Gas guide system for gas-burning double-hearth lime kiln

A double-chamber lime kiln and air guide technology, which is applied in the field of the air guide system of the gas-fired double-chamber lime kiln, can solve the problem of high use cost and daily maintenance cost, the inability to use the spray gun cooling air ring pipe at the same time, and the increase of the chain of processes. Condition and other problems, to achieve the effect of saving use cost and maintenance cost, facilitating process control, and good purging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

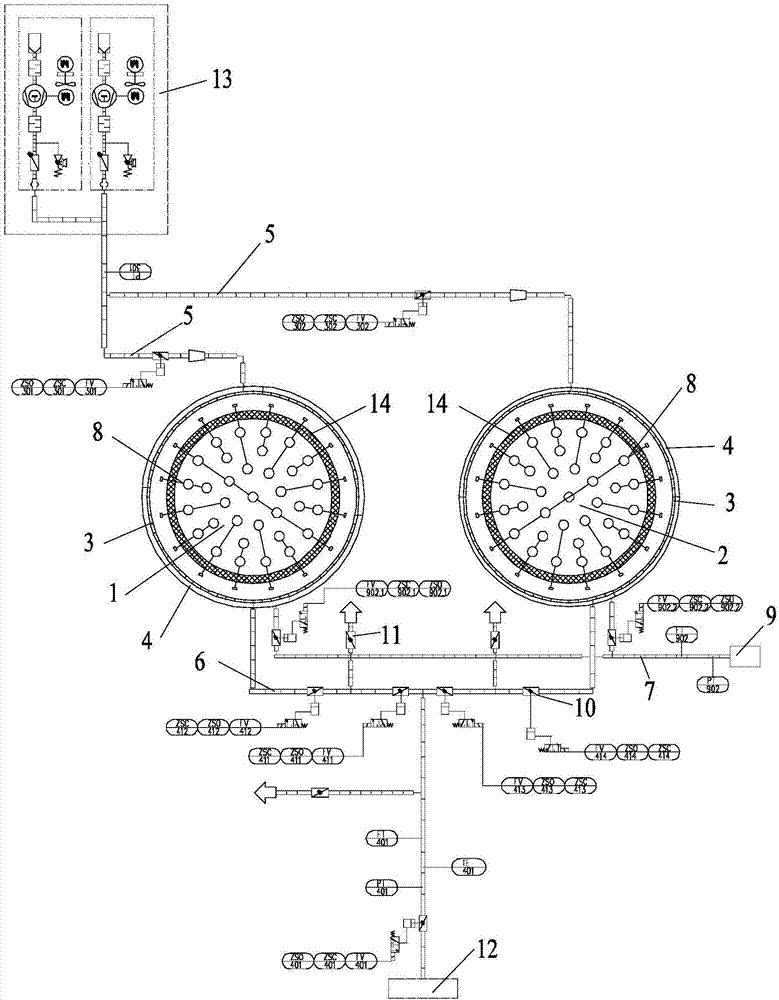

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

[0018] Such as figure 1 As shown, a gas-fired double-chamber lime kiln gas guide system includes a first kiln chamber 1 and a second kiln chamber 2, and the outer walls of the first kiln chamber 1 and the second kiln chamber 2 are provided with a first kiln chamber A ring pipe 3, the first ring pipe 3 is connected with a gas pipeline 6, a cooling air pipeline 5 and a nitrogen pipeline 7, the gas pipeline 6, the cooling air pipeline 5 and the nitrogen pipeline 7 are all connected with the first ring pipe 3, the first A plurality of spray gun hoses are connected to the ring pipe 3, and a plurality of spray guns 8 corresponding to the spray gun hoses are connected to the inner walls ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com