Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about How to "Reduce fouling and clogging" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flue gas desulfurization synergist and using method thereof

InactiveCN102091510AImprove solubilityReduce consumptionDispersed particle separationGlutaric acidAdipic acid

The invention discloses a flue gas desulfurization synergist which comprises the following components in percent by weight: 30-80 percent of adipic acid or glutaric acid, 5-30 percent of one of sodium chloride, sodium sulfate, and magnesium sulfate, and 1-50 percent of dioctyl sulfosuccinate sodium salt. A using method of the flue gas desulfurization synergist is characterized by comprising the steps of: firstly, preparing lime into limestone slurry of 50-300PPm, adding 300-1000mg / L of gas desulfurization synergist in the limestone slurry, mechanically stirring uniformly, and then pumping the limestone slurry added with the gas desulfurization synergist into a desulfuration reaction tower by using a limestone slurry pump. By using the gas desulfuration synergist, the desulfuration efficiency is improved by 5-15 percent, the consumption of limestone is reduced, the scale formation and the blockage of equipment are reduced, and the operation electric energy is saved.

Owner:马鞍山市鸿伟环化有限公司

Compound additive for limestone-gypsum wet-process flue gas desulfurization

InactiveCN106731637AHigh activityIncrease dissolution rateGas treatmentDispersed particle separationFood additiveFoaming agent

The invention relates to a compound additive for limestone-gypsum wet-process flue gas desulfurization. The compound additive is prepared from the following components in percentage by mass: 25 percent to 50 percent of a limestone dissolving promoter, 20 percent to 60 percent of a pH (Potential of Hydrogen) buffering agent, 5 percent to 15 percent of a surfactant, 3 percent to 10 percent of an oxidization catalyst, 2 percent to 5 percent of a de-foaming agent and 2 percent to 10 percent of a correlated auxiliary agent. The compound additive provided by the invention combines the dual advantages of an inorganic additive and an organic additive of rapid effect, less use amount, long lasting time, less consumption and the like in a limestone-gypsum wet-process flue gas desulfurization system of a thermal power plant; the formula is simple and components have a low price and are easy to obtain; on the basis of not doing any engineering reconstruction, the absorption efficiency of SO2 can be greatly improved, the quality of gypsum can also be improved and the scaling and blocking of the system are reduced.

Owner:鄂尔多斯市瀚博科技有限公司

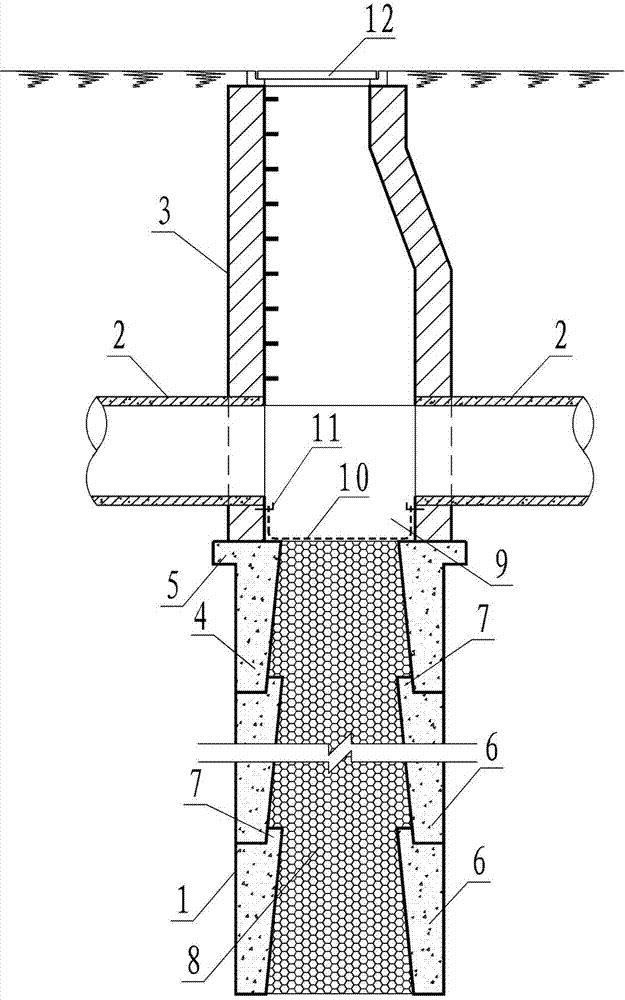

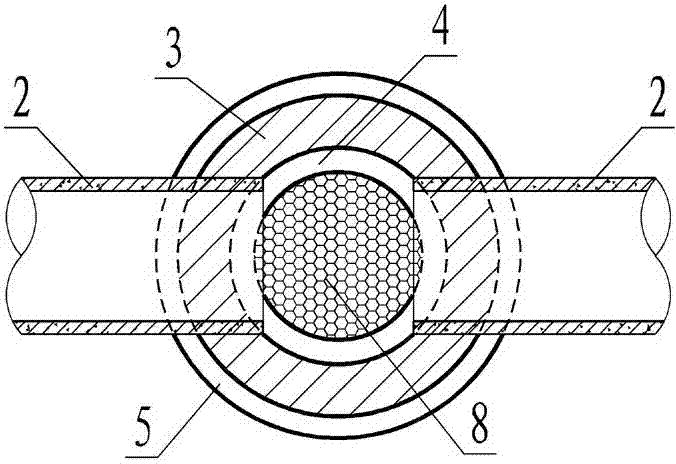

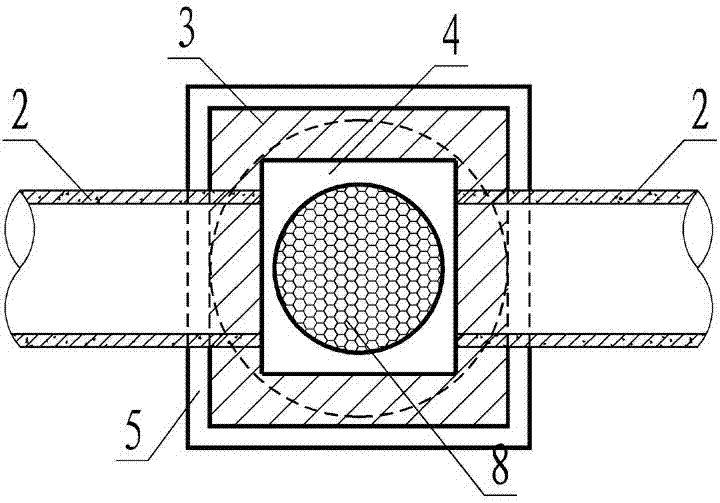

Combined rainwater seepage well and construction method

ActiveCN104499560AReduce trafficPlay the role of staggered peak regulation and storageSewerage structuresPipeflowFilter material

The invention discloses a combined rainwater seepage well and a construction method, belongs to the field of drainage projects, and particularly relates to a structure for discarding initial rainwater, adjusting the rainwater and supplying underground water by seeped rainwater. The combined rainwater seepage well mainly comprises a shaft, a pipe and a well body, wherein the shaft is positioned on the lower portion of the well body; and the pipe is connected with the well body. Seepage wells are arranged on a rainwater pipe at intervals of 1-3 inspection wells, rainwater is collected through the pipe during raining and seeps into the ground through the seepage well, the flow of the rainwater is reduced at the source, an effect of shifting peaks and adjusting storage is achieved, and waterlogging caused by accumulated water on the ground is reduced. The shaft is filled with filter materials, a slime pit is arranged on the bottom of the well body, a filter screen is arranged on the bottom of the slime pit, and the rainwater is filtered by the filter materials, seeps into the ground and supplements the underground water. The seepage well is constructed in a combined mode, the well body on the upper portion of the seepage well is constructed by using a down-top method, different sections of the shaft on the lower portion of the seepage well are constructed one by one by using a top-down method, and the construction difficulty and the manufacturing cost are greatly reduced.

Owner:洛阳城市建设勘察设计院有限公司 +1

Environment-friendly sulfur removal agent and removal technology thereof

ActiveCN107723042AReduce usageReduce fouling and cloggingGaseous fuelsHydrocarbon oils refiningWater solubleTriazine derivative

The invention relates to the technical field of organic sulfur removal, in particular to an environment-friendly sulfur removal agent and a removal technology thereof. The environment-friendly sulfurremoval agent is prepared from triazine derivatives, an anti-scaling agent and an activating agent in a certain ratio, wherein in percent by volume, the triazine derivatives accounts for 65-90%, the anti-scaling agent accounts for 1-30%, the activating agent accounts for 5-10%, the triazine derivatives react with organic sulfur, the anti-scaling agent is used for inhibiting scaling of high-hardness gas field water, the organic sulfur is insoluble in water, and the triazine derivatives are water soluble, so that the activating agent is used for quickening reaction between the triazine derivatives and the organic sulfur, and products after reaction are soluble in water. A filling technology adopts spray filling, the filling is carried out by adopting a spraying mode behind a sulfur removal tower in a gas field with high sulfur content, spray filling is directly carried out at the wellhead in a gas field with low sulfur content, and the average particle size during filling is less than 40microns. Compared with the traditional sulfur removal agent, the novel environment-friendly sulfur removal agent has the characteristics of high filling efficiency, no toxicity, no harm, no secondarypollution and applicability of products to industrial production.

Owner:CHINA PETROLEUM ENG & CONSTR +1

Method for treating ash deposition and scaling of GGH (gas-gas heater)

InactiveCN104880123AReduce cloggingGuaranteed uptimeFlush cleaningHigh pressureFlue-gas desulfurization

The invention discloses a method for treating ash deposition and scaling of a GGH (gas-gas heater). The method for treating ash deposition and scaling of the GGH has the advantages that the steps of blowing ash online by compressed air, flushing online by high-pressure water, flushing by low-pressure water before halting and performing high-pressure flushing by chemical cleaners after halting are adopted, so that the problems of severe ash deposition and scaling of a heated surface of the GGH due to ash deposition, acid coagulation, liquid drop adhesion and the like are solved, blockage resulting from ash deposition and scaling of the GGH is slowed down substantially, normal operation and flue gas desulfurization effect of a desulfurization system are guaranteed, halting times of the desulfurization system are decreased, and safety operation and safety economy of a unit are guaranteed under a rated condition.

