A bidirectional pulse purge precleaning system of a hydraulic pipeline system

A hydraulic pipeline and two-way pulse technology, which is applied in the field of hydraulic pipeline system, can solve the problems of weak cleaning ability, dirt that cannot be cleaned, and dirt accumulation that cannot be cleaned, so as to achieve high pressure, reduce purge dead angle, and blow good sweeping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

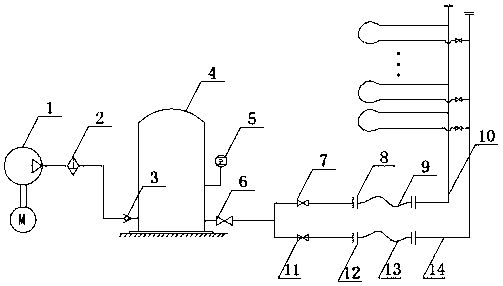

[0022] like figure 1 As shown: the flushing system involved in the present invention includes the following devices: the air compressor 1 is used to provide high-pressure compressed air. Filter 2 is used to remove oil mist, water and other impurities in the compressed air to ensure dry and clean purge air. The one-way valve 3 prevents the compressed air from flowing back to the air compressor 1. The air tank 4 is used to store high-pressure compressed air. Pressure gauge 5 is used to show the compressed air pressure in the air tank. The valve 6 is used to control the opening and closing of the compressed air in the air tank 4 . Valve 7 and valve 11 are used to control the opening and closing of the purge pipeline. Flange 8 and flange 12 are used for connecting and disconnecting pipelines and temporary connecting pipes. The temporary connecting pipe 9 and the temporary connecting pipe 13 are used for temporarily connecting the purge pipeline and the main hydraulic pipeline...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com