Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

251results about How to "Improve raw materials" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

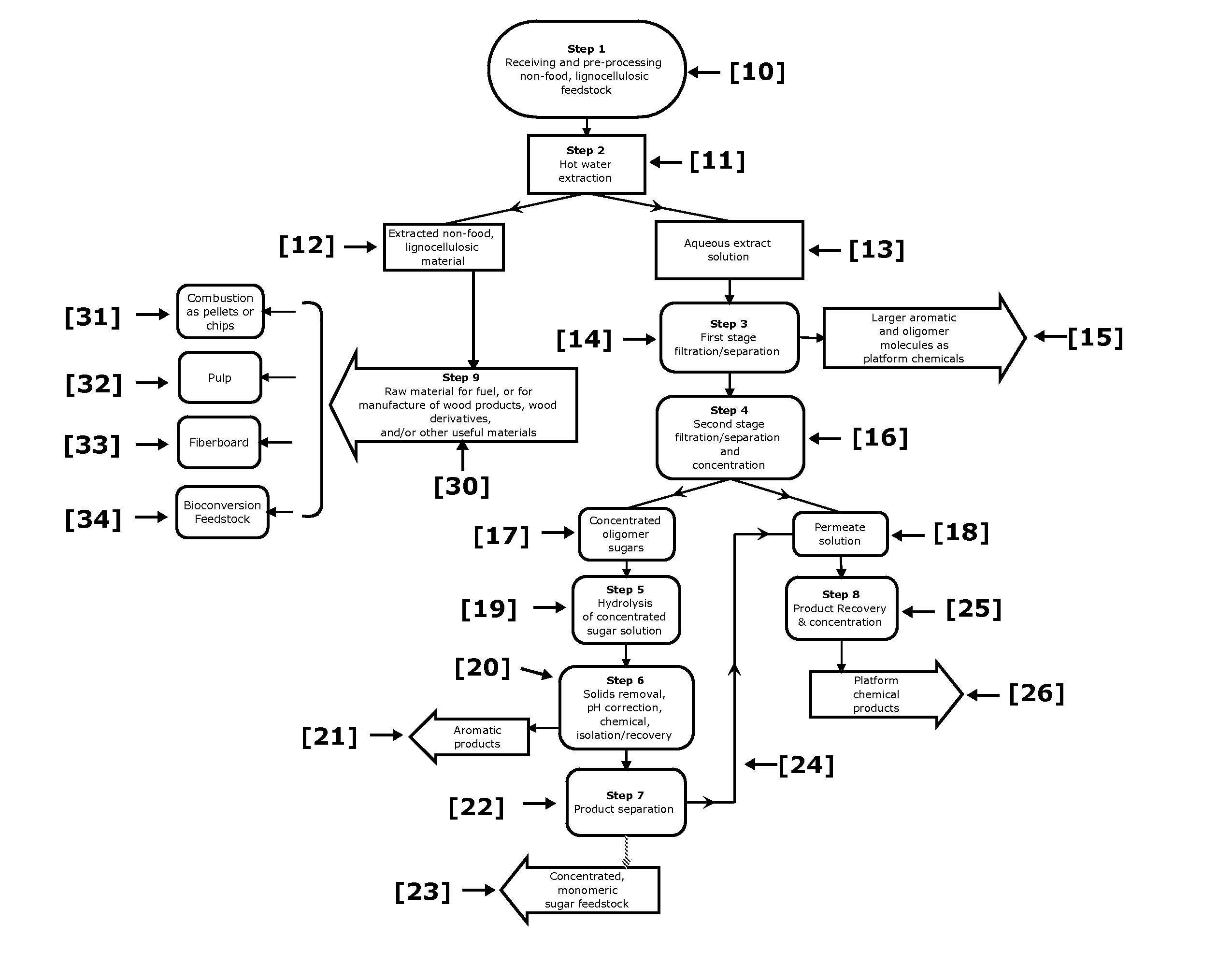

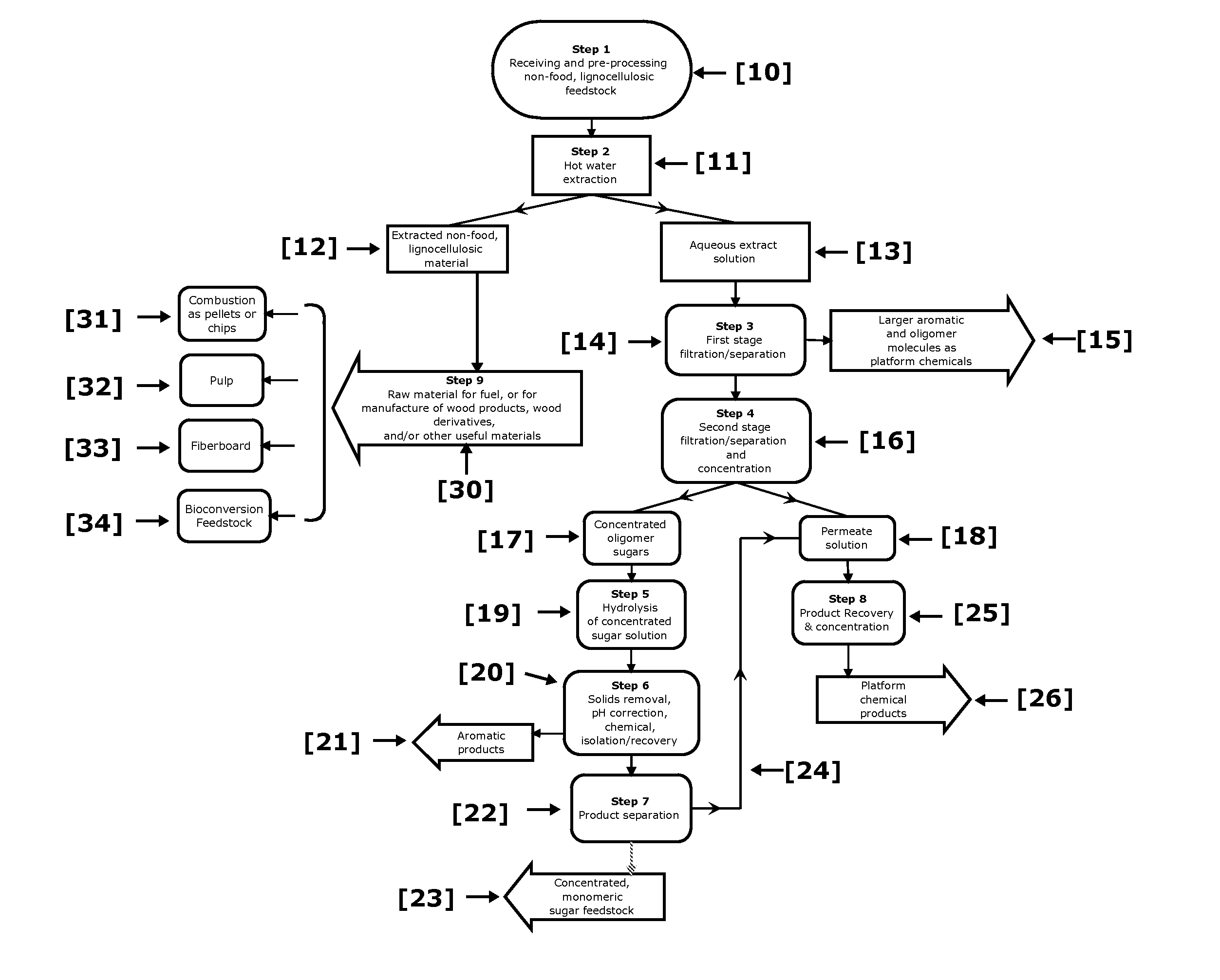

Biorefinery Process for Extraction, Separation, and Recovery of Fermentable Saccharides, other Useful Compounds, and Yield of Improved Lignocellulosic Material from Plant Biomass

ActiveUS20110129886A1Increase diversityIncrease probabilityCellulosic pulp after-treatmentBiofuelsFurfuralAqueous extract

Non-food plant biomass is subjected to hot-water extraction in a pressurized vessel at an elevated temperature up to about 250° C. and at a pH below about 7.0, to yield an aqueous extract containing hemicellulosic components, other wood-derived compounds, and a lignocellulosic residue. The separated aqueous extract or liquor is purified and concentrated through a multi-step process producing fermentable sugars. At each stage, inhibitory chemicals such as acetic acid, lignin, and furfural are separated and eventually recovered as commercial chemicals. The lignocellulosic residue may be further processed, as a material with enhanced resistance to sorption of water, for manufacture of improved pulp and paper, construction materials, pellet fuel, and / or other useful products.

Owner:APPLIED BIOREFINERY SCI

Production of biological diesel oil

InactiveCN1940021AReduce processReduce operating costsLiquid hydrocarbon mixture productionBio-feedstockOil and greaseAlcohol

Production of biological diesel oil is carried out by taking oily microbial as raw material, taking low-carbon alcohol as ester exchange agent, taking inorganic acid as catalyst, transfer esterification reacting, cooling reactive mixture, filtering, and liquid-phase purifying to obtain the final product. It's cheap and convenient.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

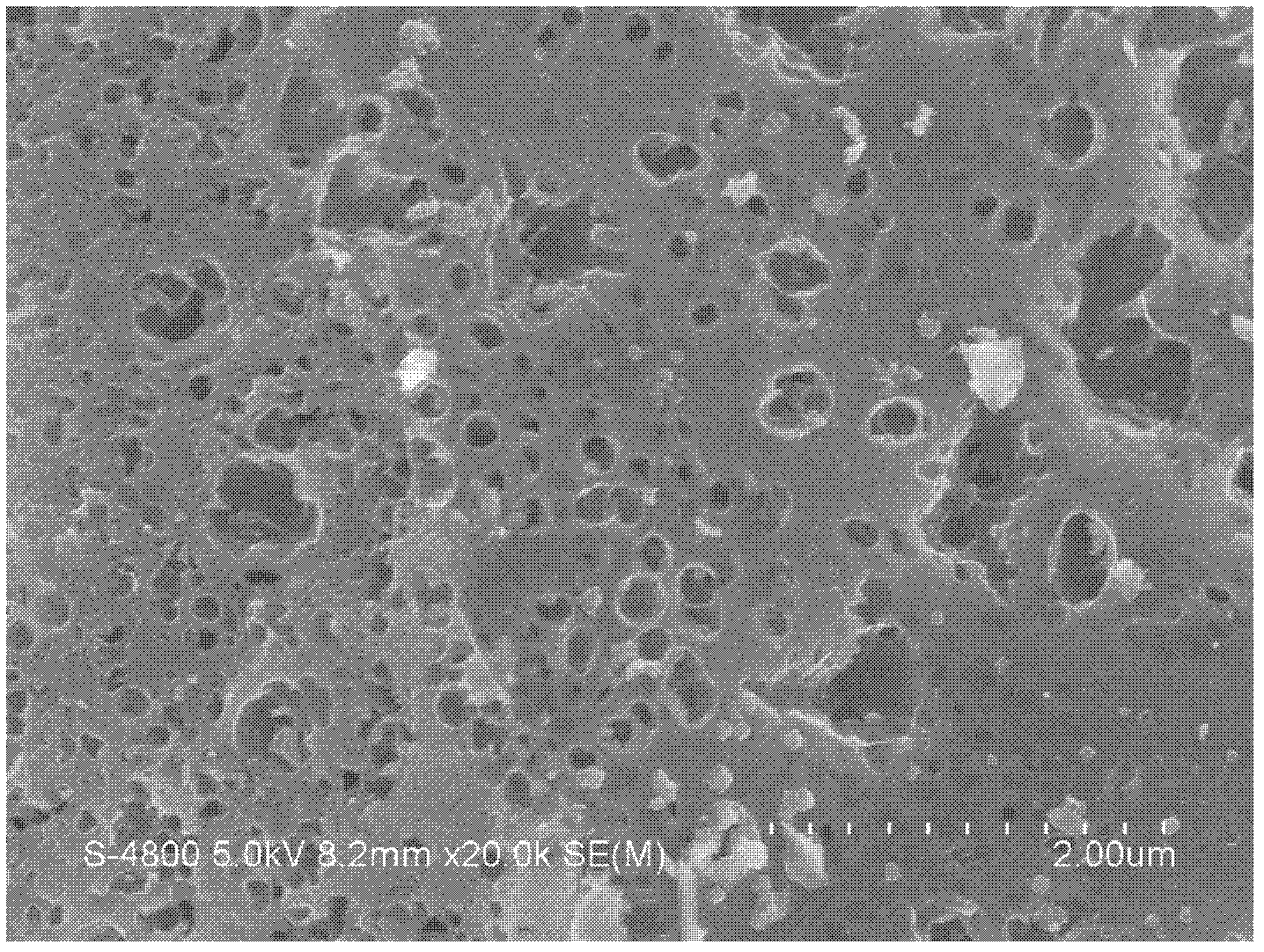

Preparation method of N (nitrogen)-enriched activated carbon electrode

InactiveCN102360959AReduce processing costsImprove raw materialsElectrolytic capacitorsHybrid/EDL manufactureActivated carbonAfter treatment

The invention provides a preparation technology of an N (nitrogen)-enriched activated carbon electrode, and belongs to the technical field of chemical processing of forestry biomass resource. In the preparation technology, N-enriched activated carbon-an electrode material used for an electric double layer capacitor (EDLC) as a new energy is prepared from waste artificial boards containing amino resin through carbonization, activation and after-treatment processes. The preparation technology has the following advantages: 1. the waste artificial boards are taken as raw materials to be prepared into the N-enriched activated carbon electrode, thus the method is simple and the cost is low; and 2. the waste artificial boards are taken as the raw materials, which is beneficial for cyclic utilization of wooden resource and meanwhile lowers the disposal expense of environmental rubbish.

Owner:BEIJING FORESTRY UNIVERSITY

Consumer virus eradicator

InactiveUS20080093210A1Enhance activitySimple constructionGas treatmentDispersed particle separationPathogenUltraviolet

Real time purification of contaminated common air is an unsolved consumer health problem inside residences and the workplace, and outside air pollution by industry and transportation. Currently popular consumer grade electrostatic air filters accumulate suspended contaminants onto accumulation plates which require subsequent disposal or cleaning of the highly concentrated contaminates, a maintenance requirement that creates new jeopardy to consumer health. Disclosed are a method and apparatus with several embodiments that structurally eradicate suspended particulates after they have been electrostatically migrated to a hollow, activated dismantling rod. The dismantling rod is typically composed of a durable, UV transmitting material, such as tetrafluoroethylene, or a current carrying metal mesh coated with tetrafluoroethylene, and further over-coated with active photocatalytic material that is energized to create on its surface powerful dismantling agents, including hydroxyl radicals, from natural ambient air elements. Microorganisms, smoke particles, industrial pollutants, odor molecules, and allergens are structurally dissociated into harmless protein fragments and natural molecules when they encounter the dismantling grid purifying agents. The decontamination phenomenon is amplified by imparting, or enhancing, either a negative or positive electrostatic charge to the suspended particles, as they enter the device, and using that to migrate the particles to the activated dismantling rod containing an internal, oppositely charged attraction screen. The method can be used to eradicate particles, including lethal pathogens, that may have a naturally occurring negative, positive, or electroneutral charge. Both contaminants and suspended water molecules are drawn to the dismantling rod in this manner, providing an enhanced supply of raw material from which the decontaminating agents are created. Any trace amounts of ozone molecules produced during the process are also attracted and dissociated back to oxygen within the device. The permanent photocatalytic coating does not require renewal or cleaning, and is designed to use UV energy in a bandwidth that also physically inactivates the replication defenses of passing microorganisms until they can be dismantled, whether in the first pass on during a subsequent air exchange pass. None of the powerful dismantling agents escape the device because of their short half lives; once their job is done all return to the natural elements from which they were made, creating no environmental harm. The method and apparatus are self cleaning and maintenance free.

Owner:EDWARDS JOHN LEE

A method for preparing hydroxytyrosol by boiling and hydrolyzing

ActiveCN102276424AShort conversion timeShorten the production cycleOrganic chemistryOrganic compound preparationChemistryMethanol

The invention discloses a method for preparing hydroxytyrosol by boiling and hydrolyzing. The method comprises the following steps of: firstly, preparing plant extract, adjusting pH of the plant extract to be 1-3, and boiling and hydrolyzing the plant extract for 1-4 h under normal pressure; after cooling, adjusting the pH to be 6.8-7.2, filtering and taking supernate; sampling the supernate on macroporous adsorption resin, after adsorbing, washing and removing impurities by using water, eluting by using 10-90% by volume of methanol or ethanol, and collecting eluent; and condensing and recovering the methanol or the ethanol to obtain hydroxytyrosol extract. According to the method disclosed by the invention, the conversion time of the hydroxytyrosol is greatly shortened; the conversion rate is increased; the production cycle is shortened as a whole; the production cost is saved; after hydrolyzing, adjusting to be neutral and placing the sample on a column, the supernate is washed and purified by using water and then eluted by using the methanol or the ethanol; and, instead of placing the sample on the column and eluting by using acid liquid, the disadvantage that resin equipment can be corroded is overcome.

Owner:陕西方舟制药有限公司

Process for producing l-amino acid

ActiveUS20120015409A1Highly productive in producingEfficient productionBacteria peptidesFermentationMicroorganismL-amino acid transport

The present invention provides a method of improving efficiency of a fermentative production of an L-amino acid. To be specific, the present invention provides a process for producing a L-amino acid, comprising culturing a microorganism wherein the activity of the protein described in any one of (1) to (3) below is higher than that of the parent strain in a medium to produce the L-amino acid and accumulate the L-amino acid in the medium, and then collecting the L-amino acid from the medium:(1) a protein comprising the amino acid sequence shown by any one of SEQ ID NOS:2, 4, 6 and 8(2) a protein consisting of the amino acid sequence resulting from deletion, substitution or addition of one or more amino acids in the amino acid sequence shown in any one of SEQ ID NOS:2, 4, 6 and 8, and having L-amino acid transport activity(3) a protein consisting of the amino acid sequence having 80% or more homology to the amino acid sequence shown in any one of SEQ ID NOS:2, 4, 6 and 8, and having L-amino acid transport activity.

