Electroplating comprehensive wastewater zero-discharge treatment system and process thereof

An electroplating integrated and treatment system technology, applied in the field of electroplating integrated wastewater treatment system with zero discharge, can solve the problems of fouling and clogging of the evaporation system, high cost of hazardous waste disposal, and increase the burden on enterprises, so as to reduce fouling, clogging and cost. low, improved evaporation and crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

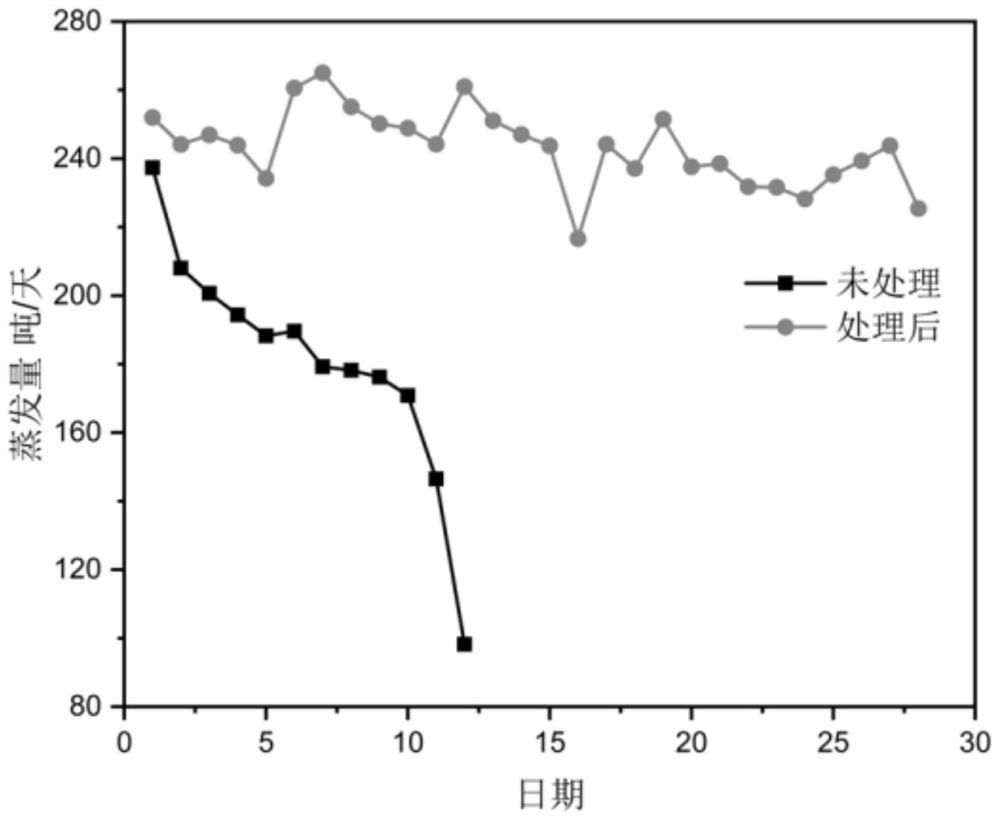

Embodiment 1

[0039] Step 1: Collect the electroplating integrated wastewater, the PH value of the comprehensive wastewater is 12, the conductivity is 12870 μS / cm, the content of iron ions is 1.2mg / L, the content of copper ions is 1.6mg / L, the content of nickel ions is 1.5mg / L, the content of chromium ions is 529mg / L, and the content of zinc ions is 9500mg / L; COD is 8650mg / L, ammonia nitrogen is 25mg / L, turbidity is 18NTU;

[0040] Step 2: Add 30% hydrochloric acid to the wastewater to adjust the PH value of 8.5, add heavy metal ion trap and flocculant PAM, precipitated sludge with plate and frame filter press filter press, to obtain the filter cake, iron, copper, nickel, chromium, zinc and other heavy metal ions in the wastewater and some organic matter present in the filter cake; The coD of the supernatant and filtrate after physicochemization is 2050mg / L, the ammonia nitrogen is 46mg / L, and the turbidity is 10NTU;

[0041] Step 3: The physicochemical supernatant and filtrate are entered into t...

