Infrared-spectroscopy online sampling detection system and infrared-spectroscopy online sampling detection method suitable for raw materials of high-purity optical fibers

A detection system and infrared spectroscopy technology, applied in the field of spectral detection and analysis, can solve the problems of cumbersome sample processing, poor sampling process safety, and complicated sampling process, and achieve the effects of protecting safety, shortening sample preparation time, and avoiding manual operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

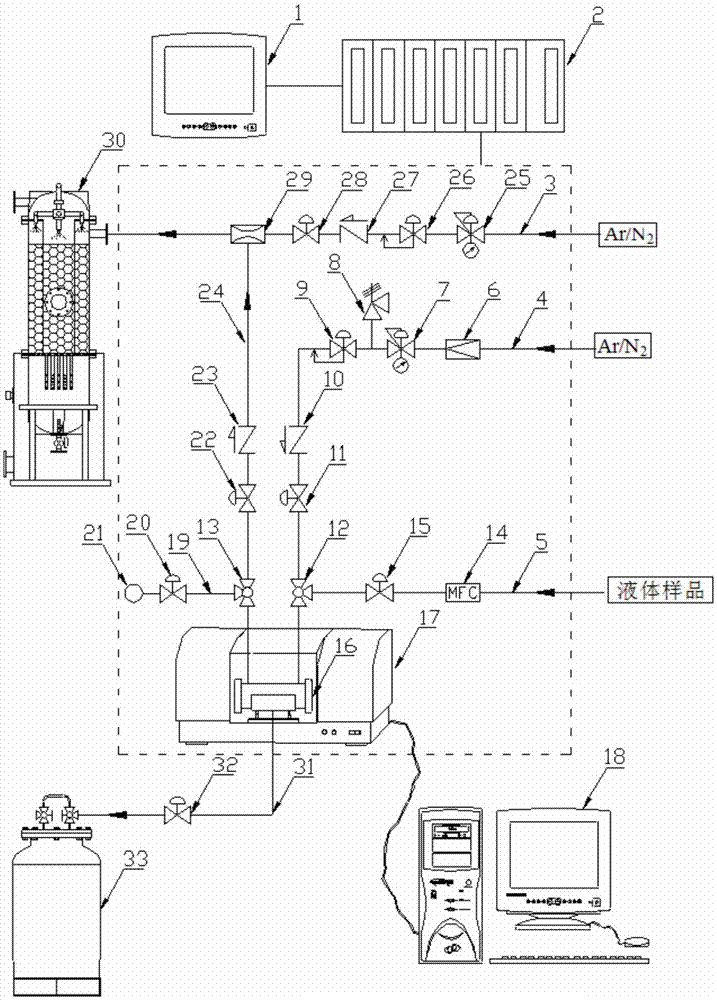

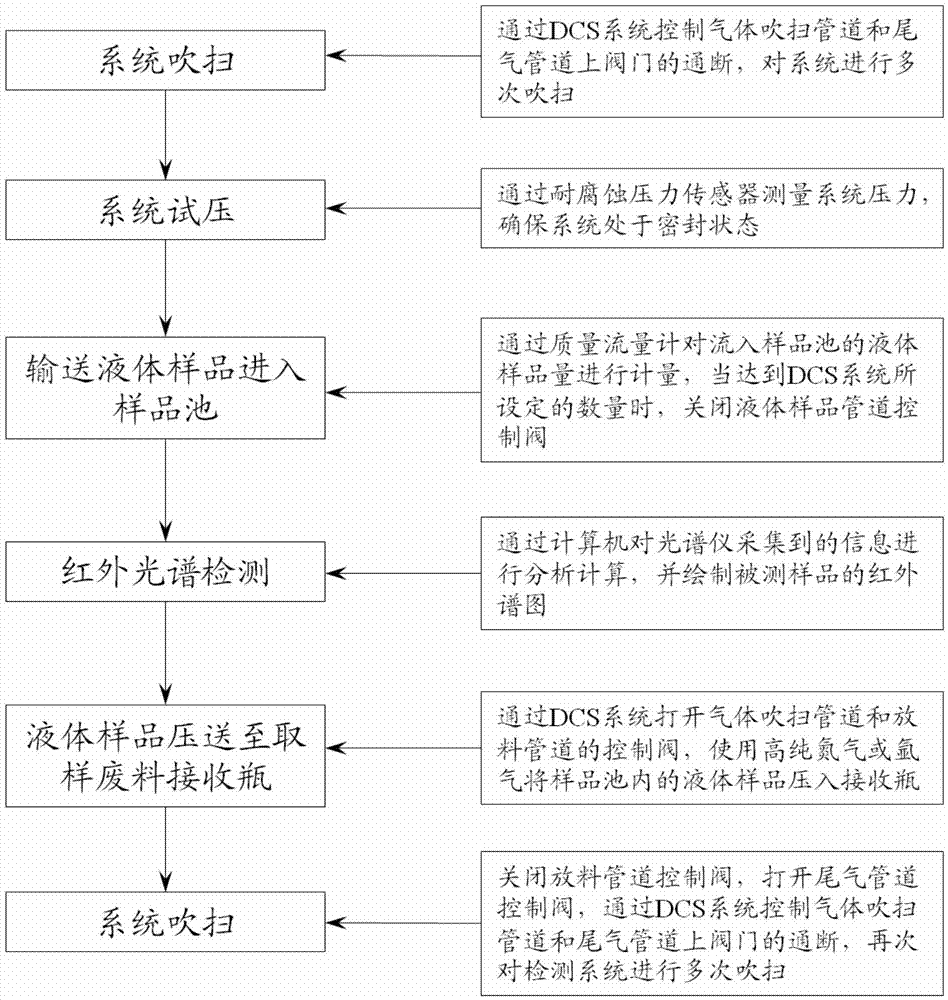

[0047] On-line sampling and detection of germanium tetrachloride intermediate products, the operation method is as follows:

[0048] First, the liquid sample pipeline 5 is connected with the sampling port of the germanium tetrachloride purification equipment, and the vacuum pipeline control valve 28 is opened, and the flow rate of the supply gas in the vacuum pipeline 3 is regulated by the vacuum pipeline pressure regulating valve 25, so that the Venturi tube The maximum vacuum produced by the vacuum generator 29 is 720 Torr. Then open the tail gas pipeline control valve 22 and the purge pipeline control valve 11 in sequence, and adjust the pressure of the purge gas in the gas purge pipeline 4 to 0.05Mpa through the purge pipeline pressure regulating valve 7 . The control valve 11 of the purge pipeline and the control valve 22 of the exhaust pipeline are controlled to open and close alternately through the DCS system 2, and the on-off time of the control valve is set to 2s eac...

Embodiment 2

[0057] Sampling and testing of silicon tetrachloride off-line products, the operation method is as follows:

[0058] First, the liquid sample pipeline 5 is connected with the outlet of the silicon tetrachloride off-line product container, and the vacuum pipeline control valve 28 is opened, and the flow of the supply gas in the vacuum pipeline 3 is regulated by the vacuum pipeline pressure regulating valve 25, so that The maximum vacuum produced by the Venturi vacuum generator 29 is 725 Torr. Then open the tail gas pipeline control valve 22 and the purge pipeline control valve 11 in sequence, and adjust the pressure of the purge gas in the gas purge pipeline 4 to 0.08Mpa through the purge pipeline pressure regulating valve 7 . The control valve 11 of the purge pipeline and the control valve 22 of the exhaust pipeline are controlled to open and close alternately through the DCS system 2, and the on-off time of the control valve is set to 1.5s each. The two valves are opened and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com