Device for cleaning filtering cloth of belt press filter for alcohol mash

A belt filter press and cleaning device technology, applied in the direction of moving filter element filters, filtration separation, separation methods, etc., can solve the problems of difficulty in ensuring sludge dewatering effect, damage, and expensive nozzles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

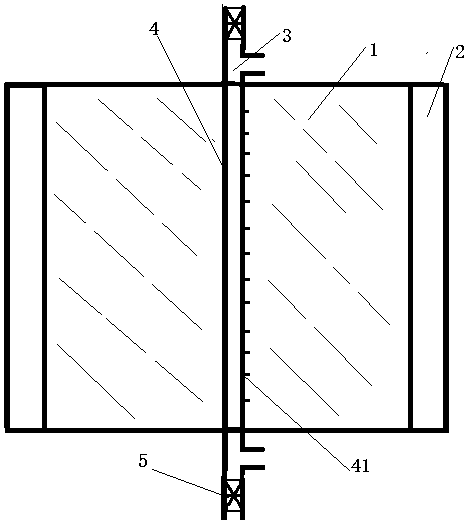

[0012] see figure 1 , the two rollers 2 of the belt filter press tension and run the filter cloth 1; the water spray port 41 of the PVC pipe 4 sprays the circulating water in the system to the filter cloth 1 to clean the filter cloth 1; at the same time, the sewage enters Cesspool.

[0013] The two ends of the PVC pipe 4 are equipped with three-way valves, and the two ports along the direction of the pipe axis are respectively provided with a gate 5, and the other nozzle is a water inlet; the gate 5 is in a closed state when the water spray pipe is cleaned. When the pipe is blocked or needs to be cleaned, the gate 5 is opened, and a cleaning rod with a cleaning head is used to move back and forth in the water spray pipe for cleaning. Also can clean PVC pipe 4 at gate 5 (being the other end of water inlet pipe) reverse flushing.

[0014] The design of the gate 5 can eliminate the need to place the cleaning rod in the PVC pipe 4 to affect the water velocity.

[0015] The nozz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com