OMS-2 catalyst used in elimination of benzene series at low temperature and preparation and application

A technology of OMS-2 and low-temperature catalysis, applied in the direction of physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problem of high reaction temperature for complete catalytic elimination of benzene series

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) the preparation method of above-mentioned catalyst provided by the present invention, comprises the steps:

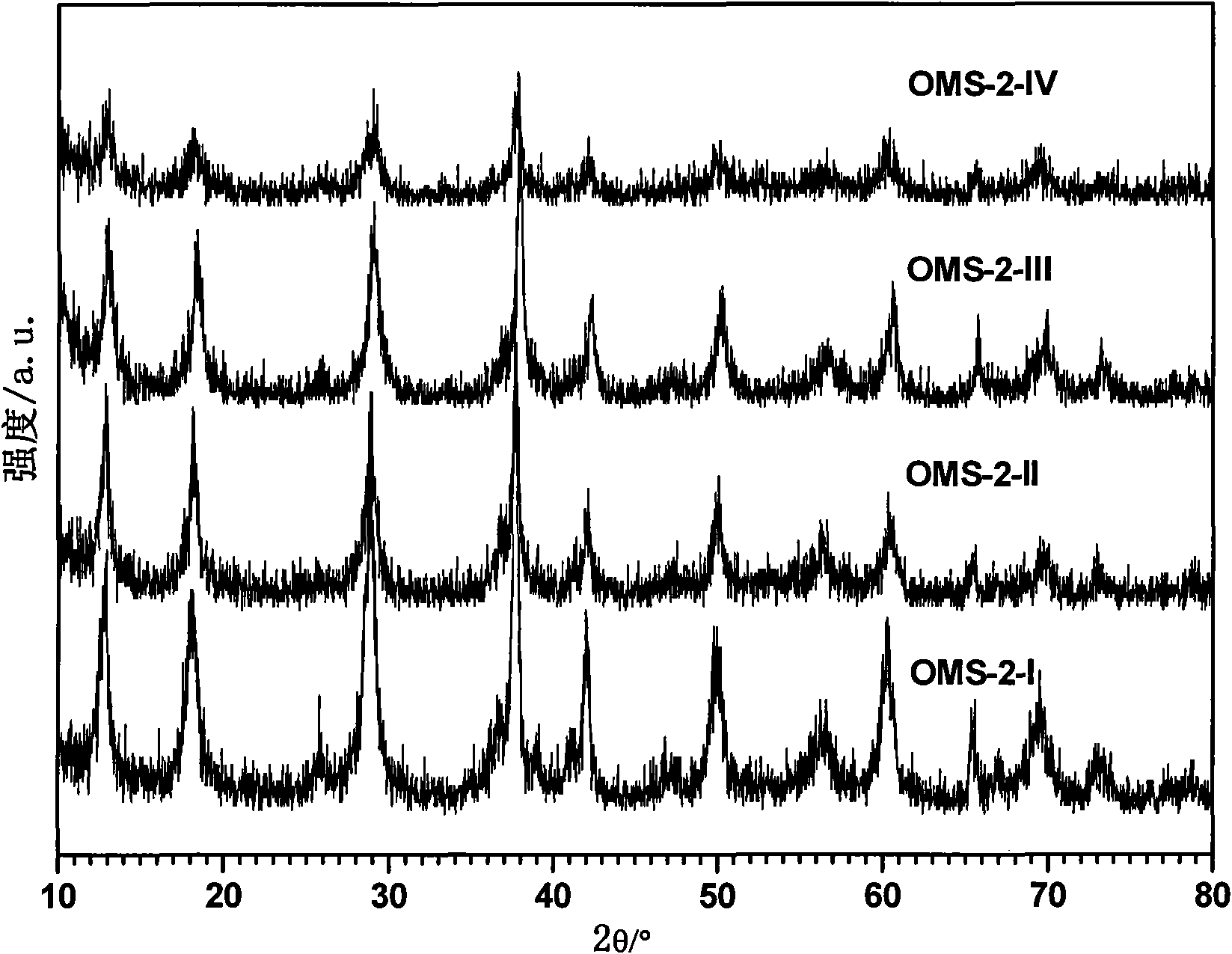

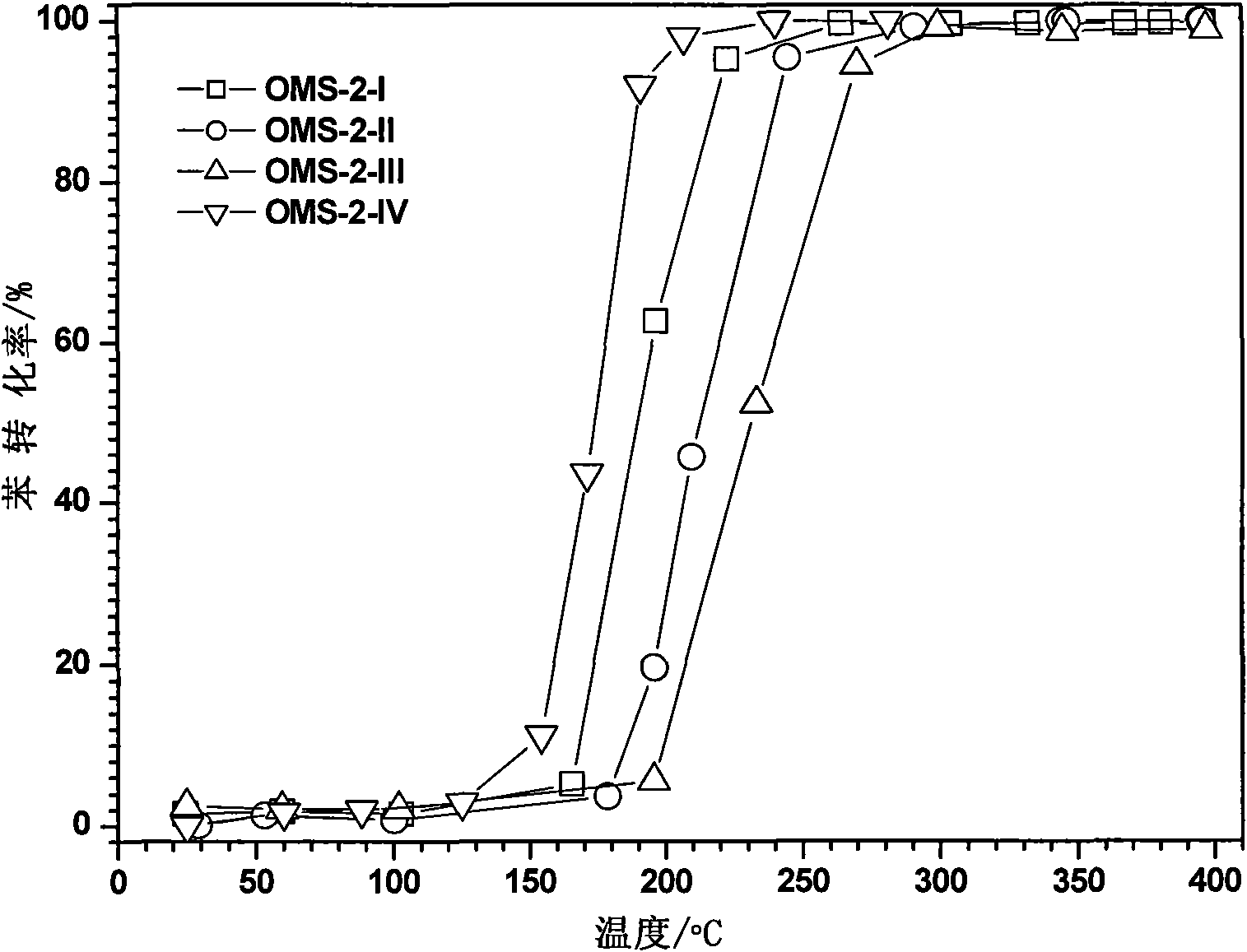

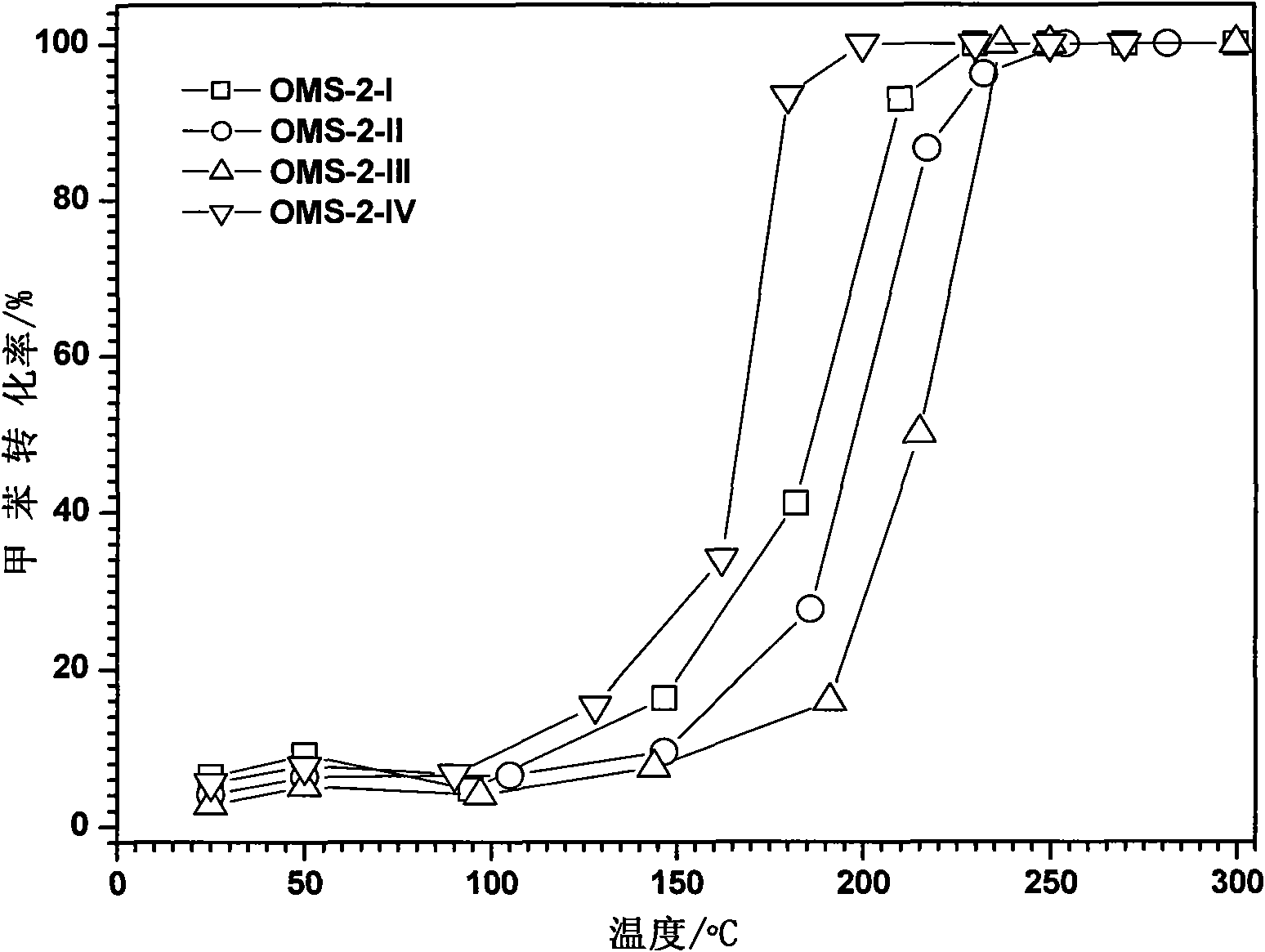

[0021] KAc with a concentration of 0.1 mol / L and 0.1 mol / L HAc are mixed to form a buffer solution at a ratio of KAc / HAc molar ratio=0.1, and the pH is adjusted to 3.7. Add this buffer solution to 1.0mol / L Mn(Ac) 2 In solution (wherein, buffer solution: Mn(Ac) 2 solution (volume ratio)=0.2:1), mix well, then add 0.1mol / LKMnO 4 The solution was slowly dropped into the above mixed solution (where KMnO 4 :Mn(Ac) 2 (molar ratio) = 0.5:1), stirred for 2 hours, sealed and aged for 12 hours, refluxed at 80 for 20 hours, vacuum filtered, rinsed with deionized