Method and device for preparing sodium nitrite by utilizing mother solution

A technology of sodium nitrite and mother liquor, which is applied in the preparation of alkali metal nitrate, etc., to achieve the effect of improving service life, increasing output and reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

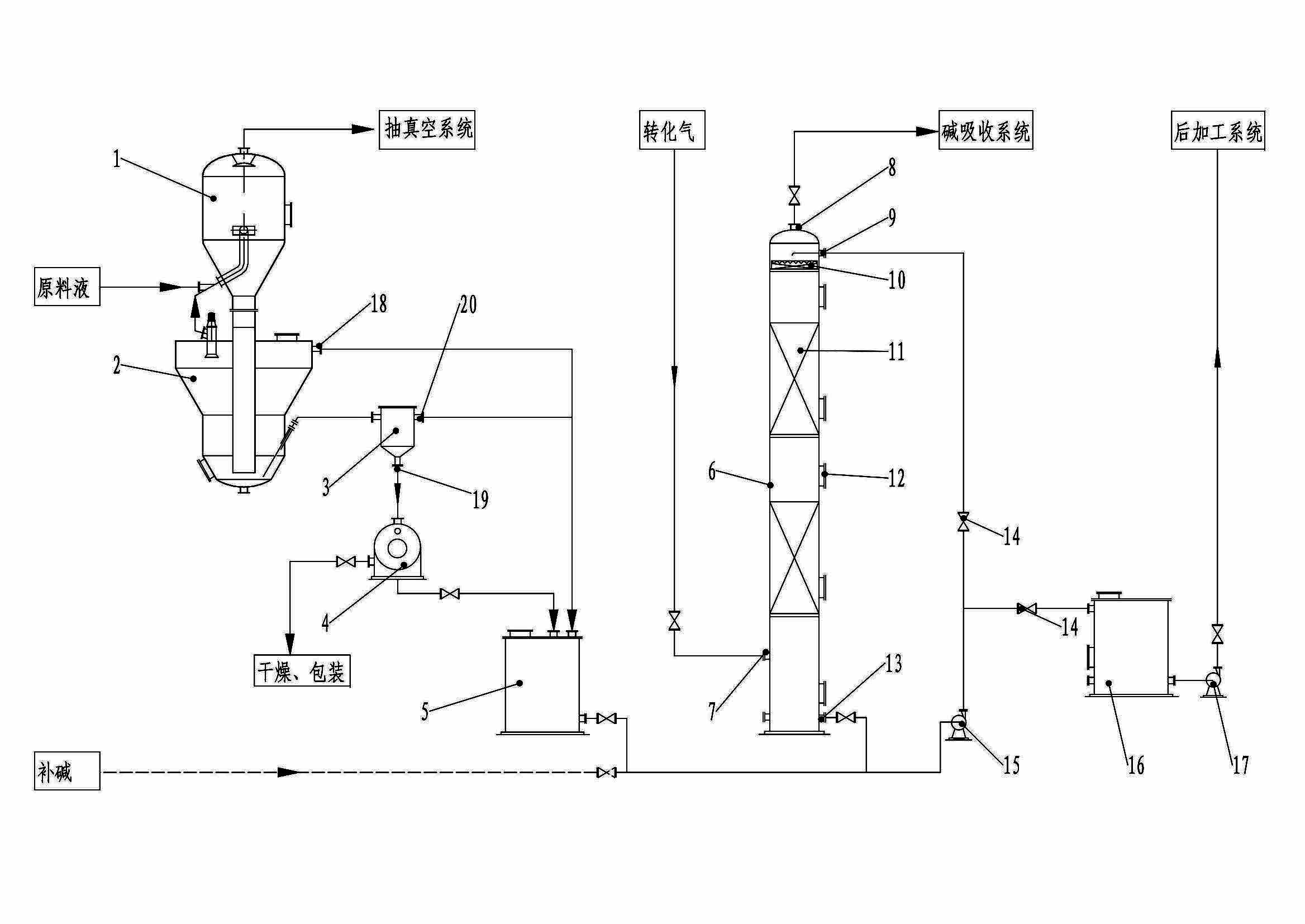

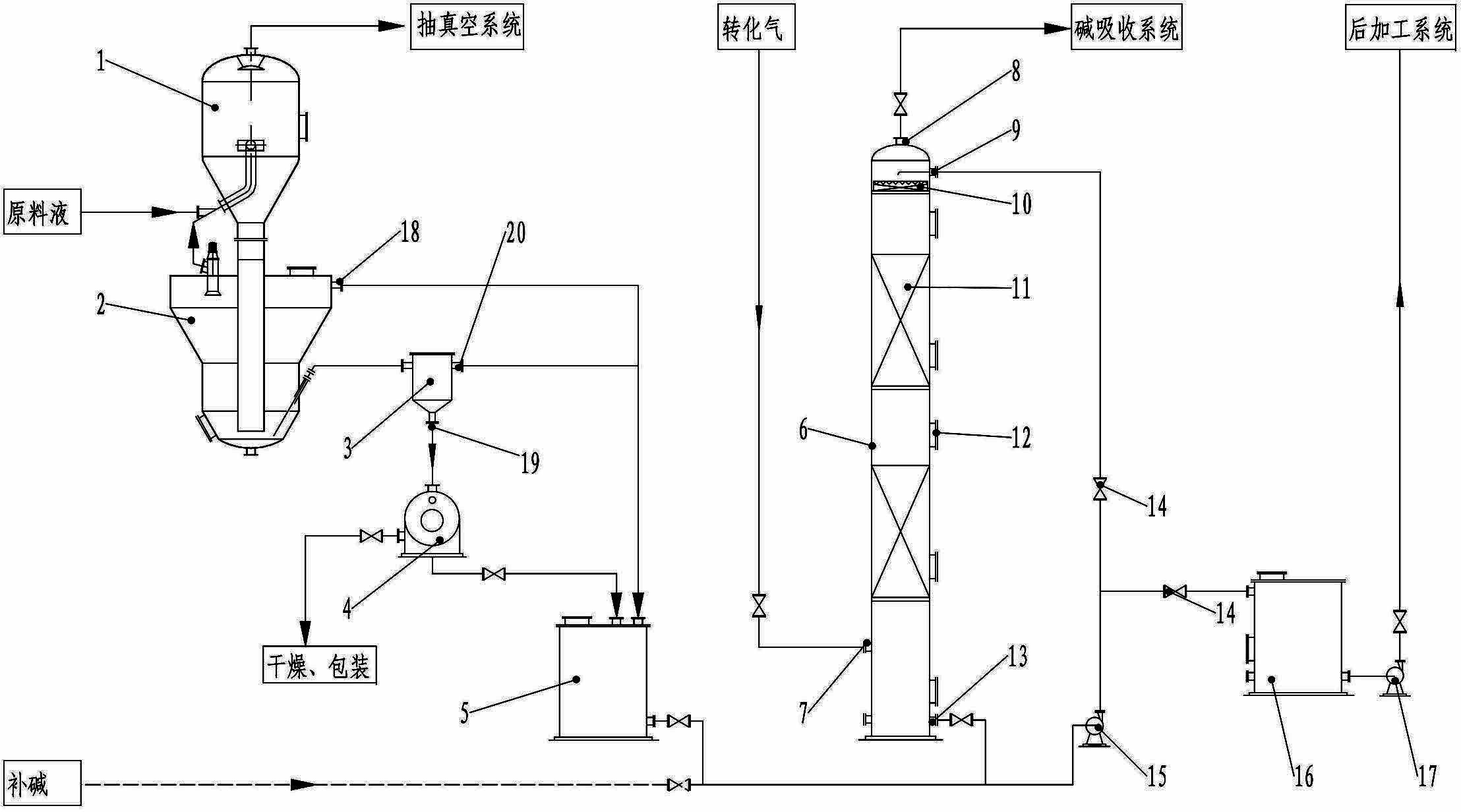

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

[0017] The present invention utilizes mother liquor to prepare the device of sodium nitrite such as figure 1 As shown, it includes a crystallizer 2, a thickener 3, a centrifuge 4, a mother liquor tank 5, a mother liquor absorption tower 6, a circulation pump 15 and a storage tank 16. The upper part of the crystallizer is equipped with a flash chamber 1, the raw material liquid pipeline is connected to the feed inlet of the flash chamber, the gas outlet at the top of the flash chamber is connected to the vacuum system, and the flash chamber and the lower evaporator have a raw material liquid connection path . The crystallization solution outlet 19 of the crystallizer is connected to the centrifuge through the thickener 3, and the mother liquor outlet of the centrifuge is connected to the mother liquor tank. The crystallizer overflow outlet 18 and the thickener overflo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com