Method for detecting solid content of slurry

A detection method, solid content technology, applied in the direction of weighing by removing certain components, can solve the problem of short detection time, and achieve the effect of simple operation, less pollution, and shortened detection time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] A method for detecting the solid content of slurry, comprising the following steps: a. taking and weighing a certain amount of chlorosilane slurry sample; b. centrifuging the stirred chlorosilane slurry slurry sample with a centrifuge; c. blowing nitrogen gas to blow out the remaining volatile chlorosilane liquid; d. weighing the mass of the remaining solid to obtain the solid content in the slurry.

[0018] When testing: 1. Take the stirred chlorosilane slurry sample (30ml of chlorosilane slurry mixture) and place it in a pre-dried and weighed (accurate to 0.02g) polytetrafluorocentrifuge test tube, quickly cover it, Weigh (accurate to 0.02g) to obtain the sample mass m 0 .

[0019] 2. Put the chlorosilane slurry sample in a centrifuge and centrifuge at 3000r / min for 3min. After centrifugation, pour the supernatant into the waste liquid bottle.

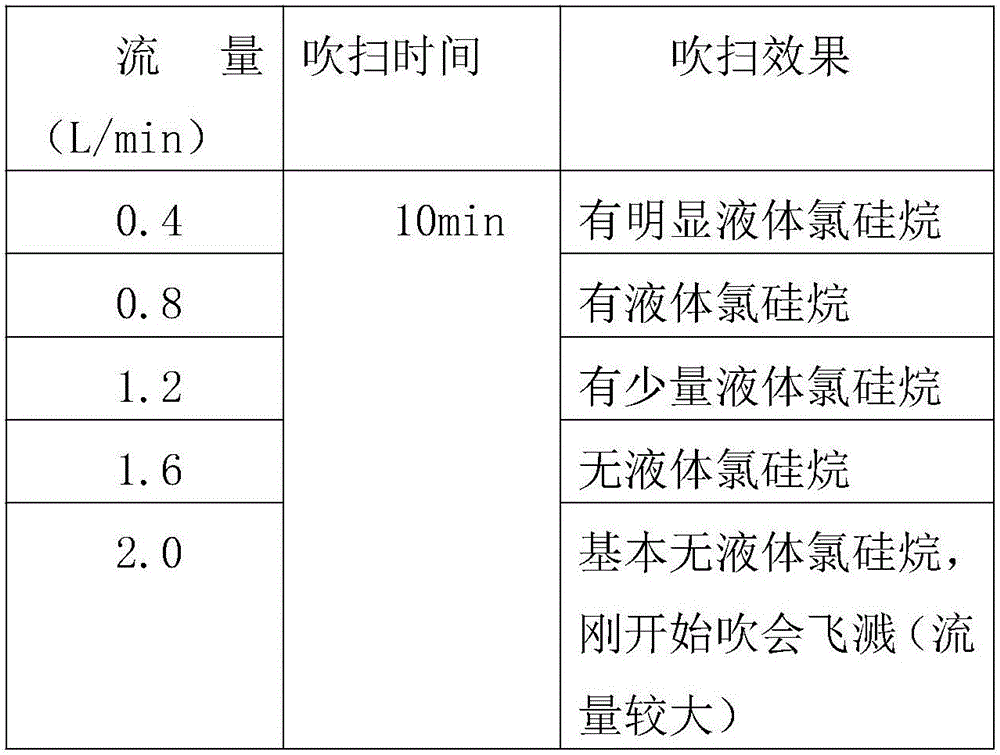

[0020] 3. Connect the PTFE centrifuge test tube through the flow meter and the nitrogen pipeline, then pass through the ni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com