Owner:KYOWA HAKKO BIO CO LTD

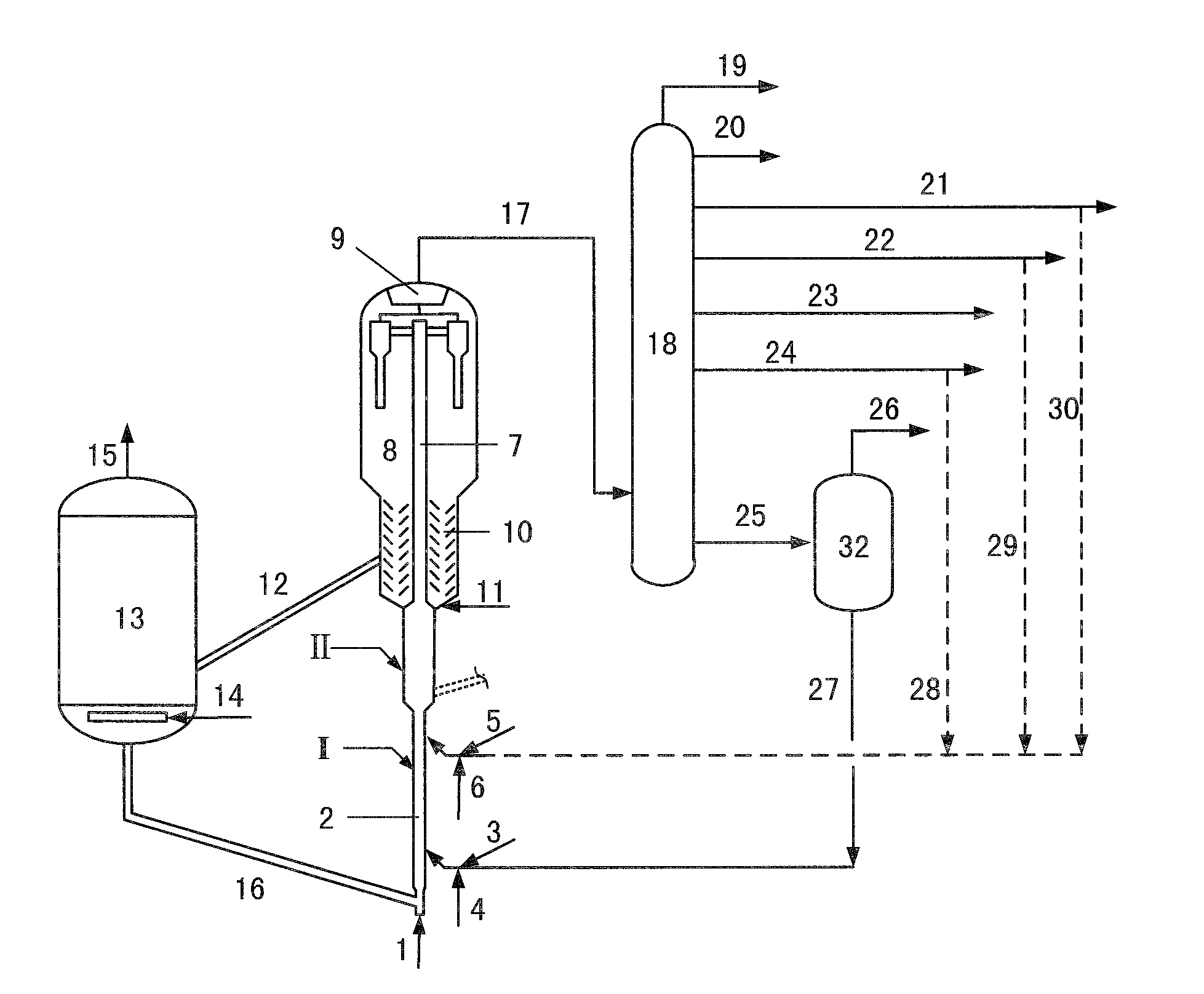

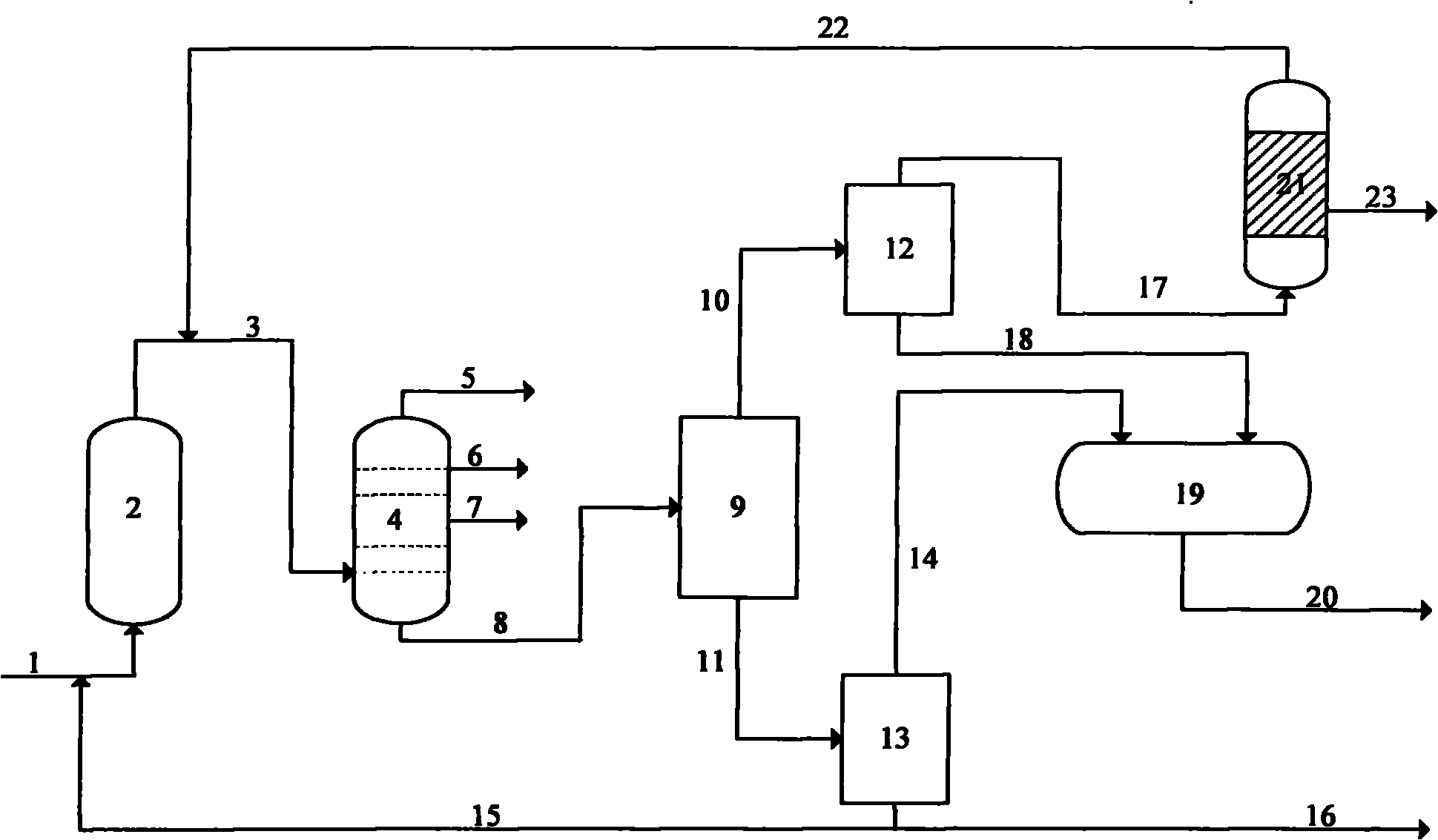

Process for converting inferior feedstock to high quality fuel oil

ActiveUS20110000818A1Improve propylene yieldQuality improvementCatalytic crackingTreatment with plural serial stages onlyAlkaneFuel oil

A catalytic conversion process can convert inferior feedstock to high quality fuel oil and propylene. A inferior feedstock is introduced into first and second reactor zone, wherein the feedstock carry out first step and second step reactions by contacting with catalytic conversion catalyst. Product vapors separate from spent catalyst by gas-solid separation. The spent catalyst is stripped, regenerated by burning off coke and then returns to reactor. The product vapors are introduced into separation system to obtain propylene, gasoline, diesel, fluid catalytic cracking gas oil (FGO) and other products. The FGO is introduced into hydrotreating unit and / or extraction unit to obtain hydrotreated FGO and / or extracted FGO. Said hyrotreated FGO and / or extracted FGO return to the first reactor zone and / or another catalytic cracking unit to obtain propylene and gasoline. The extracted oil of said FGO is rich in double ring aromatics which are good chemical materials. The raffinate of said FGO is rich in chain alkane and cycloalkane which are suitable for catalytic cracking. More particularly, the invention relates to a process to utilize petroleum oil resources efficiently for decreasing the yield of dry gas and coke significantly.