water until neutral, and dried at 100°C for 10 hours to obtain black OMS-2 The body is then ground into powder, and fired at 300°C at a rate of 1°C / min for 4 hours to obtain OMS-2-I. Its specific surface area is 100m 2 / g, high thermal stability (heating to 600 ° C structure does not change), figure 1 The...

Embodiment 2

[0023] (1) the preparation method of above-mentioned catalyst provided by the present invention, comprises the steps:

[0024] KAc with a concentration of 0.1 mol / L and 0.1 mol / L HAc are mixed to form a buffer solution at a ratio of KAc / HAc molar ratio=0.1, and the pH is adjusted to 3.7. Add this buffer solution to 1.0mol / L Mn(Ac) 2 In solution (wherein, buffer solution: Mn(Ac) 2solution (volume ratio)=0.2:1), mix well, then add 0.1mol / LKMnO 4 The solution was slowly dropped into the above mixed solution (where KMnO 4 :Mn(Ac) 2 (molar ratio) = 1:1), stirred for 2 hours, sealed and aged for 12 hours, refluxed at 80 for 20 hours, vacuum filtered, rinsed with deionized water until neutral, and dried at 100°C for 10 hours to obtain black OMS-2 The body is then ground into powder, and fired at 500°C at a rate of 1°C / min for 1 hour to obtain OMS-2-II. Its specific surface area is 105m 2 / g, high thermal stability (heating to 600 ° C structure does not change), figure 1 The XR...

Embodiment 3

[0027] (1) the preparation method of above-mentioned catalyst provided by the present invention, comprises the steps:

[0028] KAc with a concentration of 0.1 mol / L and 0.1 mol / L HAc are mixed to form a buffer solution according to the ratio of KAc / HAc molar ratio=10.0, and the pH is adjusted between 5.6. With 2.0g of PVP (molecular formula (C 6 h 9 NO) n , molecular weight 10000) dissolved in 2.0mol / L Mn(Ac) 2 In solution (wherein, PVP:Mn(Ac) 2 (number of moles)=0.004:1), the above buffer solution is added in this solution (wherein, buffer solution: Mn(Ac) 2 solution (volume ratio)=0.5:1), mix well, and then add 0.4mol / L KMnO 4 The solution was slowly dropped into the above mixed solution (wherein, KMnO 4 :Mn(Ac) 2 (molar ratio)=0.5:1), stirred for 4 hours, sealed and aged for 12 hours, refluxed at 120°C for 26 hours, vacuum filtered, rinsed with deionized water until neutral, and dried at 140°C for 12 hours to obtain black OMS-2 The precursor was then ground into pow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com