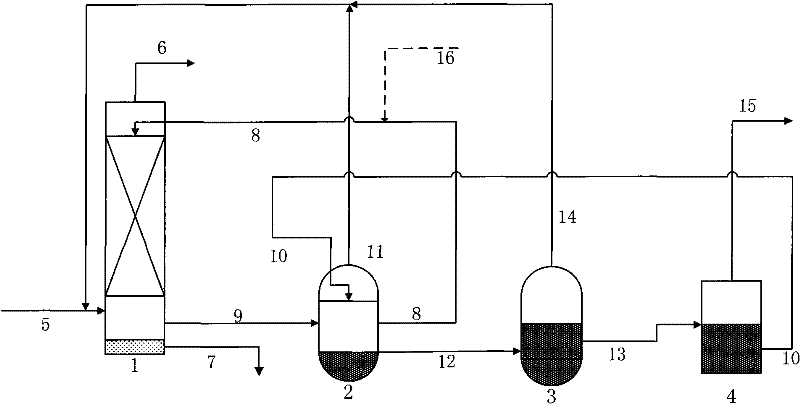

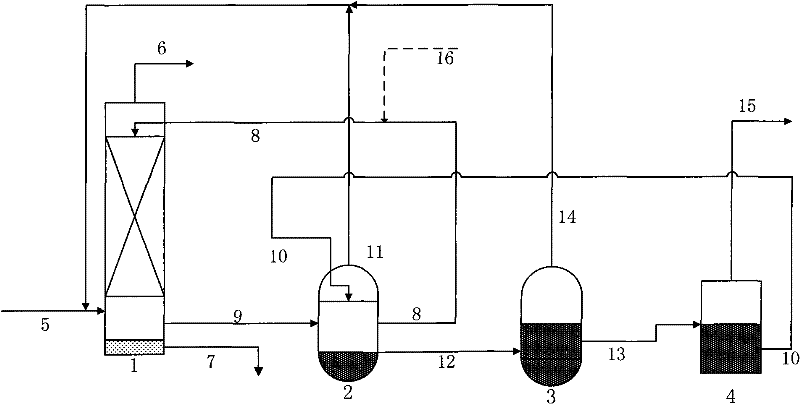

Process for desulphurizing flue gas and producing sulfur dioxide by sodium-zinc method

A technology of sulfur dioxide and flue gas, which is applied in the fields of electric power, building materials, metallurgy, and chemical industry. It can solve the problems of low decomposition temperature, desulfurization and scaling, and achieve the effects of reducing scaling and clogging, saving usage and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) Feed SO into the desulfurization tower at a flow rate of 1.5L / min 2 The flue gas with a volume fraction of 5% is sprayed with 1.0mol / L Na in the desulfurization tower at a flow rate of 0.4L / min 2 CO 3 solution, in order to ensure that the SO 2 The conversion rate, in the implementation to ensure that the Na passing through the desulfurization tower per minute 2 CO 3 The number of moles is the amount of SO passed into the desulfurization tower 2 more than three times. And at the outlet of the desulfurization tower, use a flue gas analyzer to detect SO in the gas discharged to the atmosphere 2 volume concentration. The flue gas analyzer measures 10 times evenly within 20 minutes, SO 2 The volume concentration is between N.D. and 22ppm, SO 2 The conversion rate is above 99.9%.

[0037] (2) after the product solution in the desulfurization tower is drawn, pass into circulation tank with the flow rate of 0.4L / min, utilize rotary feeder to feed ZnO solid with the...

Embodiment 2

[0041] (1) Feed SO into the desulfurization tower at a flow rate of 0.5L / min 2 The flue gas with a volume fraction of 30% is sprayed with 0.5mol / L Na at a flow rate of 1.5L / min into the desulfurization tower at the same time 2 CO 3 solution, in order to ensure that the SO 2 The conversion rate, in the implementation to ensure that the Na passing through the desulfurization tower per minute 2 CO 3 The number of moles is the amount of SO passed into the desulfurization tower 2 more than three times. And at the outlet of the desulfurization tower, use a flue gas analyzer to detect SO in the gas discharged to the atmosphere 2 volume concentration. The flue gas analyzer measures 10 times evenly within 20 minutes, SO 2 The volume concentration is between 12ppm and 29ppm, SO 2 The conversion rate is above 99.9%.

[0042] (2) After the product solution in the desulfurization tower is drawn, it is passed into the circulation tank with a flow rate of 1.5L / min, and the ZnO solid...

Embodiment 3

[0046] (1) Feed SO into the desulfurization tower at a flow rate of 1.5L / min 2 The flue gas with a volume fraction of 1% is sprayed with 0.1mol / L Na in the desulfurization tower at a flow rate of 1L / min 2 CO 3 solution, in order to ensure that the SO 2 The conversion rate, in the implementation to ensure that the Na passing through the desulfurization tower per minute 2 CO 3 The number of moles is the amount of SO passed into the desulfurization tower 2 more than three times. And at the outlet of the desulfurization tower, use a flue gas analyzer to detect SO in the gas discharged to the atmosphere 2 volume concentration. The flue gas analyzer measures 10 times evenly within 20 minutes, SO 2 The volume concentration is between N.D. and 13ppm, SO 2 The conversion rate is above 99.9%.

[0047] (2) after the product solution in the desulfurization tower is drawn, pass into circulation tank with the flow rate of 0.4L / min, utilize rotary feeder to feed ZnO solid with the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com