Method for producing porous carbon for super capacitor by utilizing lignosulfonate

A lignosulfonate and supercapacitor technology, which is applied in the preparation/purification of carbon, can solve the problems of no porous carbon materials, etc., and achieve the effects of simple preparation method, good capacitance characteristics, and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Utilize calcium lignosulfonate to prepare supercapacitor porous carbon material in the present embodiment and operate according to the following steps:

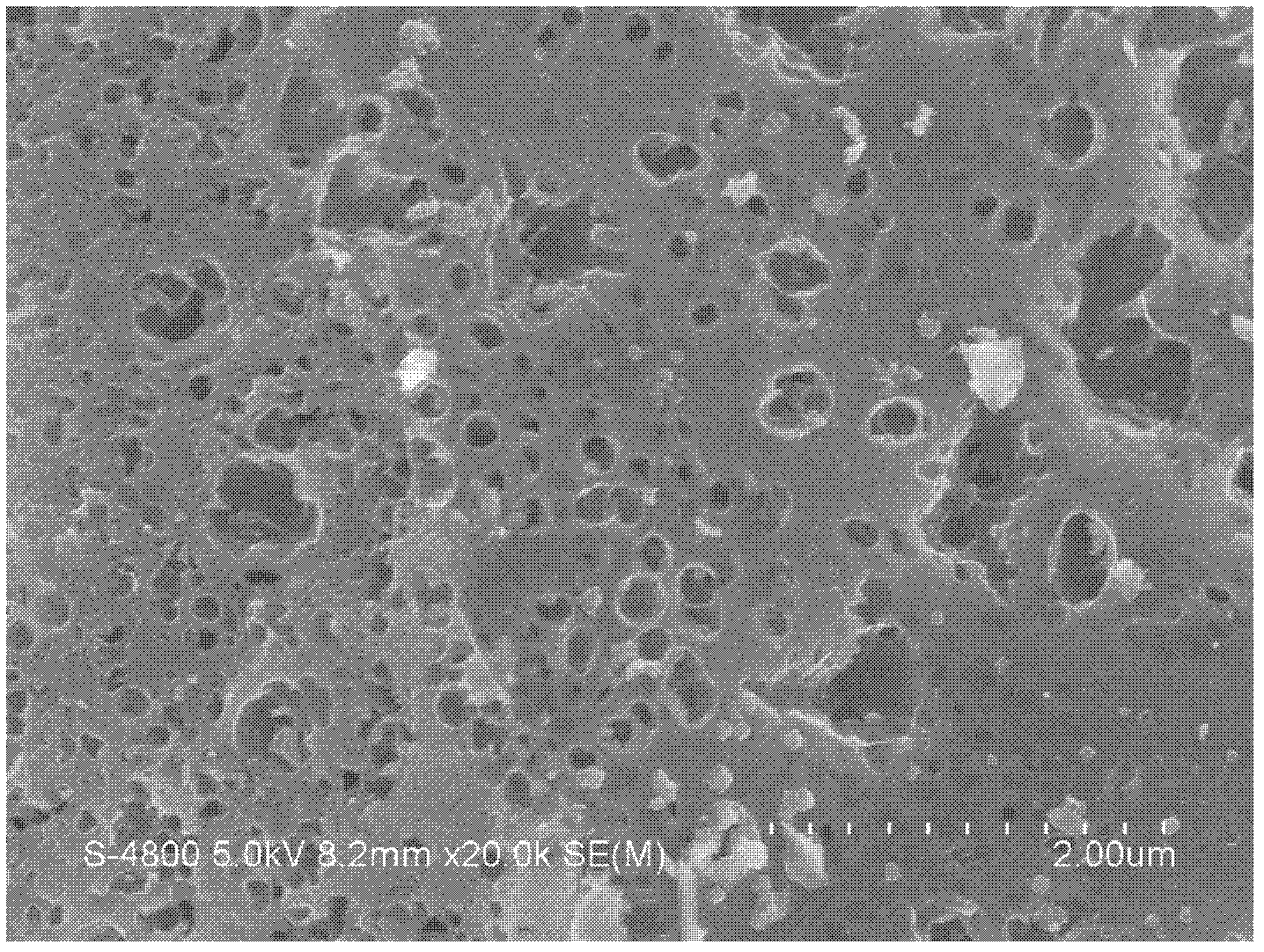

[0021] (1) Preparation of porous carbon using calcium lignosulfonate as raw material

[0022] Place commercial calcium lignosulfonate directly in a tube furnace, raise the temperature from room temperature to 800 °C at a heating rate of 5 °C / min in a nitrogen atmosphere, keep the temperature for 2 hours, and then lower it to room temperature. Ultrasonic cleaning with dilute hydrochloric acid for 4 minutes, stirring and reacting for 7 hours, suction filtration, washing with water until neutral, and drying at 120°C to obtain the finished product.

[0023] figure 1 It is the XRD pattern of the sample after pyrolyzing calcium lignosulfonate in this embodiment before washing (a) and after washing (b). Calcium carbonate (CaCO 3 ), calcium sulfide (CaS) and other components, the symbols marked in the figure * represent cal...

