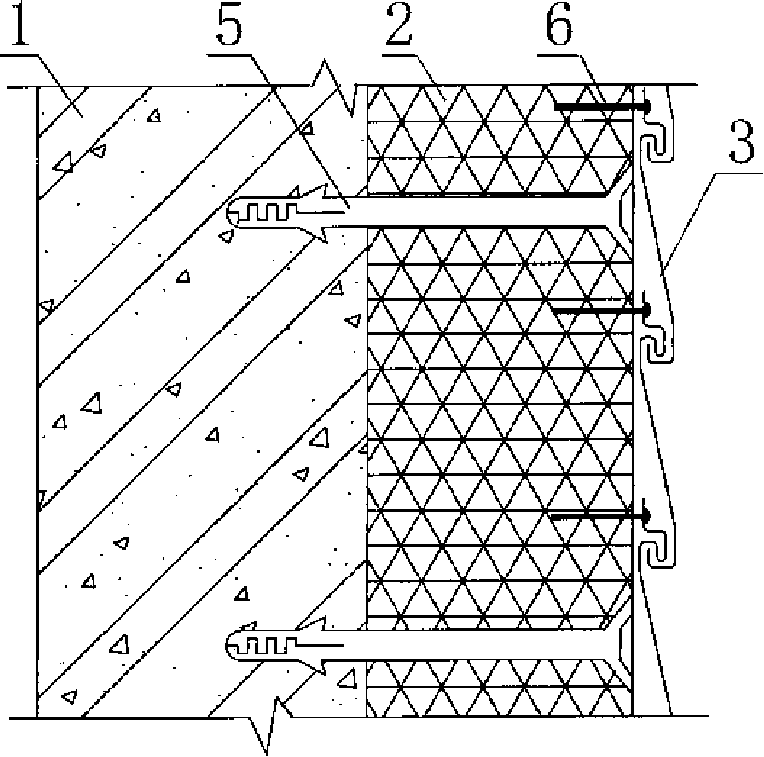

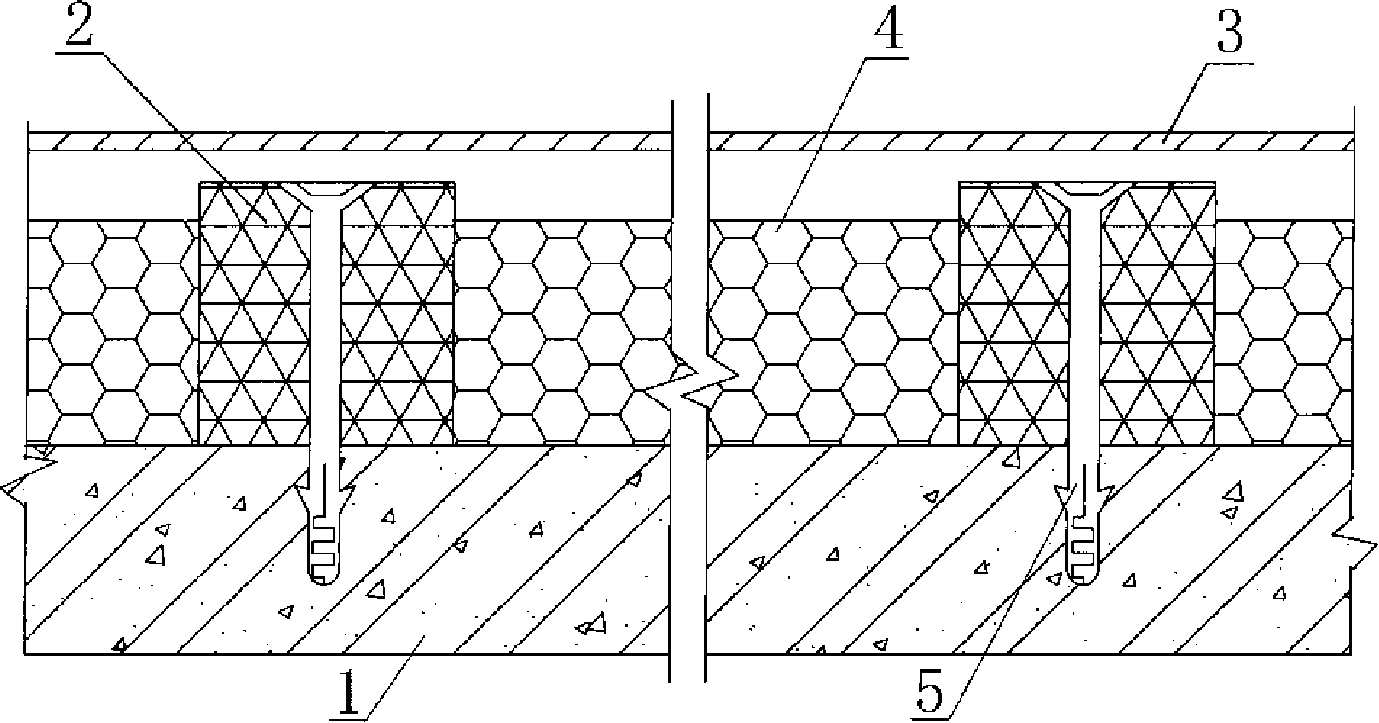

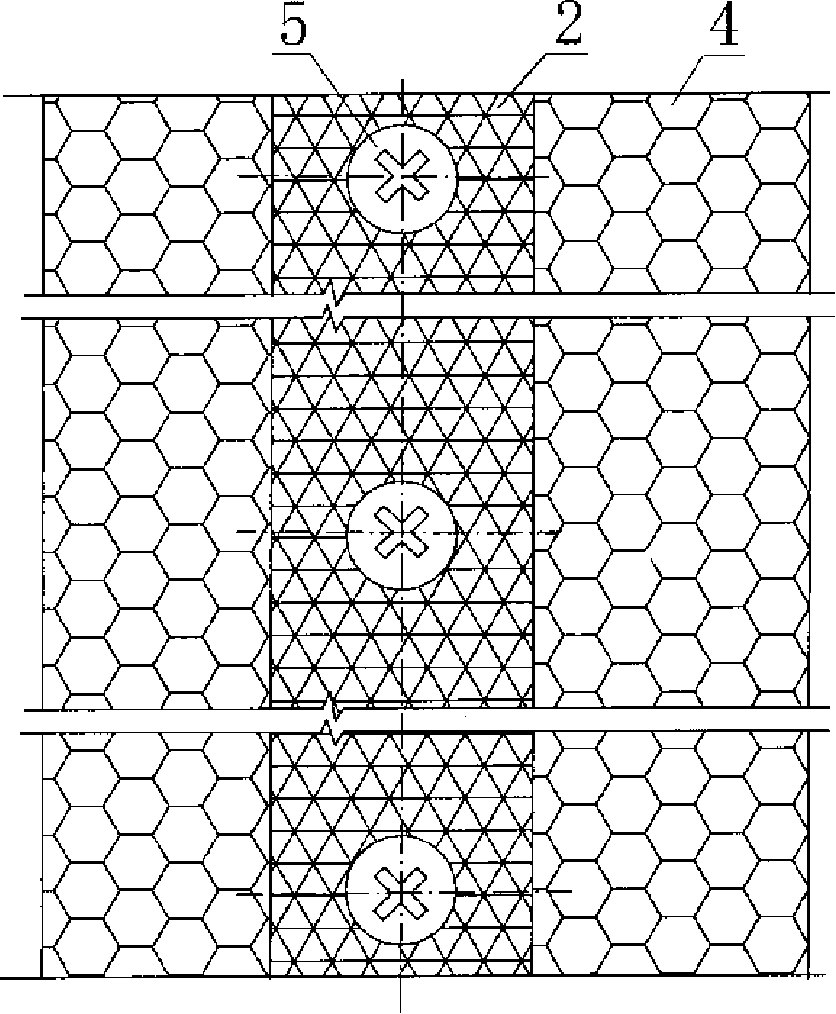

Dry-hanging keel decorative board heat insulation composite wall and its construction method

A thermal insulation composite and construction method technology, applied in covering/lining, building, building construction, etc., can solve the problems of heavy wet work workload, monotonous building appearance, easy cracking, etc., and achieve convenient processing, good thermal insulation effect, and not easy pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The steps of the construction method of the dry-hanging keel decorative board thermal insulation composite wall of the present invention are as follows:

[0047] [1]. After the base surface is prepared, the elastic line: vertical control reference line: According to the building facade design and the technical requirements of the thermal insulation keel decorative cladding board, the vertical control reference line of the external doors and windows, the outer corner column and the inner corner column is ejected on the outer wall. Vertical control line: Between the ejected vertical control reference lines, pop up the vertical control line every 400mm from one end to the other. When the distance between the control line and the reference line is greater than 400mm and less than 800mm, the vertical control line will pop up according to its equal distance. In order to facilitate the installation of the thermal insulation keel, the reference line and the control line can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com