Recycling system integration apparatus used for zero discharge of sewage produced in gas making

A system-integrated, zero-emission technology, applied in the coal chemical industry to reduce fuel costs, reduce costs and increase benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

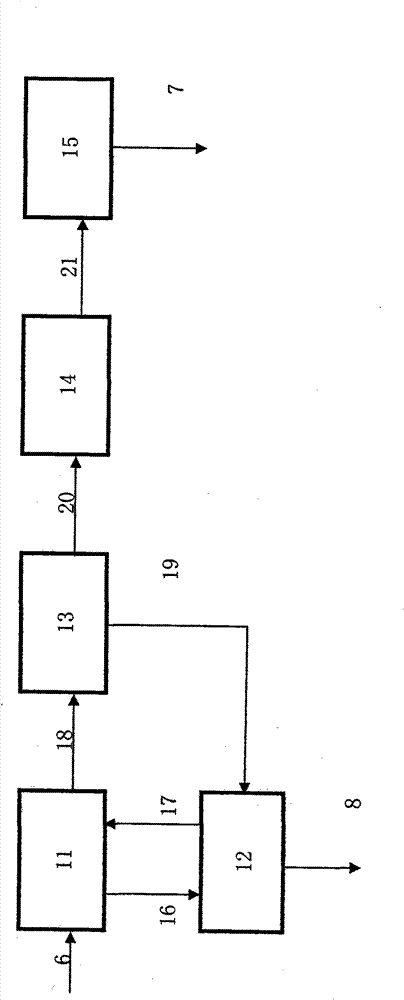

[0021] 1. After the semi-coal gas produced in the gas-making section passes through the gas scrubber 1, the sewage generated containing a large amount of dust, organic compounds, unburned coal and other substances enters the advection of the gas-making sewage treatment and recycling device 2 through 6 After the sedimentation tank 11 settles, the sludge enters the sludge thickening tank 12 through 16, and the sewage enters the micro-vortex desilter 13 through 18. After desilting again, the sludge enters the sludge thickening tank 12 through 19, and the sludge thickening tank 12 The water obtained from sludge concentration is returned to the advection sedimentation tank 11 through 17, and the desiltered water in the vortex desilter 13 enters the cooling tower 14 through 20, and then enters the cooling pool 15 through 21, and the clear water in the cooling pool returns to the gas scrubber through 7 and repeats use.

[0022] 2. The black sludge with oily surface, large water conte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com