Owner:CHINA PETROCHEMICAL CORP +1

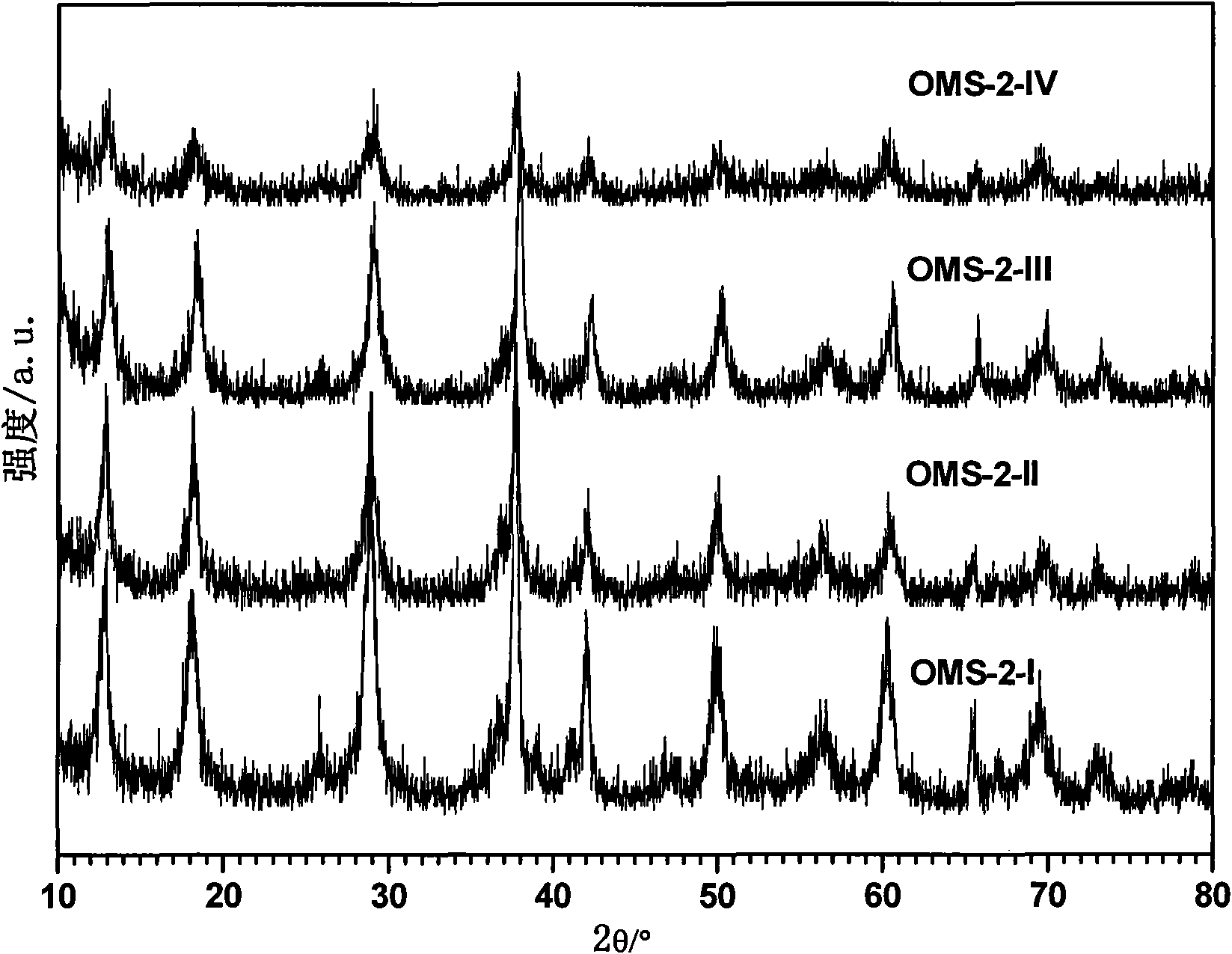

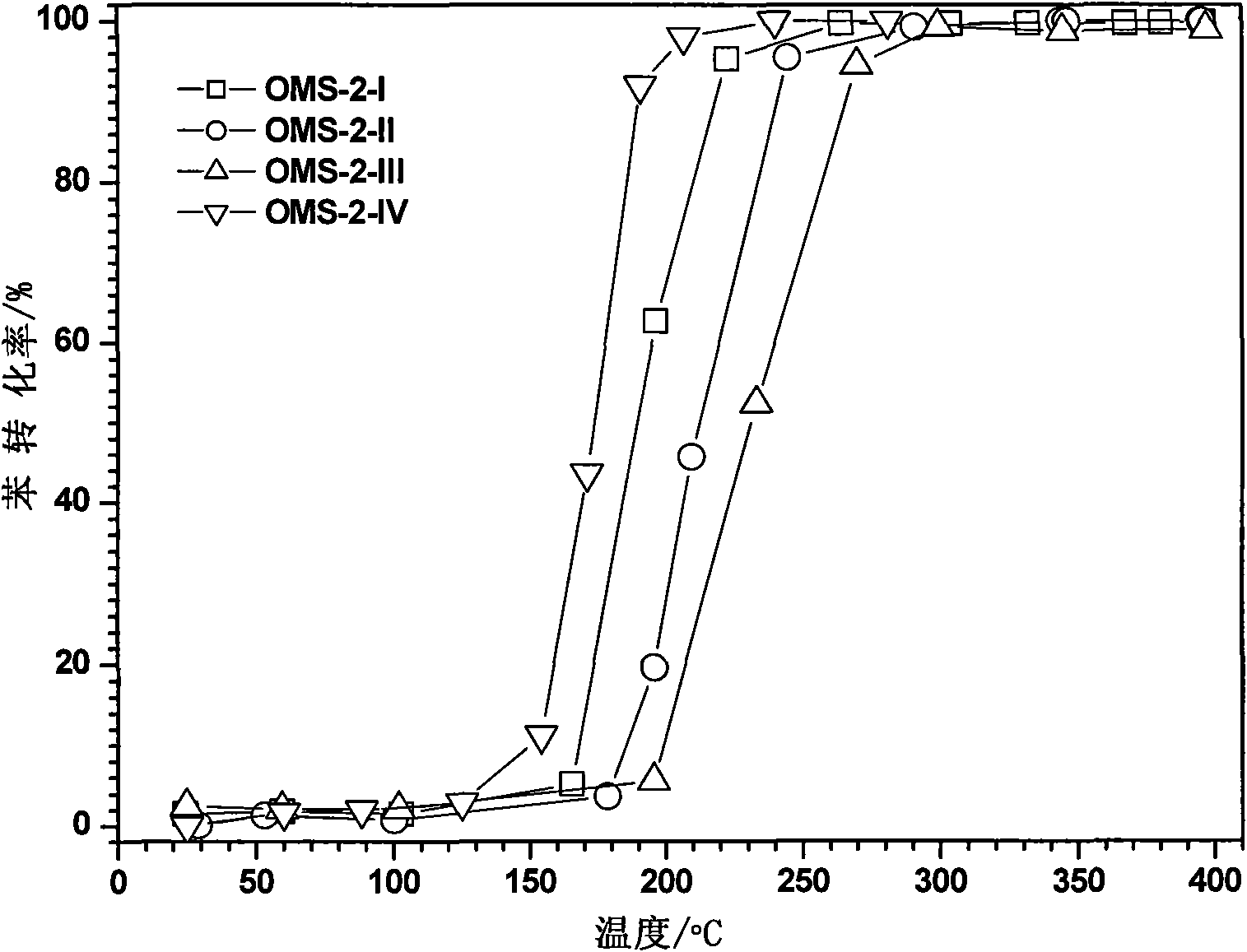

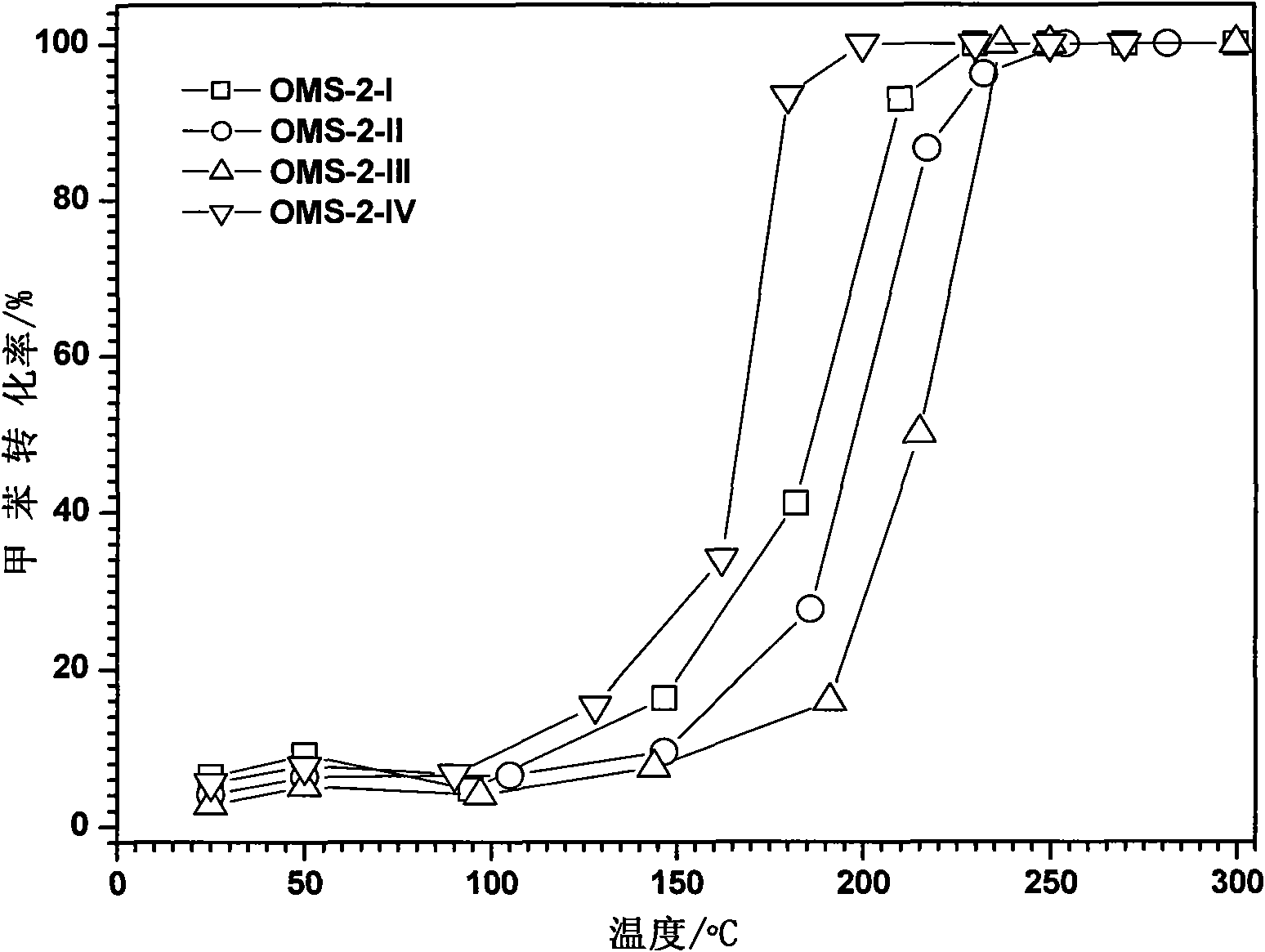

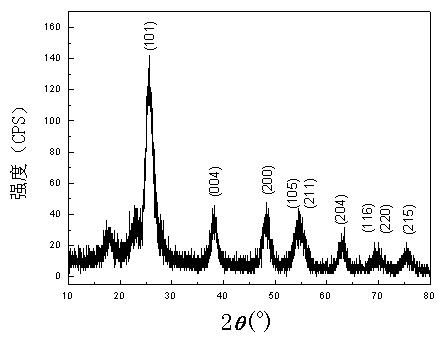

OMS-2 catalyst used in elimination of benzene series at low temperature and preparation and application

InactiveCN101927179AEasy to makeHigh and low temperature catalytic combustion to eliminate activityMolecular sieve catalystsDispersed particle separationMANGANESE ACETATEMolecular sieve

The invention discloses an OMS-2catalyst used in the elimination of benzene series at the low temperature, preparation and application. The catalyst is a manganese oxide octahedral molecular sieve and has a molecular formula of KMn8O16.nH2O. The material is prepared by using a reflux method which comprises the following steps of: preparing buffer solution of KAc-HAc with a pH value of 3.7 to 5.6; adding the buffer solution into PVP-containing Mn(Ac)2 solution; adding solution of KMnO4; stirring; refluxing; aging by sealing; filtering; washing with water; drying; baking; and performing other processing. The catalyst of the invention has the advantages of higher specific area and heat stability, high activity and high stability when the catalyst is applied to the elimination of the benzene series through low-temperature catalytic combustion, capacity of keeping the elimination ratio of the benzene series over 90 percent and not changed within 100 hours, cheap used raw material, namely manganese acetate, simple preparation process, no load of other metals or noble metals,.

Owner:BEIJING UNIV OF TECH

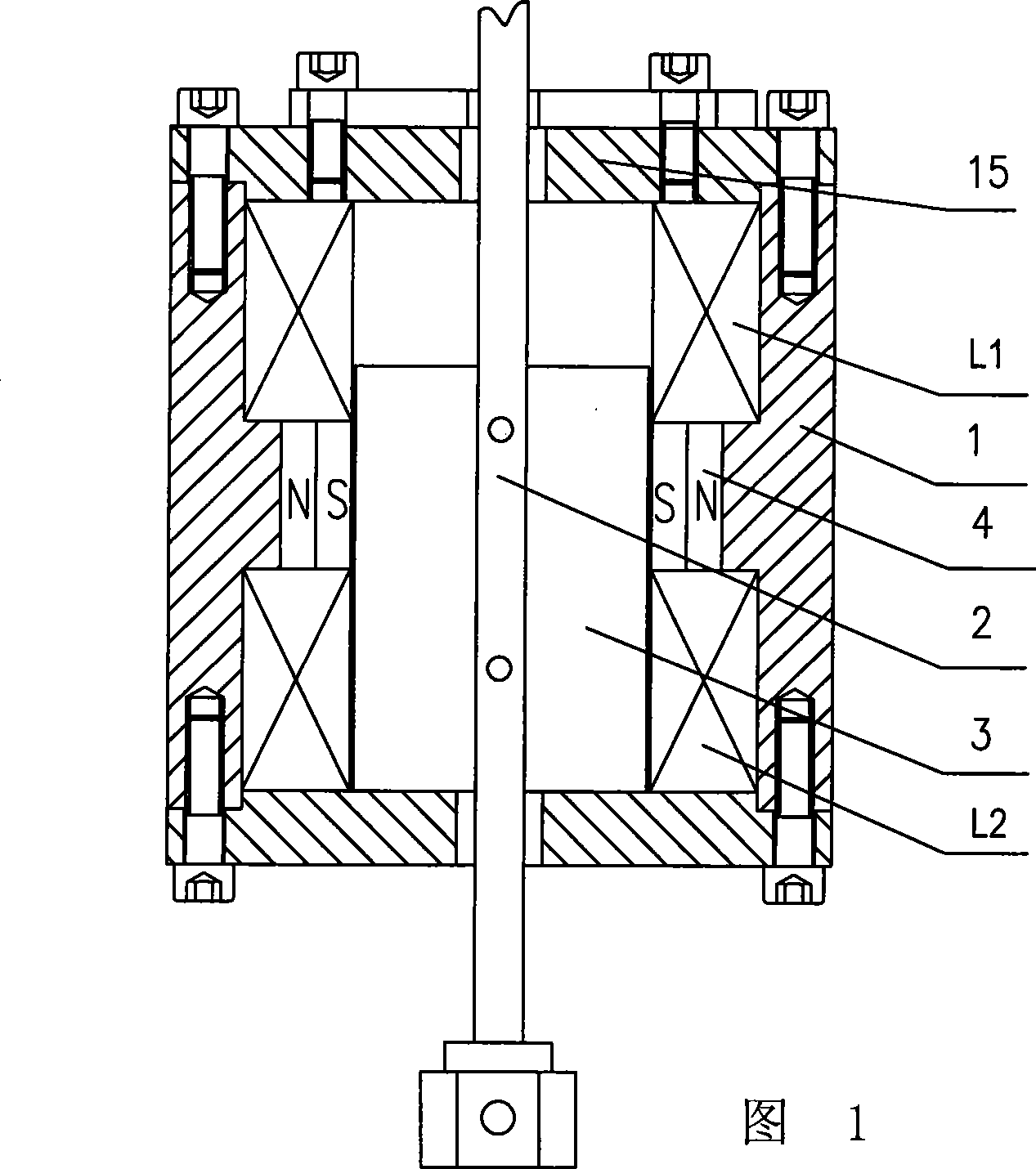

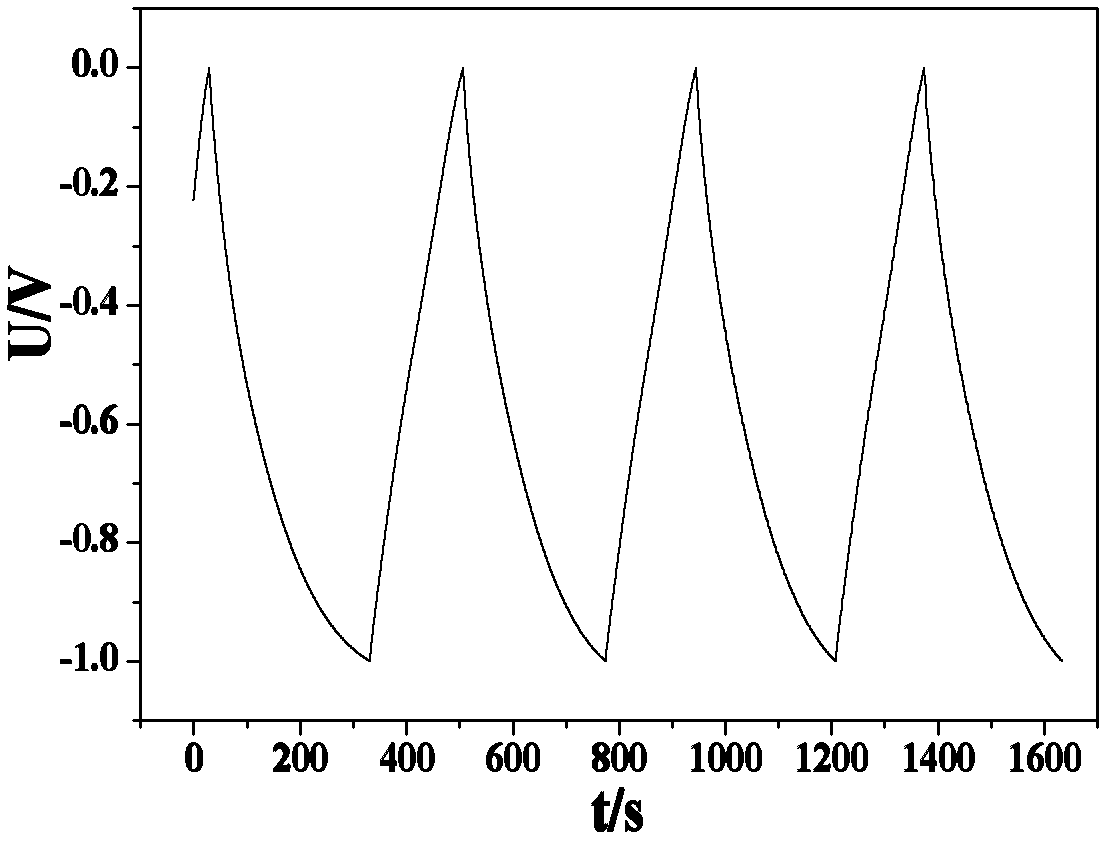

Control circuit for bistable state permanent magnet operating mechanism

InactiveCN101399124ASlow downReduce generationSwitch power arrangementsHigh-tension/heavy-dress switchesAutomatic controlEngineering

The invention relates to an automatically controlled operational mechanism, in particular to a control circuit of a bistable permanent magnetic operational mechanism, comprising a permanent operational mechanism and an impulse signal control circuit which is connected with an impulse coil of the permanent operational mechanism. The impulse signal control circuit comprises a brake separating energy storing circuit, a brake closing energy storing circuit, a brake separating contact switch and a brake closing contact switch. The impulse coil of the permanent operational mechanism is connected with the circuits by the brake separating contact switch and the brake closing contact switch. And the impulse coil of the permanent operational mechanism and the circuits are used in serial during the brake closing and in parallel during the brake separating. Thus, the high operational speed of gadgets during the earlier stage is lowered, and closing noises are lowered and the service life of the gadgets is prolonged. The instantaneous speed during the initial stage of the closing is improved. The generation of brake separating arc is lowered. The two coils in the bistable permanent operational mechanism are utilized completely. Raw materials are saved, the volume of the mechanism is reduced, and the fault rate is lowered.

