Integrated tower backwashing assembly

A technology of backwashing and components, which is applied in the direction of furnace components, cleaning hollow objects, waste heat treatment, etc., and can solve the problems of affecting the performance of the environmental protection tower, easy fouling and clogging, and difficult cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

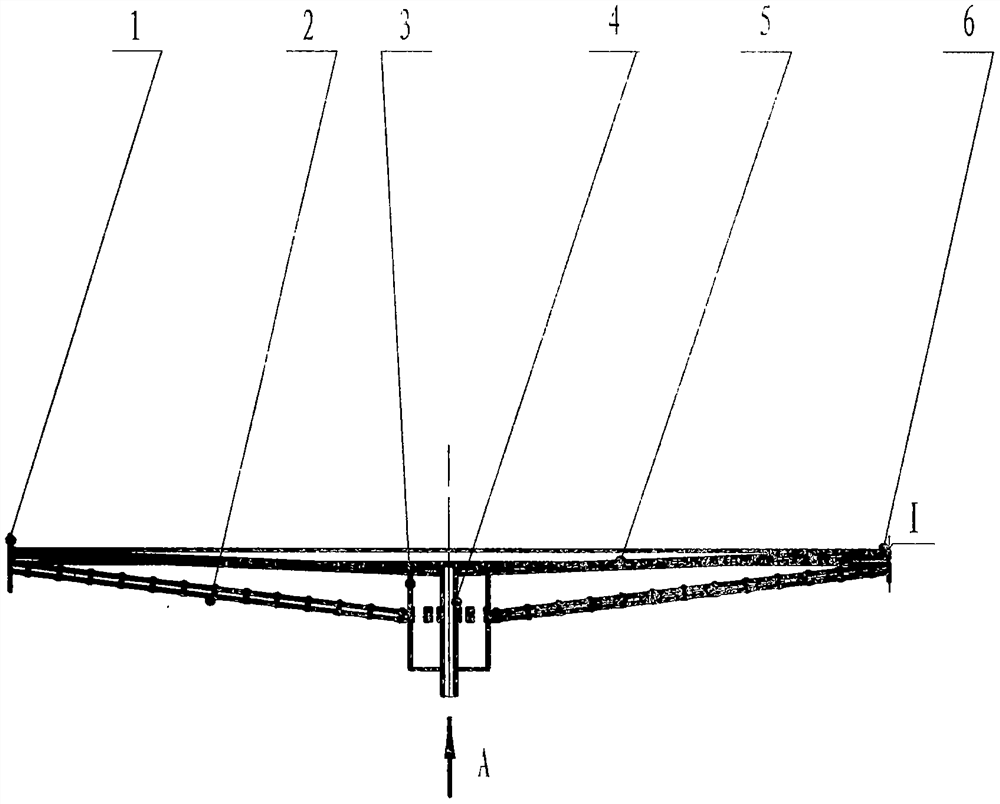

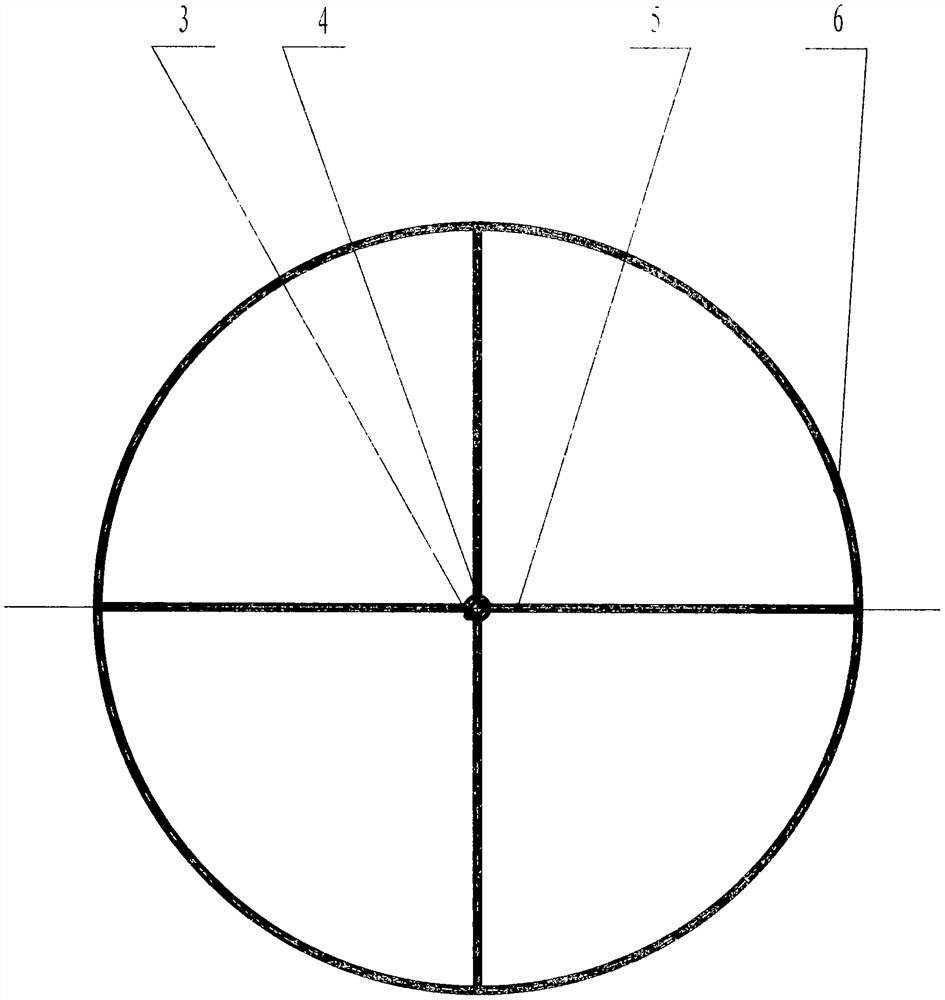

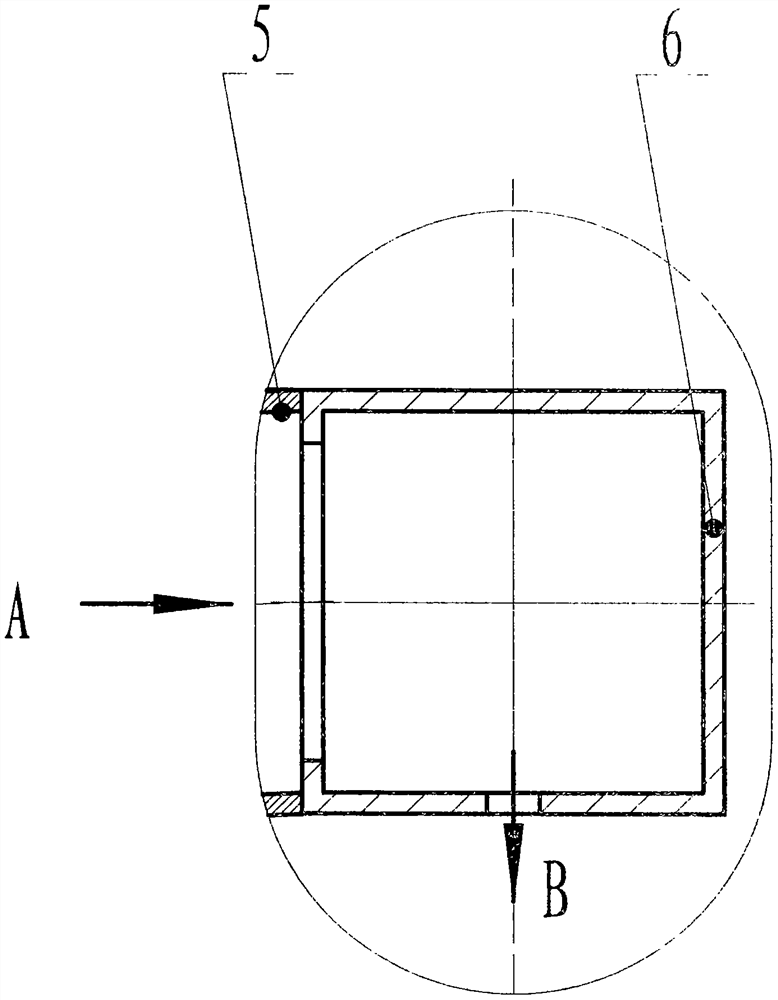

[0011] Below in conjunction with accompanying drawing, the present invention will be further described: the object of the present invention is achieved in that a kind of integrated tower backwash assembly is made up of water inlet pipe (4), water inlet horizontal pipe (5) and circumferential spray pipe (6) , the lower part of the circumferential water spray pipe is drilled with small holes, the water inlet pipe, the water inlet horizontal pipe and the circumferential water spray pipe are welded into one, the water inlet horizontal pipe (5) is welded on the sludge pipe (3), and the circumferential pipe is welded on (6 ) on the inner wall (1) of the flue; high-pressure water enters the circumferential pipe from the water inlet pipe A and sprays out from the small hole B at the lower part of the circumferential water spray pipe to flush the sludge on the damping orifice assembly into the sludge pipe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com