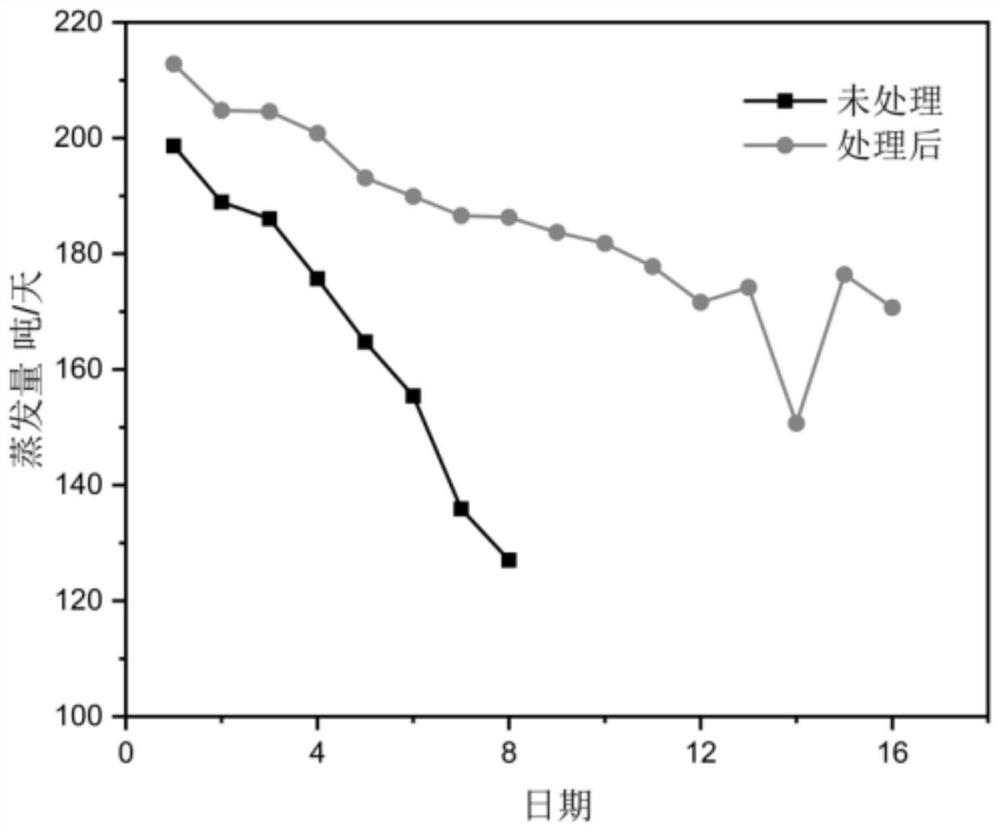

Embodiment 2

[0053] Step 1: Collect the electroplating integrated wastewater, the PH value of the comprehensive wastewater is 2.3, the conductivity is 35800μS / cm, the content of iron ions is 21000mg / L, the content of copper ions is 8500mg / L, the content of nickel ions is 1560mg / L, the content of chromium ions is 83mg / L, and the content of zinc ions is 9500mg / L; COD is 7580mg / L, ammonia nitrogen is 25mg / L, turbidity is 17NTU;

[0054]Step 2: Add 30% hydrochloric acid to the wastewater to adjust the PH value of 8.5, add heavy metal ion trap and flocculant PAM, precipitated sludge with plate and frame filter press filter press, to obtain the filter cake, iron, copper, nickel, chromium, zinc and other heavy metal ions in the wastewater and some organic matter present in the filter cake; The coD of the supernatant and filtrate after physicochemization is 1560mg / L, the ammonia nitrogen is 65mg / L, and the turbidity is 12NTU;

[0055] Step 3: The filtrate is entered into the biochemical system, and af...