Owner:王光顺

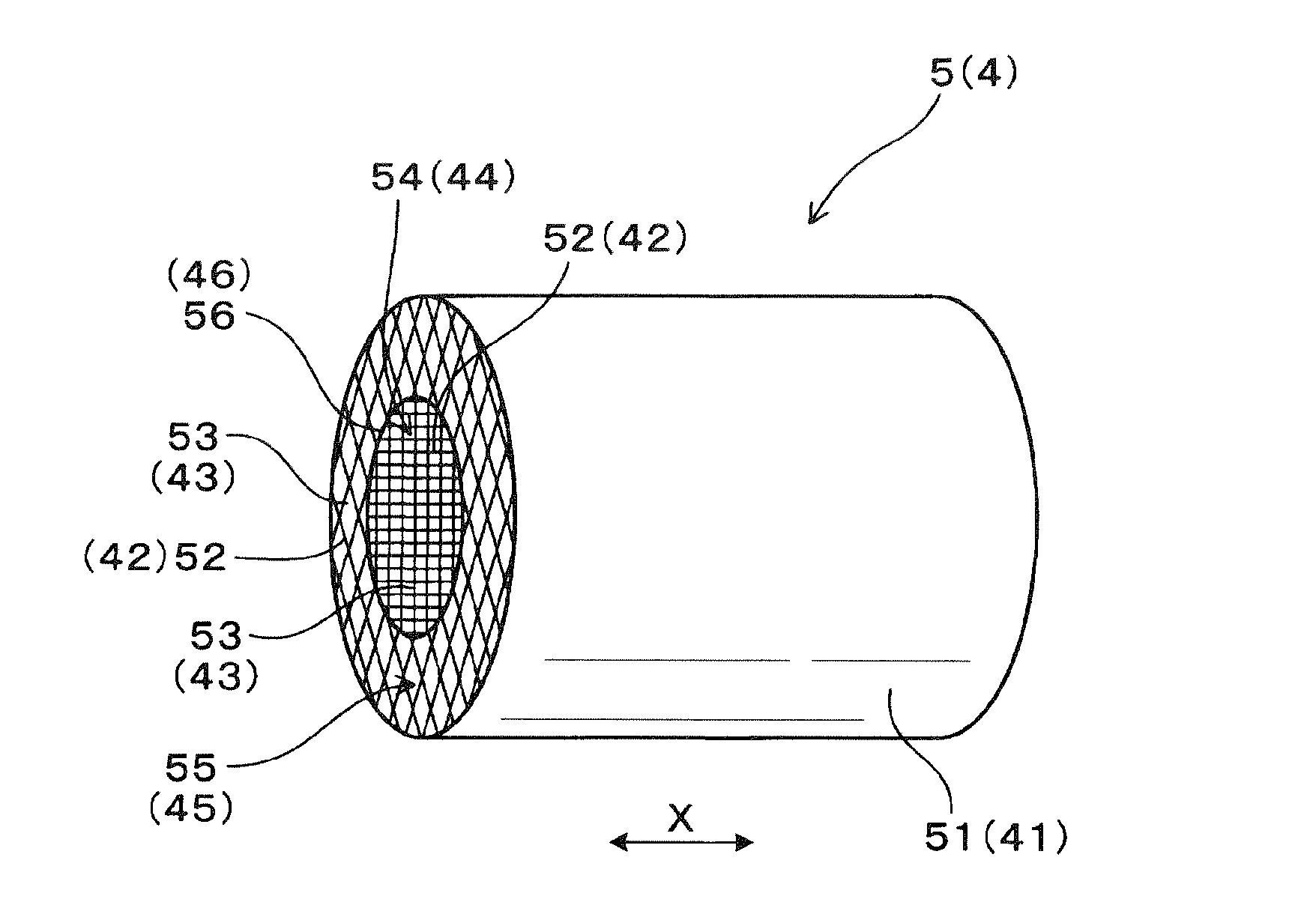

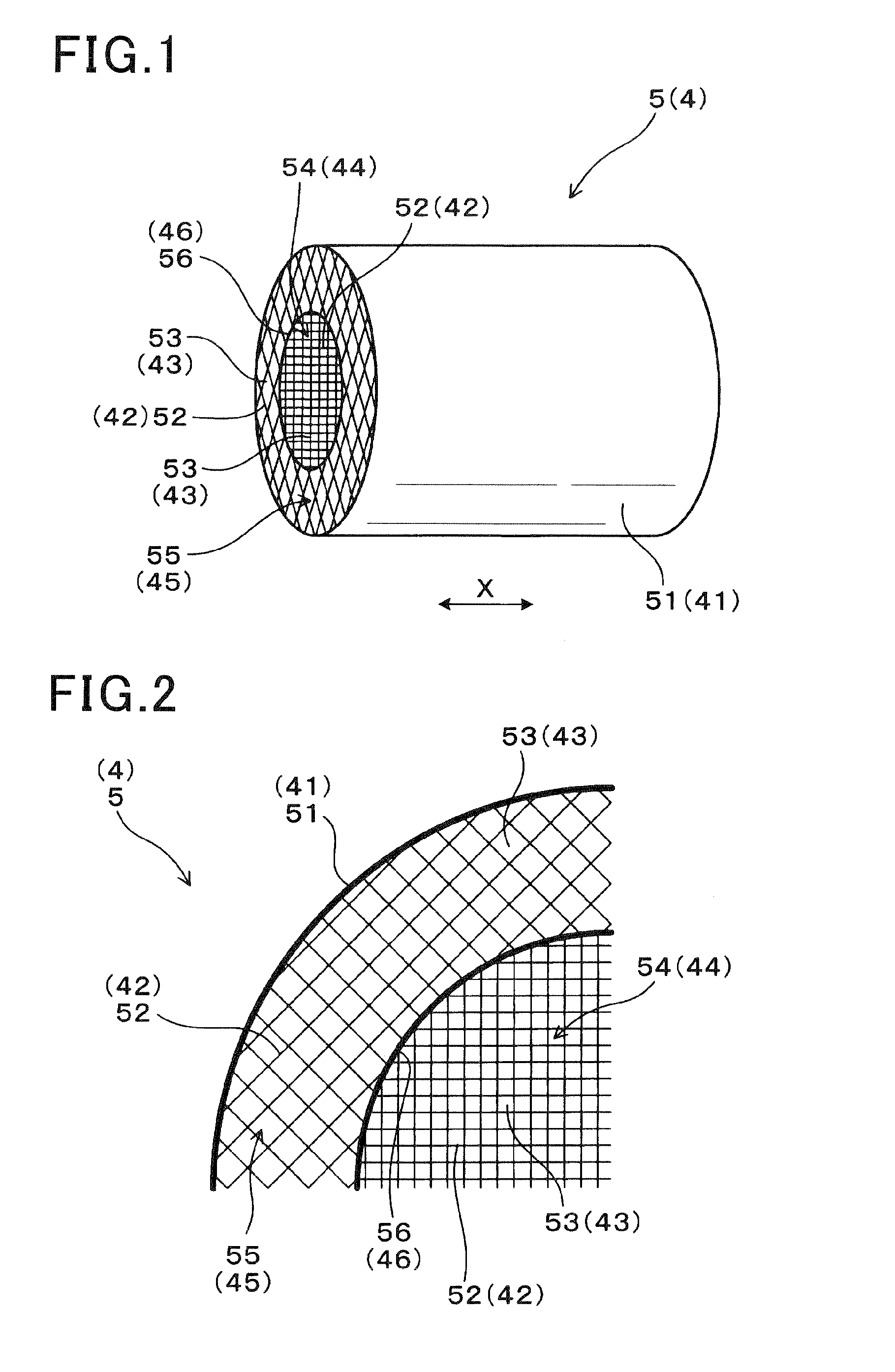

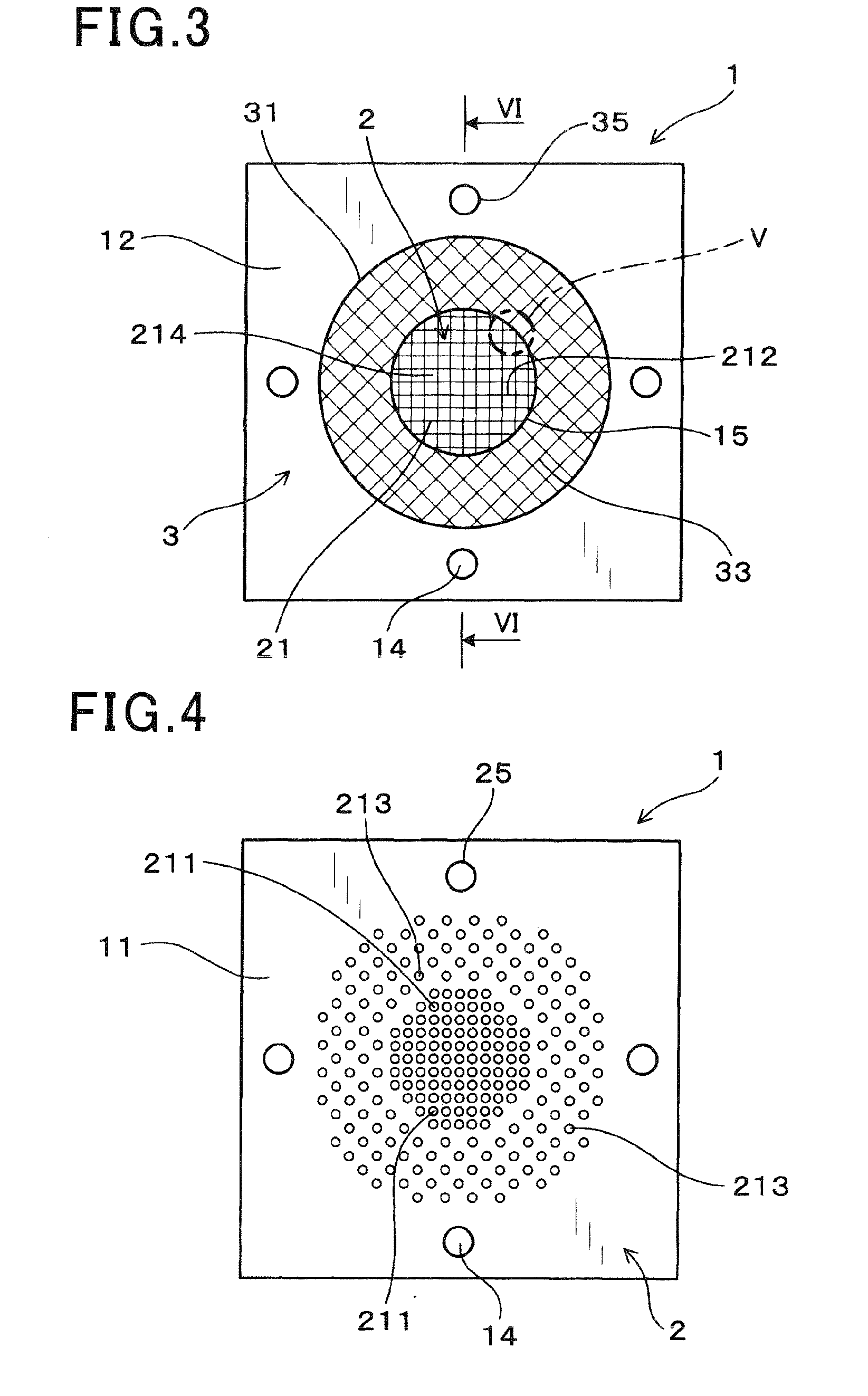

Method of producing honeycomb structural body

ActiveUS20150137431A1Suppress generation of localIncrease production capacityDispersed particle filtrationTransportation and packagingHoneycomb structureMetal

A method feeds raw material into a metal die and extrudes the raw material to produce a honeycomb molded body. The method fires the honeycomb molded body to make a honeycomb structural body. The metal die has a first metal die and a second metal die arranged at an upstream side of an extrusion direction of the raw material and a second metal die arranged at a downstream side of the extrusion direction of the raw material. The first metal die has a projection section and the second metal die has a penetration hole. The projection section is fitted to the penetration hole to assemble the first metal die and the second metal die. Communication holes formed in the second metal die communicate with raw material second feeding holes formed in the first metal die.

Owner:DENSO CORP

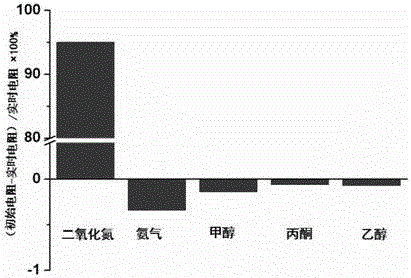

Carbon dioxide chemical fluorescent sensor material on basis of amidine/guanidine group and preparation detection method thereof

InactiveCN102721681AImprove raw materialsSave raw materialsChemiluminescene/bioluminescenceLuminescent compositionsCompound (substance)Sensor materials

The invention discloses a carbon dioxide chemical fluorescent sensor material on the basis of an amidine / guanidine group and a preparation detection method thereof. The chemical fluorescent sensor material consists of a fluorescent substance and a matrix substance; the matrix substance is formed by a liquid organism or a liquid organic mixture comprising the amidine group and / or the guanidine group and a liquid organism or a liquid organic mixture comprising a hydroxyl group and / or an amidogen group, or the matrix substance is a liquid organism comprising the amidine group and / or the guanidine group and the hydroxyl group and / or the amidogen group; the ratio of amounts of substances of the amidine group and / or the guanidine group to the hydroxyl group and / or the amidogen group in the matrix substance meets 1:10 to 10:1; and the chemical fluorescent sensor material comprises 0.5mg / mL to 4mg / mL of fluorescent substance. The raw materials for preparing the chemical fluorescent sensor material are simple, convenient and cheap; the chemical fluorescent sensor material is environmental-friendly; in the using process of the chemical fluorescent sensor material, other residual energy cannot be consumed; and the chemical fluorescent sensor material has simple and convenient testing process and a visual and visible result.

Owner:BEIHANG UNIV

A kind of method that prepares nano titanium dioxide film on the surface of polyester fabric

InactiveCN102277723AImprove wash resistanceImproves UV resistancePhysical treatmentFibre typesPolyesterTitanium sulfate

The invention discloses a method for preparing a nano titanium dioxide thin film on the surface of a dacron. The method provided by the invention comprises the following steps of: firstly, ultrasonically vibrating and washing the dacron to be treated for 10-30 min at a temperature in a range of 60-90 DEG C by utilizing treating fluid under the conditions that the frequency is 28 kHz and the poweris 100 w; then drying the dacron for future use; secondly, utilizing titanium sulfate solution and urea solution to subject the dacron to a hydro-thermal reaction; finally, washing the dacron by utilizing the washing solution in the bath ratio of 1 to 30-50 for 15-30 min at a temperature of 100 DEG C; repeatedly washing the dacron by hot water and cold water and then drying to prepare the nano titanium dioxide thin film on the surface of the dacron. The method for preparing the nano titanium dioxide thin film on the surface of the dacron provided by the invention saves raw materials, is convenient for operating and has a good use effect; and the washing resistance of the modified dacron is obviously improved.

Owner:XI'AN POLYTECHNIC UNIVERSITY

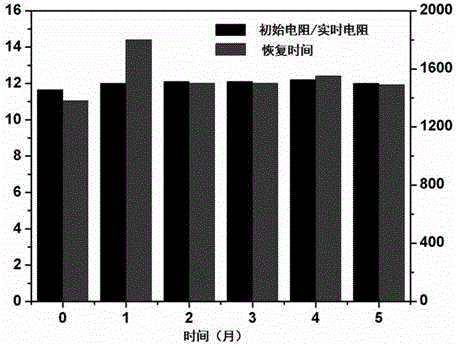

Composite gas sensitive material of organic molecule based on D-pi-A structure and graphene, and preparation method thereof

The invention discloses a composite gas sensitive material of an organic molecule based on a D-pi-A structure and graphene and a preparation method thereof, and belongs to the technical field of preparation of graphene based gas sensitive material. The gas sensitive material is prepared from an organic molecule with D-pi-A structure and a matrix material. The organic molecule with D-pi-A structure contains naphthalene ring or benzene ring, and anthracene ring, and both electron withdrawing groups and electron donating groups, and a series of similar structures. The method is as below: first dispersing graphene oxide in deionized water to prepare a dispersion, then adding the organic molecule with D-pi-A structure, adding hydrazine hydrate, and heating in an oil bath for reduction reaction; and then conducting suction filtration and washing by using acetate fiber membrane so as to finally obtain a uniform dispersion. The invention provides the composite gas sensitive material of the organic molecule based on the D-pi-A structure and graphene and the preparation method thereof. The prepared gas sensitive material has high selectivity, sensitivity, recovery and stability to NO2. In addition, the raw materials used in the invention re low in cost, green and environment-friendly.