Owner:DATANG HUAIBEI POWER PLANT

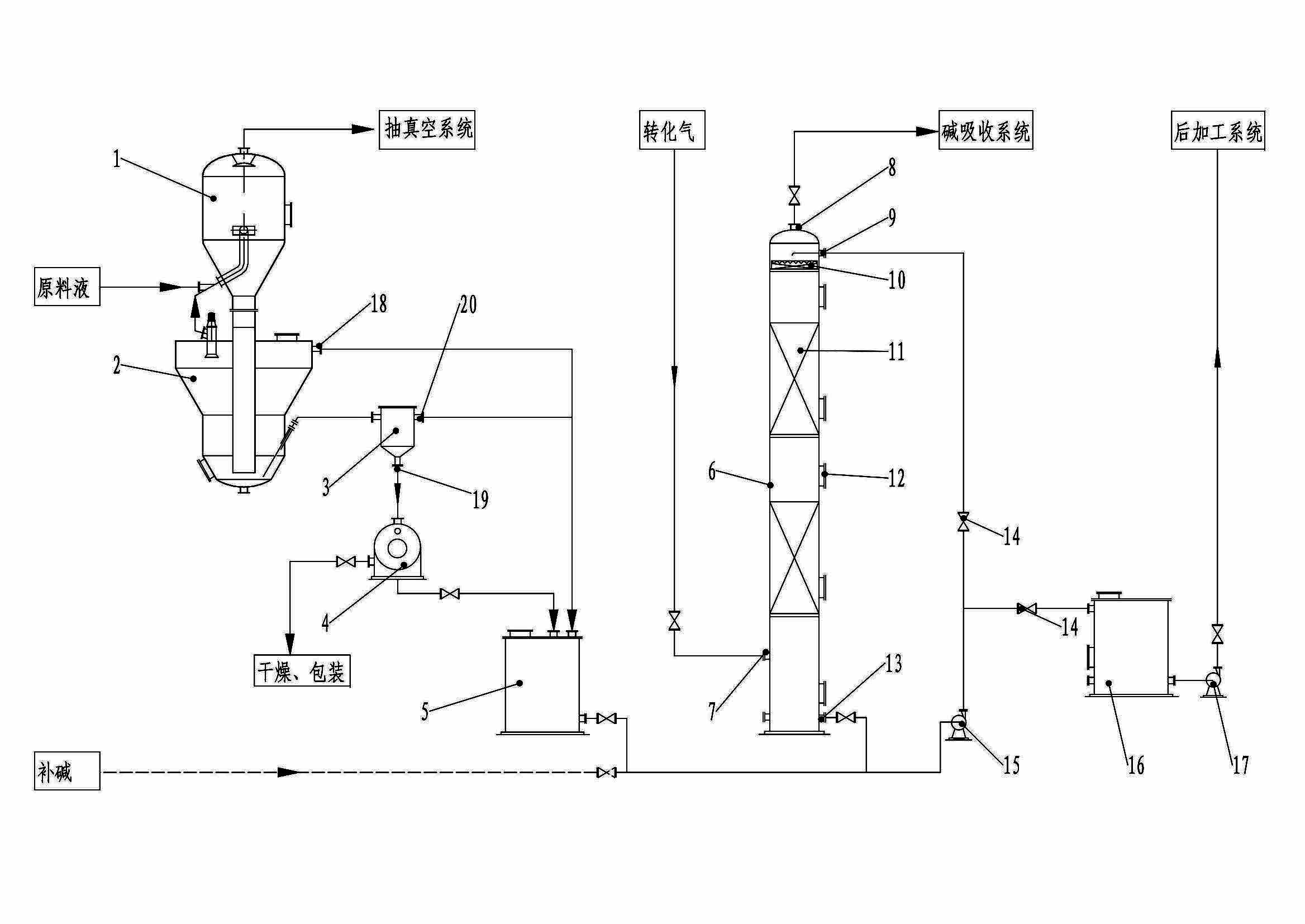

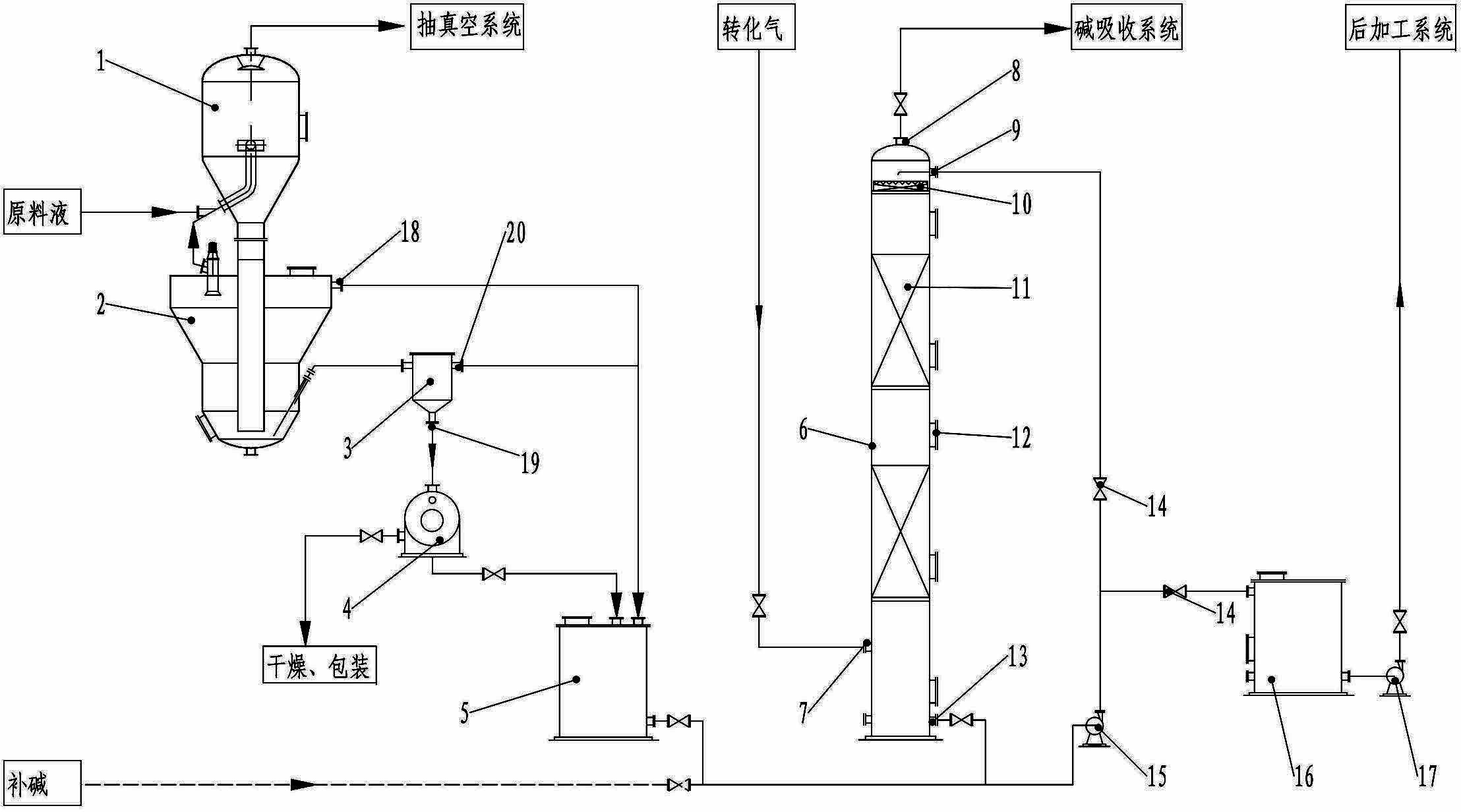

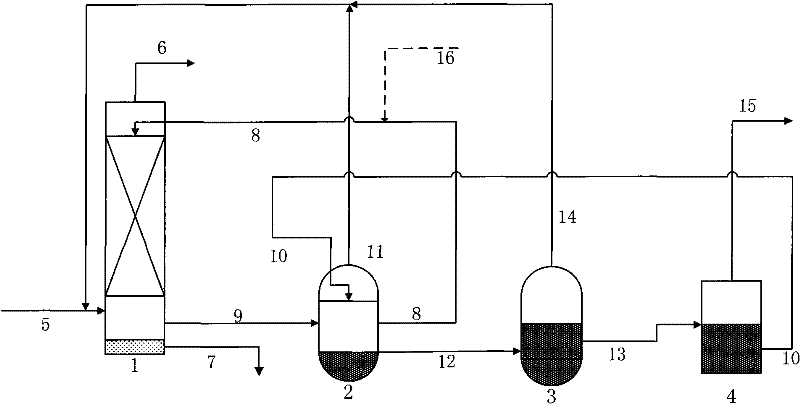

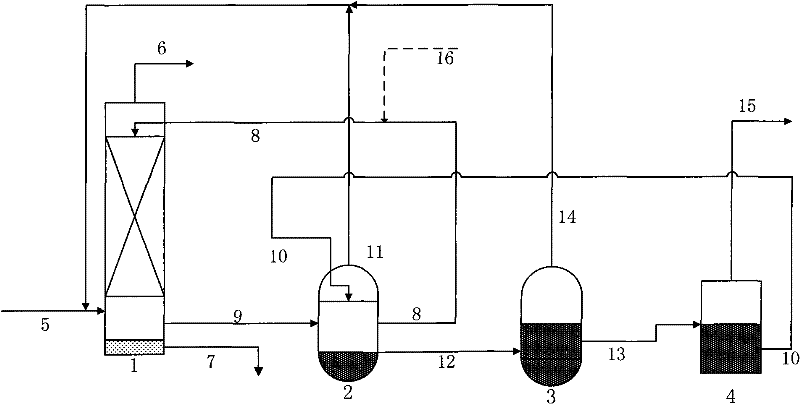

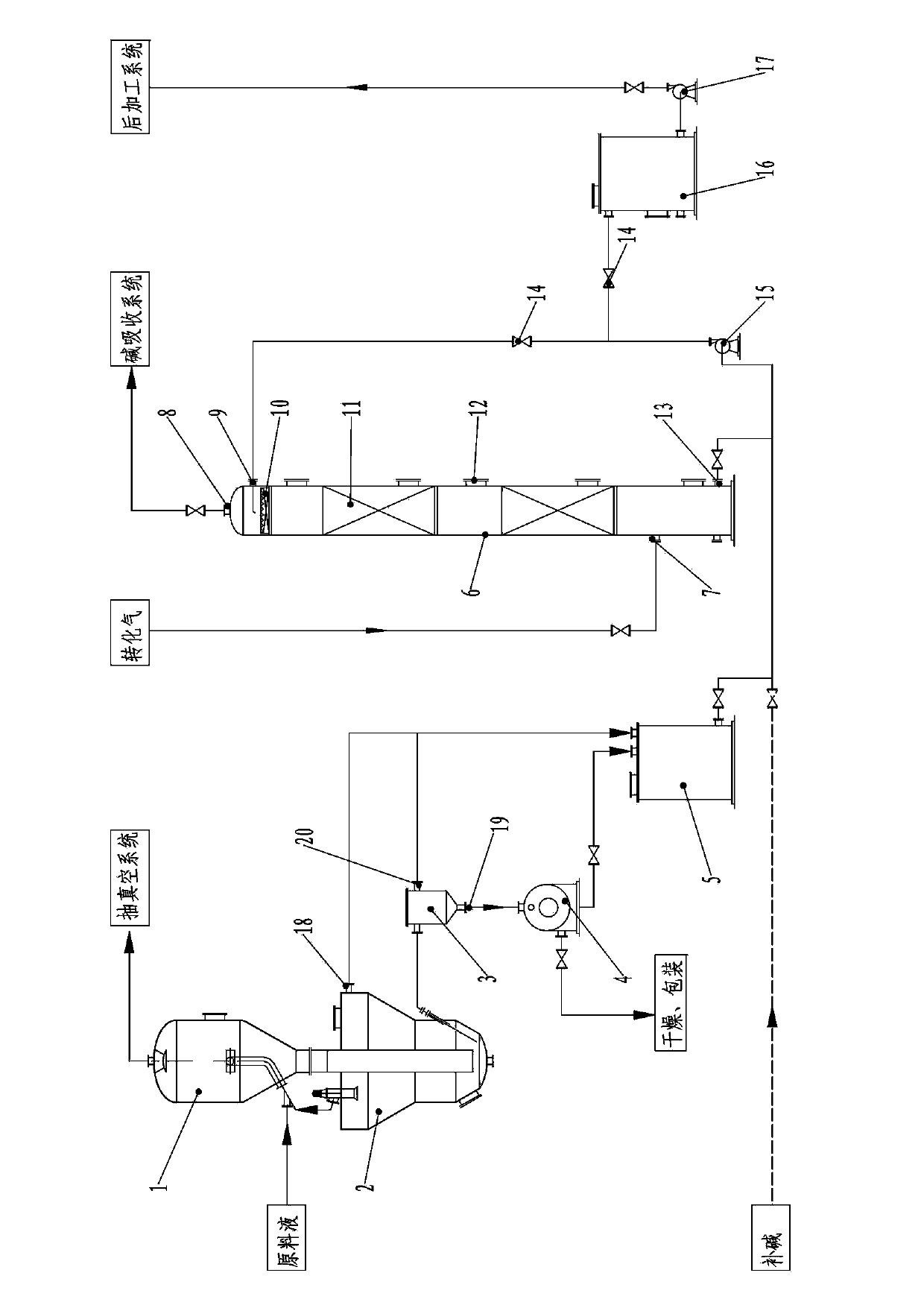

Method and device for preparing sodium nitrite by utilizing mother solution

ActiveCN102491376AImprove raw materialsIncrease productionAlkali metal nitrate preparationSodium nitrite productPhysical chemistry

The invention relates to a method and a device for preparing sodium nitrite by utilizing a mother solution. The device comprises a crystallizer, a thickner, a centrifugal machine, a mother solution absorption tower, a circulating pump and a storage tank, wherein a converted gas pipeline is connected to a converted gas inlet of the mother solution absorption tower; a mother solution tank outlet and a mother solution outlet of the mother solution absorption tower are connected to an inlet of the circulating pump; an outlet of the circulating pump is divided into two paths, one path is connectedto a mother solution inlet, and the other path is connected to the storage tank; the mother solution contacts converted gas reversely in the mother solution absorption tower, so that the content of Na2CO3 is reduced; the absorbed mother solution flows to the storage tank by the mother solution outlet and the circulating pump; and the absorbed mother solution which is deviated from the storage tank is mixed with a raw material solution and is evaporated, crystallized and subjected to centrifugal separation to obtain a sodium nitrite product. According to the method, the raw materials of the sodium nitrite is enlarged and a nitrous ratio of the product is improved by reducing the content of Na2CO3 in the mother solution; and the sodium nitrite can be produced by reducing the content of Na2CO3 in the mother solution according to market demands, and the mother solution also can be conveyed to a conversion tower to produce sodium nitrate.

Owner:SHIJIAZHUANG FENGSHAN CHEM

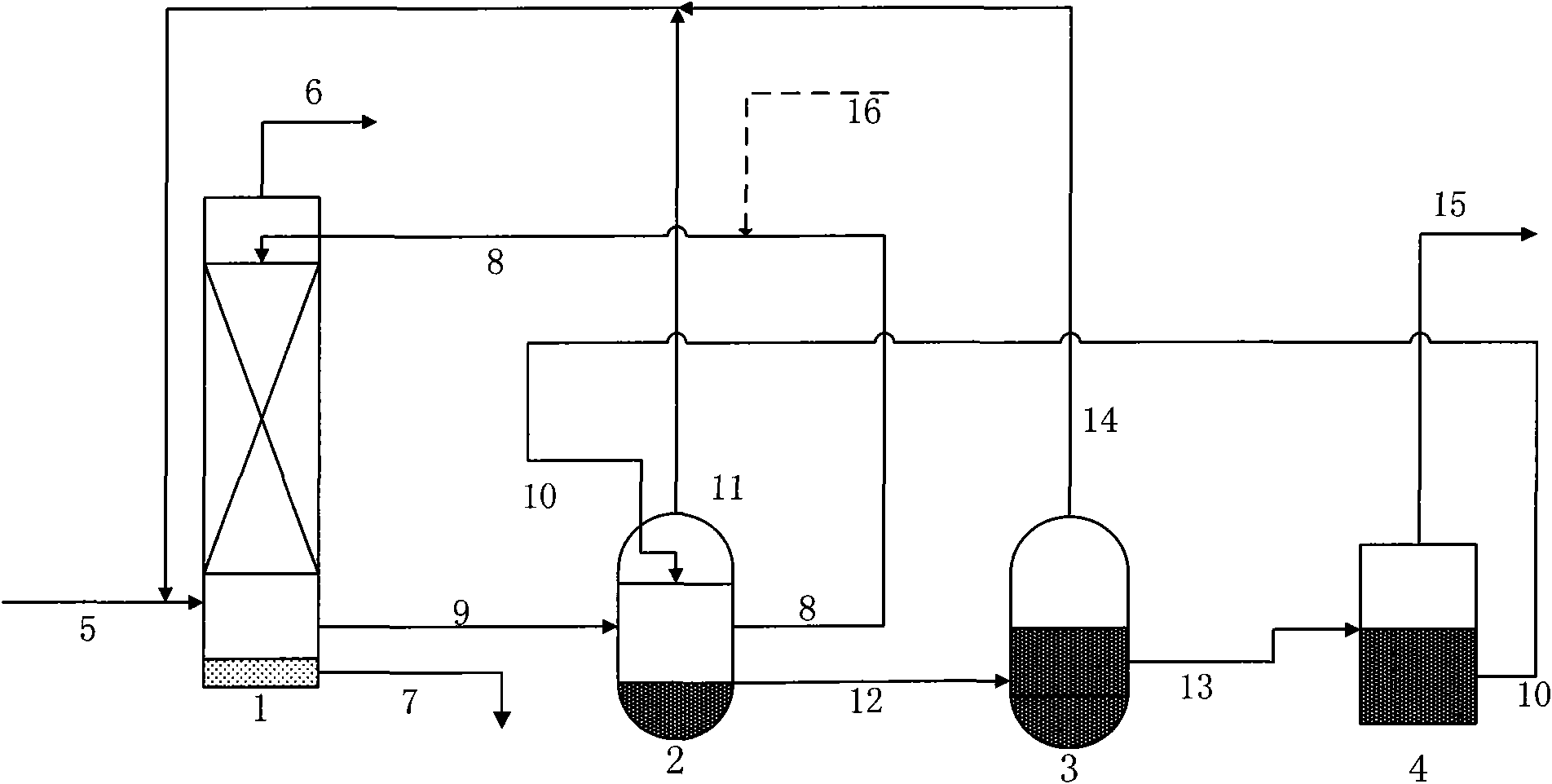

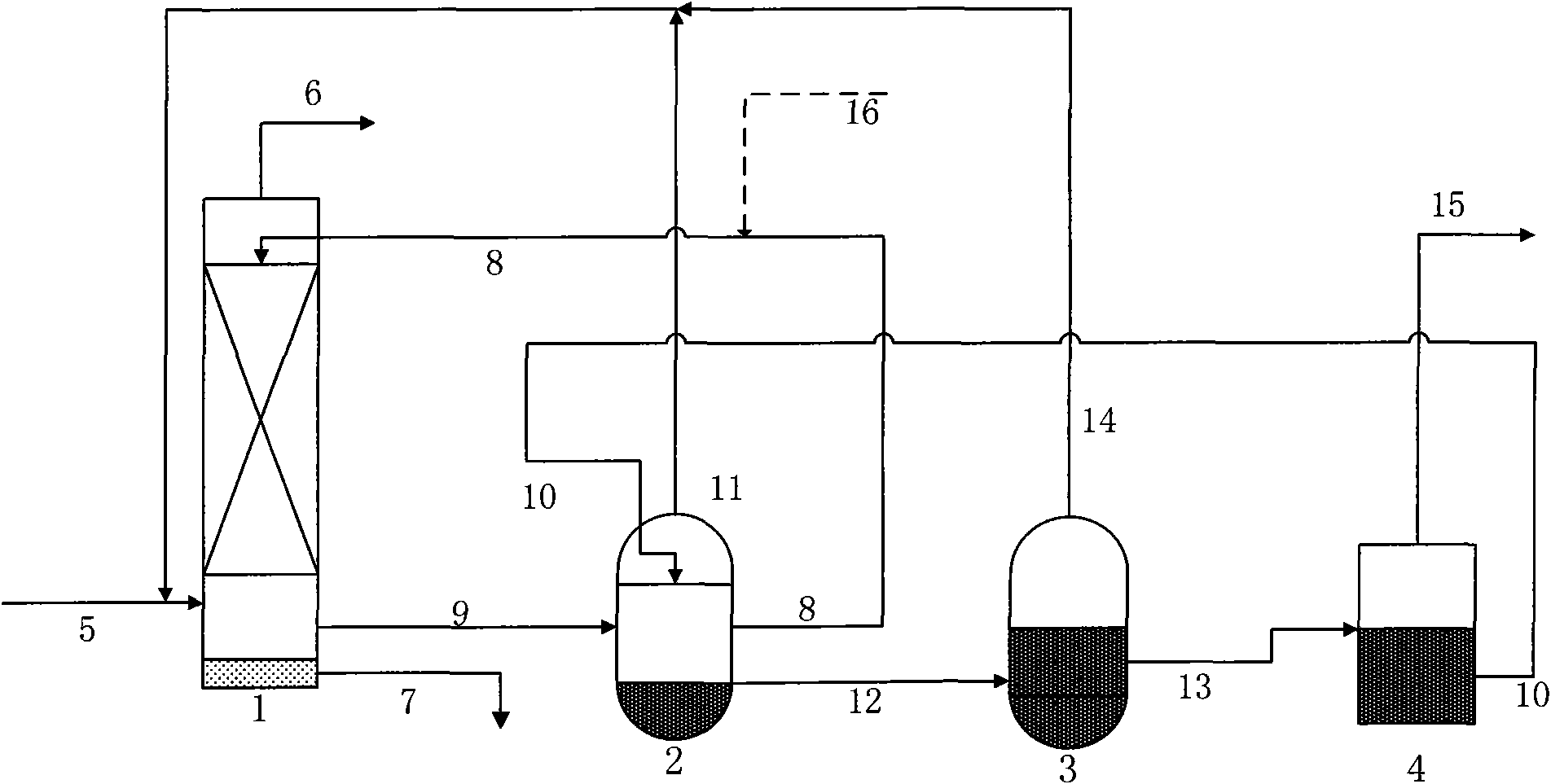

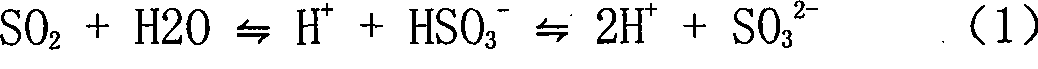

Process for desulphurizing flue gas and producing sulfur dioxide by sodium-zinc method

ActiveCN101972593AReduce fouling and cloggingReduce usageDispersed particle separationSulfur compoundsChemical industryCalcium sulfite

The invention relates to a process for desulphurizing flue gas and producing high-concentration sulfur dioxide by a sodium-zinc method, which can be widely used in the technical fields of chemical industry, electric power, construction materials, metallurgy and the like. In the invention, a sodium sulfite solution is used for absorbing sulfur dioxide in the flue gas, zinc oxide is used for realizing the concentration and the purification of the sulfur dioxide, and a thermal decomposition method is used to obtain the sulfur dioxide product. The invention avoids the problem that calcium sulfate produced by calcium-method desulphurization is difficult to use, solves the problem on scaling in zinc-method desulphurization, and effectively saves the flue gas desulphurization cost, thereby having good application prospects.

