Automatic pointing glue injection machine of single-component glue

A seam glue injection machine and a technology of dispensing glue, which is applied in the field of glue injection machines, can solve the problems of joint glue strips with different widths, high manual labor intensity, and pollution of the working surface, and achieve uniform width, convenient operation, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

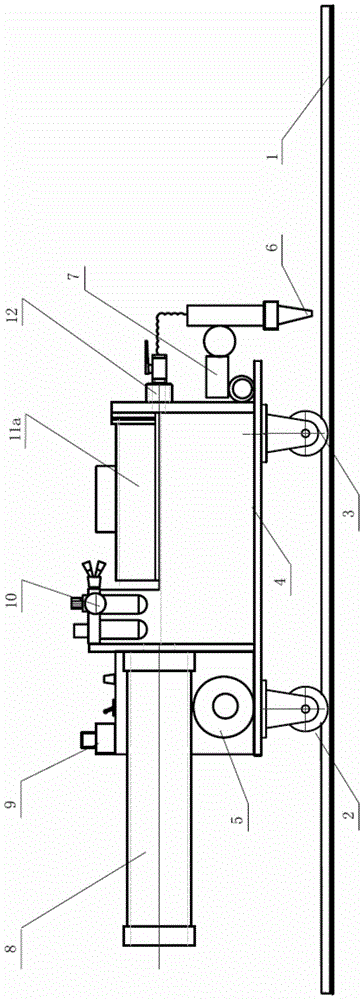

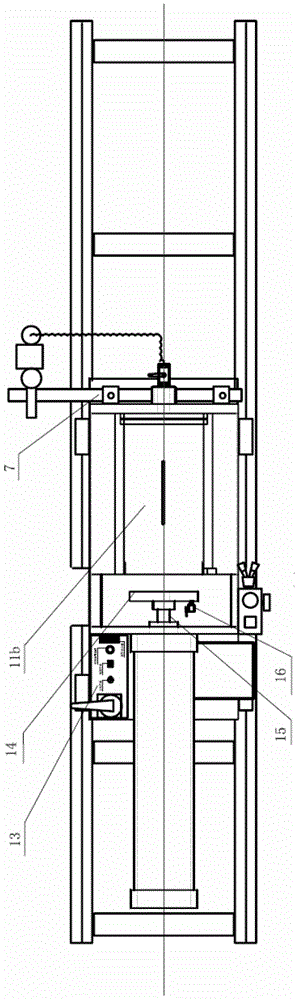

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

[0019] refer to figure 1 and figure 2 The one-component glue automatic pointing glue injection machine shown includes a base 4, a guide drive wheel 2 and a guide pulley 3 installed under the base 4, and a shock-absorbing and anti-skid mechanism for carrying the guide drive wheel 2 and the guide pulley 3 Track 1, the variable frequency motor 5 installed on the base 4 for driving the guide drive wheel 2 and the guide pulley 3, the pneumatic piston cylinder 8 installed on the base 4, the rubber barrel protective cover 11a in front of the pneumatic piston cylinder 8, The rubber material tube 11b arranged in the rubber material tube protective cover 11a,

[0020] Wherein, a piston rod 15 is installed in the pneumatic piston cylinder 8, and the piston rod 15 is connected to a rubber pushing plate 14 for pushing out the rubber material in the rubber material cylinder 11b, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com