Flat membrane bioreactor

A bioreactor, flat membrane technology, applied in biological treatment devices, biological water/sewage treatment, chemical instruments and methods, etc., can solve the problems of reducing membrane flux, foaming and foaming in the fermentation process, and reducing contamination. The possibility of scale clogging, the overall structure is simple, the effect of improving the mass transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

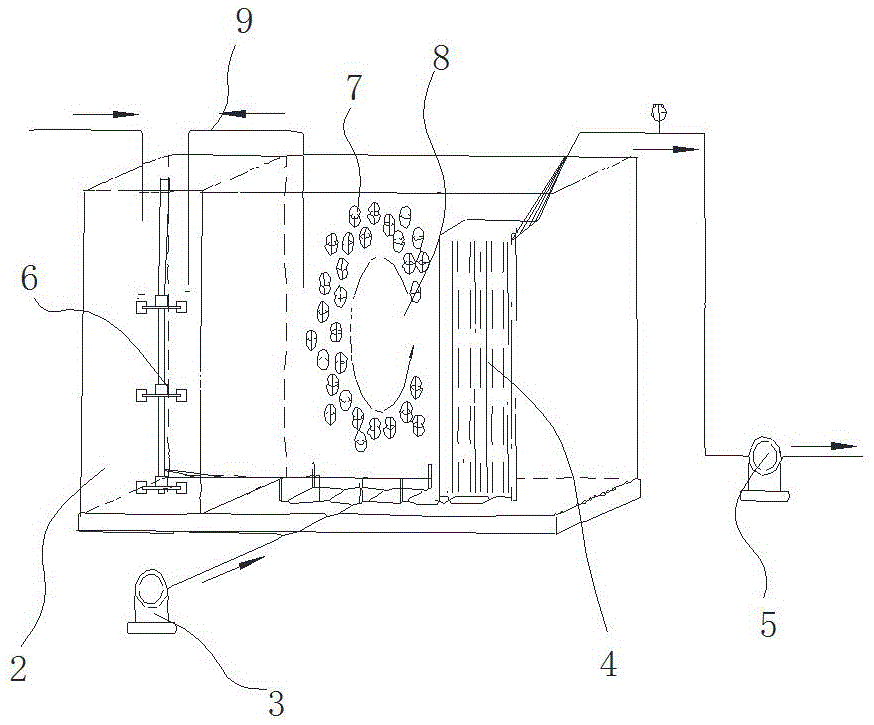

[0018] The flat membrane bioreactor of the present embodiment, such as figure 1 As shown, it includes an anaerobic tank 2, an aerobic tank 8 and a membrane module 4 connected in sequence. The aerobic tank 8 is supplied with air by the air pump 3, and the membrane module 4 is discharged by the suction pump 5. The anaerobic tank 2 is provided with a water inlet, and a stirring shaft 6 is vertically arranged in the anaerobic tank 2, and a plurality of stirring paddles are arranged at intervals on the stirring shaft 6, and the lower end of the stirring shaft 6 extends To the bottom of the anaerobic pool 2, the inner wall of the anaerobic pool 2 is sequentially provided with multiple sections of spiral channels (not shown in the figure) from top to bottom, and each section of the spiral channel is fixed on the inner wall of the anaerobic pool by multiple pieces The helical blades are spliced around, and each section of the helical channel is formed with a through channel for acco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com