Owner:TAIYUAN BOILER GROUP

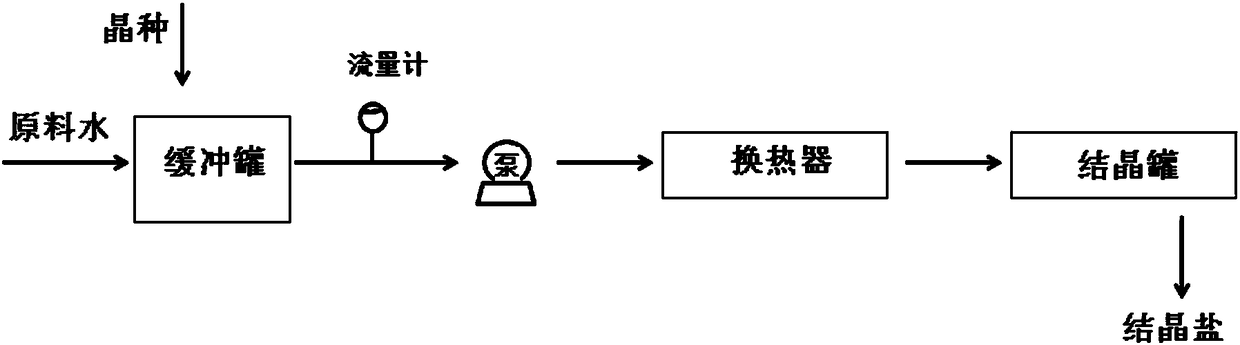

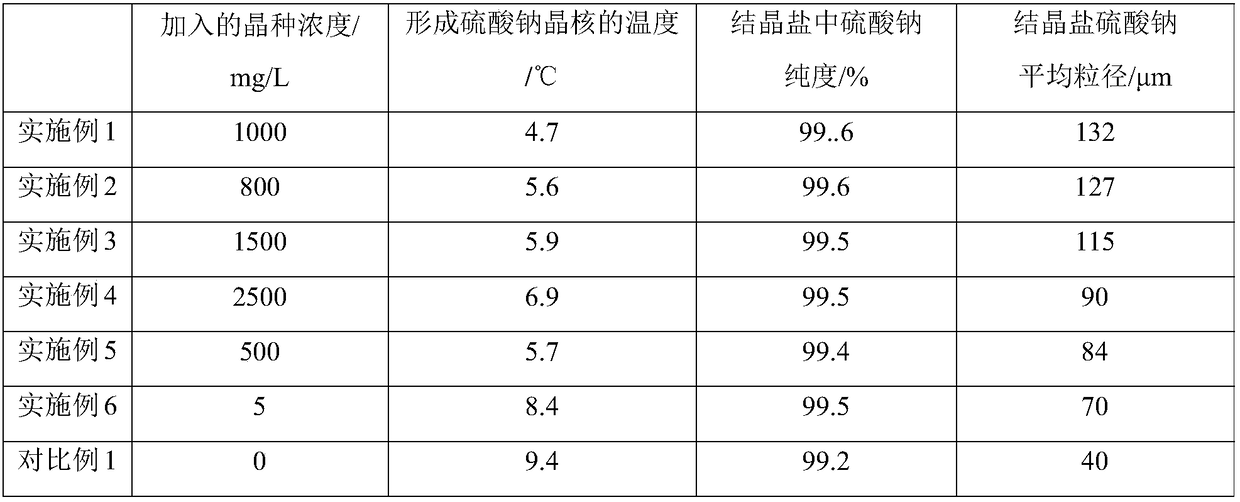

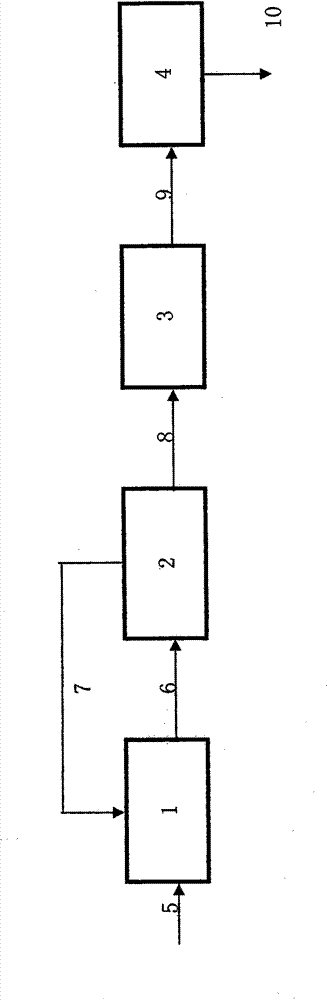

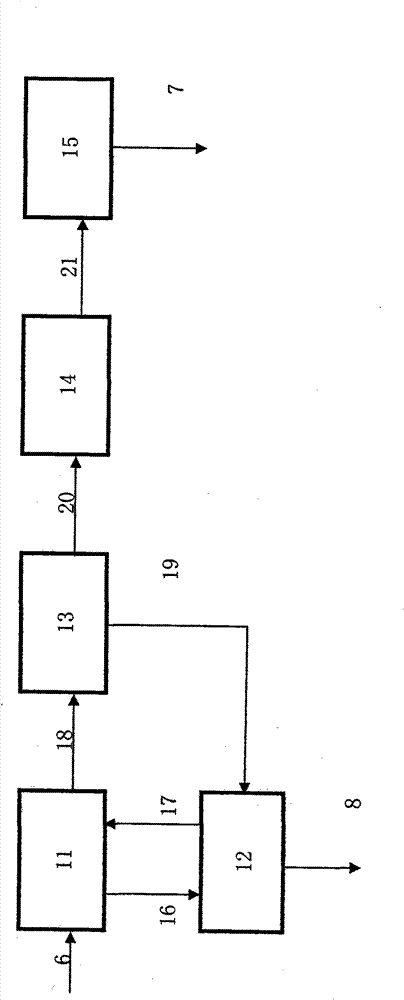

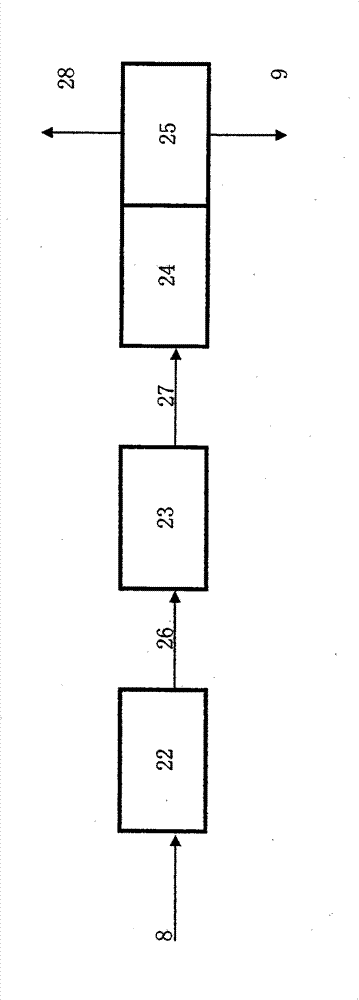

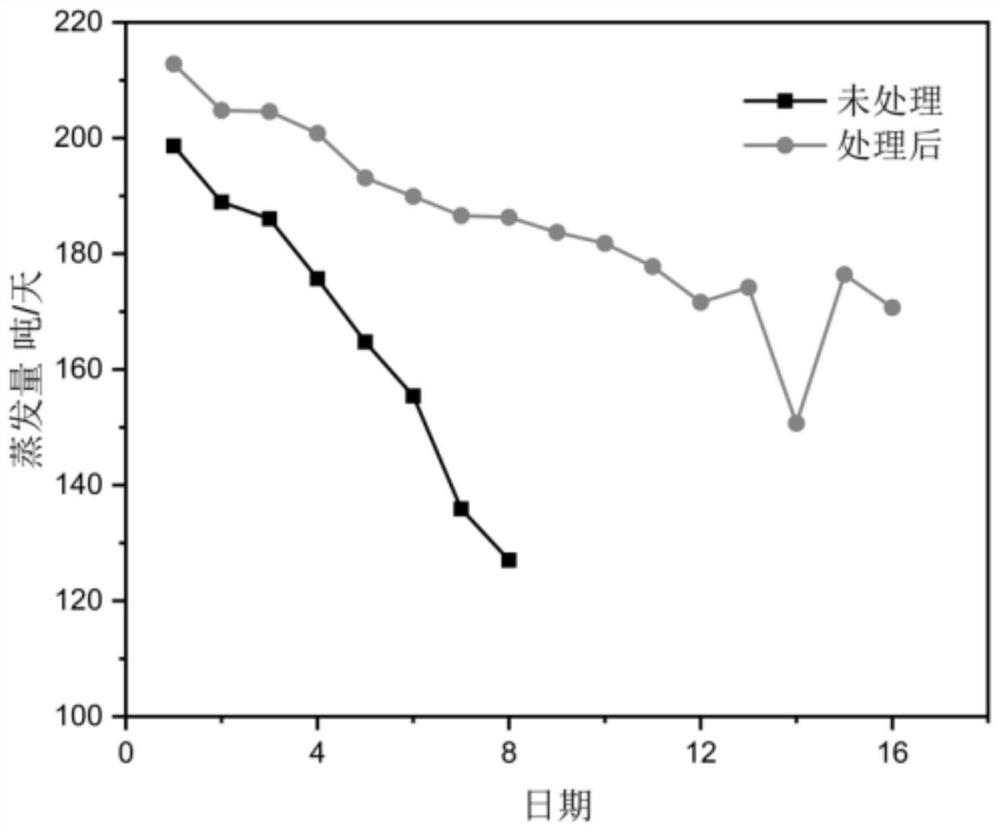

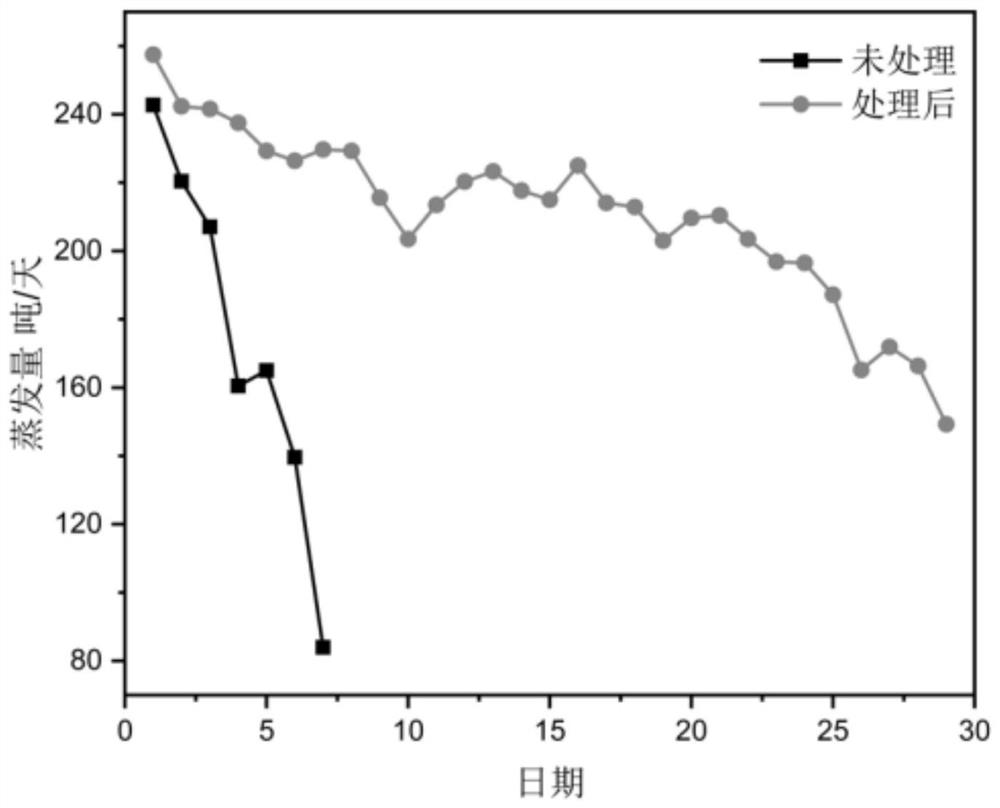

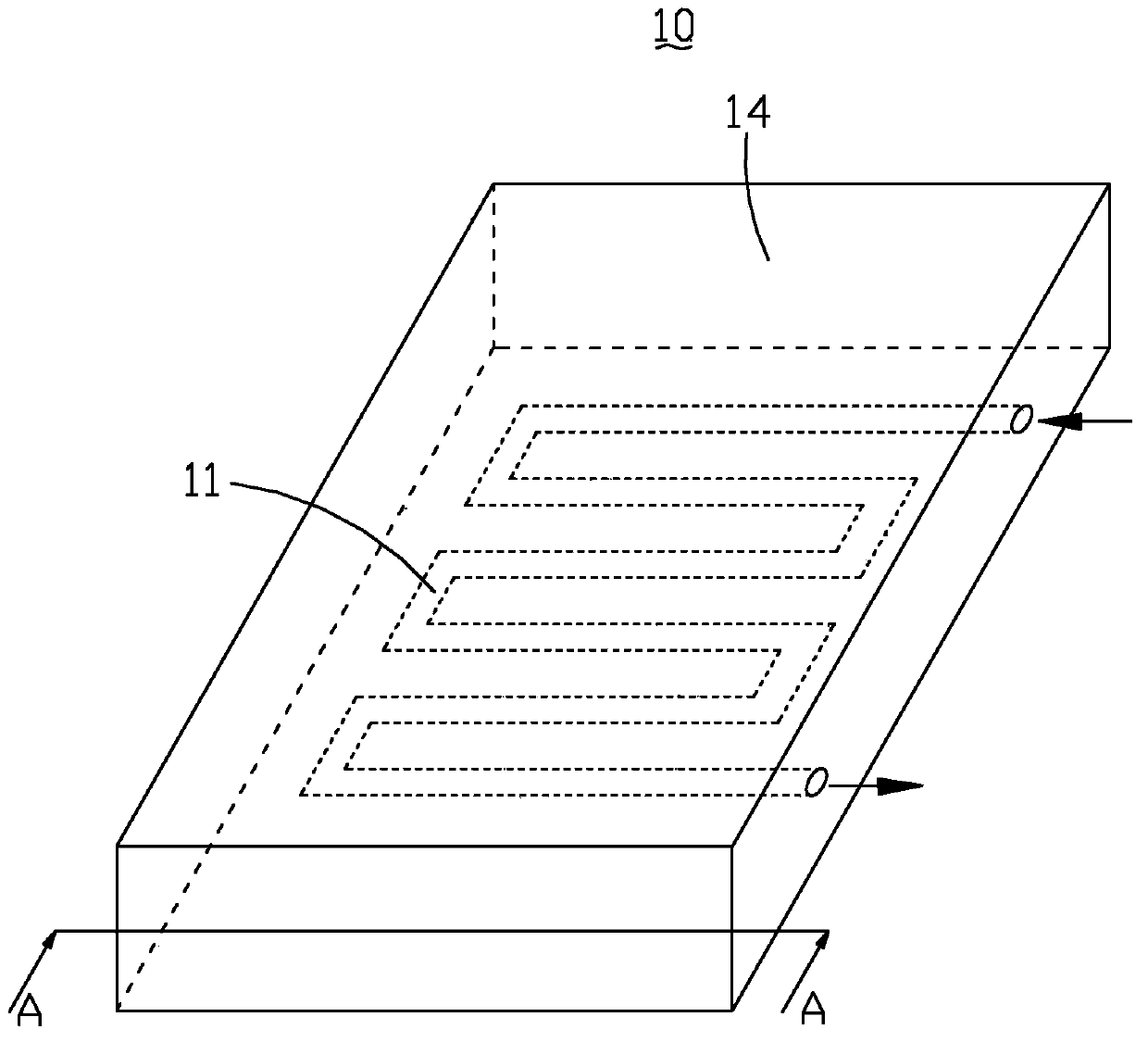

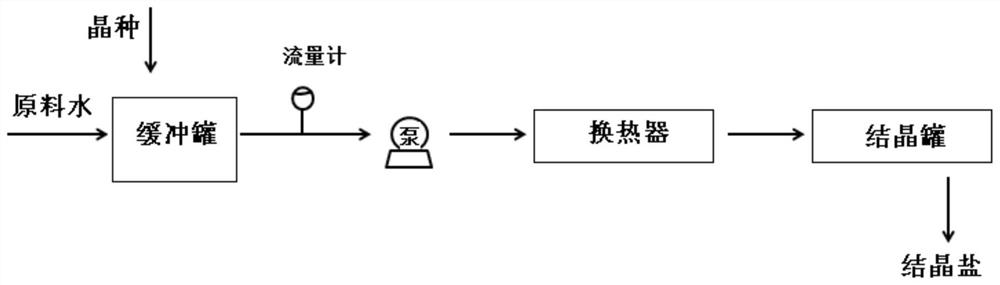

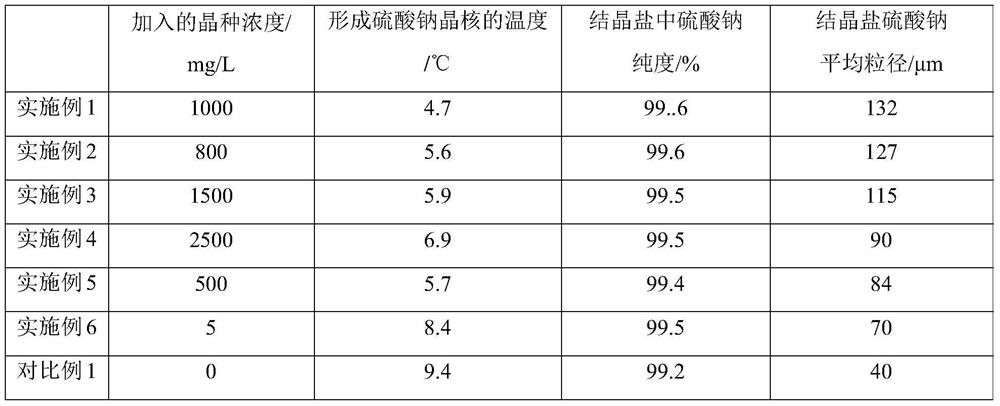

Salt preparing method and system

ActiveCN108726540AReduce foulingReduce fouling and cloggingSolution crystallizationHeat exchange cooling cystallizationHigh concentrationSolubility

The invention relates to the field of water treatment, and discloses a salt preparing method and system. The method comprises the following steps: (1) adding bivalent anionic salt seed crystals to rawwater to obtain a buffering solution; (2) cooling the buffering solution; and (3) separating crystals of the cooled buffering solution to obtain bivalent anionic salt crystal salt, wherein the raw water contains dianionic salt and random single valence anion; the mass concentration of the dianionic salt in the raw water is less than the saturability of the dianionic salt under the cooling temperature in step (2); the solubility of the dianionic salt under the temperature of 0-32.4 DEG C decreases as the temperature decreases, and the average solubility of the dianionic salt within the temperature range of 0-32.4 DEG C is decreased at the rate exceeding 0.03g / DEG C. With the adoption of the method, scaling in a tube pass or on the wall of a heat exchanger in the process of cooling high-concentration saline water can be effectively reduced; and moreover, high-purity and high-average-particle-size crystal salt can be obtained; and subsequent separation is conveniently carried out.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

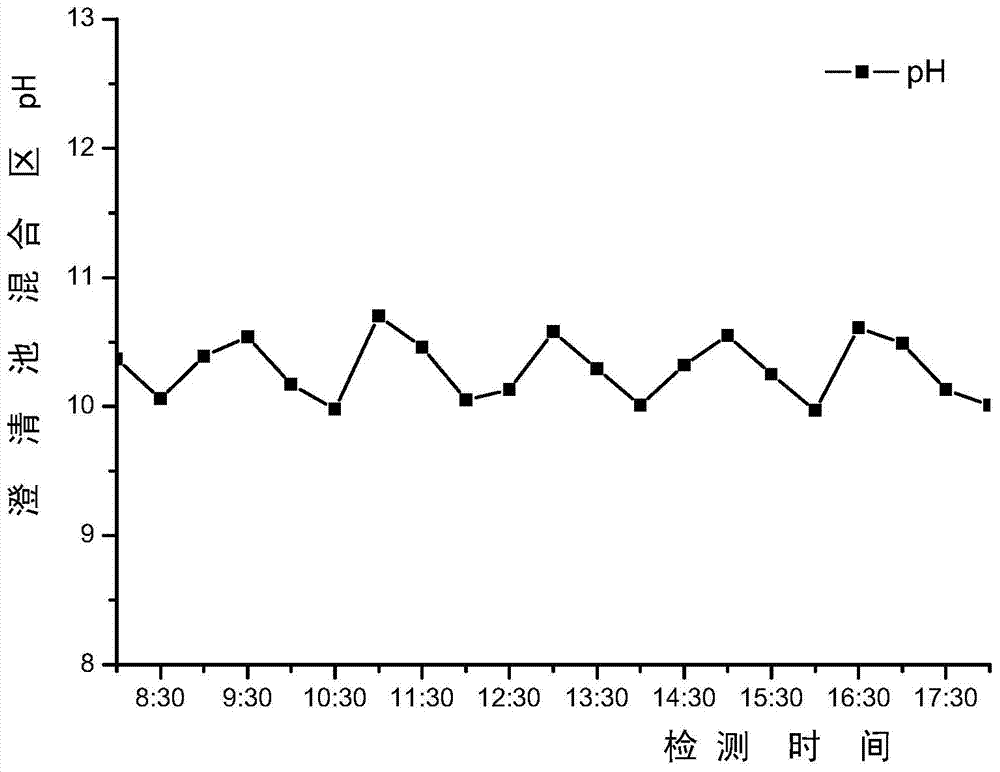

Coal-fired flue gas desulfurization, denitrification and foam inhibition catalytic synergist and use method thereof

InactiveCN111569634AHigh activityImprove utilization efficiencyGas treatmentDispersed particle separationPtru catalystCalcium sulfite

The invention discloses a coal-fired flue gas desulfurization, denitrification and foam inhibition catalytic synergist and a use method thereof. The catalytic synergist comprises the following raw materials in percentage by mass: 10-80% of a cosolvent; 5-40% of an oxidation catalyst; 5-30% of a co-activator; 1-10% of a scale and foam inhibitor; 1-10% of a co-dispersant; and 0.1-2% of an analysis regulator. With the coal-fired flue gas desulfurization, denitrification and foam inhibition catalytic synergist is adopted, desulfurization and denitrification efficiency can be improved; the semi-ablation time of limestone is reduced; the dissolution speed of the limestone is obviously accelerated; the activity of limestone can be greatly improved; the fluctuation of the PH value of slurry is mitigated; the liquid-gas ratio L / G of a system is reduced; the resistance of a spraying layer is reduced; the utilization efficiency of oxidation air is improved; the consumption of a booster fan is reduced; the Ca / L ratio of the system is reduced; the consumption of the limestone is reduced; the dispersity of the limestone is improved; calcium sulfite oxidation is promoted; scaling blockage and foaming of a desulfurization system are reduced; and the reliability of the desulfurization system is improved.

Owner:河北丰强科技有限公司

Recycling system integration apparatus used for zero discharge of sewage produced in gas making

InactiveCN102774971AReduce fouling and cloggingLow costSludge treatment by de-watering/drying/thickeningSolid waste disposalSystem integrationCombustion

The invention discloses a recycling system integration apparatus used for zero discharge of sewage produced in gas making, which belongs to the field of the coal chemical industry. The invention especially relates to the recycling system integration apparatus used for zero discharge of sewage and sludge produced in the workshop sections of gas making and gas washing in the coal chemical industry. The apparatus is a novel technical scheme brought forward after innovation of the prior art and comprises a washing tower washing tower, a gas making sewage treating and recycling device, a sludge combustion generation treating device and a solid waste integrated utilization device. The recycling system integration apparatus has the advantages of a reasonable structure, low operation cost, high sewage treatment efficiency, capacity of producing a byproduct, i.e., a building material, etc.