Owner:BEIHANG UNIV

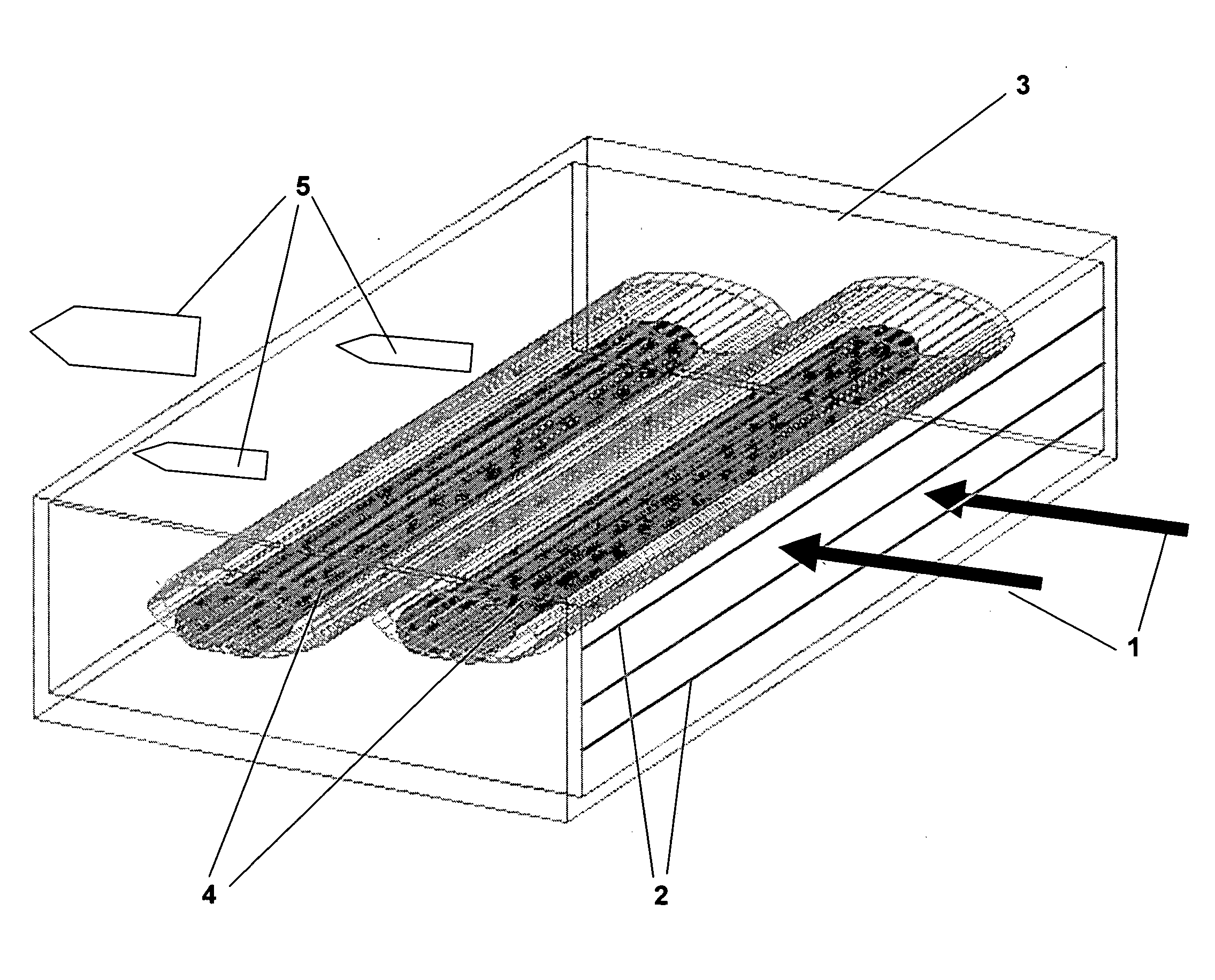

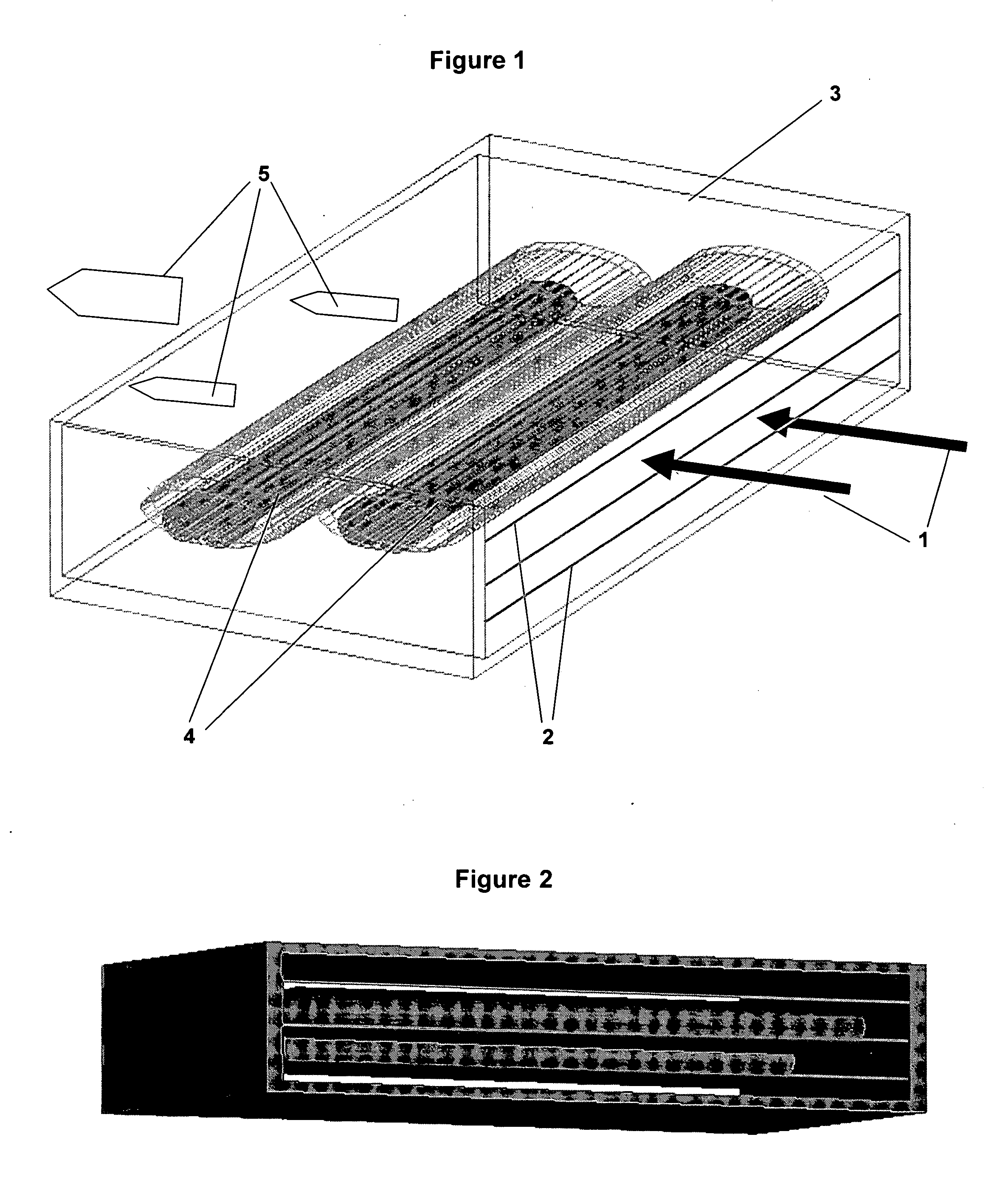

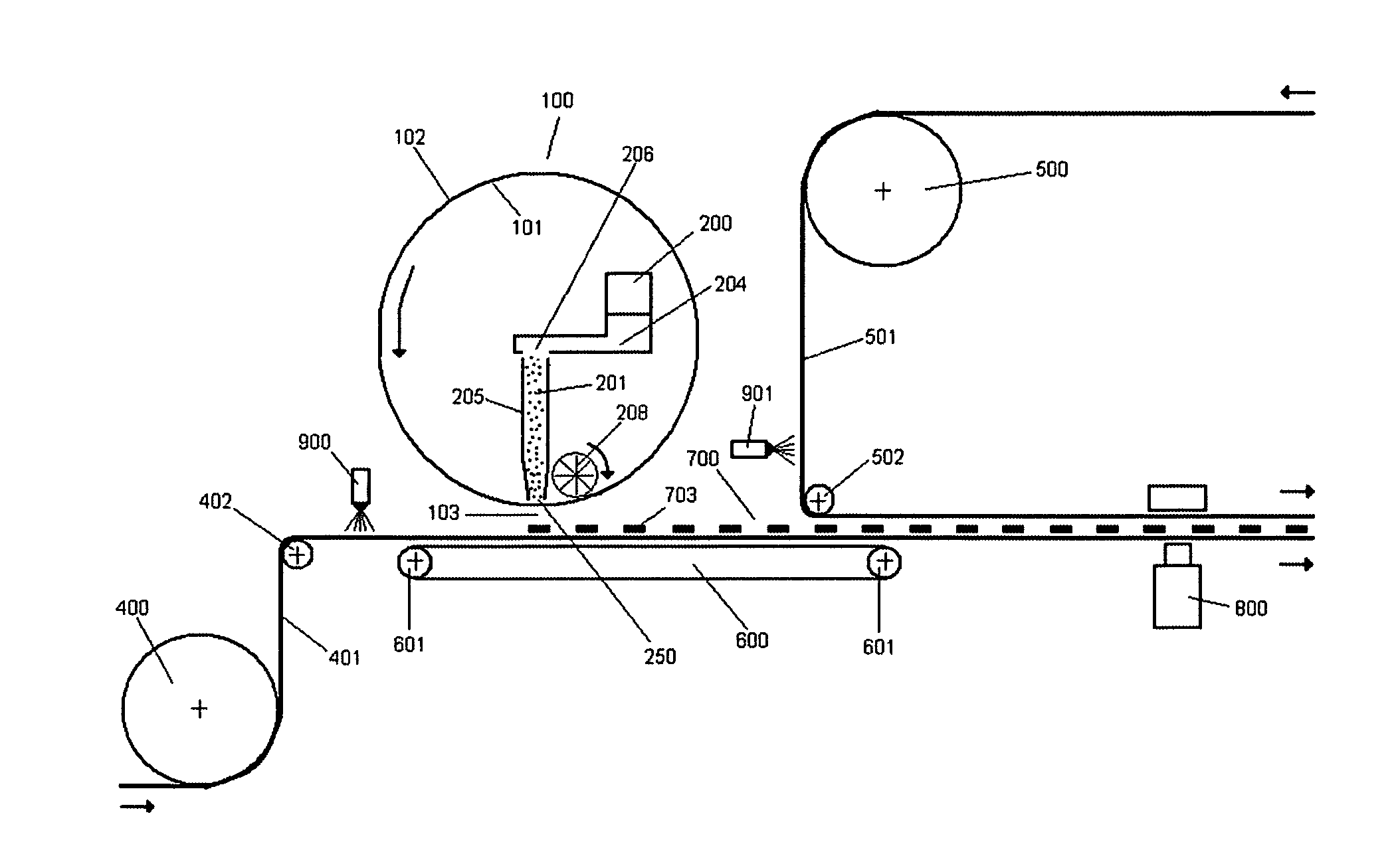

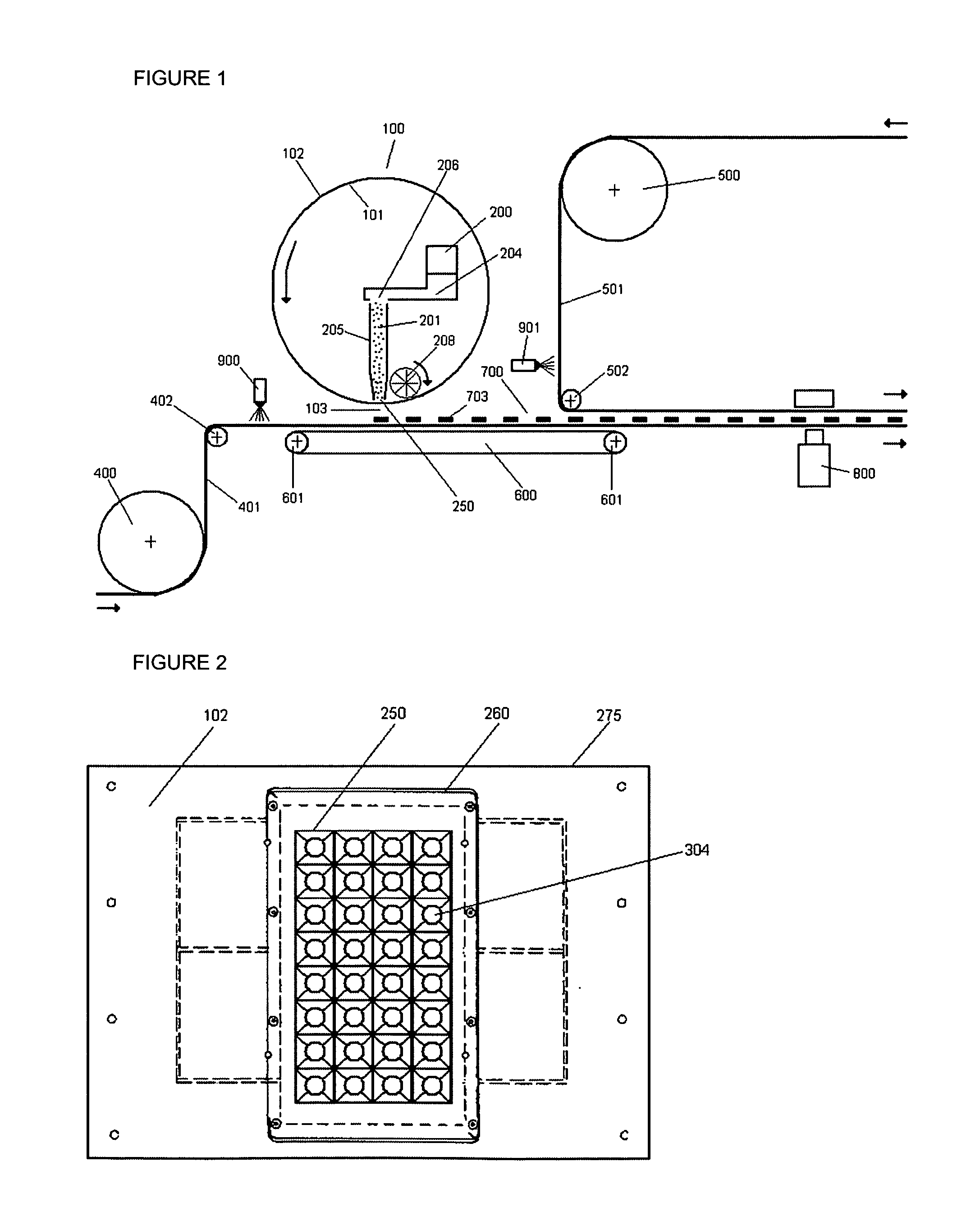

Method and apparatus for producing an environmentally friendly absorbent structure

InactiveUS20140296817A1Prevent overflowImprove accuracyLap forming devicesLap-winding devicesFEMININE HYGIENEBiomedical engineering

The present invention relates to a method and apparatus for forming a composite structure, preferably for use in an absorbent structure used within the personal hygiene industry, such as for instance feminine hygiene garments, baby diapers and pants and adult incontinence garments. The present invention preferably provides a method and apparatus for depositing particulate material in a desired pattern onto a moving carrier layer and positioning it into a pocketing pattern. The method allows accurate forming of a pre-determined pattern of particulate material clusters at high production speed, with reduced raw material usage and relative low cost. As such method allows manufacturing of absorbent structures being substantially cellulose free and substantially glue free, considered technically, economically and environmentally friendly. The present invention foresees in the need for an improved thin, flexible, lightweight particulate material absorbent structure which overcomes the problems of the prior art having optimal absorption, distribution and retention.

Owner:DRYLOCK TECHNILOGIES NV

Process for removing silica from cellulosic material

InactiveUS20060225852A1Simple and economical mannerEconomical and simplePulp liquor regenerationPretreatment with alkaline reacting compoundsCelluloseBlack liquor

A method of cellulosic raw material desilication involves the steps of impregnating the cellulosic raw material with a solution containing sodium carbonate to form a silica-containing impregnation black liquor and an at least partially desilicated raw material, separating the silica-containing impregnation black liquor from the at least partially desilicated raw material, causticizing the separated silica-containing impregnation black liquor to precipitate silica-enriched calcium carbonate and separating the precipitated silica-enriched calcium carbonate from the causticized impregnation liquor. Up to 100% of the silica contained in the cellulosic raw material can be removed before the raw material is processed by any of conventional pumping methods.

Owner:WESTERN MICHIGAN UNIVERSITY +1

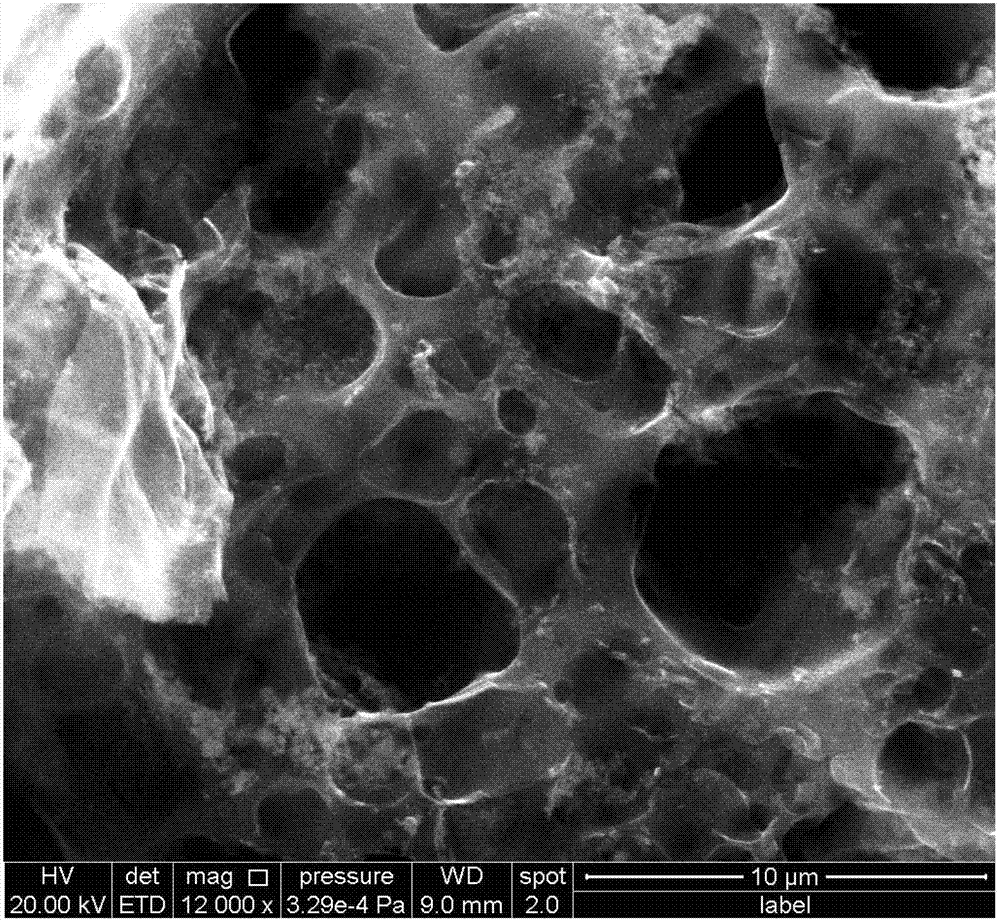

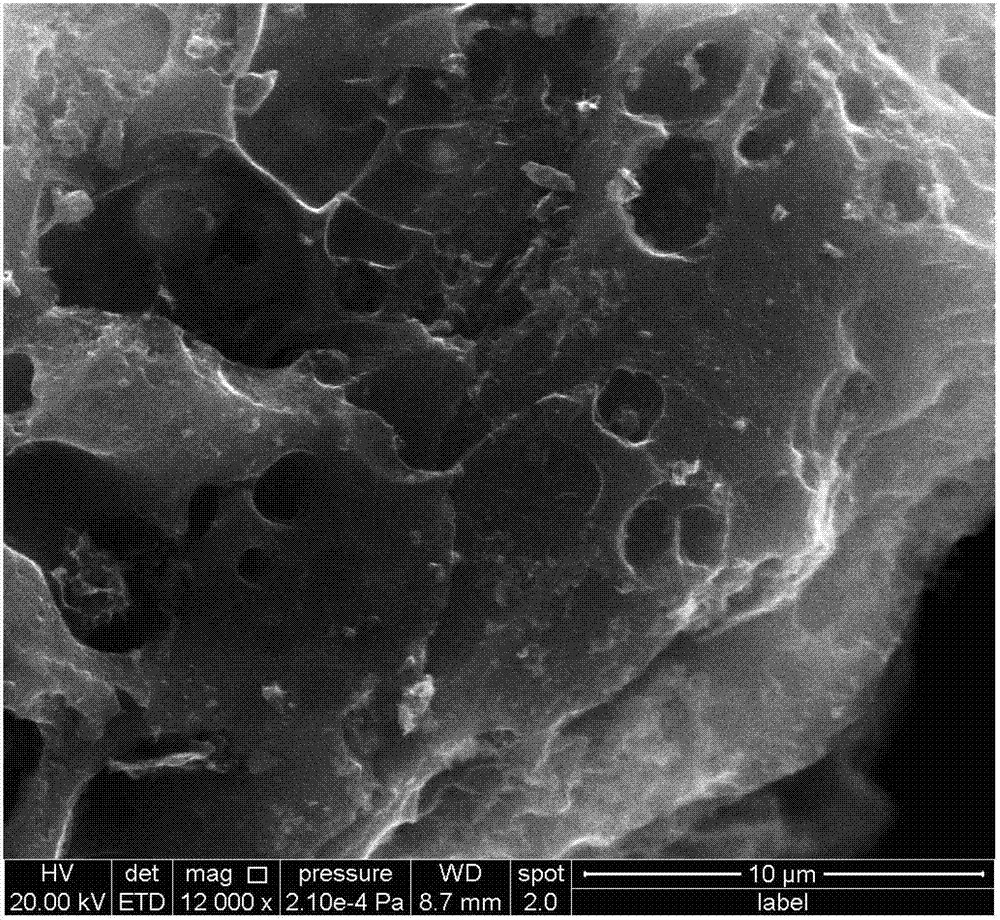

Method for producing porous carbon for super capacitor by utilizing lignosulfonate

InactiveCN102633252AImprove raw materialsLarge specific surface areaCarbon preparation/purificationCapacitancePorous carbon

The invention discloses a method for producing porous carbon for a super capacitor by utilizing a lignosulfonate. The method is characterized by comprising the following steps of: putting calcium lignosulphonate or magnesium lignosulphonate in nitrogen or argon atmosphere and keeping at 600-800 DEG C for 1-4 hours; after cooling to the room temperature, soaking calcium lignosulphonate or magnesium lignosulphonate in diluted hydrochloric acid or diluted nitric acid having a mass concentration of 10-30%, carrying out ultrasonic dispersion to even distribution and then stirring for not less than 6 hours; next, performing suction filtering and water washing until the eluate is neutral, and then drying, thereby obtaining porous carbon material suitable for manufacturing the super capacitor. The preparation method disclosed by the invention is simple and convenient for operation; and the obtained porous carbon material can be used for preparing the super capacitor which is capable of showing excellent capacitance characteristics.

Owner:HEFEI UNIV OF TECH

Duplication method of rat acute or persistent hyperuricemia model

InactiveCN1698906AReduce the wayShort copy cycleIn-vivo testing preparationsIntraperitoneal routeHypodermoclysis

The invention discloses a duplication method of rat acute or persistent hyperuricemia model which comprises, (1) selecting male, female healthy rats with the specie of SD and Wistar and 150-450g of body weight, simultaneously administering purines by 100-2000 mg / kg and uric acid depressant by 5-1000mg / kg through stomach filling, hypodermic injection or abdominal cavity injection, (2) after 5-24 hours, administering the rats by the same mode and medicament dose, (3) administering the rats daily continually according to the step (1) and (2), continuing administration for one to two weeks.

Owner:NANJING UNIVERSITY OF TRADITIONAL CHINESE MEDICINE

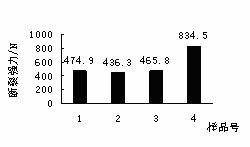

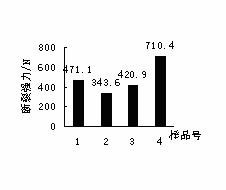

Cleaning method of polycrystalline silicon raw material

The invention discloses a cleaning method of a polycrystalline silicon raw material. The cleaning method comprises the following steps of crushing a polycrystalline silicon raw material, removing iron from silicon powder by a magnet, immersing the silicon powder in a hydrogen peroxide solution for 2-24h, carrying out wet-oxygen oxidation of the silicon powder, immersing the silicon powder in a mixed acid of hydrochloric acid and hydrofluoric acid, immersing the silicon powder in hydrofluoric acid for corrosion, putting the silicon powder into an ultrasonic water tank, carrying out ultrasonic cleaning, and drying the silicon powder in a vacuum furnace to obtain a target product. The cleaning method removes metal impurities in the silicon powder by pickling, realizes diffusion of the impurities into SiO2 by utilization of a ratio of the equilibrium concentration of boron in silicon to the equilibrium concentration of boron in SiO2, wherein the ratio is less than 1, and realizes removal of SiO2 containing a large amount of boron by pickling so that 4N-5N polycrystalline silicon can be obtained. The cleaning method has the advantages of simple processes, low cost, good safety and low pollution.

