Nitrogen purging device of hydraulic line and method for cleaning hydraulic line

A technology for hydraulic pipelines and nitrogen purging, which is used in cleaning methods and utensils, cleaning hollow objects, chemical instruments and methods, etc. Waste manpower, material and financial resources, etc., to achieve the effect of preventing and controlling secondary pollution, saving manpower and saving construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

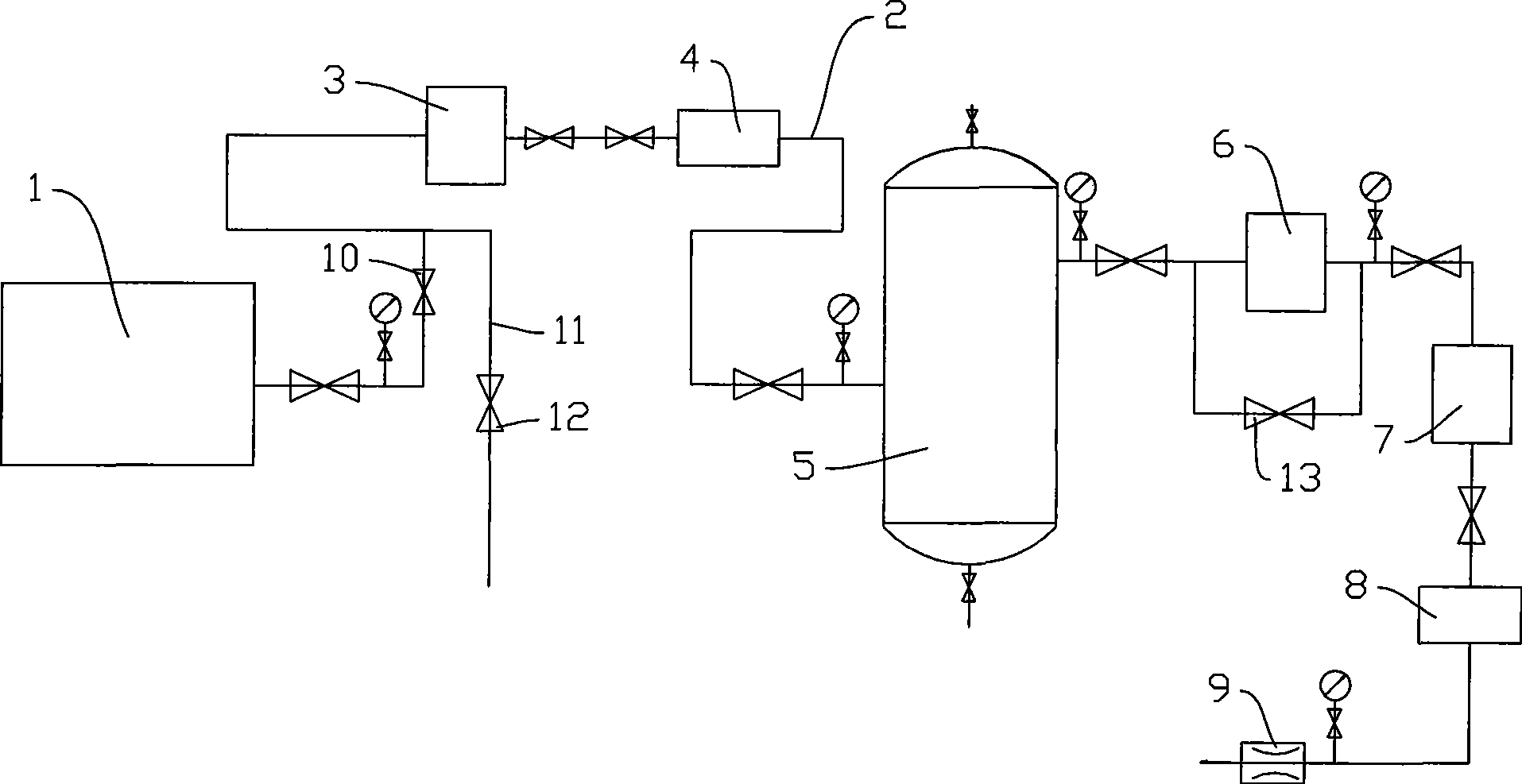

[0023] The nitrogen purge device used in the hydraulic pipeline in the figure, on the output pipeline 2 connected with the PSA nitrogen generator (nitrogen source) 1, there are in series a shut-off valve 10, a gas drying device 3, a gas filtering device 4, a gas storage Tank 5, gas pressurization device 6, gas drying device 7, gas filtering device 8, flow regulating valve 9. A branch 11 is bypassed on the output pipeline between the stop valve 10 and the gas drying device 3 , and a stop valve 12 is connected in series on the branch 11 . The shut-off valve 13 is connected in parallel with the gas pressurization device 6 .

[0024] During use, the shut-off valves 12 and 13 are closed, and the nitrogen separated from the PSA nitrogen generator passes through the shut-off valve 10, is dried by the gas drying device 3, is filtered by the gas filter device 4, and flows into the gas storage tank 5. The nitrogen gas flowing out from the gas storage tank 5 is pressurized by the gas bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com