Owner:江苏晋煤恒盛化工股份有限公司

Vertical sieve plate and its application method in the separation system of ethyl acetate esterification

ActiveCN1706795AReduce fouling and cloggingIncreased crude ester contentOrganic compound preparationCarboxylic acid esters preparationHybrid typeEngineering

The present invention is one kind of vertical sieve plate and its application in the separation system of ethyl acetate esterification, and aims at solving the problems of common sieve plate, which has low mass transfer efficiency, low mass transfer space utilization, easy jamming of meshes, exceed resistance, hard control in acidity of top ethyl acetate product and less operation elasticity. The vertical sieve plate is used in the separation system of ethyl acetate esterification, and the separation system includes esterifying tower, top condensator, ester-water separator and reactor. The vertical sieve plate features the calotte in special shape, the airlift hole of venturi form in the column plate, several rows of small holes on the side wall of calotte, and the optimal designed of the column plate and calotte structure based on the push force mathematic mold. The metal column plate is vertical sieve plate or the combination of common sieve plate and vertical sieve plate.

Owner:SHANGHAI HUAYI ENERGY CHEM

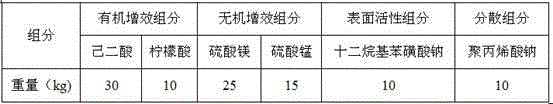

Desulphurization synergist used for wet desulphurization

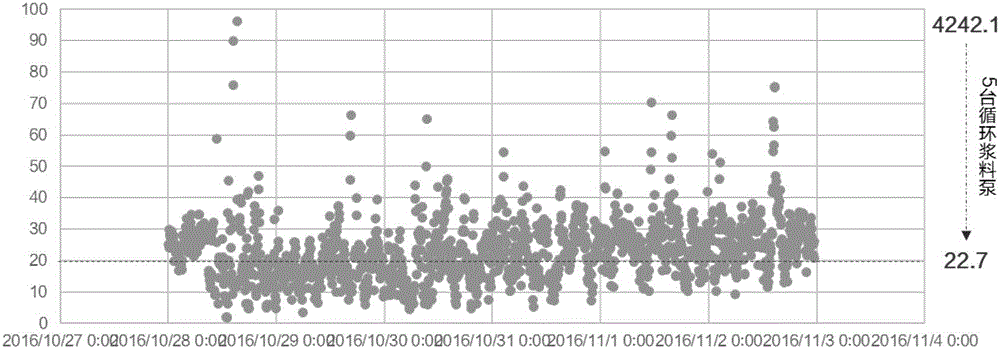

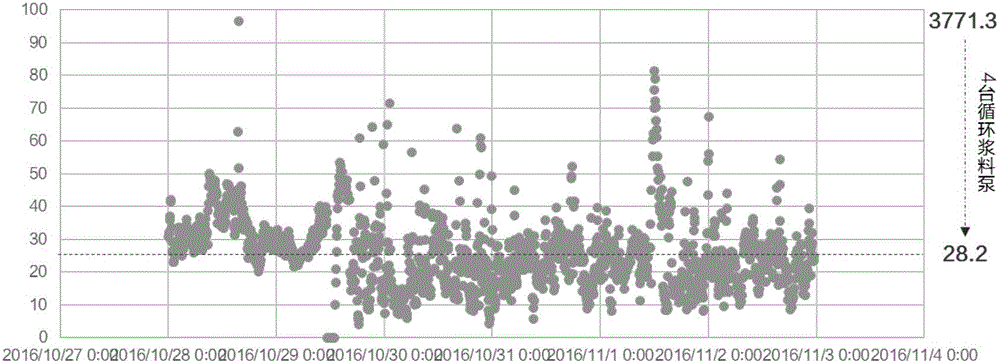

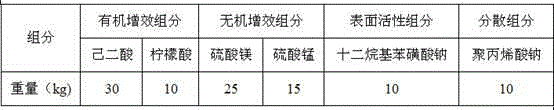

InactiveCN105983328AEasy to makeNo heating requiredDispersed particle separationSlurryCirculating pump

The invention discloses a desulfurization synergist suitable for wet desulfurization. According to the mass percentage, the raw materials include: 40%-60% of organic synergistic components, 20%-40% of inorganic synergistic components, surfactants 5%-10%, disperse components 5%-10%. The invention is simple to manufacture, does not need heating, is convenient to use, uses less, and is low in cost. The gas ratio can be reduced by 10-20%, and a slurry circulation pump is shut down, and the outlet SO 2 It complies with the emission standard of air pollutants for thermal power plants GB13223-2011.

Owner:陕西安得科技实业有限公司

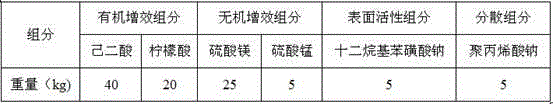

Water-saving clean drinking machine and concentrated water control method thereof

InactiveCN106186401AAdjustable split ratioAdjustable control split ratioTreatment involving filtrationReverse osmosisWater dischargeSolenoid valve

The invention discloses a water-saving clean drinking machine and a concentrated water control method thereof. The water-saving clean drinking machine comprises a water making system and a control system. The water making system comprises a raw water tank, a water pump, a front filter element system and a reverse osmosis membrane filter element which are communicated in sequence. A clean water outlet of the reverse osmosis membrane filter element is communicated with the clean water tank, and a concentrated water outlet of the reverse osmosis membrane filter element is communicated with a concentrated water discharging system. The concentrated water discharging system comprises a wastewater ratio solenoid valve, a water discharging valve and a throttling valve. The wastewater ratio solenoid valve and the throttling valve are communicated with the concentrated water outlet, the water discharging valve is communicated with the wastewater ratio solenoid valve, and the throttling valve is communicated with a water path in front of the water pump. The ratio of the flow of concentrated water generated by the reverse osmosis membrane filter element to the flow of clean water is lager than 2, and the total amount of concentrated water generated by the reverse osmosis membrane filter element is proportionally distributed. According to the water-saving clean drinking machine and the concentrated water control method thereof, the distribution proportion of concentrated water produced by a reverse osmosis system can be regulated and controlled, it is avoided that overlarge working pressure is increased for the system, the situations of scaling blockage and the like of a reverse osmosis membrane and a filter system are relieved, and the service life of the reverse osmosis membrane is guaranteed while concentrated water is recycled.