Owner:PROPOWER RENEWABLE ENERGY SHANGHAI

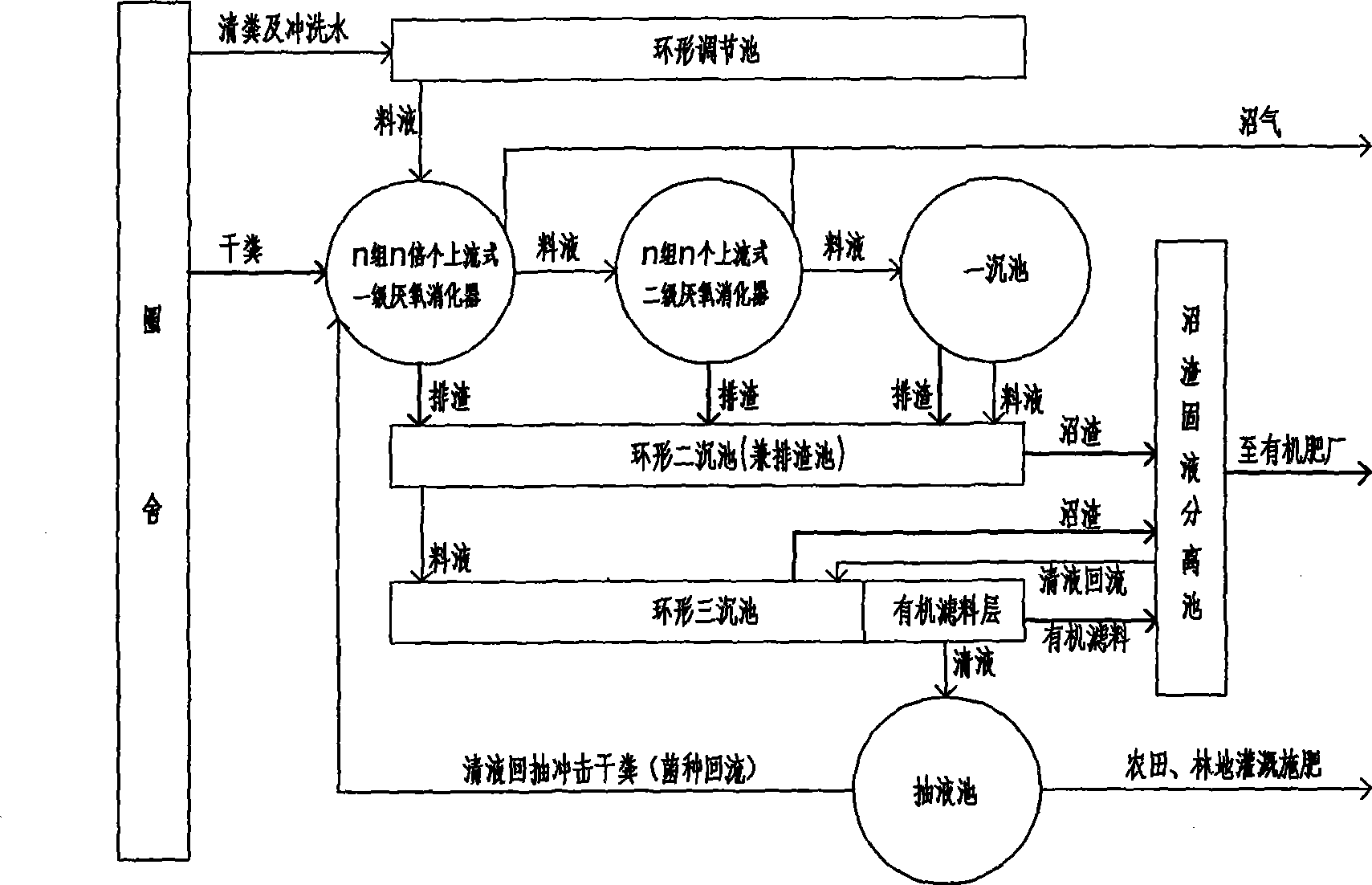

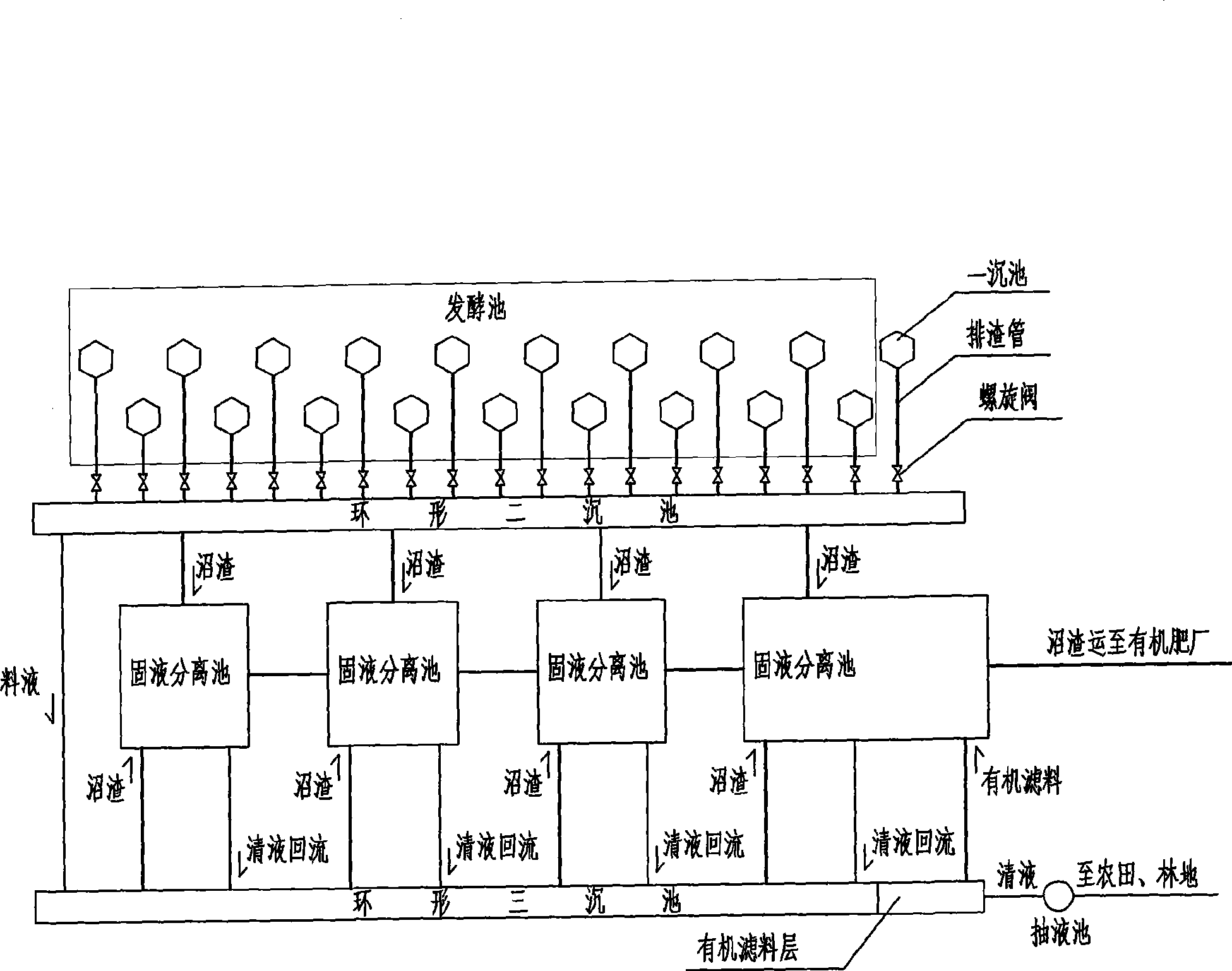

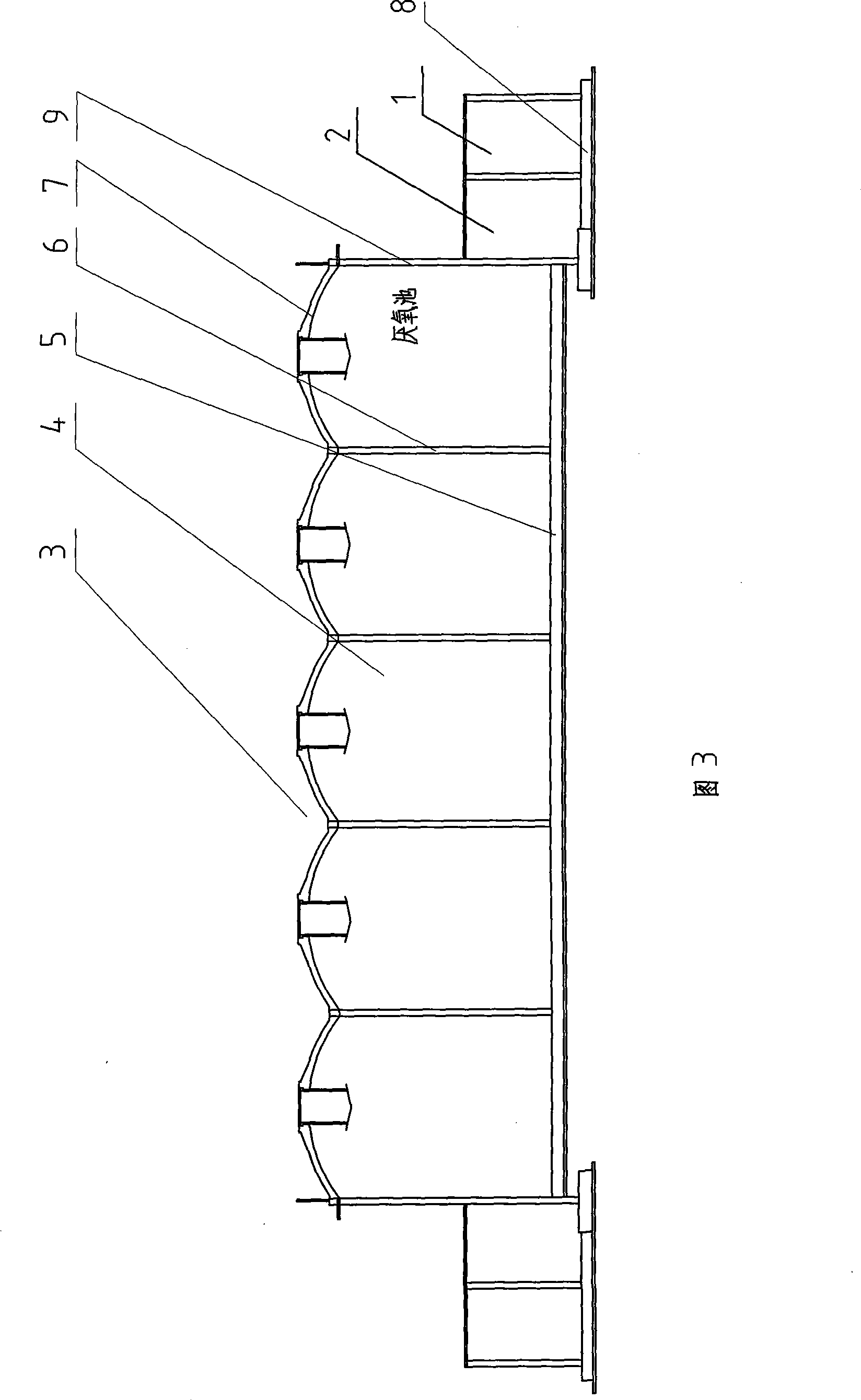

Anaerobic digestion processing method and apparatus in biogas production process

InactiveCN101434450ASimple processSolve the problem of neglecting the otherBio-organic fraction processingClimate change adaptationSlagNew energy

The invention relates to a process and a device for methane anaerobic digestion treatment, which consists of two parts: anaerobic fermentation gas production, and slag discharge, solid-liquid separation and collection thereof; wherein, the anaerobic fermentation gas production process comprises feed manner, process arrangement, the closure reflux of strains, prolonged fermentation gas production time of organic solids, and the like; the processes of the slag discharge, solid-liquid separation and collection thereof comprises low point fall slag discharge, hydraulic agitation slag discharge, strengthened solid-liquid separation, circulation sedimentation separation, organic filtering material filtering and separation, filtering and draining combined separation, and the like; and the device comprises a honeycomb type anaerobic pool, a circular regulation pool and a circular sedimentation pool thereof. The process and the device have an unique feed manner, an effective slag discharge way, full and strengthened solid-liquid separation, and organic solid recycling with high proportion, particularly, fermented gas production materials after the strengthened solid-liquid separation can be guaranteed, meanwhile, organic material recycling with high proportion and water discharge with low concentration can be realized. The process and the device can effectively combine new energy development, organic fertilizer production and the treatment for environment protection; besides, processes are simple and practical, thus being suitable for popularization.

Owner:LESHAN FOZHOU NEW ENERGY DEV

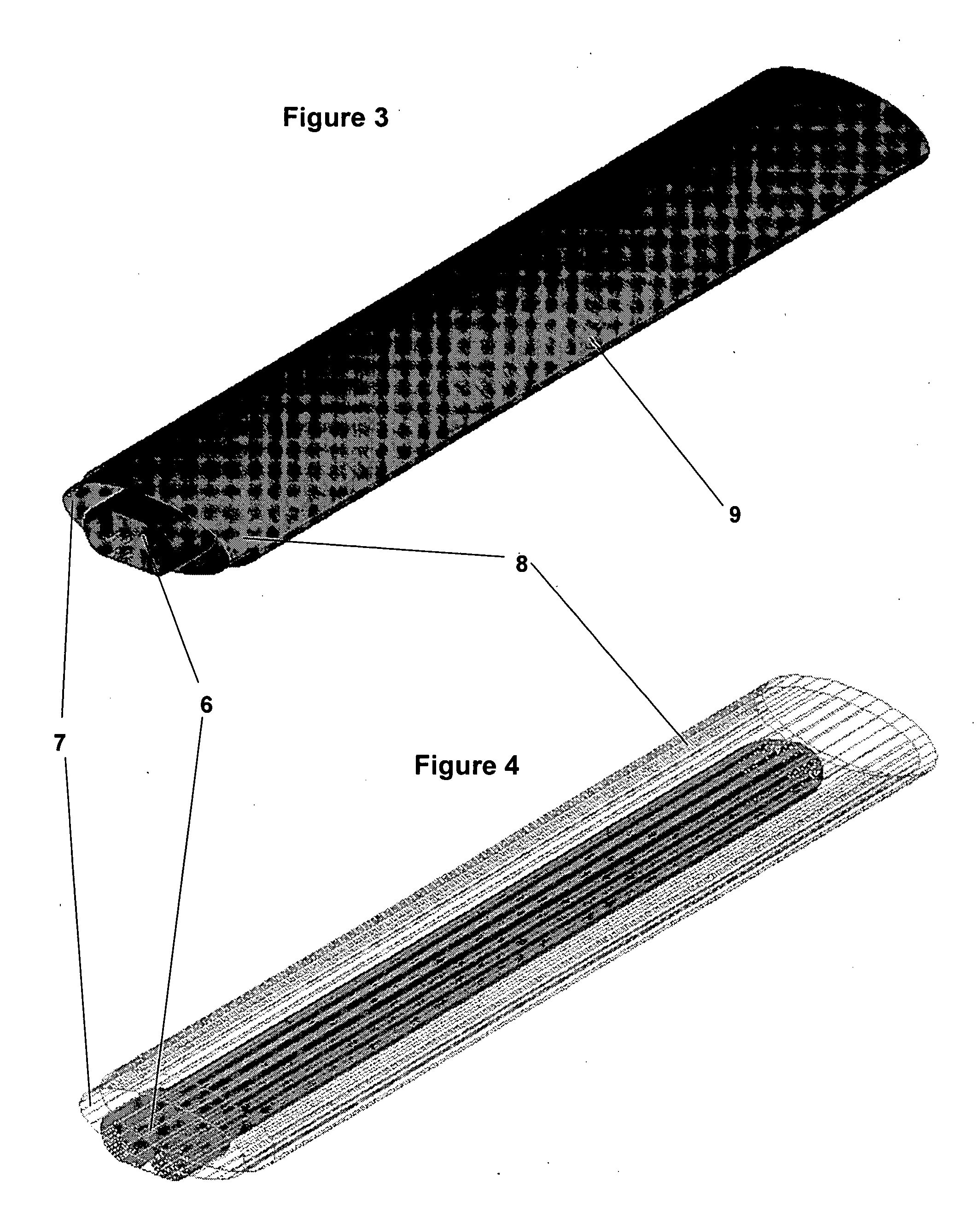

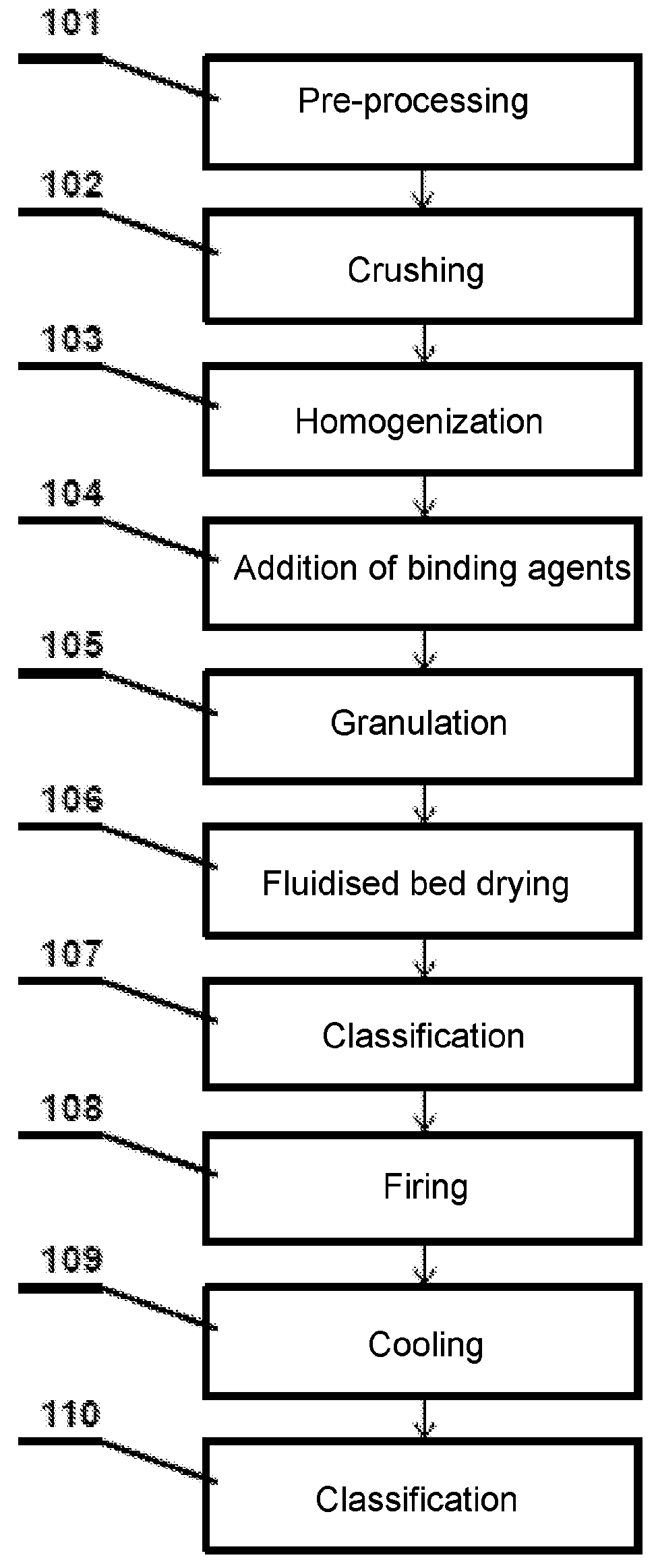

Method of manufacturing of light ceramic proppants and light ceramic proppants

InactiveUS20160053162A1High strengthLow specific gravityFluid removalFlushingFluidized bed dryingMoisture

