected, and the discharge port of the abrasive bin 4 is provided with an abrasive solenoid valve 41, which is installed on the feeding pipe 3, and the control end of the abrasive solenoid valve 41 is connected to the control unit 5. In this embodiment, the transformati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com