Owner:QINYUAN GRP CO LTD

Electroplating comprehensive wastewater zero-discharge treatment system and process thereof

PendingCN114620889ALow viscosityAccelerate evaporationWater treatment parameter controlSludge treatmentDesalinationSewage treatment

The invention provides a treatment system for zero discharge of comprehensive electroplating wastewater and a treatment process thereof. The invention belongs to the technical field of sewage treatment, and relates to a zero-discharge treatment system for comprehensive electroplating wastewater. Comprising a physicochemical system, a biochemical system, a membrane concentration system, a special pretreatment system and an evaporation system which are connected in sequence. According to the invention, the high-salt concentrated water subjected to membrane concentration can be treated by the pretreatment system before entering the evaporation system, so that pollutants influencing evaporation in the high-salt concentrated water are removed, the viscosity of the concentrated water is reduced, the evaporation and crystallinity of the concentrated water are improved, and the concentrated water enters the evaporation crystallization system to obtain a byproduct salt; the evaporated and crystallized mother liquor is returned to the pretreatment system to be mixed with the membrane concentration high-salt concentrated water for circular treatment, pollutants enriched in the mother liquor are removed, and the mother liquor can be continuously evaporated and desalted, so that zero mother liquor of the evaporation system is realized, and zero emission of the electroplating comprehensive wastewater is realized.

Owner:李鹏

Process for desulphurizing flue gas and producing sulfur dioxide by sodium-zinc method

ActiveCN101972593BWill not oxidizeAvoid secondary pollutionDispersed particle separationSulfur compoundsHigh concentrationChemical industry

The invention relates to a process for desulphurizing flue gas and producing high-concentration sulfur dioxide by a sodium-zinc method, which can be widely used in the technical fields of chemical industry, electric power, construction materials, metallurgy and the like. In the invention, a sodium sulfite solution is used for absorbing sulfur dioxide in the flue gas, zinc oxide is used for realizing the concentration and the purification of the sulfur dioxide, and a thermal decomposition method is used to obtain the sulfur dioxide product. The invention avoids the problem that calcium sulfateproduced by calcium-method desulphurization is difficult to use, solves the problem on scaling in zinc-method desulphurization, and effectively saves the flue gas desulphurization cost, thereby having good application prospects.

Owner:TAIYUAN BOILER GROUP

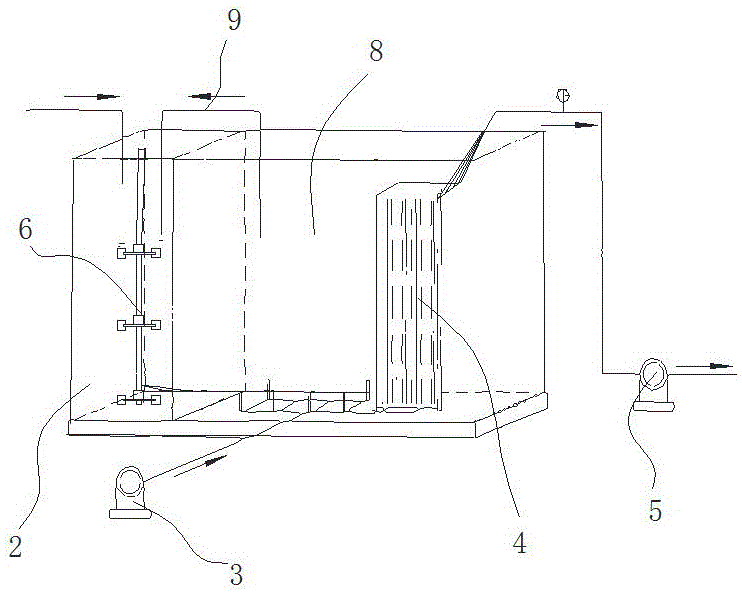

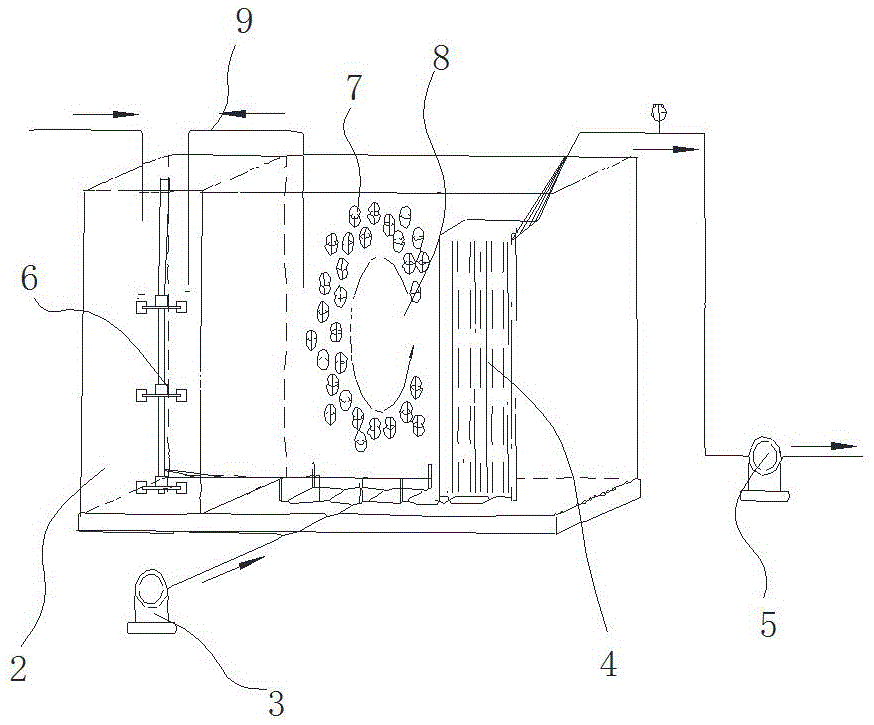

Flat sheet membrane bioreactor

InactiveCN106336073AImprove mass transfer efficiencyPromote fermentationSemi-permeable membranesTreatment involving filtrationProduction rateBiochemical engineering

The invention relates to a flat sheet membrane bioreactor which comprises an anaerobic pool, an aerobic pool and a membrane component which are sequentially connected, a water inlet is formed in the anaerobic pool, a stirring shaft is vertically arranged in the anaerobic pool, a plurality of stirring paddles are arranged on the stirring shaft at intervals, the lower end of the stirring shaft extends to the bottom part of the anaerobic pool, a plurality of sections of spiral channels are arranged on the inner wall of the anaerobic pool at intervals from top to bottom, each spiral channel is formed by encircling and splicing a plurality of spiral blades fixed on the inner wall of the anaerobic pool, each spiral channel is provided with a penetrating channel for holding the stirring paddle, a filter screen is coated at the periphery of the membrane component, the mesh number of the filter screen is 30-50, the bore diameter of the filter screen is 0.4-0.5mm, and a return passage is arranged between the anaerobic pool and the aerobic pool. The flat sheet membrane bioreactor is simple in structure and high in production rate.

Owner:JIANGSU LVYANG BIOLOGICAL ELECTRONICS ENG CO LTD

Method and device for preparing sodium nitrite by utilizing mother solution

ActiveCN102491376BImprove raw materialsIncrease productionAlkali metal nitrate preparationSodium nitrite productPhysical chemistry

The invention relates to a method and a device for preparing sodium nitrite by utilizing a mother solution. The device comprises a crystallizer, a thickner, a centrifugal machine, a mother solution absorption tower, a circulating pump and a storage tank, wherein a converted gas pipeline is connected to a converted gas inlet of the mother solution absorption tower; a mother solution tank outlet and a mother solution outlet of the mother solution absorption tower are connected to an inlet of the circulating pump; an outlet of the circulating pump is divided into two paths, one path is connected to a mother solution inlet, and the other path is connected to the storage tank; the mother solution contacts converted gas reversely in the mother solution absorption tower, so that the content of Na2CO3 is reduced; the absorbed mother solution flows to the storage tank by the mother solution outlet and the circulating pump; and the absorbed mother solution which is deviated from the storage tank is mixed with a raw material solution and is evaporated, crystallized and subjected to centrifugal separation to obtain a sodium nitrite product. According to the method, the raw materials of the sodium nitrite is enlarged and a nitrous ratio of the product is improved by reducing the content of Na2CO3 in the mother solution; and the sodium nitrite can be produced by reducing the content of Na2CO3 in the mother solution according to market demands, and the mother solution also can be conveyed to a conversion tower to produce sodium nitrate.

Owner:SHIJIAZHUANG FENGSHAN CHEM

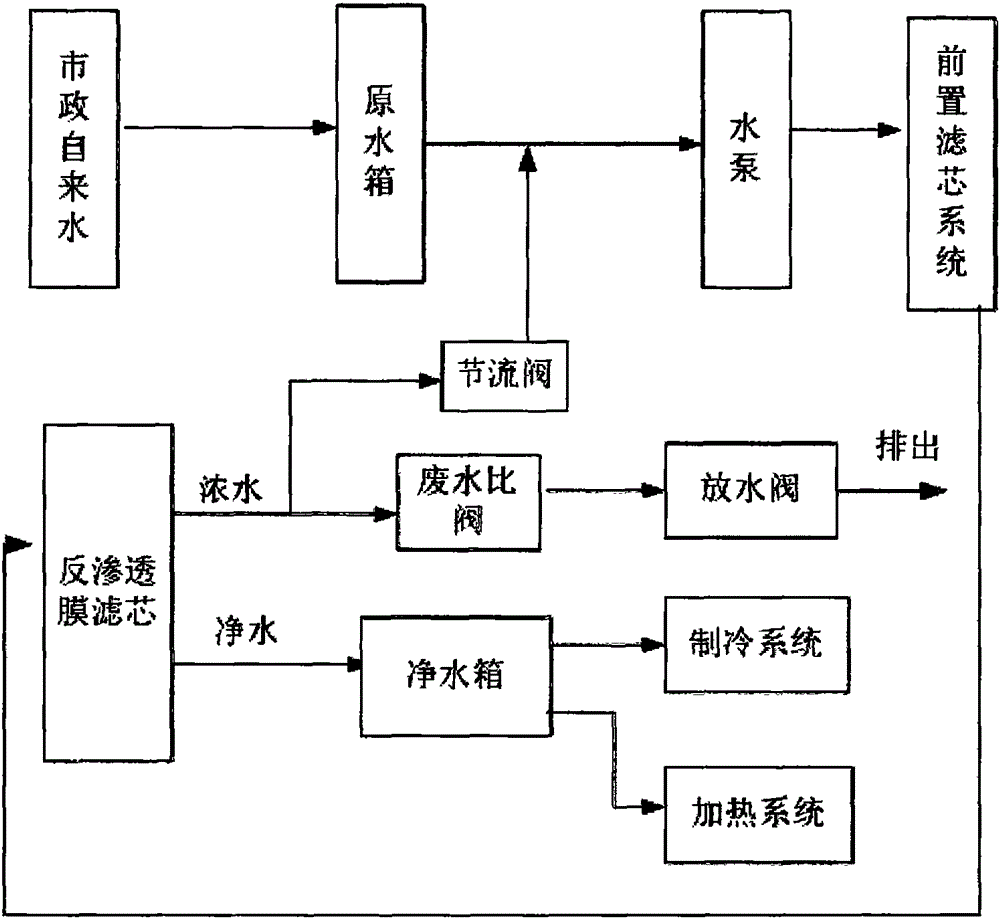

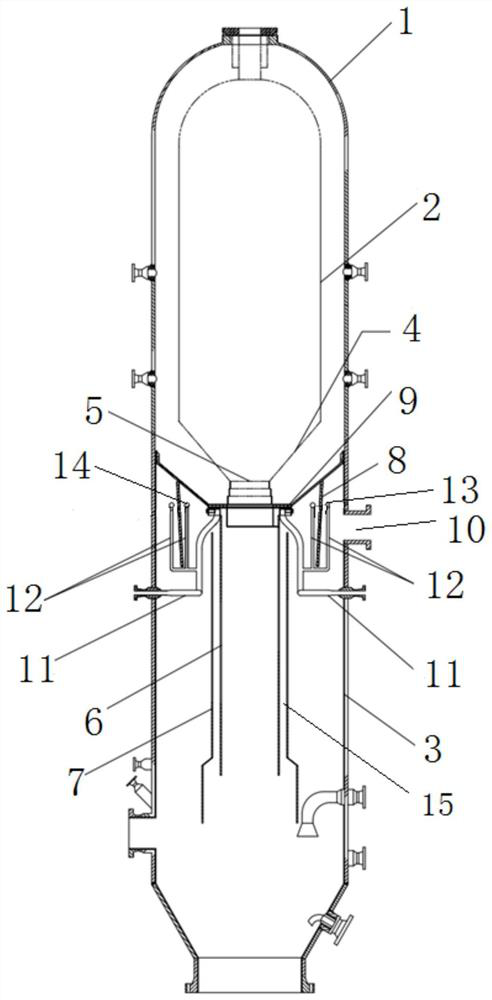

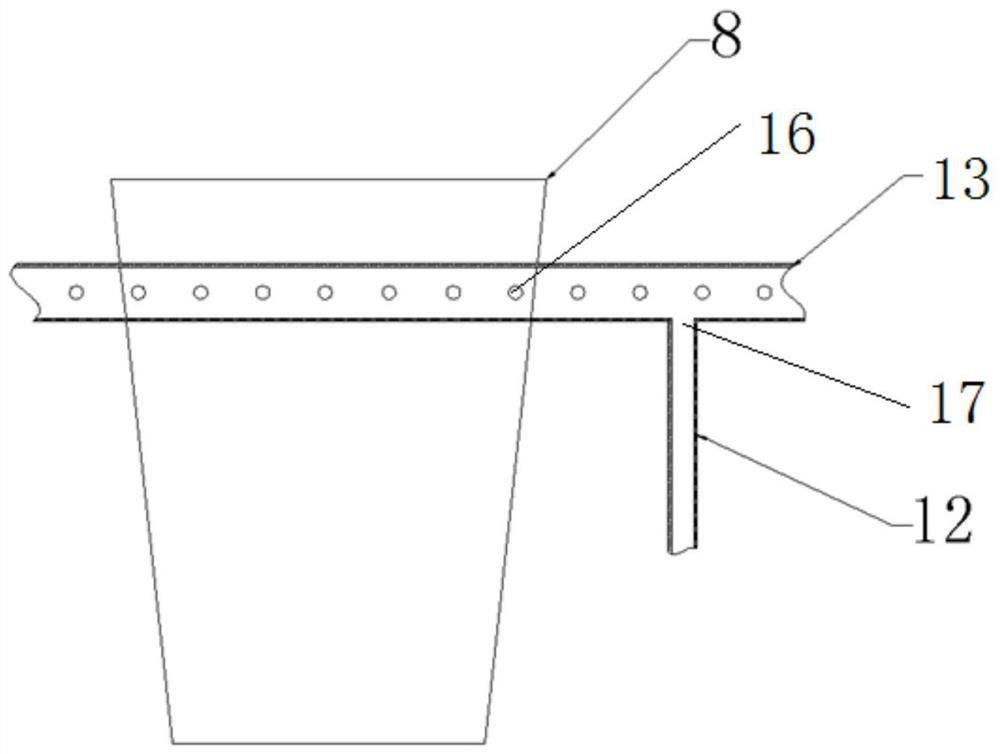

Method for cooling and deashing synthesis gas of gasification furnace and gasification furnace

ActiveCN114686274AReduce fouling and cloggingLow ash contentGas purification by non-gaseous materials condensationGas dust removalSyngasThermodynamics

According to the method for cooling and deashing the synthesis gas of the gasification furnace and the gasification furnace, the baffle plate and the synthesis gas outlet pipeline can be effectively prevented from being blocked by accumulated dust based on the gasification furnace and the method for cooling and deashing the synthesis gas, and the synthesis gas can be effectively cooled and dedusted. The gasification furnace comprises a combustion chamber and a chilling chamber located below the combustion chamber, a slag opening is formed in the bottom of the combustion chamber, the combustion chamber is communicated with the chilling chamber through the slag opening, a downcomer is arranged below the slag opening, a chilling ring is arranged between the slag opening and the top end of the downcomer, the downcomer is sleeved with an ascending pipe, and the ascending pipe is connected with the chilling ring. The synthesis gas cooling and ash removing assembly is arranged in the chilling chamber and comprises a baffle plate, an inner ring water distributor and an outer ring water distributor.