A method for manufacturing of light ceramic proppants made from a mixture of raw materials that is mechanically granulated in a granulator or that is granulated in a spray dryer from a pourable ceramc mass, to obtain granulate having a granule size of 150-1700 μm (12-100 U.S. Mesh, ASTM E11-04, ISO 13503-2), and next the granulate is fired and the fired granulate is fractioned. The mixture of raw materials is prepared from: illite-beidellite-ka-olinite high-plastic clays of the Poznan series in the amount of 10% to 40% by weight; kaolinite clays in the amount of 10% to 45% by weight; kaolin in the amount of 20% to 40% by weight; fly ash from brown coal combusted in a power plant in the amount of 10% to 35% by weight; and treatment agents in the amount of up to 10% by weight. The mixture of raw materials is mixed and homogenized in a homogenizer, and the obtained granulate is fed to a fluidised bed dryer, in which it is dried to a moisture content below 3%, and the granulate is fired in a rotary furnace in a temperature from 1150° C. up to 1410° C. in time from 120 to 600 min, obtaining proppants which contain from 18% to 32% by weight of Al203, from 40% to 76% by weight of SiO2, and have a specific gravity from 2.15 Mg / m3 to 2.90 Mg / m3 and a bulk density from 1.35 Mg / m3 to 1.70 Mg / m3, depending on the firing time.

Owner:BALTIC CERAMICS

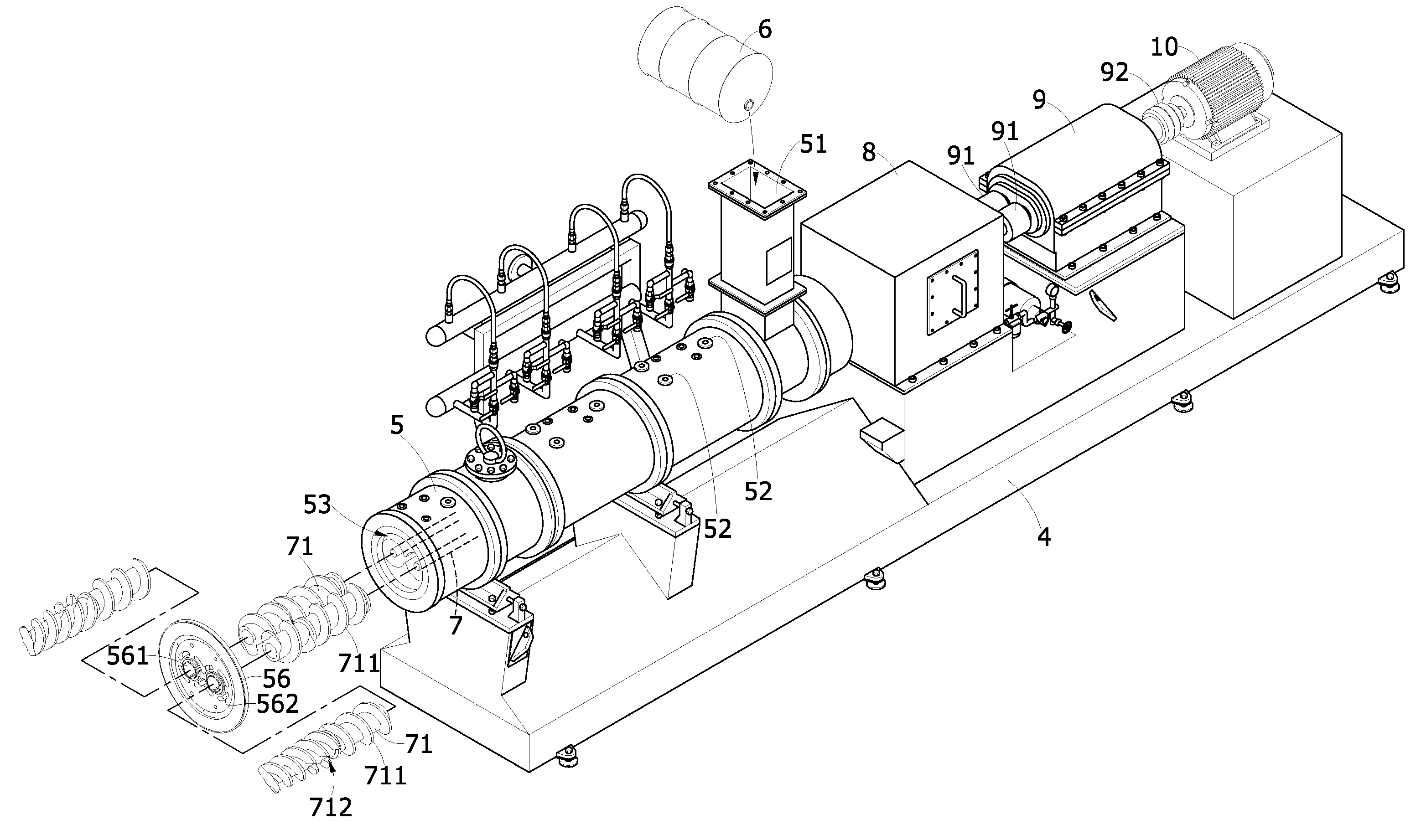

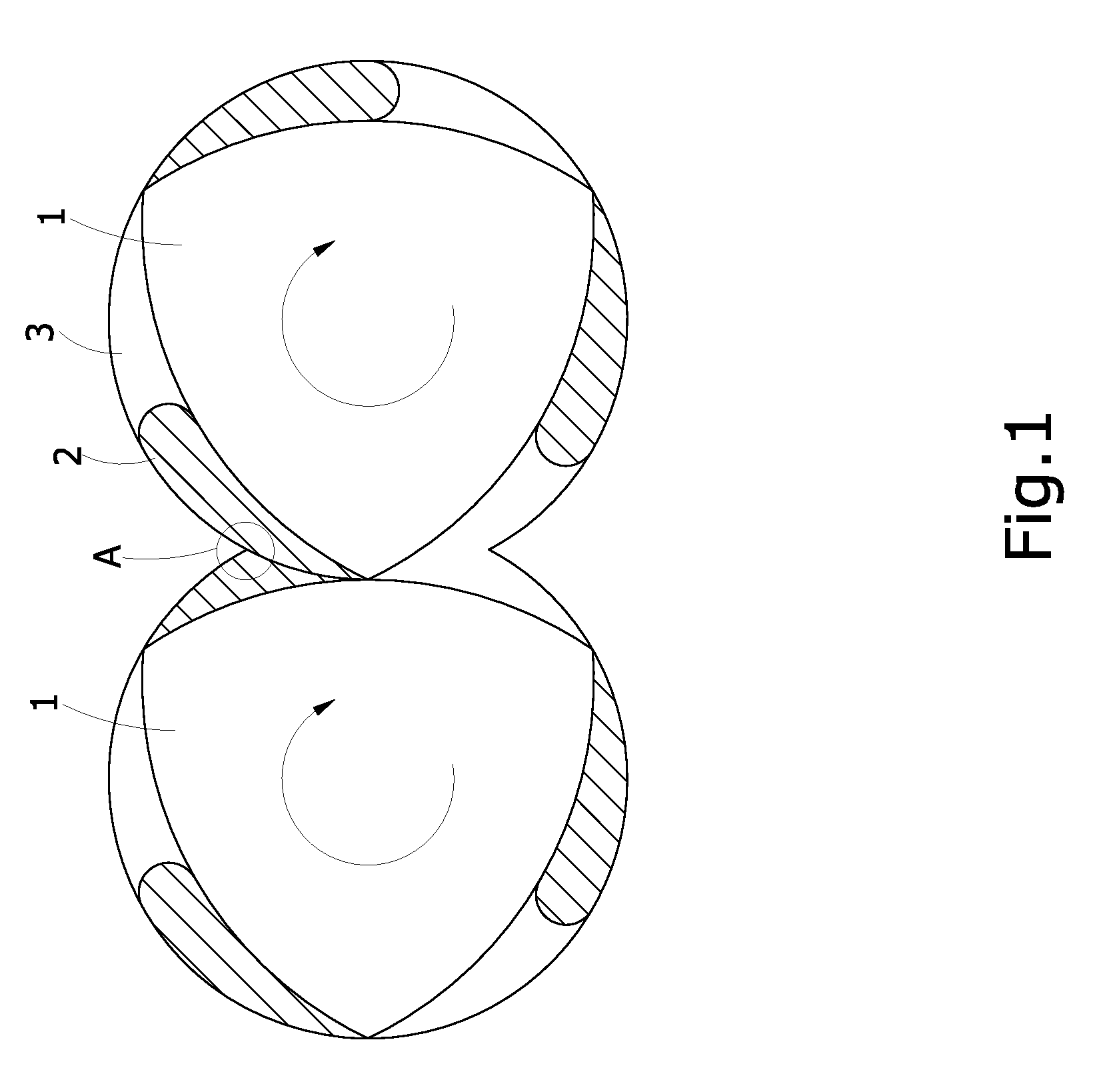

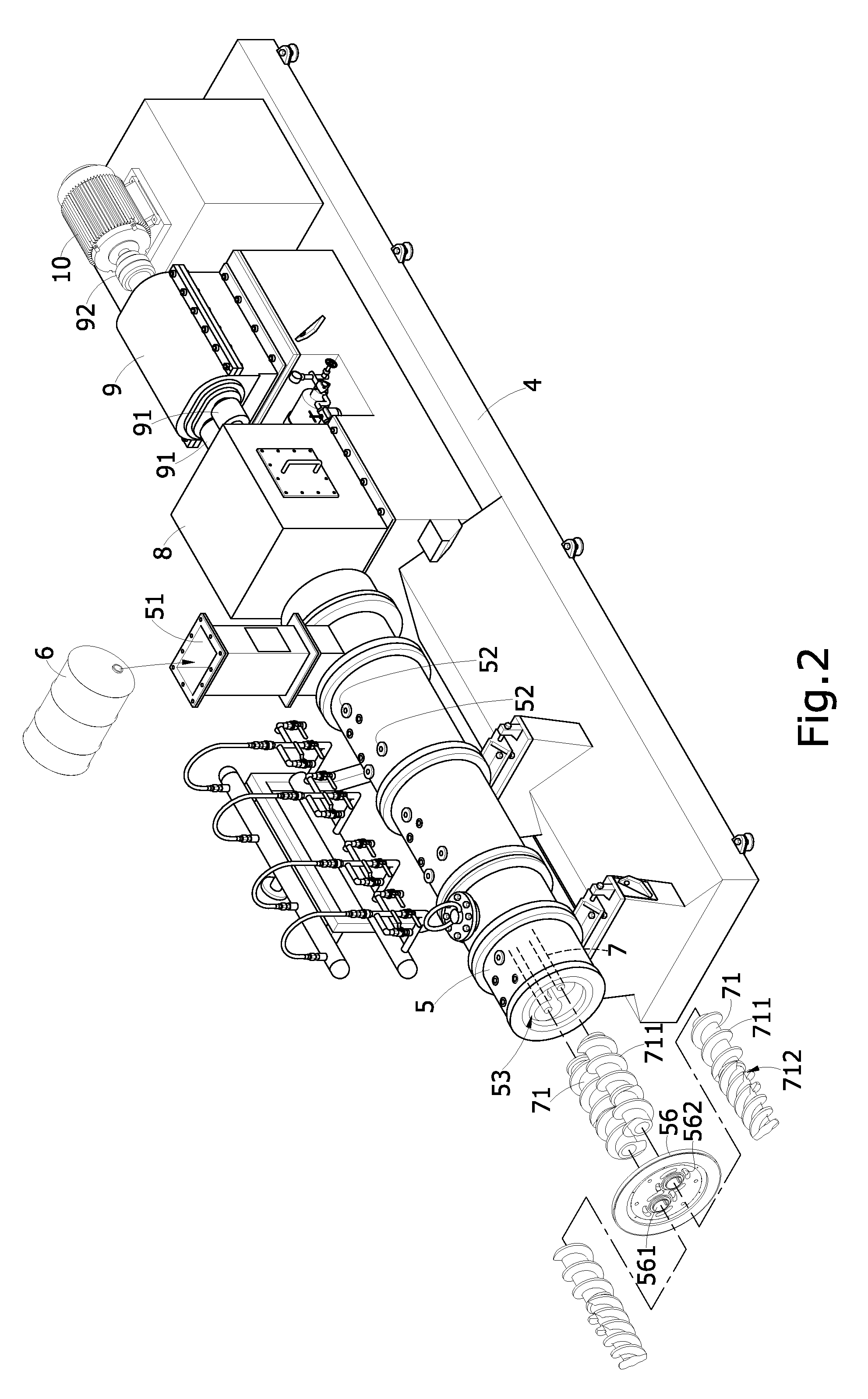

Counter-rotating twin screw extruder

ActiveUS20100143523A1Minimal heatHigh in fiberRotary stirring mixersTransportation and packagingMechanical energyEngineering

A counter-rotating twin screw extruder includes a motor that generates power through speed reduction of a gear box to directly or indirectly drive two symmetric screw shafts inside an enclosure barrel for synchronous but opposite rotations. Each screw shaft is fit with at least one section of screw and the two screws forms screw flight that are set in opposite directions and alternating each other. The barrel contains therein at least one flow restriction die. A bearing box is set between the barrel and the gear box. The purpose is to reduce unnecessarily induced mechanical energy during the conveyance of material and the advantages of using an independent bearing box are that manufacturing costs are reduced and consumption of energy is cut down. Parts wearing is reduced and durability is enhanced to eventually realize carbon reduction and energy saving.

