Banana tree base activated carbon and preparation method thereof

A technology of activated carbon and banana tree, which is applied in the field of banana tree-based activated carbon and its preparation, can solve the problems of polluting the environment, waste of resources, etc., and achieves the effects of high specific surface area, strong adsorption capacity, and beneficial to comprehensive utilization and environmental protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

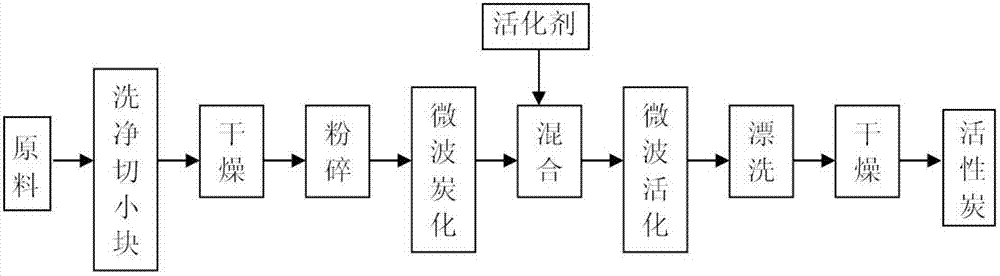

Method used

Image

Examples

Embodiment 1

[0030] (1) Wash and cut the banana trees (banana stems, banana stems, banana leaves) into small pieces, and dry them at 110°C;

[0031] (2) Crush the dried banana trees to a particle size of 40 mesh to obtain banana tree powder;

[0032] (3) Place the banana tree powder in a microwave irradiation device, and heat and carbonize under oxygen barrier for 15 minutes under the microwave power of 560W to obtain the carbonized material;

[0033] (4) The carbonized material is ground and mixed evenly with the activator potassium hydroxide powder (the mass ratio of carbonized material to potassium hydroxide powder is 1:2) to obtain a mixture;

[0034] (5) The mixture is placed in a microwave radiation device, and activated under oxygen barrier heating for 8 minutes at a microwave power of 560W to obtain an activated material;

[0035] (6) The activation material is first soaked in 10% hydrochloric acid solution for 1 hour, and the solid and liquid are separated. The solid material is ...

Embodiment 2

[0038] (1) Wash and cut the banana trees (banana stems, banana stems, banana leaves) into small pieces, and dry them at 110°C;

[0039] (2) Crush the dried banana trees to a particle size of 40 mesh to obtain banana tree powder;

[0040] (3) Place the banana tree powder in a microwave irradiation device, and heat and carbonize under oxygen barrier for 15 minutes under the microwave power of 560W to obtain the carbonized material;

[0041] (4) The carbonized material is ground and mixed evenly with the activator potassium hydroxide powder (the mass ratio of carbonized material to potassium hydroxide powder is 1:2) to obtain a mixture;

[0042] (5) The mixture is placed in a microwave radiation device, and activated under oxygen barrier heating for 6 minutes at a microwave power of 700W to obtain an activated material;

[0043] (6) The activation material is first soaked in 10% hydrochloric acid solution for 1 hour, and the solid and liquid are separated. The solid material is ...

Embodiment 3

[0046] (1) Wash and cut the banana trees (banana stems, banana stems, banana leaves) into small pieces, and dry them at 110°C;

[0047] (2) Grinding the dried banana trees to a particle size of 50 mesh to obtain banana tree powder;

[0048] (3) Place the banana tree powder in a microwave irradiation device, and heat and carbonize under oxygen barrier for 15 minutes under the microwave power of 560W to obtain the carbonized material;

[0049] (4) The carbonized material is ground and mixed evenly with the activator potassium hydroxide powder (the mass ratio of carbonized material to potassium hydroxide powder is 1:1) to obtain a mixture;

[0050] (5) The mixture is placed in a microwave radiation device, and activated under oxygen barrier heating for 7 minutes at a microwave power of 420W to obtain an activated material;

[0051] (6) The activation material was first soaked in 10% hydrochloric acid solution for 1 hour, and the solid and liquid were separated. The solid materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Iodine adsorption value | aaaaa | aaaaa |

| Iodine adsorption value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com