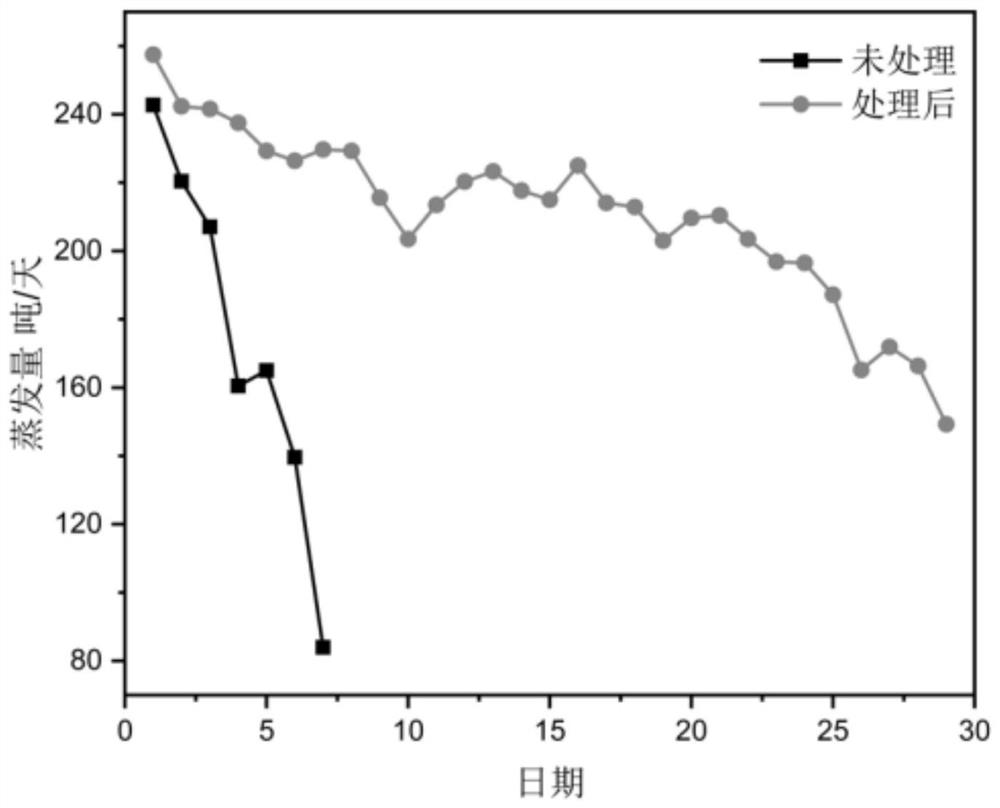

Embodiment 3

[0067] Step 1: Collect the electroplating integrated wastewater, the PH value of the comprehensive wastewater is 3.8, the conductivity is 25500μS / cm, the content of iron ions is 3560mg / L, the content of copper ions is 1690mg / L, the content of nickel ions is 3670mg / L, the content of chromium ions is 95mg / L, and the content of zinc ions is 4580mg / L; COD is 9650mg / L, ammonia nitrogen is 18mg / L, turbidity is 26NTU;

[0068] Step 2: Add 30% hydrochloric acid to the wastewater to adjust the PH value of 8.5, add heavy metal ion trapping agent and flocculant PAM, press the filter with a plate and frame filter press to obtain filtrate and filter cake; the COD of the filtrate is 2950mg / L, the ammonia nitrogen is 18mg / L, and the turbidity is 22NTU; Most of the heavy metal ions such as iron, copper, nickel, chromium, zinc and some organic matter in the wastewater are present in the filter cake;

[0069]Step 3: The filtrate is entered into the biochemical system, and after aerobic, anaerobic a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com