Owner:AVANTRON MICRO CO LTD

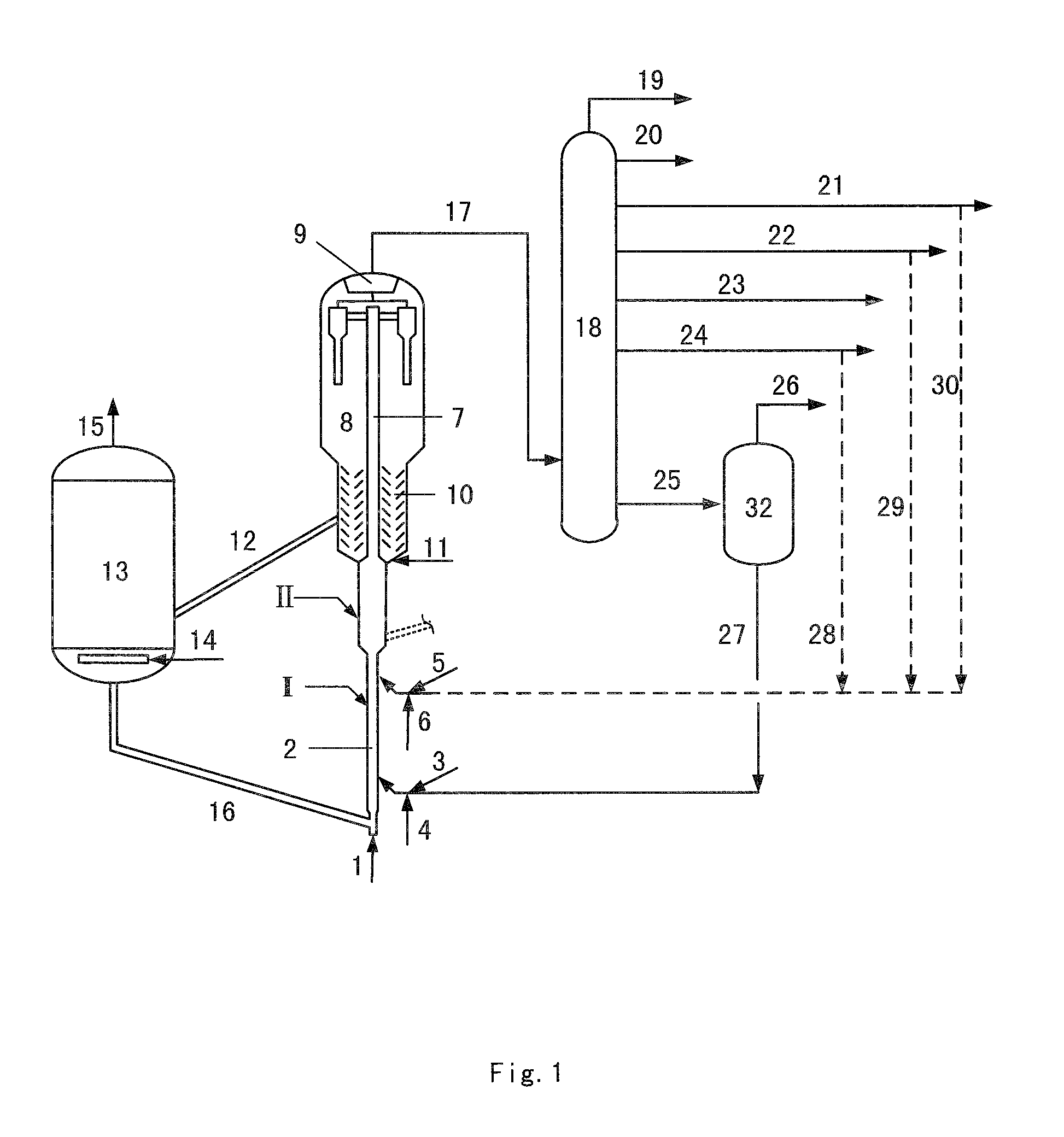

Method for producing needle coke by combined process

InactiveCN102051215AEfficient use ofImprove raw materialsThermal non-catalytic crackingTreatment with plural serial stages onlyGasolineFuel oil

The invention discloses a method for producing needle coke by a combined process. In the method, catalytic cracking and delay coking liquid-phase products enter a fractionating tower together, gas, gasoline, diesel oil and heavy oil are separated, the heavy oil directly enters an aromatic hydrocarbon extraction device, raffinate oil from which a solvent is recycled directly enters a catalytic cracking device to be recycled, and extract oil from which the solvent is recycled enters a delay coking device. In the process, the heavy oil part of the catalytic cracking and delay coking products is subjected to aromatic hydrocarbon extraction, and the raffinate oil is subjected to catalytic cracking to be recycled, so that the property of catalytic cracking recycle oil is improved, the yield of the coke is reduced, and the processing capacity of the catalytic cracking device is improved; and the extract oil is rich in aromatic hydrocarbons, and the needle coke with high performance can be produced through the delay coking device.

Owner:CHINA PETROLEUM & CHEM CORP +1

Cleaning of oil- contaminated granular solids, in particular spent catalysts

InactiveCN101166837AChange pressureSpeed up the gas flowProcess efficiency improvementSolid solvent extractionMetalChemistry

Owner:LINDE AG

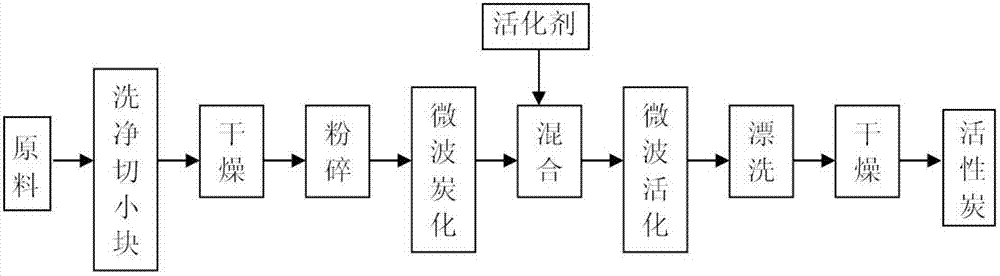

Banana tree base activated carbon and preparation method thereof

InactiveCN102826548AHigh specific surface areaStrong adsorption capacityCarbon compoundsActivated carbonIndustrial waste

The invention discloses banana tree base activated carbon and a preparation method of the banana tree base activated carbon. The preparation method of the activated carbon comprises the following steps of: taking banana tree as a raw material, and treating banana tree by a microwave radiation process and a chemical activation process, so that the banana tree base activated carbon which is multiple in micropores, high in specific surface area and high in adsorption ability can be obtained, and can be taken as high-performance activated carbon adsorbent. The banana tree base activated carbon belongs to the waste utilization of agricultural and sideline products, and is good for the environment protection. After the invention is used, the abundant carbon resources of the special industrial waste material can be abundantly used, the environment pollution caused by the special industrial waste material can be avoided, and the sources channel of the high-performance activated carbon production raw material in China can be widened; and the added value of the banana industry can be effectively improved, and the banana tree base activated carbon is considerable in economic benefit and social benefit.

Owner:YULIN NORMAL UNIVERSITY

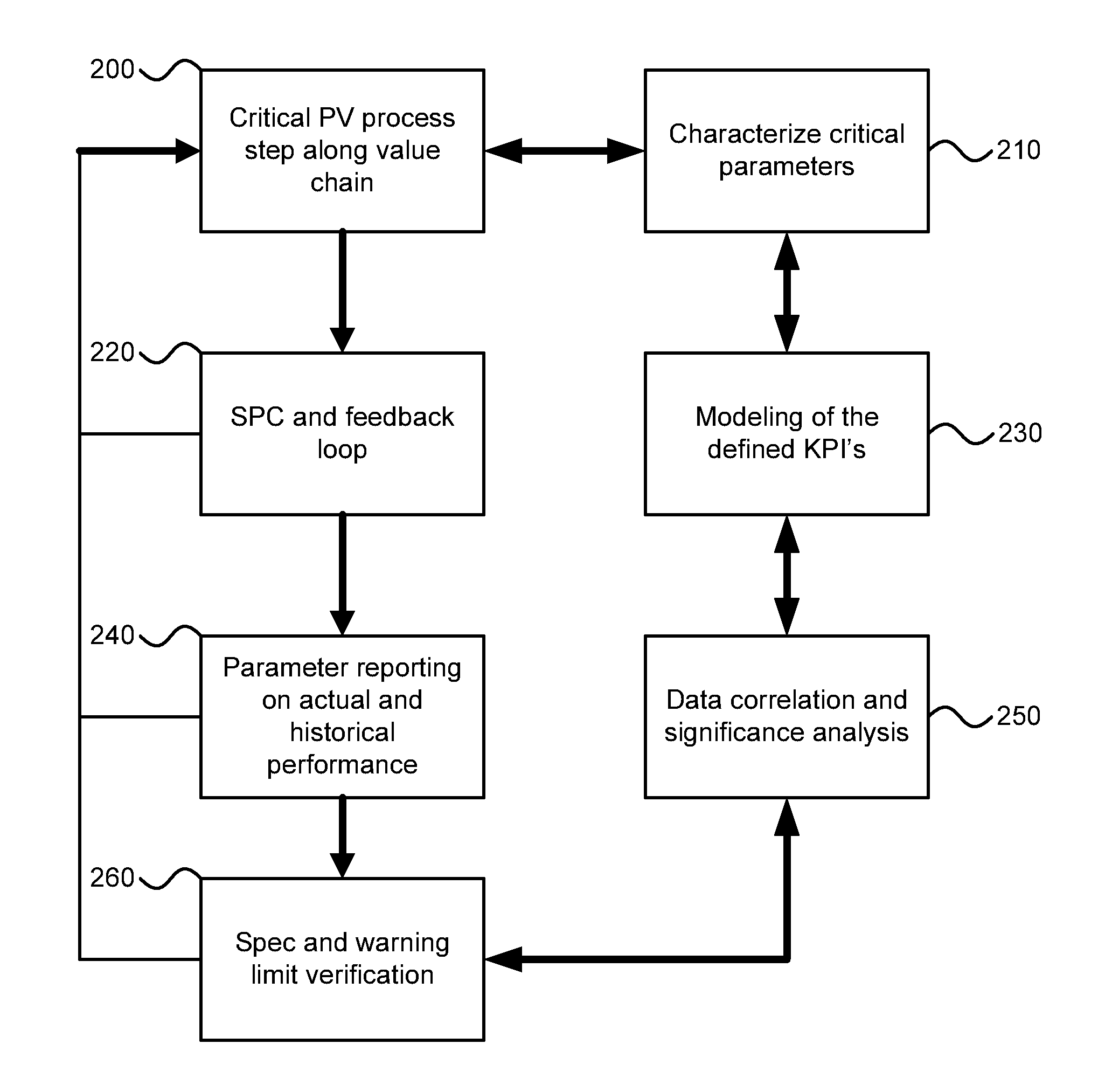

Managing a performance of solar devices throughout an end-to-end manufacturing process

InactiveUS20120179283A1Easy to manageOvercome problemsSpecial data processing applicationsAdaptive controlPower flowIndustrial engineering

Owner:IBM CORP

Method for synthesis of poly alpha-olefin lubricating oil base oil

InactiveCN104250564AImprove raw materialsImprove comprehensive utilization valueLiquid hydrocarbon mixtures productionWaxTitanium

The invention relates to a method for the synthesis of poly alpha-olefin lubricating oil base oil, and mainly solves the problems of single raw material of poly alpha-olefin lubricating oil base oil and low utilization rate of coal liquefaction product coal wax in the prior art. According to the method, a stream which contains alpha-olefin and is prepared by cracking coal wax is used as the raw material, and is contacted with a catalyst for polymerization under the conditions of reaction temperature of 40 and 140 DEG C, reaction pressure of 0.1-0.5MPa, and reaction time of 1-10 hours, and the polymerization product is processed to obtain the poly alpha-olefin lubricating oil base oil; the catalyst is a mixture of halogenated aluminum and titanium halide, the technical scheme can well solve the problems, and the method can be used for industrial production of the poly alpha-olefin lubricating oil base oil by the coal wax cracking.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing metachromatic linear flat polyester filaments

InactiveCN102586912ASatisfied with the style effectBrilliant optical effectNew-spun product collectionArtificial filament heat treatmentPolyesterYarn

The invention discloses a method for preparing metachromatic linear flat polyester filaments, which includes the steps of drying, melting, spinning, cooled oiling and hot-rolled winding. In the step of drying, crystallization temperature is 170 DEG C, crystallization time ranges from 15 minutes to 30 minutes, drying temperature is 175 DEG C, drying time ranges from 8 hours to 10 hours, the intrinsic viscosity of slices is lower than 0.005dL / g, and water content is below 20ppm. According to the technical scheme, thick-and-thin yarns are ingeniously applied to the flat filaments by means of non-uniform stretching on a conventional one-step spinning and drawing combination machine, the characteristics of flat sections and longitudinal non-uniform thicknesses are sufficiently combined, a fabric made of the flat filaments has the unique appearance effect of silk rain grains, and the defect of single style of a fabric made of pure flat fibers is overcome.

Owner:SHAOXING UNIV YUANPEI COLLEGE

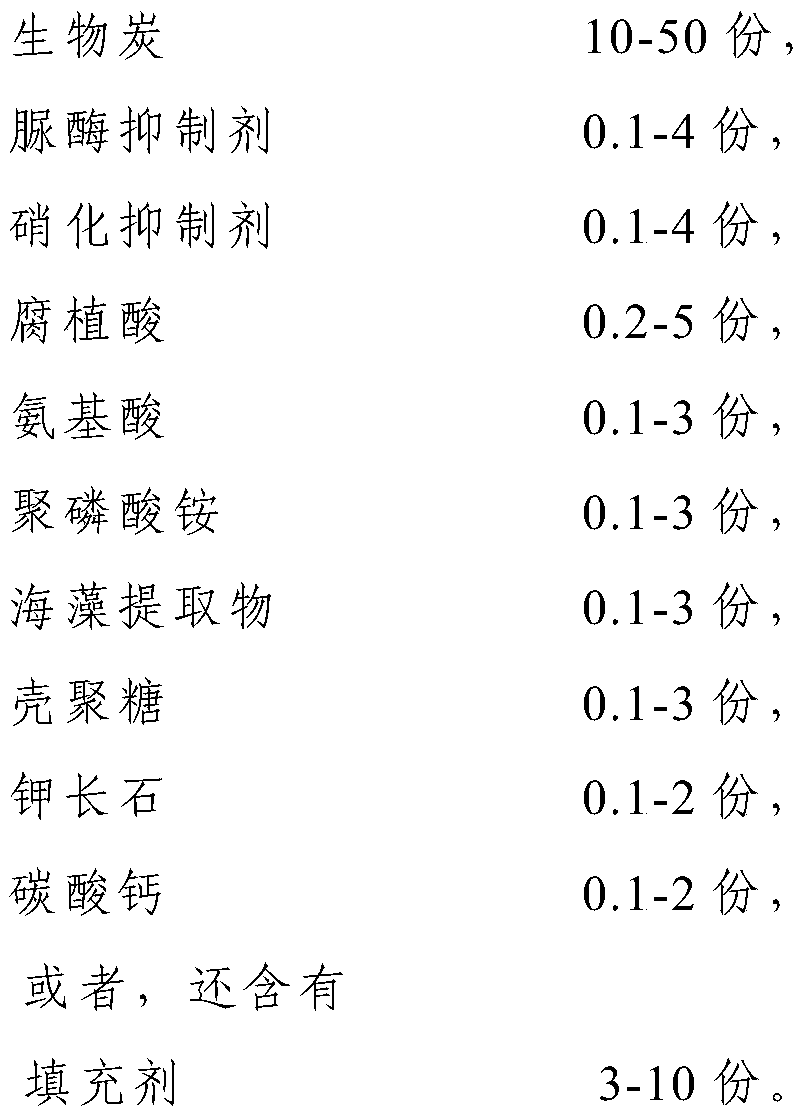

Fertilizer synergist as well as preparation method and application thereof

InactiveCN110078557AReduce dosageImprove Nutrient Utilization EfficiencyAlkali orthophosphate fertiliserClimate change adaptationPotassiumNitrification inhibitors

The invention belongs to the technical field of synergistic fertilizers, and particularly relates to a fertilizer synergist as well as a preparation method and application thereof. The fertilizer synergist comprises the following effective components: biochar, a urease inhibitor, a nitrification inhibitor, humic acid, amino acid, ammonium polyphosphate, a seaweed extract, chitosan, potassium feldspar and calcium carbonate. The fertilizer synergist provided by the invention has strong pertinence and stable synergism, can be applied by being mixed with fertilizers to further improve the fertilizer effect, increase absorption and utilization of nutrients by crops and improve the yield and quality, and is worthy of popularization and application.

Owner:STANLEY AGRI GRP CO LTD

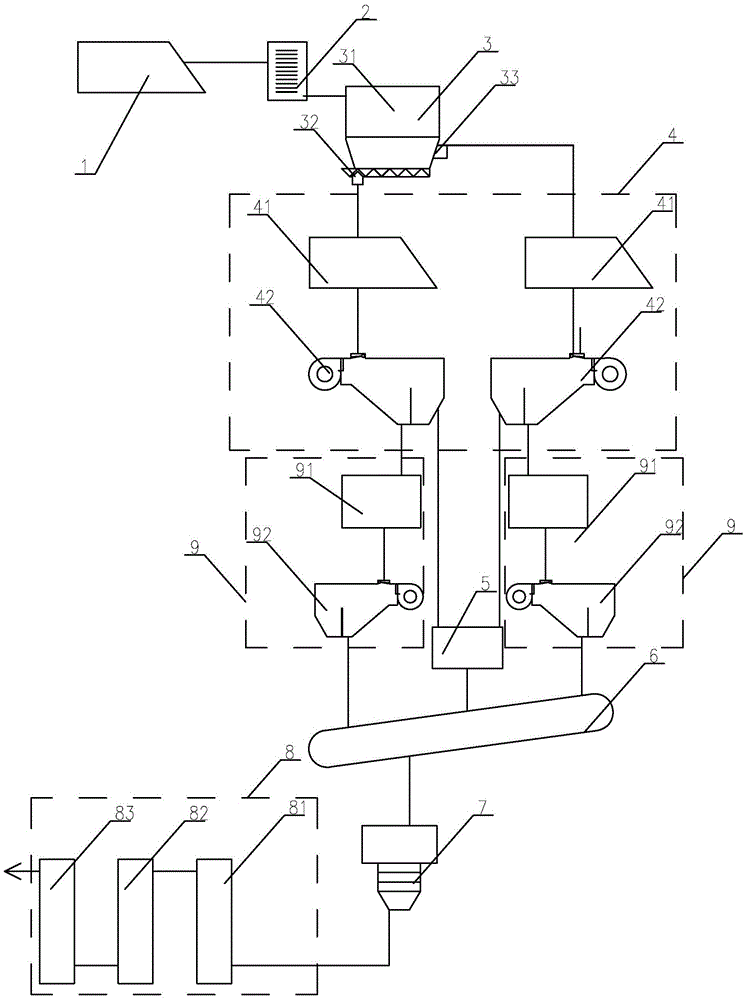

Camellia oil cold pressing and molecular distillation device and oil preparation method

PendingCN105462680AUnique fragranceUnique tasteFatty-oils/fats refiningFatty-oils/fats productionHuskDistillation

The invention relates to the camellia-seed oil pressing and refining technology, in particular to a camellia oil cold pressing and molecular distillation device and an oil preparation method. The camellia oil cold pressing and molecular distillation device comprises a camellia seed screening system, a low-temperature drying system, a husk-kernel separating system, a fine screening system, a smashing system, a low-temperature pressing system, a fine filtering system and a molecular distillation system which are connected in sequence, and the fine screening system comprises a screening machine and a winnowing machine. Camellia oil prepared with the device and method is of the first pressing grade according to the national standard, has the unique fragrance and taste of camellia seeds, is free of odor, and has a clear and transparent color. According to the camellia oil cold pressing and molecular distillation device and method, husks obtained through separation of a husking machine and wrongly classified kernels and husks in kernels are picked out through the fine screening system, picking and utilizing of kernel residues in the husks can be achieved, high-quality materials are provided for molecular distillation, and then camellia seed materials are saved and the oil yield is increased.

Owner:福建省阿嬷家健康科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com