A Wiggins-type gas cabinet constant cabinet capacity replacement device and replacement method

A technology of Wiggins type and gas cabinet, which is applied in the field of replacement device, and can solve the problems of nitrogen consumption, frequent lifting and lowering of piston position, and long replacement period, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

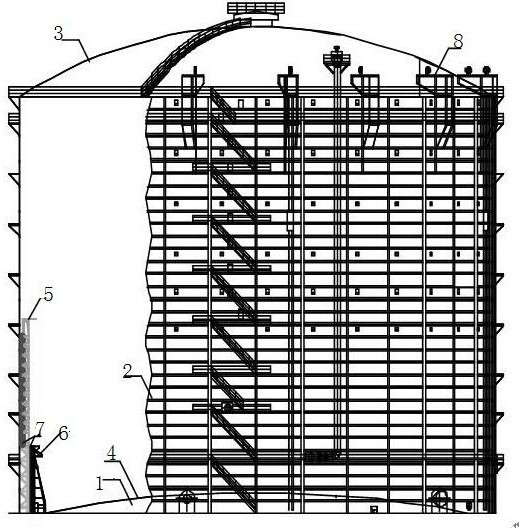

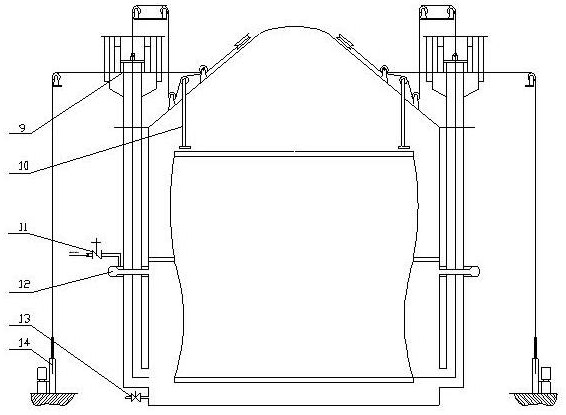

[0023] Embodiment 1: see figure 1 , figure 2 , a Wiggins-type gas tank constant cabinet capacity replacement device, the replacement device includes a bottom plate 1, a side plate 2, a top plate 3, a movable piston 4, a sleeve type guardrail 5 and a piston bar 6, and the side plate is set Between the base plate and the top plate, the movable piston is arranged on the base plate, and the sleeve type guardrail 5 and the piston bar are arranged on one side of the replacement device, and the replacement device also includes a sealing curtain 7, and the sealing curtain is arranged On the sleeve-type guardrail 5, the replacement device also includes a balance device 8, which is arranged above the inside of the entire replacement device, and the part below the height of 1 / 3 of the bottom plate and the side plate is required to be sealed, and the side plate 1 / 3 3 Ventilation windows are set up between the height and the top of the tank, and inspection doors are installed at vertical...

Embodiment 2

[0024] Example 2: see figure 1 , figure 2 , Wiggins-type gas cabinet constant cabinet capacity replacement method, nitrogen enters the ring pipe 12 under a section of the gas cabinet through the main valve 11, and enters the gas cabinet body through four access points through the ring pipe 12, and the gas cabinet releases 9 according to the PLC in advance The set cabinet capacity is opened by the hydraulic cylinder automatic control 14 to open the top of the cabinet to disperse 9 to complete the purging and replacement operations of the Wiggins type gas cabinet. In addition, the original operation mode: the piston of the gas cabinet rises, and when the cabinet capacity reaches 98%, the ram 10 opens the top of the cabinet to disperse 9; before the ram 10 opens the top of the cabinet to disperse 9, the patent utilizes hydraulic cylinder automatic control 14 and the cabinet capacity Interlocking, when the cabinet capacity reaches 96%, the top vent 9 will be opened automatically...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com