Owner:CHINA SHENHUA COAL TO LIQUID & CHEM CO LTD +1

Flow swirling and flow intercepting device

The invention discloses a flow swirling and flow intercepting device. The device comprises a flow swirling valve and a water collecting well. The flow swirling valve is fixedly installed in the watercollecting well, an inlet and an outlet are formed in the water collecting well, an inlet and an outlet are formed in the flow swirling valve, and the outlet of the flow swirling valve is communicatedwith the outlet of the water collecting well; the flow swirling valve is mainly formed by a cylindrical shell body connecting with a truncated cone-shaped shell body, the cylindrical shell body is composed of three fan-shaped cylinders and a square cylinder, and a through slot is formed in the outer surface of the square cylinder as a valve inlet; the water collecting well is of a rectangular structure, the inlet and the outlet are respectively formed in the two symmetrical side walls, the central axes of the inlet and the outlet are overlapped, and the central axis of the outlet of the flowswirling valve is overlapped with the central axes of the inlet and the outlet of the water collecting well. According to the device, an air intercepting cylinder can be formed in the center of the flow swirling and flow intercepting device, the diameter size of the air intercepting cylinder is controlled by water levels, stability of installation of the device is improved, flow intercepting effect is achieved, phenomenons of water seepage, water leakage and water overflow in down stream due to water level difference are reduced, deposit and blocking are slowed down, and flow capacity of a pipe is improved.

Owner:MIN OF WATER RESOURCES HANGZHOU MACHINERY DESIGN INST

A kind of environment-friendly sulfur removal agent and removal process

ActiveCN107723042BReduce usageReduce fouling and cloggingGaseous fuelsHydrocarbon oils refiningEnvironmental resistanceTriazine derivative

The invention relates to the technical field of organic sulfur removal, in particular to an environment-friendly sulfur removal agent and a removal technology thereof. The environment-friendly sulfurremoval agent is prepared from triazine derivatives, an anti-scaling agent and an activating agent in a certain ratio, wherein in percent by volume, the triazine derivatives accounts for 65-90%, the anti-scaling agent accounts for 1-30%, the activating agent accounts for 5-10%, the triazine derivatives react with organic sulfur, the anti-scaling agent is used for inhibiting scaling of high-hardness gas field water, the organic sulfur is insoluble in water, and the triazine derivatives are water soluble, so that the activating agent is used for quickening reaction between the triazine derivatives and the organic sulfur, and products after reaction are soluble in water. A filling technology adopts spray filling, the filling is carried out by adopting a spraying mode behind a sulfur removal tower in a gas field with high sulfur content, spray filling is directly carried out at the wellhead in a gas field with low sulfur content, and the average particle size during filling is less than 40microns. Compared with the traditional sulfur removal agent, the novel environment-friendly sulfur removal agent has the characteristics of high filling efficiency, no toxicity, no harm, no secondarypollution and applicability of products to industrial production.

Owner:CHINA PETROLEUM ENG & CONSTR +1

Flat membrane bioreactor

InactiveCN106219753AImprove mass transfer efficiencyPromote fermentationSpecific water treatment objectivesBiological treatment apparatusProduction rateSpiral blade

The invention relates to a flat membrane bioreactor. The flat membrane bioreactor comprises an anaerobic pool, an aerobiotic pool and a membrane component which are successively connected with each other, wherein a water inlet is arranged on the anaerobic pool; a stirring shaft is vertically arranged in the anaerobic pool; a plurality of stirring blades are arranged on the stirring shaft at intervals; the lower end of the stirring shaft extends to the bottom of the anaerobic pool; multiple sections of spiral channels are successively arranged on an inner wall of the anaerobic pool at intervals from top to bottom; each section of spiral channel is formed by surrounding and splicing a plurality of spiral blades fixed on the inner wall of the anaerobic pool; each section of spiral channel is equipped with a penetrating channel for accommodating the stirring blades; a filtering screen is wrapped on the periphery of the membrane component; the filtering screen is of 30-50 meshes; the aperture of the filtering screen is 0.4-0.5mm; a backflow pipeline is arranged between the anaerobic pool and the aerobiotic pool; a suspended filler fills the aerobiotic pool; an ultrasonic generator is arranged on the side wall of the aerobiotic pool. The flat membrane bioreactor has a simple structure and is high in production efficiency.

Owner:JIANGSU LVYANG BIOLOGICAL ELECTRONICS ENG CO LTD

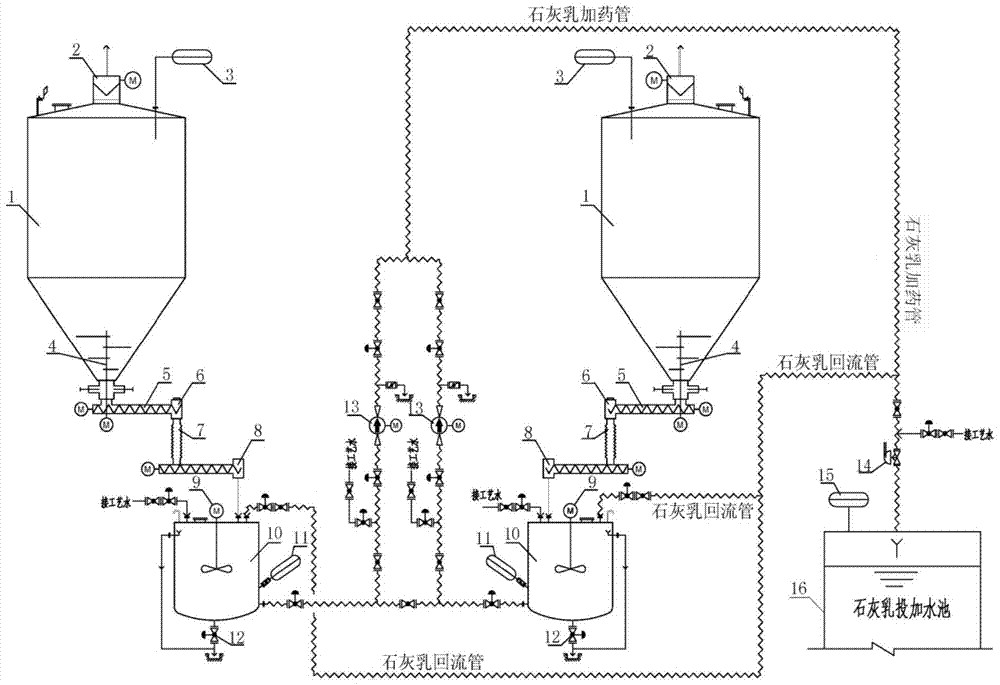

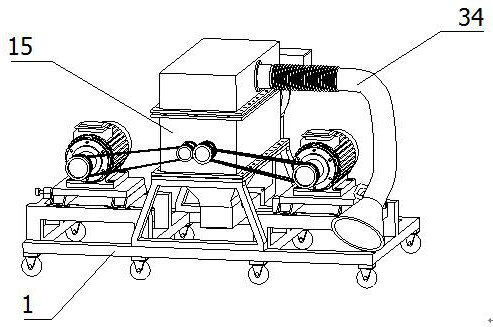

Slaked lime dosing system in a water treatment system

InactiveCN104986845BReduce labor intensityReduce fouling and cloggingWater/sewage treatment by neutralisationWater treatment systemPh control

A slaked lime dosing system in a water treatment system, including a lime powder silo, a feeder is installed at the outlet of the lower end of the lime powder silo, the feeder is connected to a metering conveyor, and the metering conveyor is connected to a dosing conveyor through a transparent material pipeline. The doser is connected with a milk of lime solution tank, which is equipped with an automatic sand discharge valve, and the milk of lime solution tank is connected with the milk of lime dosing pool through the milk of lime dosing pipe. In the present invention, since the pipeline of transparent material is used, the transportation and flow of materials can be observed in the whole process, and once a blockage is found, it can be unblocked in time and conveniently handled. Due to the automatic sand discharge valve, the sand can be automatically discharged at regular intervals; the labor intensity of workers and the problem of sedimentation and blockage caused by sand particles are reduced, and the concentration of lime agent prepared by the lime dosing device remains stable, with an error of no more than ±0.5%, which can ensure that the input Add point pH value control is precise, the error is not more than ± 0.3.

Owner:XIAN TPRI WATER & ENVIRONMENTAL PROTECTION

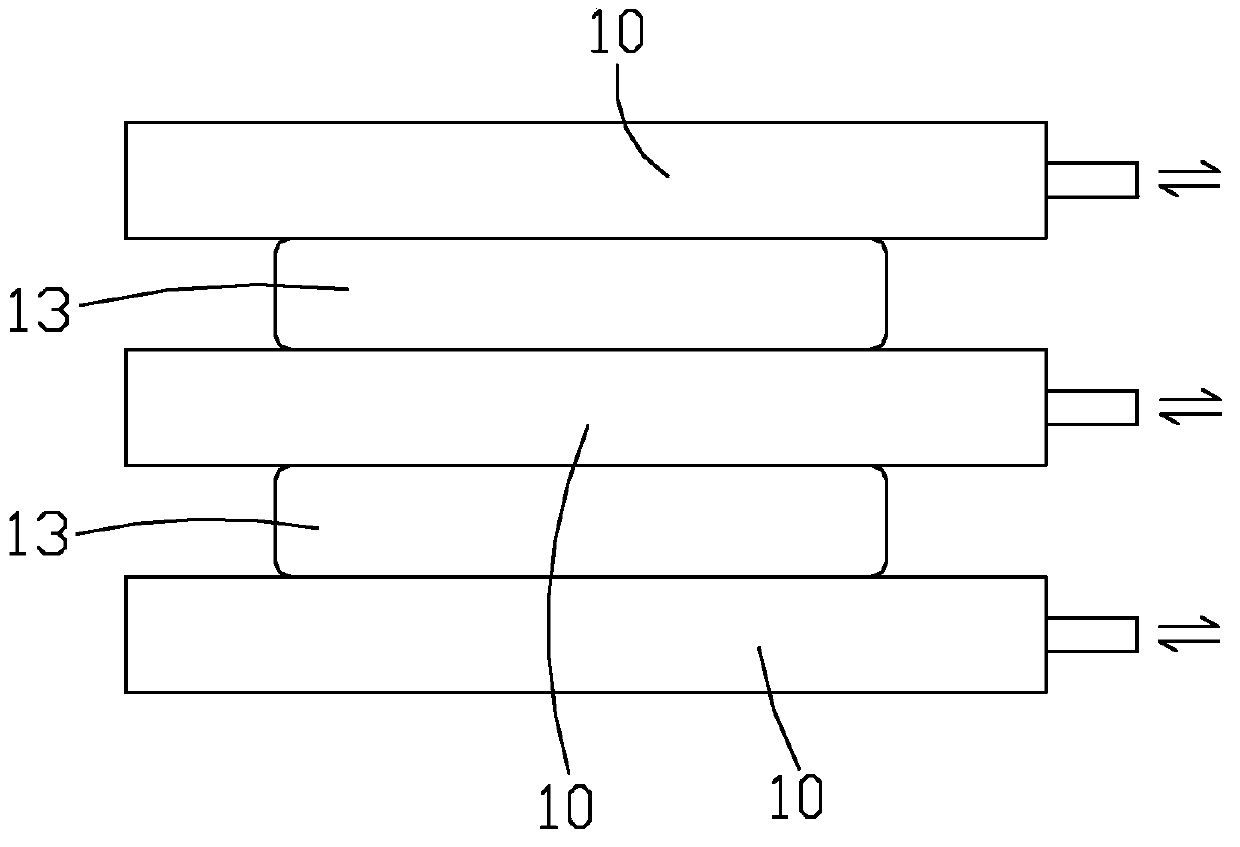

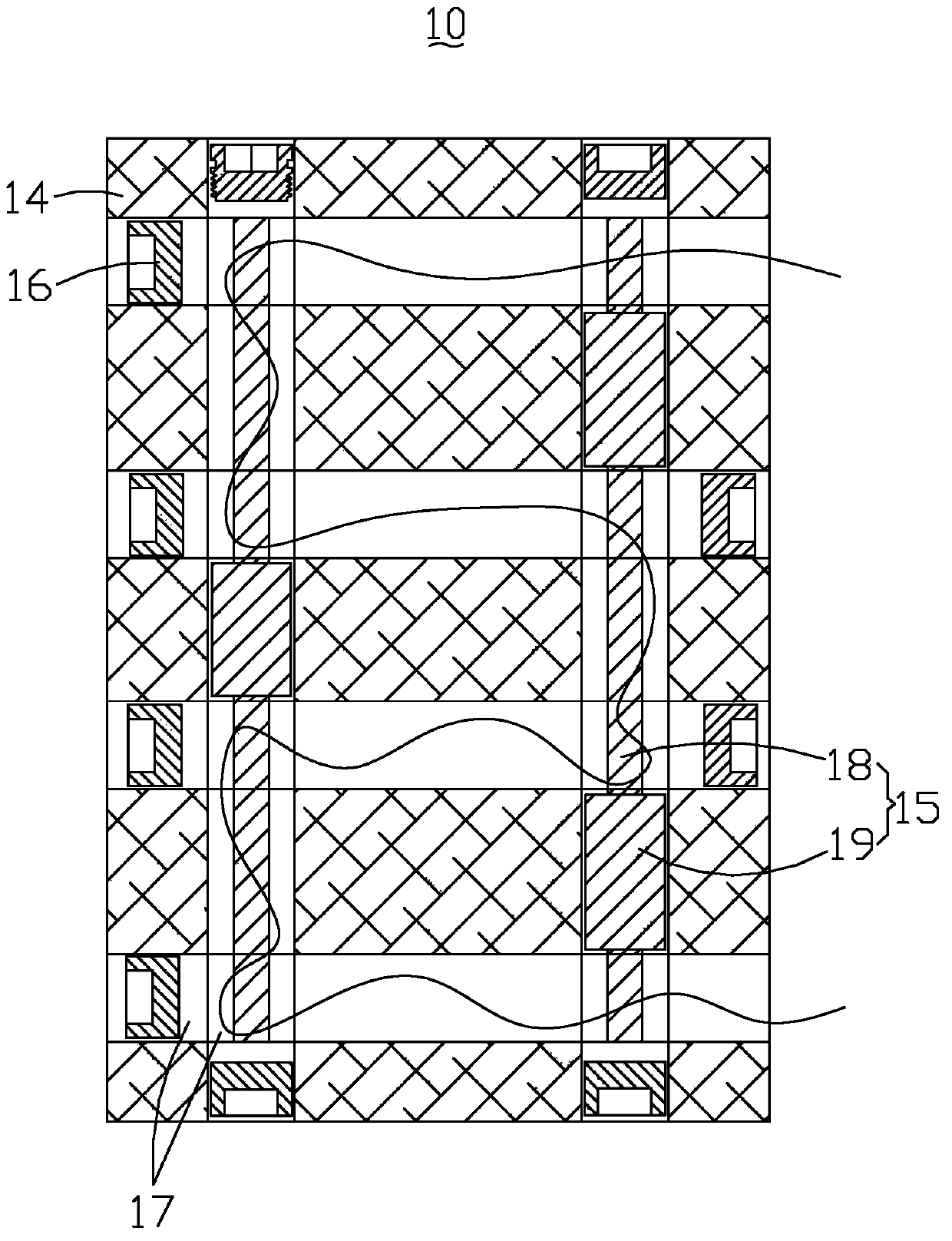

Heat exchange tray used for laminator

Owner:SHENNAN CIRCUITS

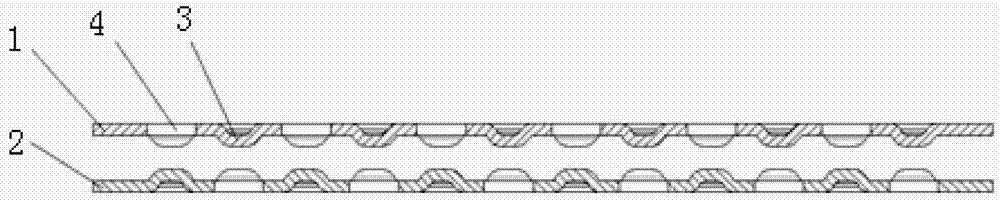

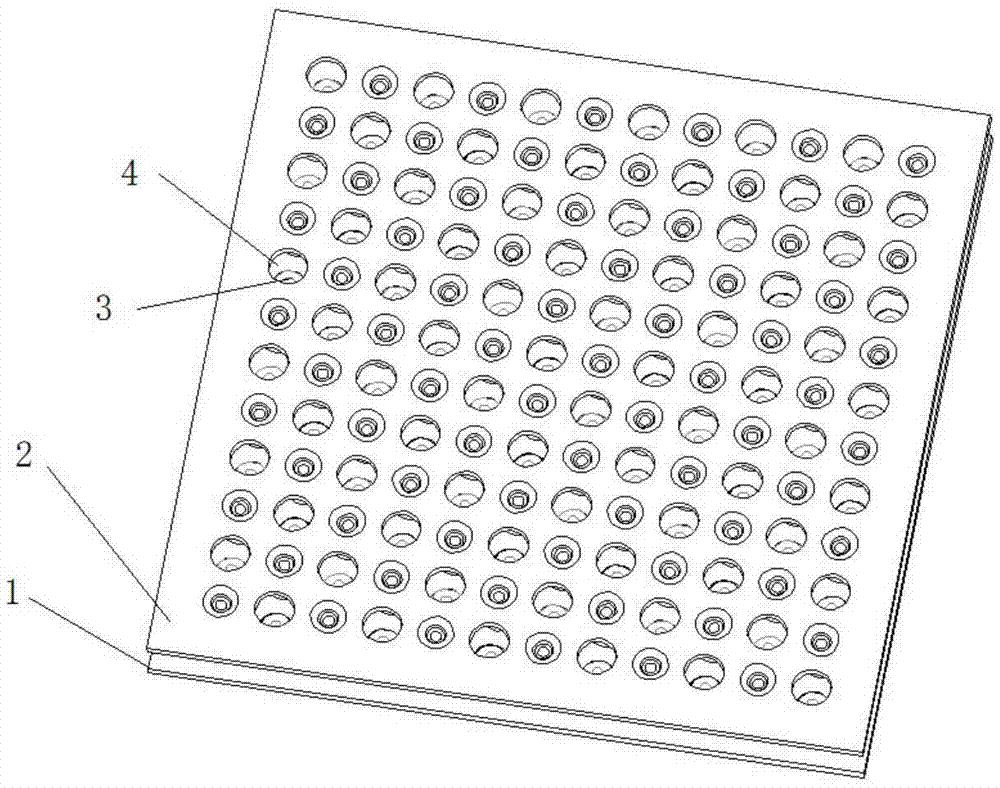

Dielectrophoresis electrode structure for emitting non-homogeneous electric field outwards

