Automatic purging system and method for aluminum strip mill

An aluminum plate and strip rolling technology, applied in metal rolling, metal rolling, metal processing equipment, etc., can solve the problems of uneven distribution of purging power, unsatisfactory purging results, and inability to ensure uniform oil purging. , to achieve uniform and thorough purging and good effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

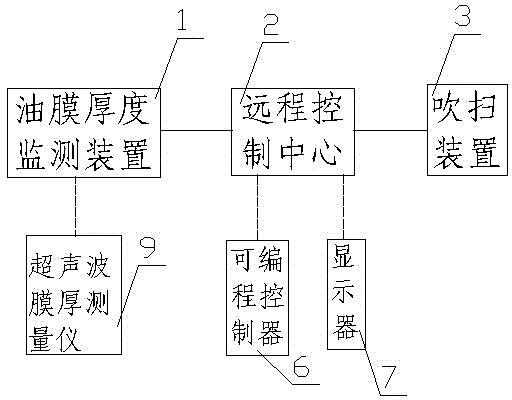

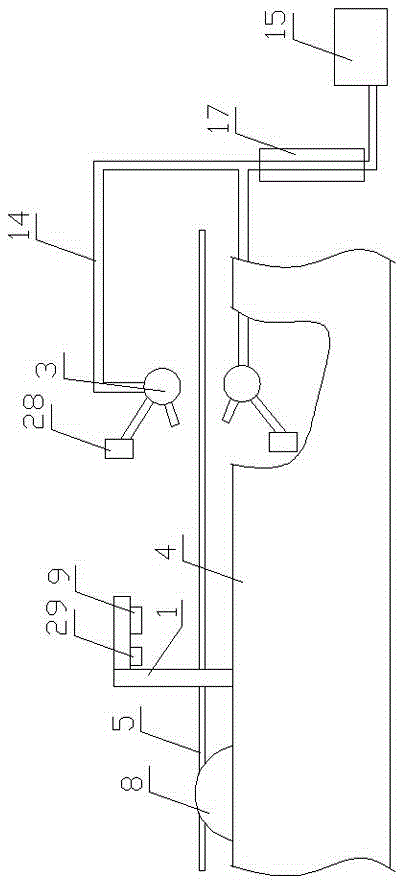

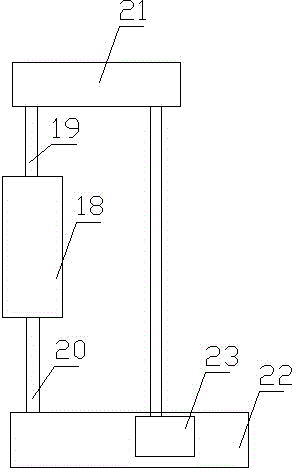

[0035] Such as figure 1 and figure 2 As shown: the present invention provides an automatic purging system for an aluminum plate and strip mill, comprising an oil film thickness monitoring device 1, a remote control center 2, a rolling mill and a purging device 3, the oil film thickness monitoring device 1, a remote control center 2 and a blowing device The sweeping devices 3 are connected in sequence, and the oil film thickness monitoring device 1 and the purging device 3 are arranged on the rolling mill, and the rolling mill includes a rolling mill body 4 and an aluminum strip 5 on the rolling mill body 4 . The system realizes the purging of excess oil in the cold rolling process of aluminum strips. The oil film thickness on the aluminum strips can be monitored through the oil film thickness monitoring device, and the monitored information is sent to the remote control center. When the oil film thickness is relatively high When it is large, the power of the control air pump...

Embodiment 5

[0043] The present invention also provides an operation method of the automatic purging system of an aluminum strip rolling mill, comprising the following steps:

[0044] 1) Monitor the oil film thickness on the upper and lower surfaces of the aluminum strip during the rolling process of the aluminum strip, and send the oil film thickness information to the remote control center;

[0045] 2) The programmable controller judges the oil film thickness information. When the oil film is greater than 0.2mm, increase the power of the air pump. When the oil film thickness is less than 0.2mm, reduce the power of the air pump. The aluminum strip is continuously purged of excess oil;

[0046] 3) Use the infrared temperature sensor to collect the temperature information of the aluminum strip, and send the collected temperature information to the remote control center;

[0047] 4) When the temperature of the aluminum strip is lower than 25°C, the gas blown out by the purging device is hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com