Embodiment 2

[0030] Utilize lignin sulfonate to prepare porous carbon for supercapacitor in the present embodiment and operate according to the following steps:

[0031] Place the commercial calcium lignosulfonate directly in a tube furnace, raise the temperature from room temperature to 700 °C at a heating rate of 5 °C / min in an argon atmosphere, keep the temperature for 3 hours, and then lower it to room temperature. The dilute nitric acid was ultrasonically cleaned for 4 minutes, stirred and reacted for 6 hours, washed with water until neutral after suction filtration, and dried to obtain the finished product.

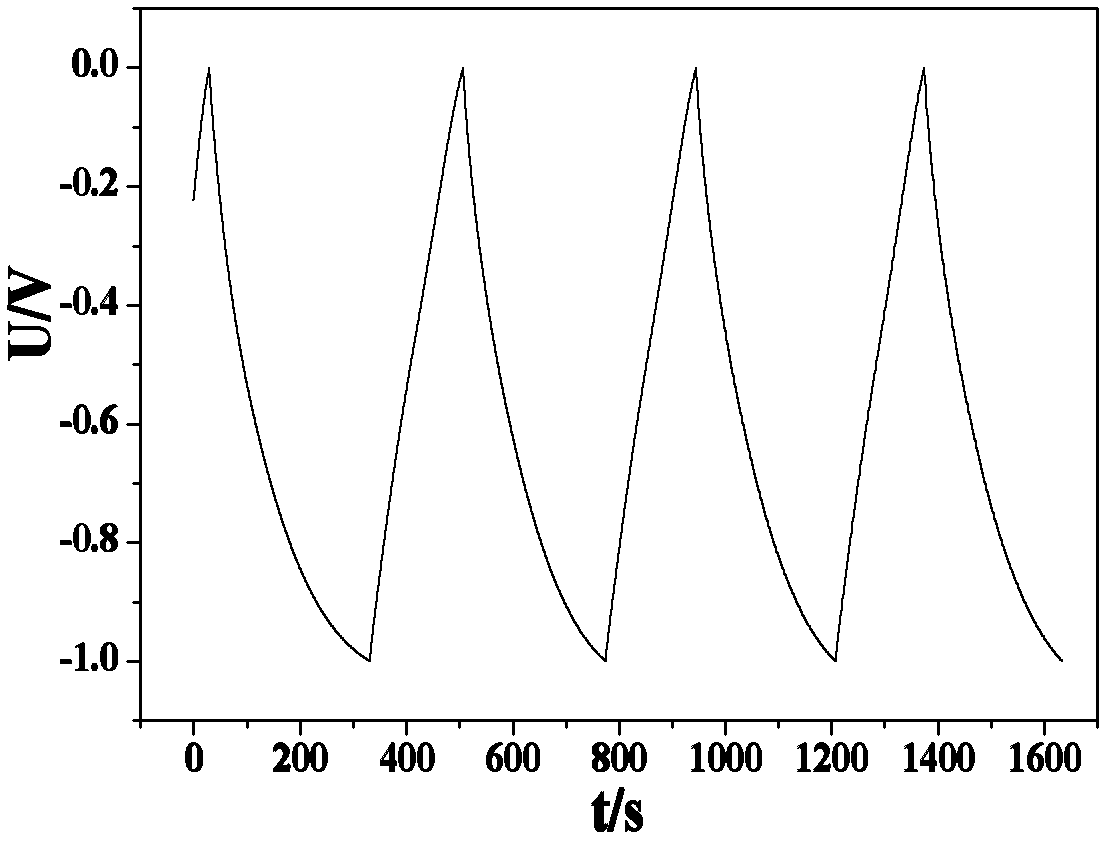

[0032] In the same manner as in Example 1, the porous carbon material prepared in this example was made into a porous carbon electrode for electrochemical testing. Figure 4 Curve B in 1 -B 2 It is the cyclic voltammetry curve of the porous carbon electrode prepared in this example. It presents a relatively regular rectangle without redox peaks, indicating that its capacity m...

Embodiment 3

[0034] Place the commercial magnesium lignosulfonate directly in a tube furnace, raise the temperature from room temperature to 800 °C at a heating rate of 5 °C / min in a nitrogen atmosphere, keep the temperature for 1 h, and then lower it to room temperature. Ultrasonic cleaning with dilute nitric acid for 4 minutes, stirring and reacting for 7 hours, suction filtration, washing with water until neutral, and drying to obtain the finished product.

[0035]In the same manner as in Example 1, the porous carbon material prepared in this example was made into a porous carbon electrode for electrochemical testing. Figure 4 Curve C in 1 -C 2 It is the cyclic voltammetry curve of the porous carbon electrode prepared in this example. It presents a relatively regular rectangle without redox peaks, indicating that its capacity mainly comes from the electric double layer capacitance at the interface between the porous carbon electrode and the electrolyte.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com