ActiveCN106925123AStrong dielectrophoretic forceReduce filter effectMembranesDispersed particle separationDielectrophoresisMaterials science

The invention relates to a dielectrophoresis electrode structure for emitting a non-homogeneous electric field outwards. The dielectrophoresis electrode structure is characterized by comprising a first electrode plate and a second electrode plate; columnar protrusions and hole sites are evenly distributed on the first electrode plate and the second electrode plate, and the positions of the columnar protrusions and hole sites of the first electrode plate and the positions of the column protrusion and hole sites of the second electrode plate are complementary; after the protruding faces, with the columnar protrusions, of the first electrode plate and the second electrode plate are oppositely buckled, the columnar protrusions of the first electrode plate are embedded into the hole sites of the other electrode plate; the first electrode plate and the second electrode plate are connected with different output ends of a high-frequency alternating current power source respectively, and acting faces for emitting the non-homogeneous electric field outwards are formed on the non-protruding faces of the first electrode plate and the second electrode plate. By means of the columnar protrusions on the electrode plates, the electric field can be emitted to the outside of the acting faces without being closed between the electrode plates, and therefore the dielectrophoresis effect is enhanced.

Owner:天津津盛远航知识产权运营管理有限公司 +1

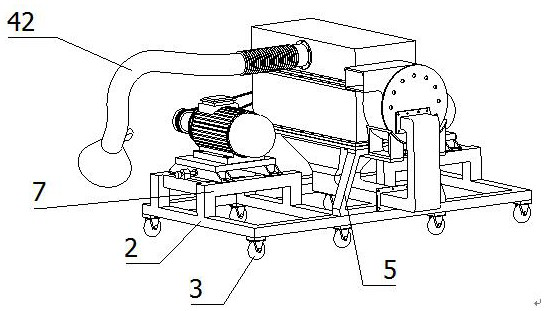

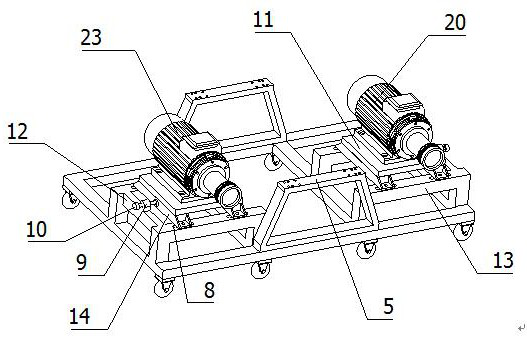

Silt suction device for municipal pipeline desilting

InactiveCN112227448AAchieve the effect of crushing garbageFlexible operationMechanical machines/dredgersGrain treatmentsWaste materialGeotechnical engineering

The invention relates to the technical field of pipeline desilting, in particular to a silt suction device for municipal pipeline desilting. The silt suction device comprises a bearing assembly, a crushing assembly and a silt suction assembly. The bearing assembly comprises a base and a supporting frame. The crushing assembly comprises a crushing device and a material collecting device. The silt suction assembly comprises a suction pipe and an air bellow. Crushed and cut silt is sucked into the air bellow and discharged through a silt discharging opening in one side of the air bellow, and dueto the crushing and silt suction design, cake and solid waste in the silt can be crushed conveniently, and silt blockage of a pipeline is reduced. By designing an adjustable silt suction head, silt suction at pipeline desilting dead corners is facilitated. By designing silt suction of a box body module, cleaning and maintenance of the interior of the device are facilitated, the risk of equipment silt solidification is reduced, silt suction in the pipeline desilting process is more convenient, and the silt suction effect in the pipeline desilting process is better.

Owner:石忠滚

Device for cleaning filtering cloth of belt press filter for alcohol mash

InactiveCN108607265AReduce fouling and cloggingAvoid damageMoving filtering element filtersAlcoholFilter press

The invention provides a device for cleaning filtering cloth of belt press filter for alcohol mash. The device comprises a roller with two ends for supporting the filtering cloth, a water spraying pipe is arranged on the filtering cloth, a three-way pipe is arranged at each of two ends of the water spraying pipe, and a gate convenient for dredging is mounted on each of the three-way pipes at two ends of the axial direction of the water spraying pipe; a system water incoming pipe is arranged at another through port of a three-way valve, a plurality of water spraying ports are formed in the water spraying pipe at intervals, diameter of each water spraying port is 2mm, and the water spraying pipe is a PVC water pipe. When the gate is opened, a cleaning head of a cleaning rod or cleaning wateris utilized to clean the water spraying pipe. The device has the advantages that one-way feeding of the water spraying pipe is changed into two-way feeding, and feeding direction is changed constantly, so that scaling, blocking and damaging of the water spraying ports of the water spraying pipe are reduced; the water spraying pipe is the PVC water pipe, so that cost can be reduced, and easiness in drilling is realized; by designing the gate, convenience is brought to cleaning, and cleaning can be realized by using the cleaning water or the cleaning head.

Owner:HUBEI JINGYUAN BIOTECH CO LTD

A kind of salt making method and salt making system

ActiveCN108726540BReduce foulingReduce fouling and cloggingSolution crystallizationHeat exchange cooling cystallizationSaline waterBuffer solution

The invention relates to the field of water treatment, and discloses a salt production method and a salt production system. The method comprises: (1) adding dianion salt crystal seeds to raw water to obtain a buffer solution; (2) cooling the buffer solution; 3) The cooled buffer solution is subjected to crystallization and separation treatment to obtain a divalent anion salt crystalline salt; the raw material water contains a divalent anion salt and an optional monovalent anion salt, and the mass concentration of the divalent anion salt in the raw material water is not less than the step ( 2) Saturation of the dianion salt at medium cooling temperature, the solubility of the dianion salt at 0-32.4°C decreases as the temperature decreases and the average solubility of the dianion salt in the range of 0-32.4°C decreases The rate is greater than 0.03g / °C. The method of the present invention can effectively slow down the fouling phenomenon in the tube side of the heat exchanger or on the wall of the heat exchanger during the cooling process of the high-concentration brine, and can obtain crystalline salt with high purity and large average particle size, which is beneficial to subsequent separation .

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

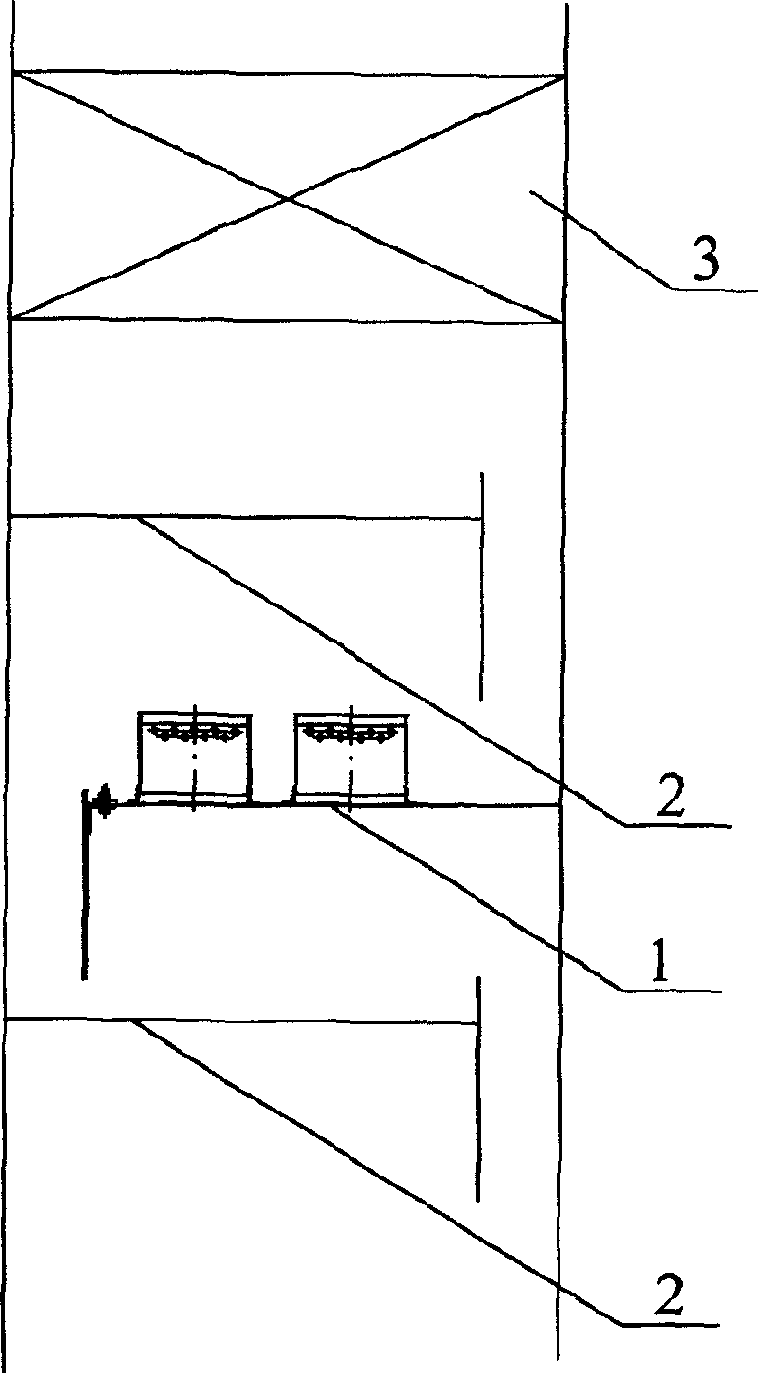

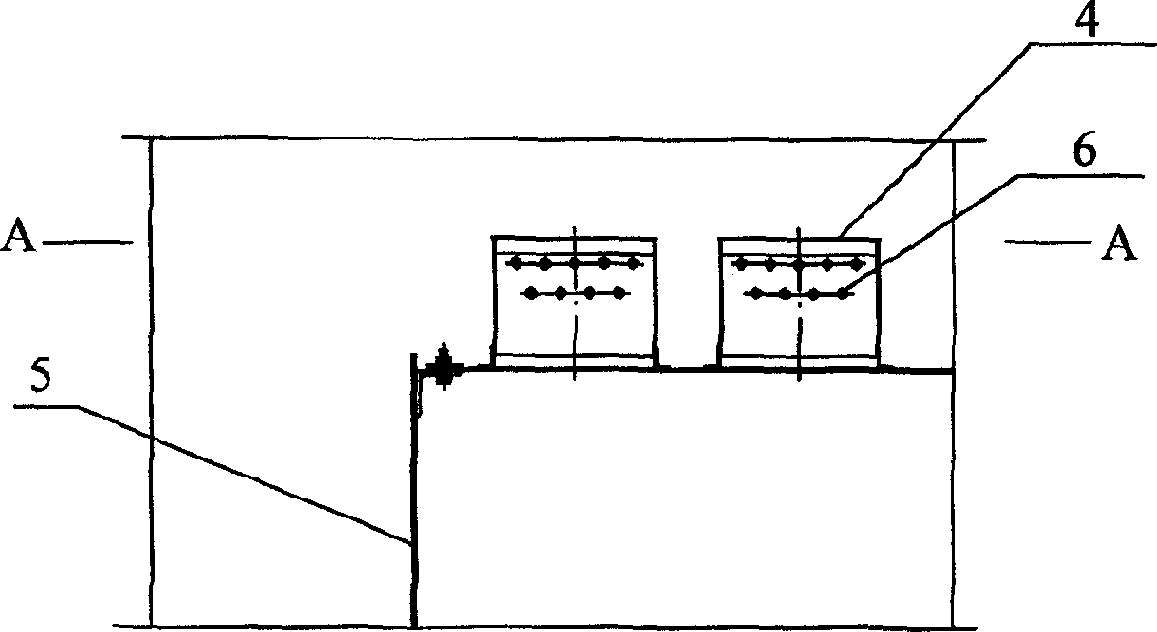

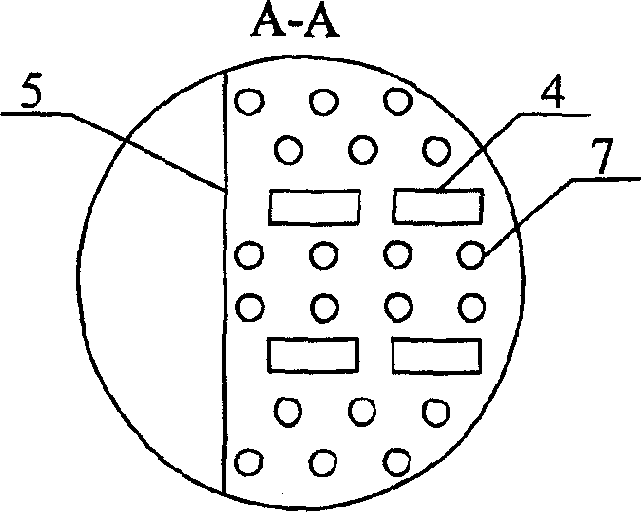

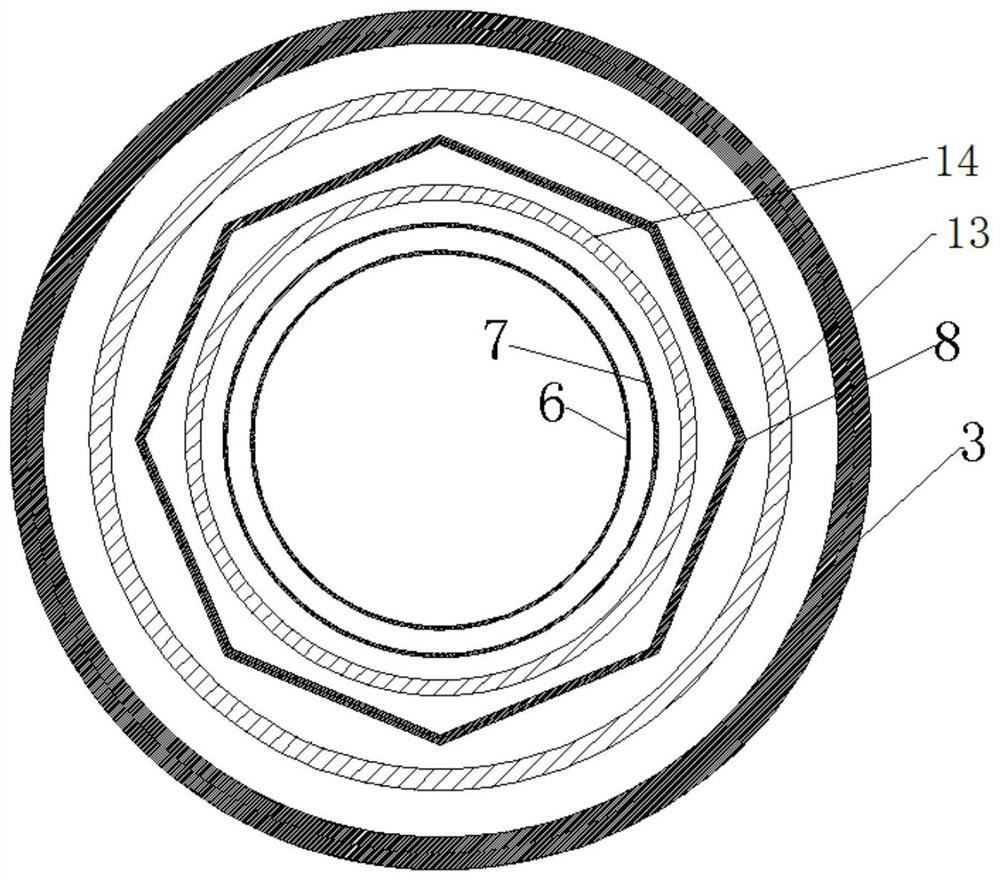

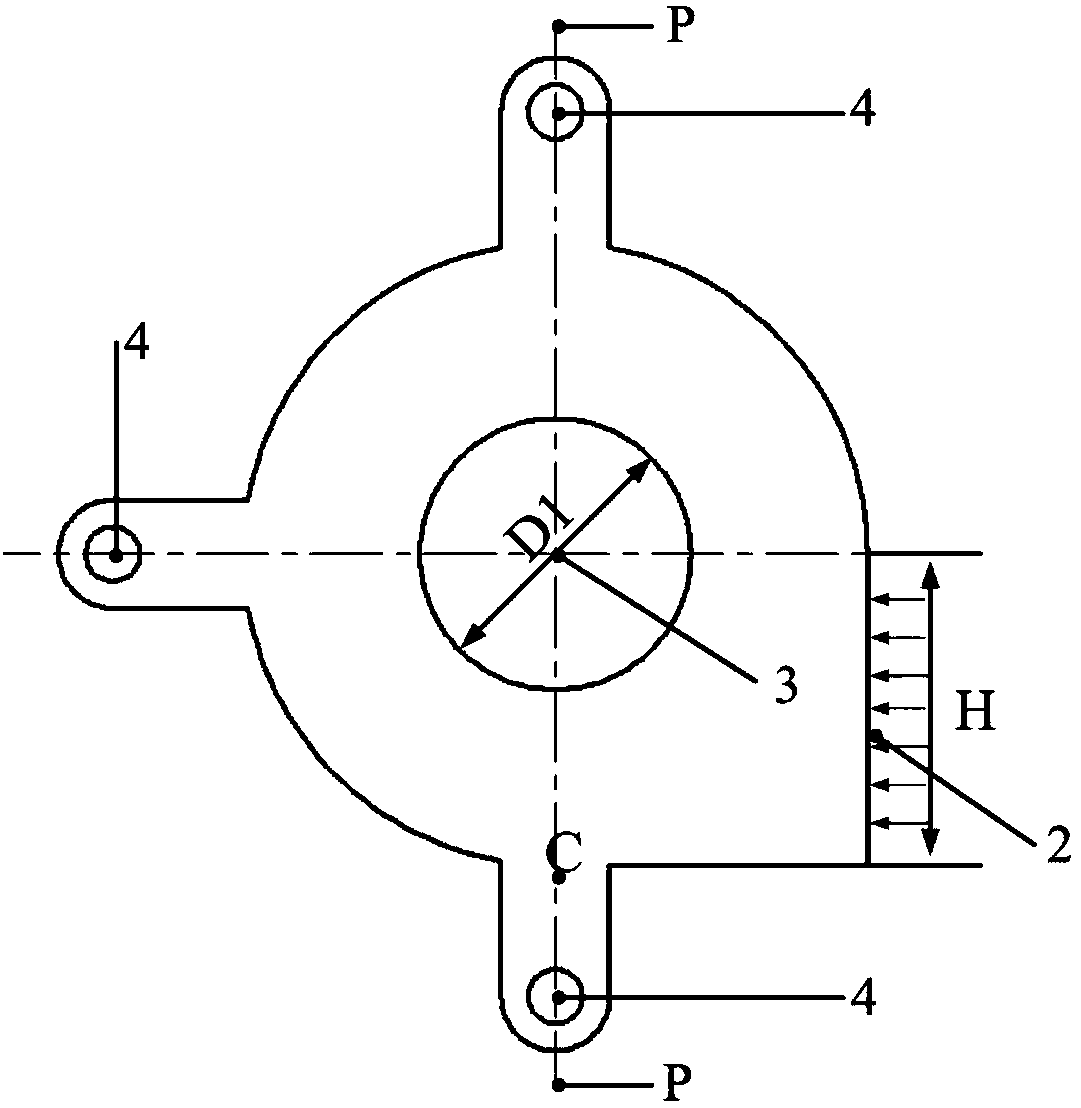

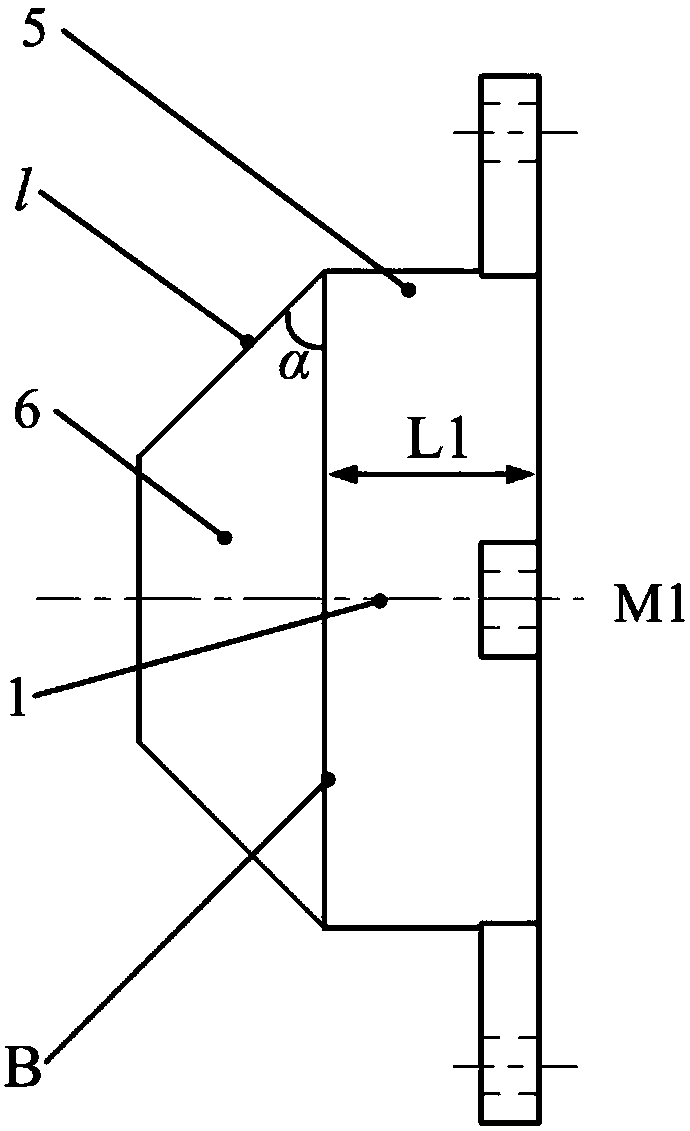

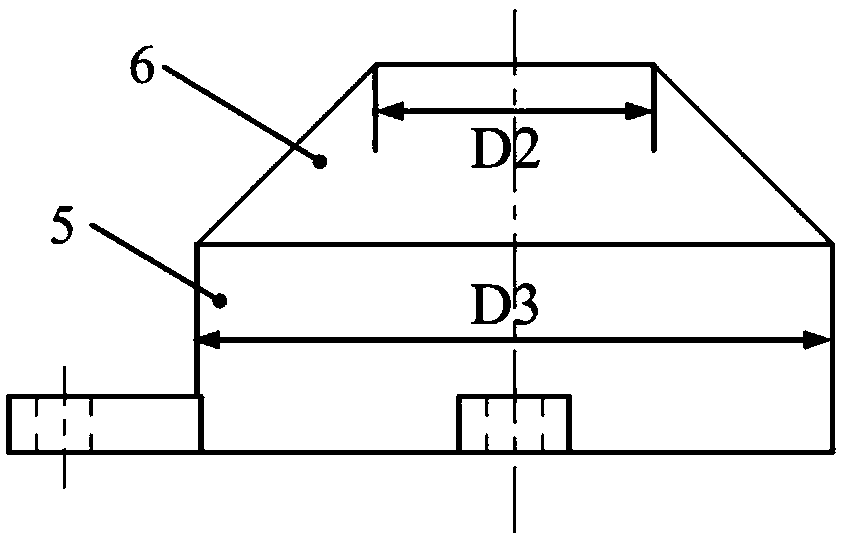

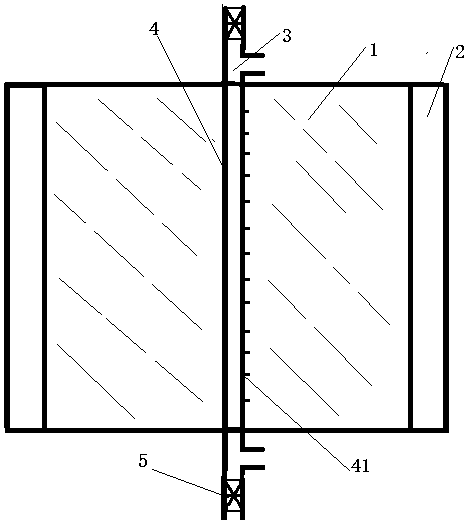

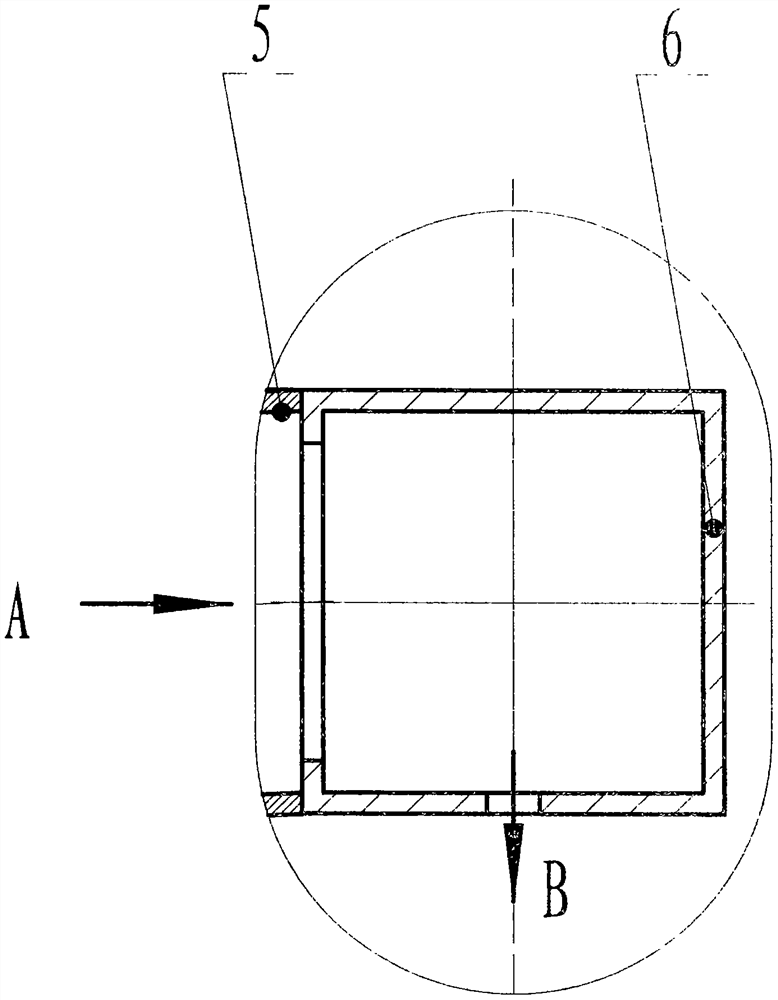

Integrated tower backwashing assembly

InactiveCN112620269AReduce fouling and cloggingHollow article cleaningIncreasing energy efficiencySludgeHigh pressure water

The invention discloses an integrated tower backwashing assembly. The integrated tower backwashing assembly is composed of a water inlet pipe (4), a water inlet transverse pipe (5) and a circumferential water spraying pipe (6), wherein small holes are drilled in the lower portion of the circumferential water spraying pipe; and the water inlet pipe, the water inlet transverse pipe and the circumferential water spraying pipe are welded into a whole, the water inlet transverse pipe (5) is welded to a sludge pipe (3), and the circumferential water spraying pipe (6) is welded to a flue inner wall (1). High-pressure water enters the circumferential water spraying pipe from the water inlet pipe A and is sprayed out from the small holes B in the lower portion of the circumferential water spraying pipe, and sludge on a damping pore plate assembly is flushed into the sludge pipe.

Owner:江苏华东正大空调设备有限公司

Efficient inhibitor for cracking gas alkali washing operation polymerization reaction

PendingCN114751803APolymerization is effectively inhibitedReduce fouling and cloggingDispersed particle separationHydrocarbonsKetoneSolvent

The invention discloses a high-efficiency inhibitor for cracking gas alkali washing operation polymerization reaction, the inhibitor contains a synergist, the synergist is gamma-valerolactone, and the addition amount is 0.5-3 wt%. The inhibitor also contains a polymerization inhibitor, an antioxidant, a metal ion passivator, a dispersant and a solvent. The inhibitor comprises the following components in percentage by mass: 1 to 15 percent of polymerization inhibitor and antioxidant, 1 to 25 percent of polymerization inhibitor and solvent, 1 to 20 percent of dispersing agent and polymerization inhibitor, and the mass ratio of synergist to metal ion passivator to dispersing agent to solvent is (0.1 to 3): (1 to 50): (1 to 50): (1 to 100). The high-efficiency inhibitor for the cracking gas alkali washing operation polymerization reaction can effectively inhibit the polymerization reaction of trace carbonyl compounds such as aldehyde, ketone and alcohol, unsaturated olefin and the like in cracking gas in an alkali washing tower, and can dissolve generated butter polymers, so that the generated bulk polymers are dispersed and dissolved in alkali liquor to be discharged, and the polymerization reaction of the cracking gas alkali washing operation is realized. And the scaling blockage of the butter polymer on the packing of the alkaline washing tower is effectively reduced.

Owner:PETROCHINA CO LTD

Flue gas desulfurization synergist and using method thereof

InactiveCN102091510BImprove solubilityReduce consumptionDispersed particle separationInorganic saltsSulfosuccinic acid

The invention discloses a flue gas desulfurization synergist which comprises the following components in percent by weight: 30-80 percent of diacid, 5-30 percent of inorganic salt and 1-50 percent of wetting agent. A using method of the flue gas desulfurization synergist is characterized by comprising the steps of: firstly, preparing lime into lime slurry of 50-300PPm, adding 300-1000mg / L of gas desulfurization synergist in the lime slurry, mechanically stirring uniformly, and then pumping the lime slurry added with the gas desulfurization synergist into a desulfuration reaction tower by using a lime slurry pump. By using the gas desulfuration synergist, the desulfuration efficiency is improved by 5-15 percent, the consumption of limestone is reduced, the scale formation and the blockage of equipment are reduced, and the operation electric energy is saved.

Owner:马鞍山市鸿伟环化有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com